1. Introduction

The manuscript considers unsteady and turbulent channel flows of non-Newtonian viscoelastic and elastoviscoplastic fluids. The dynamics of non-Newtonian turbulence has attracted a growing interest due to numerous industrial applications dealing with non-Newtonian fluids. Real industrial and natural fluids often present several non-Newtonian effects at the same time, such as plasticity (yield stress) and elasticity. Turbulent flows of yield-stress fluids are found in several industries such as petroleum, paper, mining and sewage treatment (Hanks Reference Hanks1963, Reference Hanks1967; Maleki & Hormozi Reference Maleki and Hormozi2018). Highly inertial flows of elastoviscoplastic fluids can also be found in geophysical applications, such as mudslides and the tectonic dynamics of the Earth (Oishi, Martins & Thompson Reference Oishi, Martins and Thompson2017).

Yield-stress fluids behave like solids below a local stress threshold, and flow like liquids above this threshold. Assuming that the material is a rigid solid at stresses lower than the yield stress, purely viscoplastic models are obtained, such as the Bingham model (Bingham Reference Bingham1922), where the solvent viscosity of the yielded fluid flow follows a Newtonian law, and the Herschel–Bulkley model (Herschel & Bulkley Reference Herschel and Bulkley1926), where the yielded fluid flow is shear thinning. However, many yield-stress fluids deform like elastic solids in the unyielded state and behave as viscoelastic liquids in the yielded state, displaying elastic (![]() $E$), viscous (

$E$), viscous (![]() $V$) and plastic (

$V$) and plastic (![]() $P$) properties.

$P$) properties.

A simple dynamic elastoviscoplastic (EVP) constitutive model that can be integrated with direct numerical simulations was proposed by Saramito (Reference Saramito2007). The model has proven to capture viscoplastic and elastic effects (Cheddadi et al. Reference Cheddadi, Saramito, Dollet, Raufaste and Graner2011; Fraggedakis, Dimakopoulos & Tsamopoulos Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016) and to properly match experimental results and observations (Holenberg et al. Reference Holenberg, Lavrenteva, Shavit and Nir2012) (common materials used to study this type of EVP fluids are Carbopol solutions and liquid foams Firouznia et al. Reference Firouznia, Metzger, Ovarlez and Hormozi2018; Zade et al. Reference Zade, Shamu, Lundell and Brandt2020). The model was extended by the same author to account for shear-thinning effects (Saramito Reference Saramito2009), combining the Oldroyd viscoelastic model with the Herschel–Bulkley viscoplastic model, with a power-law index that allows a shear-thinning behaviour in the yielded state. When the index is equal to unity, the model reduces to the one proposed in his previous work, i.e. Saramito (Reference Saramito2007). Apart from the models proposed by Saramito, many other EVP models exist in the literature. The interested reader is referred to Crochet & Walters (Reference Crochet and Walters1983), Balmforth, Frigaard & Ovarlez (Reference Balmforth, Frigaard and Ovarlez2014), Saramito (Reference Saramito2016) and Saramito & Wachs (Reference Saramito and Wachs2017) for a thorough review of models and numerical methods.

Turbulent flow of purely viscoelastic fluids has gained attention in the drag-reduction and flow control communities, since a tiny amount of polymer (parts per million) has proven efficient in reducing friction drag in pipe flows (Virk Reference Virk1971). Drag reduction by polymers is related to their ability to modify coherent structures in wall-bounded turbulence (Dubief et al. Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004, Reference Dubief, Terrapon, White, Shaqfeh, Moin and Lele2005). Polymers influence the turbulent cycle in two ways: they attenuate near-wall vortices, but at the same time they also increase the streamwise kinetic energy of the near-wall streaks. The net balance of these two opposite actions leads to a self-sustained drag-reduced turbulent flow. More recently, Xi & Graham (Reference Xi and Graham2010, Reference Xi and Graham2012a,Reference Xi and Grahamb) proposed that polymeric drag reduction is a time-dependent process: turbulent flows with polymers spend relatively more time in hibernating phases, where the turbulence is weak, and less time in active phases with strong turbulence. The turbulent coherent structures, streamwise vortices and streaks, were found to differ in appearance depending on whether the flow was in an active or a hibernating phase. Biancofiore, Brandt & Zaki (Reference Biancofiore, Brandt and Zaki2017) examined the secondary instability of streaks in viscoelastic flows, showing that the streaks reach a lower average energy with increasing elasticity due to a resistive polymer torque that opposes the streamwise vorticity and, as a result, opposes the lift-up mechanism. Numerous studies have addressed the topic of polymeric drag reduction and all cannot be reviewed here for brevity; the interested reader is referred to White & Mungal (Reference White and Mungal2008) for a thorough introduction to this subject.

Turbulent flow of yield-stress fluids (plasticity) has been studied much less, despite its relevance for applications. The reason is twofold. Time-resolved measurements in yield-stress fluids are very challenging, even in laminar flows. Most real-life yield-stress fluids are opaque and hence do not provide optical access. The transparent laboratory fluid Carbopol, often used in these experiments, needs careful preparation to achieve well-controlled properties (Dinkgreve, Fazilati & Bonn Reference Dinkgreve, Fazilati, Denn and Bonn2018; Tabuteau, Coussot & De Bruyn Reference Tabuteau, Coussot and De Bruyn2018), and exhibits slip on smooth surfaces that needs to be avoided or carefully controlled (Firouznia et al. Reference Firouznia, Metzger, Ovarlez and Hormozi2018). On the other hand, direct numerical simulations of yield-stress fluids have not been affordable until recently. Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a) first studied the turbulent channel flow of a yield-stress fluid in a near-viscoplastic limit using the Saramito EVP model (Saramito Reference Saramito2007), adding a tiny amount of elasticity to achieve numerical stability (the Weissenberg number was ![]() $Wi=0.01$). When the Bingham number was gradually increased from zero, the flow became less turbulent and more correlated in the streamwise direction, until it completely relaminarised at

$Wi=0.01$). When the Bingham number was gradually increased from zero, the flow became less turbulent and more correlated in the streamwise direction, until it completely relaminarised at ![]() $Bi=2.8$. The velocity correlations revealed that the size and length of the near-wall streaks increased with the Bingham number. The friction factor decreased with the Bingham number in the turbulent regime, while it increased with the same in the laminar regime. Le Clainche et al. (Reference Le Clainche, Izbassarov, Rosti, Brandt and Tammisola2020) analysed further the simulation data of Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a) using high-order dynamic mode decomposition, and compared the modes with those in Newtonian fluids, and also in purely viscoelastic fluids. Their results indicated that elasticity and plasticity have similar effects on the coherent structures; in both cases, the flow is dominated by long streaks disrupted by rapid, localised perturbations. The Newtonian flow, on the other hand, displays short streaks and a more chaotic dynamics. Very recent experiments in a duct flow of Carbopol confirmed that the energy content at low wavenumbers and streamwise anisotropy were higher than in Newtonian turbulence (Mitishita et al. Reference Mitishita, MacKenzie, Elfring and Frigaard2021), indicating that streamwise near-wall structures (streaks) were enhanced in Carbopol. These experiments at higher Reynolds numbers also confirmed the qualitative changes that viscoplasticity causes in mean flow profiles and Reynolds stresses, as observed by Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a).

$Bi=2.8$. The velocity correlations revealed that the size and length of the near-wall streaks increased with the Bingham number. The friction factor decreased with the Bingham number in the turbulent regime, while it increased with the same in the laminar regime. Le Clainche et al. (Reference Le Clainche, Izbassarov, Rosti, Brandt and Tammisola2020) analysed further the simulation data of Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a) using high-order dynamic mode decomposition, and compared the modes with those in Newtonian fluids, and also in purely viscoelastic fluids. Their results indicated that elasticity and plasticity have similar effects on the coherent structures; in both cases, the flow is dominated by long streaks disrupted by rapid, localised perturbations. The Newtonian flow, on the other hand, displays short streaks and a more chaotic dynamics. Very recent experiments in a duct flow of Carbopol confirmed that the energy content at low wavenumbers and streamwise anisotropy were higher than in Newtonian turbulence (Mitishita et al. Reference Mitishita, MacKenzie, Elfring and Frigaard2021), indicating that streamwise near-wall structures (streaks) were enhanced in Carbopol. These experiments at higher Reynolds numbers also confirmed the qualitative changes that viscoplasticity causes in mean flow profiles and Reynolds stresses, as observed by Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a).

In addition, many earlier direct numerical simulation studies addressed the turbulence in Bingham pseudoplastic fluids (obtained by regularising the Bingham model by a large viscosity) (Rudman & Blackburn Reference Rudman and Blackburn2006; Guang et al. Reference Guang, Rudman, Chryss, Slatter and Bhattacharya2011; Zhu et al. Reference Zhu, Yu, Shao and Deng2020), and their shear-thinning version, regularised Herschel–Bulkley fluids by Rudman et al. (Reference Rudman, Blackburn, Graham and Pullum2004) and Singh, Rudman & Blackburn (Reference Singh, Rudman and Blackburn2017). Very recently, Zhu et al. (Reference Zhu, Yu, Shao and Deng2020) studied the turbulence of a Bingham pseudoplastic fluid in a vertical channel with particles, at a higher bulk Reynolds number (![]() $Re_b=8000$) than Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a). They also obtained a drag reduction with an increasing Bingham number, along with an increasing streamwise coherence of the flow structures and observed that the turbulent statistics were asymmetric with respect to the centreline at higher Bingham numbers.

$Re_b=8000$) than Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a). They also obtained a drag reduction with an increasing Bingham number, along with an increasing streamwise coherence of the flow structures and observed that the turbulent statistics were asymmetric with respect to the centreline at higher Bingham numbers.

Transitional flows of yield-stress fluids in pipes and channels have been addressed in many studies, both experimentally and computationally. An asymmetric mean flow profile is a characteristic feature observed in pipe flow experiments of yield-stress fluids (Escudier et al. Reference Escudier, Poole, Presti, Dales, Nouar, Desaubry, Graham and Pullum2005; Peixinho et al. Reference Peixinho, Nouar, Desaubry and Théron2005; Esmael & Nouar Reference Esmael and Nouar2008; Guzel, Frigaard & Martinez Reference Guzel, Frigaard and Martinez2009), and for fluids with a Herschel–Bulkley-type rheology (Escudier & Presti Reference Escudier and Presti1996). According to Esmael & Nouar (Reference Esmael and Nouar2008), this was caused by an asymmetric nonlinear coherent structure consisting of two counter-rotating vortices. Experiments on laminar steady flow of a yield-stress fluid in a duct laden with particles were performed recently by Zade et al. (Reference Zade, Shamu, Lundell and Brandt2020). Computational studies on transitional flows have mainly focused on the linear and nonlinear stability of channel flows (Frigaard, Howison & Sobey Reference Frigaard, Howison and Sobey1994; Nouar & Frigaard Reference Nouar and Frigaard2001; Frigaard & Nouar Reference Frigaard and Nouar2003; Nouar et al. Reference Nouar, Kabouya, Dusek and Mamou2007; Metivier, Nouar & Brancher Reference Metivier, Nouar and Brancher2010; Nouar & Bottaro Reference Nouar and Bottaro2010; Bentrad et al. Reference Bentrad, Esmael, Nouar, Lefevre and Ait-Messaoudene2017). Most importantly, within the Bingham model, the central plug regions of a channel flow remain unyielded despite linear perturbations, and hence the flow is always linearly stable. In non-modal analysis, in contrast to Newtonian fluids, the optimal disturbance is found to be an oblique wave (Nouar et al. Reference Nouar, Kabouya, Dusek and Mamou2007), associated with the lift-up effect (Schmid Reference Schmid2007; Brandt Reference Brandt2014). However, Nouar & Bottaro (Reference Nouar and Bottaro2010) found that a slightly perturbed mean flow profile supports exponential amplification of streamwise-travelling waves, indicating another possible transition scenario for the plane channel flow of a yield-stress fluid.

Concluding, all previous studies on EVP turbulence focused on either purely viscoelastic or near-viscoplastic fluids. The questions remain as to what happens when both elasticity and plasticity effects are finite and interact with each other. The recent experimental study by Mitishita et al. (Reference Mitishita, MacKenzie, Elfring and Frigaard2021) also raised the question of how the findings of Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c) would be affected by finite elasticity. The present study focuses on EVP fluids at finite Weissenberg numbers, i.e. fluids with finite viscoelasticity and yield stress.

In this work, we perform direct numerical simulations of turbulent channel flows of an incompressible EVP fluid and extend the one by Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c) by considering a wide range of Weissenberg numbers ![]() $0\le Wi \le 16$ and Bingham numbers

$0\le Wi \le 16$ and Bingham numbers ![]() $0 \le Bi \le 22.4$, all at the bulk Reynolds number

$0 \le Bi \le 22.4$, all at the bulk Reynolds number ![]() $Re = 2800$. The non-Newtonian flow is simulated by solving the full unsteady incompressible Navier–Stokes equations coupled with a modified version of the model proposed by Saramito (Reference Saramito2007) for the evolution of the additional EVP stress tensor.

$Re = 2800$. The non-Newtonian flow is simulated by solving the full unsteady incompressible Navier–Stokes equations coupled with a modified version of the model proposed by Saramito (Reference Saramito2007) for the evolution of the additional EVP stress tensor.

The manuscript is organised as follows. In § 2, we first discuss the flow configuration and the governing equations, and then present the numerical methodology used. The new model with some test cases is reported in § 2.1, while the new results are presented in § 3. In particular, we discuss the role of elasticity and plasticity on a turbulent channel flow. Finally, a summary of the main findings and conclusions are collected in § 5.

2. Formulation

We consider the laminar and turbulent flows of an incompressible EVP fluid through a plane channel with two impermeable rigid walls. Figure 1(a) shows a sketch of the geometry and the Cartesian coordinate system, where ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ (

$z$ (![]() $x_1$,

$x_1$, ![]() $x_2$ and

$x_2$ and ![]() $x_3$) denote the streamwise, wall-normal and spanwise coordinates, while

$x_3$) denote the streamwise, wall-normal and spanwise coordinates, while ![]() $u$,

$u$, ![]() $v$ and

$v$ and ![]() $w$ (

$w$ (![]() $u_1$,

$u_1$, ![]() $u_2$ and

$u_2$ and ![]() $u_3$) denote the respective components of the velocity field. The lower and upper stationary impermeable walls are located at

$u_3$) denote the respective components of the velocity field. The lower and upper stationary impermeable walls are located at ![]() $y=0$ and

$y=0$ and ![]() $2h$, respectively, where

$2h$, respectively, where ![]() $h$ represents the channel half-height.

$h$ represents the channel half-height.

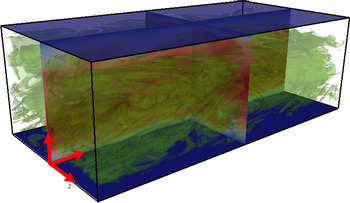

Figure 1. Sketch of the computational domain. The ![]() $XY$ and

$XY$ and ![]() $ZY$ planes in the middle of the domain show instantaneous streamwise velocity contours with the scale ranging from 0 (blue) to 1.27

$ZY$ planes in the middle of the domain show instantaneous streamwise velocity contours with the scale ranging from 0 (blue) to 1.27![]() $U_b$ (red), where

$U_b$ (red), where ![]() $U_b$ denotes the bulk velocity. Green structures represent unyielded regions.

$U_b$ denotes the bulk velocity. Green structures represent unyielded regions.

The fluid motion is governed by the conservation of momentum and the incompressibility constraint

where ![]() $\rho$ is the fluid density and

$\rho$ is the fluid density and ![]() $\sigma _{ij}$ the total Cauchy stress tensor, which is written as

$\sigma _{ij}$ the total Cauchy stress tensor, which is written as ![]() $\sigma _{ij} = -p \delta _{ij} + 2 \mu _f D_{ij} + \tau _{ij}$, where

$\sigma _{ij} = -p \delta _{ij} + 2 \mu _f D_{ij} + \tau _{ij}$, where ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $\mu _f$ the fluid molecular dynamic viscosity (also called solvent viscosity),

$\mu _f$ the fluid molecular dynamic viscosity (also called solvent viscosity), ![]() $\delta$ the Kronecker delta and

$\delta$ the Kronecker delta and ![]() $D_{ij}$ the strain rate tensor defined as

$D_{ij}$ the strain rate tensor defined as ![]() $D_{ij}=( \partial u_i / \partial x_j + \partial u_j / \partial x_i )/2$. The additional EVP stress tensor

$D_{ij}=( \partial u_i / \partial x_j + \partial u_j / \partial x_i )/2$. The additional EVP stress tensor ![]() $\tau _{ij}$ accounts for the non-Newtonian behaviour of the fluid, here described by a modified version of the model proposed by Saramito (Reference Saramito2007). In the original model, when the stress

$\tau _{ij}$ accounts for the non-Newtonian behaviour of the fluid, here described by a modified version of the model proposed by Saramito (Reference Saramito2007). In the original model, when the stress ![]() $\sigma$ is below the yield stress

$\sigma$ is below the yield stress ![]() $\tau _0$, the system predicts only recoverable Kelvin–Voigt viscoelastic deformations, while when the stress exceeds the yield value

$\tau _0$, the system predicts only recoverable Kelvin–Voigt viscoelastic deformations, while when the stress exceeds the yield value ![]() $\tau _0$, the fluid behaves as an Oldroyd-B viscoelastic fluid. Thus, the total strain rate

$\tau _0$, the fluid behaves as an Oldroyd-B viscoelastic fluid. Thus, the total strain rate ![]() $\dot {\varepsilon }$ is shared between an elastic contribution

$\dot {\varepsilon }$ is shared between an elastic contribution ![]() $\dot {\varepsilon }_e$ and a plastic one

$\dot {\varepsilon }_e$ and a plastic one ![]() $\dot {\varepsilon }_p$ (Cheddadi et al. Reference Cheddadi, Saramito, Dollet, Raufaste and Graner2011). Since the Oldroyd-B model assumes infinitely stretched dumbbells, the range of application of the model is limited to low elasticity. To overcome this drawback, we instead use the finite extensible nonlinear elastic-Peterlin (FENE-P) model. Thus, the instantaneous values of all the components of the stress tensor

$\dot {\varepsilon }_p$ (Cheddadi et al. Reference Cheddadi, Saramito, Dollet, Raufaste and Graner2011). Since the Oldroyd-B model assumes infinitely stretched dumbbells, the range of application of the model is limited to low elasticity. To overcome this drawback, we instead use the finite extensible nonlinear elastic-Peterlin (FENE-P) model. Thus, the instantaneous values of all the components of the stress tensor ![]() $\tau _{ij}$ are found by solving the following transport equation:

$\tau _{ij}$ are found by solving the following transport equation:

\begin{align} &\lambda \left( \frac{\partial \tau_{ij}}{\partial t} + \frac{\partial u_k \tau_{ij}}{\partial x_k} - \tau_{kj}\frac{\partial u_i}{\partial x_k} - \tau_{ik}\frac{\partial u_j}{\partial x_k} \right) + F f \tau_{ij} \nonumber\\ &\quad -\left(\frac{\partial \ln F}{\partial t}+\frac{\partial u_k \ln F}{\partial x_k}\right)(\lambda \tau_{ij}+\mu_m\delta_{ij})= 2 \mu_m D_{ij}, \end{align}

\begin{align} &\lambda \left( \frac{\partial \tau_{ij}}{\partial t} + \frac{\partial u_k \tau_{ij}}{\partial x_k} - \tau_{kj}\frac{\partial u_i}{\partial x_k} - \tau_{ik}\frac{\partial u_j}{\partial x_k} \right) + F f \tau_{ij} \nonumber\\ &\quad -\left(\frac{\partial \ln F}{\partial t}+\frac{\partial u_k \ln F}{\partial x_k}\right)(\lambda \tau_{ij}+\mu_m\delta_{ij})= 2 \mu_m D_{ij}, \end{align}where

\begin{equation} F=1+ \frac{\left(3+ \dfrac{\lambda}{\mu_m}\tau_{ii}\right)}{L^2}, \quad f=\max \left(0, \frac{ \vert \tau_d \vert - \tau_0}{\vert \tau_d \vert} \right). \end{equation}

\begin{equation} F=1+ \frac{\left(3+ \dfrac{\lambda}{\mu_m}\tau_{ii}\right)}{L^2}, \quad f=\max \left(0, \frac{ \vert \tau_d \vert - \tau_0}{\vert \tau_d \vert} \right). \end{equation}

Here, ![]() $\lambda$ is the relaxation time,

$\lambda$ is the relaxation time, ![]() $\mu _m$ is an additional viscosity,

$\mu _m$ is an additional viscosity, ![]() $L$ is the maximum polymer extensibility,

$L$ is the maximum polymer extensibility, ![]() $\tau _0$ the yield stress and

$\tau _0$ the yield stress and ![]() $\vert \tau _d \vert$ represents the second invariant of the deviatoric part of the added stress tensor. The EVP parameters

$\vert \tau _d \vert$ represents the second invariant of the deviatoric part of the added stress tensor. The EVP parameters ![]() $\mu _f$,

$\mu _f$, ![]() $\mu _m$,

$\mu _m$, ![]() $\lambda$ and

$\lambda$ and ![]() $\tau _0$ can be obtained by experimental data following the procedure detailed by Fraggedakis et al. (Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016), based on the determination of the linear material functions, i.e. the storage modulus

$\tau _0$ can be obtained by experimental data following the procedure detailed by Fraggedakis et al. (Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016), based on the determination of the linear material functions, i.e. the storage modulus ![]() $G'$ and the loss modulus

$G'$ and the loss modulus ![]() $G''$. The above constitutive equation gives a Kelvin–Voigt solid in the limit

$G''$. The above constitutive equation gives a Kelvin–Voigt solid in the limit ![]() $F\approx 1$, which is the case in the unyielded state, and a behaviour like a FENE-P fluid in the yielded state. The previous equation can be rewritten in terms of the conformation tensor

$F\approx 1$, which is the case in the unyielded state, and a behaviour like a FENE-P fluid in the yielded state. The previous equation can be rewritten in terms of the conformation tensor ![]() $C_{ij}$ as

$C_{ij}$ as

where the EVP stress tensor ![]() $\tau _{ij}$ is related to the conformation tensor by the relation

$\tau _{ij}$ is related to the conformation tensor by the relation

We use the log conformation method to overcome the well-known high Weissenberg number problem (Fattal & Kupferman Reference Fattal and Kupferman2004; Hulsen, Fattal & Kupferman Reference Hulsen, Fattal and Kupferman2005; Izbassarov & Muradoglu Reference Izbassarov and Muradoglu2015; De Vita et al. Reference De Vita, Rosti, Izbassarov, Duffo, Tammisola, Hormozi and Brandt2018). In this approach, (2.4) is rewritten in terms of the logarithm of the conformation tensor through an eigen-decomposition, i.e. ![]() $\boldsymbol {\varPsi }=\log \boldsymbol {C}$, which ensures the positive definiteness of the conformation tensor. The core feature of the formulation is the decomposition of the gradient of the divergence free velocity field

$\boldsymbol {\varPsi }=\log \boldsymbol {C}$, which ensures the positive definiteness of the conformation tensor. The core feature of the formulation is the decomposition of the gradient of the divergence free velocity field ![]() $\partial u_j / \partial x_i$ into two anti-symmetric tensors,

$\partial u_j / \partial x_i$ into two anti-symmetric tensors, ![]() $\varOmega _{ij}$ (pure rotation) and

$\varOmega _{ij}$ (pure rotation) and ![]() $N_{ij}$, and into a symmetric tensor,

$N_{ij}$, and into a symmetric tensor, ![]() $B_{ij}$, which commutes with the conformation tensor, i.e.

$B_{ij}$, which commutes with the conformation tensor, i.e.

The modified transport equation to be solved is thus

Once this equation is solved, the conformation tensor can be obtained using the inverse transformation ![]() $\boldsymbol {C} = \textrm {e}^{\boldsymbol {\varPsi }}$.

$\boldsymbol {C} = \textrm {e}^{\boldsymbol {\varPsi }}$.

Finally, the full system of equations can be rewritten in a non-dimensional form as

$$\begin{gather}F =1+ \frac{\left(3+ \dfrac{Wi}{1-\beta}\tau_{ii}\right)}{L^2}, \quad f =\max \left(0, \frac{ \vert \tau_d \vert - Bi}{\vert \tau_d \vert} \right), \end{gather}$$

$$\begin{gather}F =1+ \frac{\left(3+ \dfrac{Wi}{1-\beta}\tau_{ii}\right)}{L^2}, \quad f =\max \left(0, \frac{ \vert \tau_d \vert - Bi}{\vert \tau_d \vert} \right), \end{gather}$$

where we have used the same symbols to define the non-dimensional variables for simplicity. Four non-dimensional numbers appear in the previous set of equations: the Reynolds number ![]() $Re$, the Weissenberg number

$Re$, the Weissenberg number ![]() $Wi$, the Bingham number

$Wi$, the Bingham number ![]() $Bi$ and the viscosity ratio

$Bi$ and the viscosity ratio ![]() $\beta$, defined as

$\beta$, defined as ![]() $Re = \rho U \mathcal {L} / \mu _0$,

$Re = \rho U \mathcal {L} / \mu _0$, ![]() $Bi = \tau _0 \mathcal {L} / \mu _0 U$,

$Bi = \tau _0 \mathcal {L} / \mu _0 U$, ![]() $Wi = \lambda U / \mathcal {L}$ and

$Wi = \lambda U / \mathcal {L}$ and ![]() $\beta =\mu _f/\mu _0$, where

$\beta =\mu _f/\mu _0$, where ![]() $U$ and

$U$ and ![]() $\mathcal {L}$ are a characteristic velocity and length scales of the flow,

$\mathcal {L}$ are a characteristic velocity and length scales of the flow, ![]() $\rho$ the fluid density and

$\rho$ the fluid density and ![]() $\mu _0$ the total viscosity, i.e.

$\mu _0$ the total viscosity, i.e. ![]() $\mu _0=\mu _f+\mu _m$.

$\mu _0=\mu _f+\mu _m$.

The equations of motion are solved with an extensively validated in-house code (Rosti & Brandt Reference Rosti and Brandt2017; De Vita et al. Reference De Vita, Rosti, Izbassarov, Duffo, Tammisola, Hormozi and Brandt2018; Izbassarov et al. Reference Izbassarov, Rosti, Niazi Ardekani, Sarabian, Hormozi, Brandt and Tammisola2018; Rosti et al. Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c; Alghalibi, Rosti & Brandt Reference Alghalibi, Rosti and Brandt2019; Shahmardi et al. Reference Shahmardi, Zade, Ardekani, Poole, Lundell, Rosti and Brandt2019). The governing equations are discretised with the second-order centred finite difference scheme on a staggered uniform grid, except for the advection term in (2.7) where the fifth-order WENO (weighted essentially non-oscillatory) scheme is adopted (Shu Reference Shu2009; Sugiyama et al. Reference Sugiyama, Ii, Takeuchi, Takagi and Matsumoto2011). The time integration is performed with a fractional-step method (Kim & Moin Reference Kim and Moin1985) and a third-order explicit Runge–Kutta scheme except for the EVP stress term which is advanced with the Crank–Nicolson method.

In all the simulations, periodic boundary conditions are used in the streamwise and spanwise directions, while the no-slip and no-penetration boundary conditions are enforced on the solid walls. For all the turbulent cases considered hereafter with a bulk Reynolds number equal to ![]() $Re_b=2800$, the equations of motion are discretised by using

$Re_b=2800$, the equations of motion are discretised by using ![]() $1728 \times 576 \times 864$ grid points on a computational domain of size

$1728 \times 576 \times 864$ grid points on a computational domain of size ![]() $6h \times 2h \times 3h$ in the streamwise, wall-normal and spanwise directions, with the resolution satisfying the constraint

$6h \times 2h \times 3h$ in the streamwise, wall-normal and spanwise directions, with the resolution satisfying the constraint ![]() $\Delta x^{+} = \Delta y^{+} = \Delta z^{+} < 0.6$, where the superscript

$\Delta x^{+} = \Delta y^{+} = \Delta z^{+} < 0.6$, where the superscript ![]() $^+$ indicates the wall units. The spatial resolution has been chosen equal to the one used in a previous work (Rosti et al. Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a) in order to properly resolve the turbulent scales as well as the unyielded plug regions which form intermittently in the domain, and verified a posteriori with a grid refinement study. In the low Reynolds fully laminar cases, the spatial resolution was relaxed and the domain size in the homogeneous directions reduced. Finally, all the turbulent cases are initialised with a fully developed channel flow with zero EVP stress (

$^+$ indicates the wall units. The spatial resolution has been chosen equal to the one used in a previous work (Rosti et al. Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018a) in order to properly resolve the turbulent scales as well as the unyielded plug regions which form intermittently in the domain, and verified a posteriori with a grid refinement study. In the low Reynolds fully laminar cases, the spatial resolution was relaxed and the domain size in the homogeneous directions reduced. Finally, all the turbulent cases are initialised with a fully developed channel flow with zero EVP stress (![]() $\tau _{ij}=0$); after the flow and stresses have reached a statistically steady state, the calculations are continued for an interval of approximately

$\tau _{ij}=0$); after the flow and stresses have reached a statistically steady state, the calculations are continued for an interval of approximately ![]() $500$ bulk time units, during which the statistics are computed.

$500$ bulk time units, during which the statistics are computed.

2.1. Validations of the FENE-P-based EVP model

The present implementation for single and multiphase flows of an EVP fluid has been extensively validated in the past; here, we report further test cases of the new FENE-P-based EVP model also to present its rheological behaviour.

First, we consider a three-dimensional uniaxial elongational flow, with a constant elongational rate ![]() $\dot {\epsilon }_0$: the Weissenberg number

$\dot {\epsilon }_0$: the Weissenberg number ![]() $Wi=\lambda \dot {\epsilon }_0$ and extensibility parameter

$Wi=\lambda \dot {\epsilon }_0$ and extensibility parameter ![]() $L^2$ are varied in the range of

$L^2$ are varied in the range of ![]() $0.25 \le Wi \le 0.75$ and

$0.25 \le Wi \le 0.75$ and ![]() $10\le L^2 \le \infty$, respectively, while the Bingham number

$10\le L^2 \le \infty$, respectively, while the Bingham number ![]() $Bi=\tau _0/(\mu _0 \dot {\epsilon _0})=1$ and the viscosity ratio

$Bi=\tau _0/(\mu _0 \dot {\epsilon _0})=1$ and the viscosity ratio ![]() $\beta =0$. The fluid flow is assumed to have a constant velocity gradient

$\beta =0$. The fluid flow is assumed to have a constant velocity gradient ![]() $\partial u_i / \partial x_j = \text {diag} \lbrace 1, -1/2, 1/2 \rbrace$ and (2.2) can be simplified as

$\partial u_i / \partial x_j = \text {diag} \lbrace 1, -1/2, 1/2 \rbrace$ and (2.2) can be simplified as

with ![]() $\tau _{ii}(0) = 0$ for

$\tau _{ii}(0) = 0$ for ![]() $i=1, 2$ and

$i=1, 2$ and ![]() $3$. The time evolution of

$3$. The time evolution of ![]() $\tau _{11} - \tau _{22}$ (the normal stress difference) is reported in figure 2; we observe that, initially, the stress components grow linearly, but when the stress level is above a threshold, i.e. the yield stress, the Saramito model (

$\tau _{11} - \tau _{22}$ (the normal stress difference) is reported in figure 2; we observe that, initially, the stress components grow linearly, but when the stress level is above a threshold, i.e. the yield stress, the Saramito model (![]() $L^2=\infty$) predicts an unbounded growth for

$L^2=\infty$) predicts an unbounded growth for ![]() $Wi>0.5$, while the FENE-P-based model exhibits a limited growth with the stress difference reaching a plateau. This example easily explains the reason why the FENE-P-based model is chosen for the current work, where we aim to investigate the effect of finite elasticity.

$Wi>0.5$, while the FENE-P-based model exhibits a limited growth with the stress difference reaching a plateau. This example easily explains the reason why the FENE-P-based model is chosen for the current work, where we aim to investigate the effect of finite elasticity.

Figure 2. Time evolution of ![]() $\tau _{11}-\tau _{22}$ in an uniaxial elongation for

$\tau _{11}-\tau _{22}$ in an uniaxial elongation for ![]() $Bi=1$ and

$Bi=1$ and ![]() $\beta =0$: (a) the effect of

$\beta =0$: (a) the effect of ![]() $Wi$ for

$Wi$ for ![]() $L^2=\infty$ (Oldroyd-B model) and (b) the effect of

$L^2=\infty$ (Oldroyd-B model) and (b) the effect of ![]() $L^2$ (FENE-P model) for

$L^2$ (FENE-P model) for ![]() $Wi=0.75$. The stress components are normalised with

$Wi=0.75$. The stress components are normalised with ![]() $\mu _0\dot {\epsilon _0}$.

$\mu _0\dot {\epsilon _0}$.

Next, we consider a simple constant shear flow, with shear rate ![]() $\dot {\gamma }_0$; the Weissenberg number is varied

$\dot {\gamma }_0$; the Weissenberg number is varied ![]() $Wi=\lambda \dot {\gamma }_0$ in the range

$Wi=\lambda \dot {\gamma }_0$ in the range ![]() $0.01 \le Wi \le 100$, while the Bingham number

$0.01 \le Wi \le 100$, while the Bingham number ![]() $Bi=\tau _0/(\mu _0 \dot {\gamma })$ assumes 4 distinct values and the viscosity ratio

$Bi=\tau _0/(\mu _0 \dot {\gamma })$ assumes 4 distinct values and the viscosity ratio ![]() $\beta =0$. We consider two cases, with

$\beta =0$. We consider two cases, with ![]() $L^2=100$ and

$L^2=100$ and ![]() $L^2=\infty$ to study the properties of the two models. For this two-dimensional problem, we have

$L^2=\infty$ to study the properties of the two models. For this two-dimensional problem, we have ![]() $\partial u_i / \partial x_j=\left [ \begin {smallmatrix} 0 & 1\\ 0 & 0 \end {smallmatrix}\right ]$ and (2.2) can be rewritten as

$\partial u_i / \partial x_j=\left [ \begin {smallmatrix} 0 & 1\\ 0 & 0 \end {smallmatrix}\right ]$ and (2.2) can be rewritten as

with ![]() $\tau _{ij}(0) = 0, i=1,2$. The dimensionless steady shear viscosity

$\tau _{ij}(0) = 0, i=1,2$. The dimensionless steady shear viscosity ![]() $\mu _s/\mu _0 = \beta + \tau _{12}/\dot {\gamma }$ as a function of

$\mu _s/\mu _0 = \beta + \tau _{12}/\dot {\gamma }$ as a function of ![]() $Wi$ is reported in figure 3. As expected, both models exhibit a shear-thinning behaviour: in particular, for

$Wi$ is reported in figure 3. As expected, both models exhibit a shear-thinning behaviour: in particular, for ![]() $L^2=\infty$ the model tends to a plateau at both low (

$L^2=\infty$ the model tends to a plateau at both low (![]() $Wi \lesssim 0.1$) and high (

$Wi \lesssim 0.1$) and high (![]() $Wi \gtrsim 10$) Weissenberg numbers, while for

$Wi \gtrsim 10$) Weissenberg numbers, while for ![]() $L^2=100$ the steady shear viscosity reaches a plateau at low

$L^2=100$ the steady shear viscosity reaches a plateau at low ![]() $Wi$ but it decreases monotonically at high

$Wi$ but it decreases monotonically at high ![]() $Wi$. Note that the shear-thinning effect is controlled by

$Wi$. Note that the shear-thinning effect is controlled by ![]() $Bi$, which modifies the plateau value at low

$Bi$, which modifies the plateau value at low ![]() $Wi$.

$Wi$.

Figure 3. Steady shear viscosity for ![]() $\beta =0$ and (a)

$\beta =0$ and (a) ![]() $L^2=\infty$ (Oldroyd-B model); (b)

$L^2=\infty$ (Oldroyd-B model); (b) ![]() $L^2=100$ (FENE-P model).

$L^2=100$ (FENE-P model).

3. Results

3.1. Laminar flow

Our first analysis considers the laminar flow of an EVP fluid. All laminar cases are fixed at ![]() $\beta =0.9$,

$\beta =0.9$, ![]() $Re=2800$ and

$Re=2800$ and ![]() $L^2=3600$, while the Weissenberg and the Bingham numbers are varied in the range of

$L^2=3600$, while the Weissenberg and the Bingham numbers are varied in the range of ![]() $0.01 \le Wi \le 16$ and

$0.01 \le Wi \le 16$ and ![]() $0.1 \le Bi \le 100$, respectively. Note that the domain size in the homogeneous directions was kept very small to avoid the development of a turbulent flow and that no perturbations were added to the zero initial condition.

$0.1 \le Bi \le 100$, respectively. Note that the domain size in the homogeneous directions was kept very small to avoid the development of a turbulent flow and that no perturbations were added to the zero initial condition.

First, we consider the combined effects of the Bingham and the Weissenberg numbers on the frictional resistance of the flow quantified by the Fanning friction factor ![]() $f$, defined as

$f$, defined as ![]() $2 \tau _w/\rho U_b^2$ with

$2 \tau _w/\rho U_b^2$ with ![]() $\tau _w$ the total wall shear stress including both the viscous and EVP contributions. Figure 4(a) shows the Fanning friction factor

$\tau _w$ the total wall shear stress including both the viscous and EVP contributions. Figure 4(a) shows the Fanning friction factor ![]() $f$ as a function of the Weissenberg number for various Bingham numbers. In particular, the cyan, brown, purple and green lines are used for

$f$ as a function of the Weissenberg number for various Bingham numbers. In particular, the cyan, brown, purple and green lines are used for ![]() $Bi=0.1$,

$Bi=0.1$, ![]() $2.8$,

$2.8$, ![]() $11.2$ and

$11.2$ and ![]() $100$, respectively. The friction factor

$100$, respectively. The friction factor ![]() $f$ decreases nearly linearly with

$f$ decreases nearly linearly with ![]() $Wi$ (in log scale). However, at

$Wi$ (in log scale). However, at ![]() $Bi=0.1$ the factor

$Bi=0.1$ the factor ![]() $f$ is constant, which is consistent with the viscoelastic flows in the laminar regime. Results clearly show that the elastic effects become more prominent with

$f$ is constant, which is consistent with the viscoelastic flows in the laminar regime. Results clearly show that the elastic effects become more prominent with ![]() $Bi$, leading to a steeper decay with

$Bi$, leading to a steeper decay with ![]() $Wi$.

$Wi$.

Figure 4. Fanning factor as a function of (a) the Weissenberg number for ![]() $Bi=0.1,2.8,11.2$ and

$Bi=0.1,2.8,11.2$ and ![]() $100$ and (b) the Bingham number for

$100$ and (b) the Bingham number for ![]() $Wi=0.01,0.1,2$ and

$Wi=0.01,0.1,2$ and ![]() $16$.

$16$.

Next, we consider the reverse case, where we study the effects of Bingham number at a fixed ![]() $Wi$, as shown in figure 4(b). We find that

$Wi$, as shown in figure 4(b). We find that ![]() $f$ increases nonlinearly with the Bingham number

$f$ increases nonlinearly with the Bingham number ![]() $Bi$, and that the dependency on

$Bi$, and that the dependency on ![]() $Bi$ decreases with the Weissenberg number

$Bi$ decreases with the Weissenberg number ![]() $Wi$. The increase of

$Wi$. The increase of ![]() $f$ can be explained by subtle changes in the mean streamwise velocity profile. The non-dimensional streamwise velocity profile u/U b is shown in figure 5(a) at

$f$ can be explained by subtle changes in the mean streamwise velocity profile. The non-dimensional streamwise velocity profile u/U b is shown in figure 5(a) at ![]() $Wi=0.01$ and

$Wi=0.01$ and ![]() $Bi=0.1,2.8,11.2,100$ as a function of the wall-normal distance

$Bi=0.1,2.8,11.2,100$ as a function of the wall-normal distance ![]() $y/h$. It can be seen that the solid plug in the middle of the channel increases with the Bingham number. The plug moves with a uniform velocity, and its velocity decreases with

$y/h$. It can be seen that the solid plug in the middle of the channel increases with the Bingham number. The plug moves with a uniform velocity, and its velocity decreases with ![]() $Bi$ due to mass conservation, leading to an increase in the wall shear stress.

$Bi$ due to mass conservation, leading to an increase in the wall shear stress.

Figure 5. Mean streamwise velocity profile ![]() $u$ as a function of (a) the Bingham number for

$u$ as a function of (a) the Bingham number for ![]() $Bi=0.1,2.8,11.2$ and 100 at

$Bi=0.1,2.8,11.2$ and 100 at ![]() $Wi=0.01$ and (b) the Weissenberg number for

$Wi=0.01$ and (b) the Weissenberg number for ![]() $Wi=0.01,0.1,2$ and

$Wi=0.01,0.1,2$ and ![]() $16$ at

$16$ at ![]() $Bi=22.4$.

$Bi=22.4$.

The variations of the non-dimensional mean velocity profile ![]() $u/U_b$ at

$u/U_b$ at ![]() $Bi=22.4$ with the Weissenberg number, see figure 5(b), demonstrate that the solid plug in the middle of the channel decreases with

$Bi=22.4$ with the Weissenberg number, see figure 5(b), demonstrate that the solid plug in the middle of the channel decreases with ![]() $Wi$. Indeed, the total stress magnitude in a channel flow increases with elasticity, leading to earlier yielding (Chaparian & Tammisola Reference Chaparian and Tammisola2019). To further quantify these observations, the volume of the solid region is shown in figure 6 for various combinations of

$Wi$. Indeed, the total stress magnitude in a channel flow increases with elasticity, leading to earlier yielding (Chaparian & Tammisola Reference Chaparian and Tammisola2019). To further quantify these observations, the volume of the solid region is shown in figure 6 for various combinations of ![]() $Wi$ and

$Wi$ and ![]() $Bi$. The results are consistent with the observations in figure 4, since the solid volume

$Bi$. The results are consistent with the observations in figure 4, since the solid volume ![]() $Vol_s$ is proportional to the friction factor

$Vol_s$ is proportional to the friction factor ![]() $f$.

$f$.

Figure 6. Percentage of the unyielded volume ![]() $Vol_s$ as a function of (a) the Weissenberg number for

$Vol_s$ as a function of (a) the Weissenberg number for ![]() $Bi=0.1,2.8,11.2$ and

$Bi=0.1,2.8,11.2$ and ![]() $100$ and (b) the Bingham number for

$100$ and (b) the Bingham number for ![]() $Wi=0.01,0.1,2$ and

$Wi=0.01,0.1,2$ and ![]() $16$.

$16$.

3.2. Turbulent flow

We examine turbulent channel flows of an EVP fluid, together with the baseline Newtonian (![]() $Bi=0$ and

$Bi=0$ and ![]() $Wi \approx 0$), viscoelastic (

$Wi \approx 0$), viscoelastic (![]() $Bi=0$) and almost viscoplastic (

$Bi=0$) and almost viscoplastic (![]() $Wi \approx 0$) cases. All simulations have been performed until statistically steady state (at least 500 non-dimensional units). Hence, in the turbulent flow cases, the turbulence is always fully developed. However, for some parameter values the flow is not turbulent, because it has laminarised by increasing elasticity or plasticity.

$Wi \approx 0$) cases. All simulations have been performed until statistically steady state (at least 500 non-dimensional units). Hence, in the turbulent flow cases, the turbulence is always fully developed. However, for some parameter values the flow is not turbulent, because it has laminarised by increasing elasticity or plasticity.

The flow rate is constant in all simulations, so that the flow Reynolds number based on the bulk velocity is fixed, i.e. ![]() $Re=\rho U_b h/\mu _0=2800$, where the bulk velocity

$Re=\rho U_b h/\mu _0=2800$, where the bulk velocity ![]() $U_b$ is the average value of the mean velocity computed across the whole domain and

$U_b$ is the average value of the mean velocity computed across the whole domain and ![]() $\mu _0$ is the total zero-shear viscosity. In the turbulent regime, this bulk Reynolds number corresponds to a nominal friction Reynolds number

$\mu _0$ is the total zero-shear viscosity. In the turbulent regime, this bulk Reynolds number corresponds to a nominal friction Reynolds number ![]() $Re_\tau =\rho u_\tau h/ \mu _0=180$ for a Newtonian fluid,

$Re_\tau =\rho u_\tau h/ \mu _0=180$ for a Newtonian fluid, ![]() $u_\tau$ being the friction velocity. A wide range of elasticity and plasticity is investigated: the Weissenberg number

$u_\tau$ being the friction velocity. A wide range of elasticity and plasticity is investigated: the Weissenberg number ![]() $Wi=\lambda U_b/h$ is varied in the range

$Wi=\lambda U_b/h$ is varied in the range ![]() $0\le Wi \le 16$ to study the role of fluid elasticity, while the Bingham number

$0\le Wi \le 16$ to study the role of fluid elasticity, while the Bingham number ![]() $Bi=\tau _0 h/ \mu _0 U_b$ is varied between

$Bi=\tau _0 h/ \mu _0 U_b$ is varied between ![]() $0$ and

$0$ and ![]() $22.4$. The viscosity ratio and the extensibility parameter are fixed to

$22.4$. The viscosity ratio and the extensibility parameter are fixed to ![]() $\beta =\mu _f / \mu _0 =0.9$ and

$\beta =\mu _f / \mu _0 =0.9$ and ![]() $L^2=3600$.

$L^2=3600$.

The viscous units used above are indicated by the superscript ![]() $^+$, and are built using the friction velocity

$^+$, and are built using the friction velocity ![]() $u_\tau$ as the velocity scale and the viscous length

$u_\tau$ as the velocity scale and the viscous length ![]() $\delta _\nu = \nu / u_\tau$ as the length scale. Here, we define the friction velocity as

$\delta _\nu = \nu / u_\tau$ as the length scale. Here, we define the friction velocity as

\begin{equation} u_\tau = \sqrt{ \left. \left( \frac{1}{Re_b} \frac{\textrm{d} \bar{u}}{\textrm{d} y} + \bar{\tau}_{12} \right) \right\vert_{y=0}}, \end{equation}

\begin{equation} u_\tau = \sqrt{ \left. \left( \frac{1}{Re_b} \frac{\textrm{d} \bar{u}}{\textrm{d} y} + \bar{\tau}_{12} \right) \right\vert_{y=0}}, \end{equation}where we have taken into account also the EVP shear stress at the wall. Note that the actual value of the friction velocity in our simulations is computed from the friction coefficient, obtained with the driving streamwise pressure gradient, rather than from its definition.

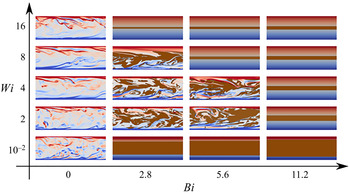

We first discuss the qualitative flow characteristics for various combinations of ![]() $Wi$ and

$Wi$ and ![]() $Bi$. A qualitative overview of the resulting flow regimes as functions of

$Bi$. A qualitative overview of the resulting flow regimes as functions of ![]() $Wi$ and

$Wi$ and ![]() $Bi$ is presented in figure 7.

$Bi$ is presented in figure 7.

Figure 7. Combined effects of elasticity and plasticity. A flow regime map is shown by symbols: ![]() $\square$ – turbulent,

$\square$ – turbulent, ![]() $\blacksquare$ – laminar. Colour scale shows drag reduction compared with the Newtonian case. (a) Colour scale:

$\blacksquare$ – laminar. Colour scale shows drag reduction compared with the Newtonian case. (a) Colour scale: ![]() $DR =[1-(Re_\tau /Re_{\tau ,Wi=0})^2] \times 100\,\%$ spanning

$DR =[1-(Re_\tau /Re_{\tau ,Wi=0})^2] \times 100\,\%$ spanning ![]() $\pm 65$ from red (drag reduction) to violet (drag increase). (b) Colour scale:

$\pm 65$ from red (drag reduction) to violet (drag increase). (b) Colour scale: ![]() $DR_2 =[1-f_{EVP} /f_{N}] \times 100\,\%$ where

$DR_2 =[1-f_{EVP} /f_{N}] \times 100\,\%$ where ![]() $f_{EVP}$ and

$f_{EVP}$ and ![]() $f_N$ denote skin friction for EVP and Newtonian cases, respectively.

$f_N$ denote skin friction for EVP and Newtonian cases, respectively.

The empty and filled symbols in figure 7 represent turbulent and laminar regimes, respectively. As expected, the flow becomes laminar and steady with an increasing Bingham number. The critical ![]() $Bi_c$ can be defined as the lowest value of

$Bi_c$ can be defined as the lowest value of ![]() $Bi$ where laminarisation occurs, at each

$Bi$ where laminarisation occurs, at each ![]() $Wi$. At

$Wi$. At ![]() $Wi=0.01$, the flow is near viscoplastic and fully laminarises at the relatively low critical

$Wi=0.01$, the flow is near viscoplastic and fully laminarises at the relatively low critical ![]() $Bi_{c}=2.8$ (Rosti et al. Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c). (Note that results for viscoplastic cases used in this work are taken from our previous work Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c).) Laminarisation of the viscoplastic flow with increasing Bingham number is closely related to the increase of the core unyielded region which grows from the centreline towards to the walls, and damps out turbulent fluctuations in the core. As described in Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c), the near-wall streaks were intensified and became more coherent. The low-speed streaks, usually associated with positive wall-normal fluctuations, reach higher wall-normal distances than the high-speed streaks, thus inducing the flow to yield at higher wall-normal distances if the local stress reaches the yield-stress threshold. Indeed, the unyielded regions preferentially form above high-speed streaks. Overall, the flow becomes more and more correlated in the streamwise direction when increasing the Bingham number, with high levels of flow anisotropy close to the wall, similarly to what observed in other drag-reducing flows. Differently from the other flows, however, both the streamwise and spanwise correlations grow with the Bingham number also away from the wall, due to the growth of the unyielded region.

$Bi_{c}=2.8$ (Rosti et al. Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c). (Note that results for viscoplastic cases used in this work are taken from our previous work Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c).) Laminarisation of the viscoplastic flow with increasing Bingham number is closely related to the increase of the core unyielded region which grows from the centreline towards to the walls, and damps out turbulent fluctuations in the core. As described in Rosti et al. (Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c), the near-wall streaks were intensified and became more coherent. The low-speed streaks, usually associated with positive wall-normal fluctuations, reach higher wall-normal distances than the high-speed streaks, thus inducing the flow to yield at higher wall-normal distances if the local stress reaches the yield-stress threshold. Indeed, the unyielded regions preferentially form above high-speed streaks. Overall, the flow becomes more and more correlated in the streamwise direction when increasing the Bingham number, with high levels of flow anisotropy close to the wall, similarly to what observed in other drag-reducing flows. Differently from the other flows, however, both the streamwise and spanwise correlations grow with the Bingham number also away from the wall, due to the growth of the unyielded region.

As the flow becomes more elastic, the critical ![]() $Bi_{c}$ shows a non-monotonic behaviour; it first increases with

$Bi_{c}$ shows a non-monotonic behaviour; it first increases with ![]() $Wi$, then decreases. The reason for this non-monotonic behaviour is attributed to the fact that the coherent structures are highly influenced by the relative width of the plug compared with the yielded regions around it, as will be described later.

$Wi$, then decreases. The reason for this non-monotonic behaviour is attributed to the fact that the coherent structures are highly influenced by the relative width of the plug compared with the yielded regions around it, as will be described later.

The colours in figure 7 represent a measure of drag reduction compared with a Newtonian fluid. Panel (a) shows ![]() $DR =[1-(Re_\tau /Re_{\tau ,Wi=0})^2] \times 100\,\%$. For flows in the turbulent regime,

$DR =[1-(Re_\tau /Re_{\tau ,Wi=0})^2] \times 100\,\%$. For flows in the turbulent regime, ![]() $DR$ increases with

$DR$ increases with ![]() $Bi$ for all

$Bi$ for all ![]() $Wi$ studied in this work. In the laminar regime, however, at low

$Wi$ studied in this work. In the laminar regime, however, at low ![]() $Wi=0.01$, the

$Wi=0.01$, the ![]() $DR$ changes sign, showing drag increase, whereas for higher

$DR$ changes sign, showing drag increase, whereas for higher ![]() $Wi\ge 2$ values, the

$Wi\ge 2$ values, the ![]() $DR$ only slightly decreases with

$DR$ only slightly decreases with ![]() $Bi$. This is consistent with the results for the Fanning factor shown in figure 8. It is well known that a finite viscoelasticity reduces drag compared with a Newtonian flow, and this has been exploited in many previous studies and in the industry. The figure seems to show that a combination of finite

$Bi$. This is consistent with the results for the Fanning factor shown in figure 8. It is well known that a finite viscoelasticity reduces drag compared with a Newtonian flow, and this has been exploited in many previous studies and in the industry. The figure seems to show that a combination of finite ![]() $Wi$ and

$Wi$ and ![]() $Bi$ results in a much greater drag reduction than a finite

$Bi$ results in a much greater drag reduction than a finite ![]() $Wi$ alone. However, a closer inspection shows that the very high drag reduction

$Wi$ alone. However, a closer inspection shows that the very high drag reduction ![]() $DR>70\,\%$ occurs when the flow laminarises, because we compare with the drag in the Newtonian flow in the turbulent regime. We wanted to eliminate the effect of laminarisation on drag reduction, and also try to exclude the effects of shear thinning. Therefore, in (b), we show another measure of drag reduction which excludes the influence of shear thinning (Housiadas & Beris Reference Housiadas and Beris2003):

$DR>70\,\%$ occurs when the flow laminarises, because we compare with the drag in the Newtonian flow in the turbulent regime. We wanted to eliminate the effect of laminarisation on drag reduction, and also try to exclude the effects of shear thinning. Therefore, in (b), we show another measure of drag reduction which excludes the influence of shear thinning (Housiadas & Beris Reference Housiadas and Beris2003): ![]() $DR_2 =[1-f_{EVP} /f_{N}] \times 100\,\%$, where

$DR_2 =[1-f_{EVP} /f_{N}] \times 100\,\%$, where ![]() $f_{EVP}$ and

$f_{EVP}$ and ![]() $f_N$ denote skin friction for EVP and Newtonian cases, respectively. Following Dean (Reference Dean1978)

$f_N$ denote skin friction for EVP and Newtonian cases, respectively. Following Dean (Reference Dean1978)

\begin{equation} f_N = \begin{cases}

12/Re_w & {laminar}\\ 0.073 Re_w^{{-}0.25} & {turbulent},

\end{cases} \end{equation}

\begin{equation} f_N = \begin{cases}

12/Re_w & {laminar}\\ 0.073 Re_w^{{-}0.25} & {turbulent},

\end{cases} \end{equation}

where ![]() $Re_w=\rho U 2h/\mu _w$ and

$Re_w=\rho U 2h/\mu _w$ and ![]() $\mu _w=\tau _w/\dot {\gamma _w}$, and subscript

$\mu _w=\tau _w/\dot {\gamma _w}$, and subscript ![]() $w$ denotes wall quantities. Using

$w$ denotes wall quantities. Using ![]() $DR_2$ as a measure, the highest drag reduction is achieved either at high

$DR_2$ as a measure, the highest drag reduction is achieved either at high ![]() $Wi$, or in EVP flow when

$Wi$, or in EVP flow when ![]() $Wi$ and

$Wi$ and ![]() $Bi$ are both moderate, in the same region where laminarisation is delayed to higher

$Bi$ are both moderate, in the same region where laminarisation is delayed to higher ![]() $Bi$. In general, the drag-reduction values remain very similar for these two measures in the turbulent regime, indicating that shear thinning has no major influence on drag reduction at the studied parameter values. Despite this, the viscosity profiles (figure 8) show shear thinning for VE, EVP and VP cases. Apparently, plasticity plays a strong role on shear thinning, as both VP and EVP show stronger shear thinning. For the EVP case at

$Bi$. In general, the drag-reduction values remain very similar for these two measures in the turbulent regime, indicating that shear thinning has no major influence on drag reduction at the studied parameter values. Despite this, the viscosity profiles (figure 8) show shear thinning for VE, EVP and VP cases. Apparently, plasticity plays a strong role on shear thinning, as both VP and EVP show stronger shear thinning. For the EVP case at ![]() $Wi=4$ and

$Wi=4$ and ![]() $Bi=5.6$, we are approaching results of VP at

$Bi=5.6$, we are approaching results of VP at ![]() $Bi=1.4$, thus elasticity seems to decrease shear thinning.

$Bi=1.4$, thus elasticity seems to decrease shear thinning.

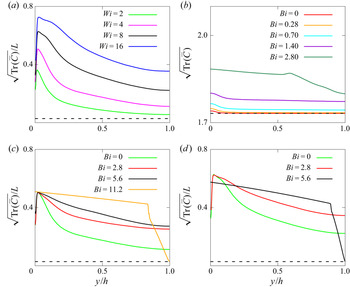

Figure 8. The shear effective viscosity ![]() $\mu _e$ for (a) VE, (b) VP and (c) EVP cases. (a) VE case: the green, magenta, black and blue colours are used for

$\mu _e$ for (a) VE, (b) VP and (c) EVP cases. (a) VE case: the green, magenta, black and blue colours are used for ![]() $Wi = 2$, 4, 8 and 16. (b) VP case: the red, orange, cyan and violet colours are used for

$Wi = 2$, 4, 8 and 16. (b) VP case: the red, orange, cyan and violet colours are used for ![]() $Bi = 0$, 0.28, 0.7 and 1.4, respectively (c) EVP case is at fixed

$Bi = 0$, 0.28, 0.7 and 1.4, respectively (c) EVP case is at fixed ![]() $Wi=4$ and the green, red and black colours are used for

$Wi=4$ and the green, red and black colours are used for ![]() $Bi = 0$, 2.8 and 5.6, respectively.

$Bi = 0$, 2.8 and 5.6, respectively.

The main area responsible for the non-monotonic trends is the unyielded region of the flow. The unyielded regions show a non-trivial and complex trend with ![]() $Bi$ and

$Bi$ and ![]() $Wi$, with significant differences also between the laminar and turbulent regimes. In order to better understand the flow, we start by showing visualisations of the instantaneous distributions of the yielded and unyielded regions in figure 9. In particular, the figure shows instantaneous cross-stream planes (

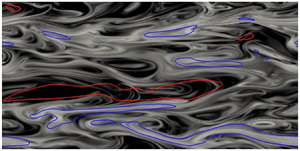

$Wi$, with significant differences also between the laminar and turbulent regimes. In order to better understand the flow, we start by showing visualisations of the instantaneous distributions of the yielded and unyielded regions in figure 9. In particular, the figure shows instantaneous cross-stream planes (![]() $x$–

$x$–![]() $y$ plane) where the unyielded regions are coloured in brown; in the yielded regions we report colour contours of the spanwise vorticity,

$y$ plane) where the unyielded regions are coloured in brown; in the yielded regions we report colour contours of the spanwise vorticity, ![]() $\omega _z$. At

$\omega _z$. At ![]() $Bi=0$ and

$Bi=0$ and ![]() $Wi \approx 0$ we recognise the classic vorticity field of turbulent channel flows, with high vorticity levels at the walls, and the footprints of the classical turbulent streaky structures. As

$Wi \approx 0$ we recognise the classic vorticity field of turbulent channel flows, with high vorticity levels at the walls, and the footprints of the classical turbulent streaky structures. As ![]() $Wi$ increases, the flow becomes smoother, the flow structures seem to be more elongated and the streamwise coherency of the flow increases, as is typical of drag-reducing flows.

$Wi$ increases, the flow becomes smoother, the flow structures seem to be more elongated and the streamwise coherency of the flow increases, as is typical of drag-reducing flows.

Figure 9. Contours of the instantaneous spanwise vorticity ![]() $-\omega _z$ in a

$-\omega _z$ in a ![]() $x$–

$x$–![]() $y$ plane As a function of the Bingham and Weissenberg numbers. Colour scale ranges from

$y$ plane As a function of the Bingham and Weissenberg numbers. Colour scale ranges from ![]() $-3U_b/h$ (blue) to

$-3U_b/h$ (blue) to ![]() $3U_b/h$ (red). The brown areas represent the instantaneous regions where the flow is not yielded.

$3U_b/h$ (red). The brown areas represent the instantaneous regions where the flow is not yielded.

Note that, although the turbulence activity is reducing with ![]() $Wi$, the purely viscoelastic flow does not laminarise. On the other hand, for every

$Wi$, the purely viscoelastic flow does not laminarise. On the other hand, for every ![]() $Wi$, the flow returns to laminar for a sufficiently high Bingham number (

$Wi$, the flow returns to laminar for a sufficiently high Bingham number (![]() $Bi > Bi_c$). In particular, we observe that as

$Bi > Bi_c$). In particular, we observe that as ![]() $Bi$ increases, the amount of fluid which is unyielded grows, eventually forming a fully connected plug spanning the whole streamwise and spanwise lengths, thus leading to the decay of turbulence and the return to a fully laminar regime. However, at intermediate

$Bi$ increases, the amount of fluid which is unyielded grows, eventually forming a fully connected plug spanning the whole streamwise and spanwise lengths, thus leading to the decay of turbulence and the return to a fully laminar regime. However, at intermediate ![]() $Wi$, we observe that a higher

$Wi$, we observe that a higher ![]() $Bi_c$ is required to laminarise the flow than at low or high

$Bi_c$ is required to laminarise the flow than at low or high ![]() $Wi$. At intermediate

$Wi$. At intermediate ![]() $Wi$, the equilibrium solutions indicate that the unyielded region is narrower than in the viscoplastic flow (Chaparian & Tammisola Reference Chaparian and Tammisola2019), and we propose that this allows instabilities to be sustained in the yielded regions. In the present simulation at intermediate

$Wi$, the equilibrium solutions indicate that the unyielded region is narrower than in the viscoplastic flow (Chaparian & Tammisola Reference Chaparian and Tammisola2019), and we propose that this allows instabilities to be sustained in the yielded regions. In the present simulation at intermediate ![]() $Wi$, a plug was formed initially and the flow seemed to laminarise, but soon a large-scale roll-up motion developed at the edges of the unyielded region, recreating the unsteadiness and turbulence. On the other hand, at higher values (

$Wi$, a plug was formed initially and the flow seemed to laminarise, but soon a large-scale roll-up motion developed at the edges of the unyielded region, recreating the unsteadiness and turbulence. On the other hand, at higher values (![]() $Wi>4$) this effect does not occur thus leading to lower

$Wi>4$) this effect does not occur thus leading to lower ![]() $Bi_c$. This phenomenon could be attributed to the fact that the unyielded region becomes too thin to create any instability. Moreover, the yielded region becomes smoother at high

$Bi_c$. This phenomenon could be attributed to the fact that the unyielded region becomes too thin to create any instability. Moreover, the yielded region becomes smoother at high ![]() $Wi$ enhancing laminarisation.

$Wi$ enhancing laminarisation.

It is not obvious what drives the instability leading to the roll-up motion, because the laminar flow profile is not inflectional. A sharp viscosity contrast can lead instabilities in channel and shear flows. The unyielded region could play a similar role as a high-viscosity fluid in the centre of the channel, a configuration which can be unstable at high Reynolds numbers (Hooper & Boyd Reference Hooper and Boyd1987; Govindarajan & Sahu Reference Govindarajan and Sahu2013). On the other hand, a channel flow of Bingham fluid is known to be linearly stable at all Reynolds numbers. Although the linear stability of EVP flow has not been studied, the transition that we observe could be subcritical, like for Bingham fluids. However, the roll-up structure we observe does not resemble the optimal non-modal instabilities in Bingham fluid: streamwise-travelling waves (Nouar et al. Reference Nouar, Kabouya, Dusek and Mamou2007) or oblique waves (Nouar & Bottaro Reference Nouar and Bottaro2010).

For laminar flows (![]() $Bi>Bi_c$), a further increase of

$Bi>Bi_c$), a further increase of ![]() $Bi$ leads to a growth of the unyielded region, which induces an increase of the wall shear stress and a consequent drag increase, as previously observed in figure 8. This is different from observations in the turbulent regime, where the drag reduces with both

$Bi$ leads to a growth of the unyielded region, which induces an increase of the wall shear stress and a consequent drag increase, as previously observed in figure 8. This is different from observations in the turbulent regime, where the drag reduces with both ![]() $Wi$ and

$Wi$ and ![]() $Bi$ (Rosti et al. Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c).

$Bi$ (Rosti et al. Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c).

3.3. Flow statistics

Here, we discuss the turbulent statistics for EVP flows. To facilitate comparisons, we provide results for the two limiting cases: near-viscoplastic and viscoelastic flows, and then compare these with the flows with finite elasticity and plasticity. The near-viscoplastic flow was presented in our earlier work (Rosti et al. Reference Rosti, Izbassarov, Tammisola, Hormozi and Brandt2018c), and was computed using the Saramito model at ![]() $Wi=0.01$,

$Wi=0.01$, ![]() $\beta =0.95$, and varying

$\beta =0.95$, and varying ![]() $Bi$. The viscoelastic flow is computed at varied Weissenberg number

$Bi$. The viscoelastic flow is computed at varied Weissenberg number ![]() $0 \le Wi \le 16$ and fixed Bingham number

$0 \le Wi \le 16$ and fixed Bingham number ![]() $Bi=0$, and the FENE-P model parameters are

$Bi=0$, and the FENE-P model parameters are ![]() $\beta =0.9$ and

$\beta =0.9$ and ![]() $L^2=3600$, unless indicated otherwise.

$L^2=3600$, unless indicated otherwise.

We first discuss the mean streamwise velocity profiles in relation to drag reduction shown in figure 7. In figure 10, the velocity profiles are shown in wall units. The profiles for viscoplastic flow in figure 10(a) are similar to the Newtonian case for ![]() $Bi<1.4$. For

$Bi<1.4$. For ![]() $Bi=1.4$, the difference becomes more significant with zero-shear region at the centreline. At

$Bi=1.4$, the difference becomes more significant with zero-shear region at the centreline. At ![]() $Bi=2.8$, the flow becomes laminar with a large zero-shear region, leading to drag increase as observed in figure 7. We can observe that the flow remains unyielded mostly in the logarithmic and outer layer, while it is always yielded in the viscous sublayer.

$Bi=2.8$, the flow becomes laminar with a large zero-shear region, leading to drag increase as observed in figure 7. We can observe that the flow remains unyielded mostly in the logarithmic and outer layer, while it is always yielded in the viscous sublayer.

Figure 10. Mean streamwise velocity profile ![]() $\bar {u}$ as a function of the wall-normal distance

$\bar {u}$ as a function of the wall-normal distance ![]() $y$ in wall units. (a) Near-viscoplastic flow (

$y$ in wall units. (a) Near-viscoplastic flow (![]() $Wi=0.01$). (b) Viscoelastic flow (

$Wi=0.01$). (b) Viscoelastic flow (![]() $Bi=0$). The dashed line and symbols in the figure correspond to the Virk curve at maximum drag reduction (Virk Reference Virk1975) and the results of Kim, Moin & Moser (Reference Kim, Moin and Moser1987), respectively.

$Bi=0$). The dashed line and symbols in the figure correspond to the Virk curve at maximum drag reduction (Virk Reference Virk1975) and the results of Kim, Moin & Moser (Reference Kim, Moin and Moser1987), respectively.

Figure 11. EVP flow: (a) drag reduction as a function of ![]() $Bi$ and (b) mean streamwise velocity profile

$Bi$ and (b) mean streamwise velocity profile ![]() $\bar {u}$ as a function of the wall-normal distance

$\bar {u}$ as a function of the wall-normal distance ![]() $y$ in wall units. The Weissenberg number

$y$ in wall units. The Weissenberg number ![]() $Wi$ and the extensibility parameter

$Wi$ and the extensibility parameter ![]() $L^2$ are fixed and equal to

$L^2$ are fixed and equal to ![]() $4$ and

$4$ and ![]() $3600$, respectively (FENE-P model).

$3600$, respectively (FENE-P model).

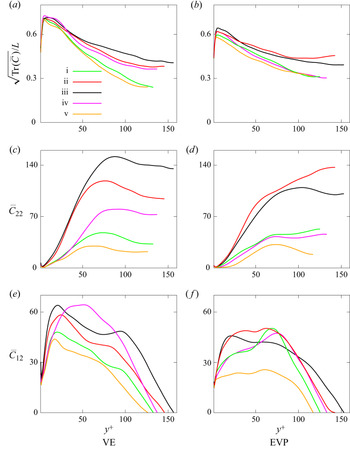

Figure 12. Wall-normal profiles of components of the Reynolds stress tensor, normalised with ![]() $u_\tau ^2$. The first column shows

$u_\tau ^2$. The first column shows ![]() $u'u'$, the second column

$u'u'$, the second column ![]() $v'v'$. (a,b) VE flow at various

$v'v'$. (a,b) VE flow at various ![]() $Wi$ and fixed

$Wi$ and fixed ![]() $Bi=0$. (c,d) VP flow at various

$Bi=0$. (c,d) VP flow at various ![]() $Bi$ and fixed

$Bi$ and fixed ![]() $Wi=0.01$. (e,f) EVP flow at various

$Wi=0.01$. (e,f) EVP flow at various ![]() $Bi$ and fixed

$Bi$ and fixed ![]() $Wi=4$. The extensibility parameter

$Wi=4$. The extensibility parameter ![]() $L^2$ is fixed and equal to

$L^2$ is fixed and equal to ![]() $3600$. The

$3600$. The ![]() $\bullet$, blue symbols indicate the direct numerical simulation (DNS) data of Kim et al. (Reference Kim, Moin and Moser1987).

$\bullet$, blue symbols indicate the direct numerical simulation (DNS) data of Kim et al. (Reference Kim, Moin and Moser1987).

Figure 13. Wall-normal profiles of components of the Reynolds stress tensor, normalised with ![]() $u_\tau ^2$. The first column shows

$u_\tau ^2$. The first column shows ![]() $w'w'$, the second column

$w'w'$, the second column ![]() $u'v'$. (a,b) VE flow at various

$u'v'$. (a,b) VE flow at various ![]() $Wi$ and fixed

$Wi$ and fixed ![]() $Bi=0$. (c,d) VP flow at various

$Bi=0$. (c,d) VP flow at various ![]() $Bi$ and fixed

$Bi$ and fixed ![]() $Wi=0.01$. (e,f) EVP flow at various

$Wi=0.01$. (e,f) EVP flow at various ![]() $Bi$ and fixed

$Bi$ and fixed ![]() $Wi=4$. The extensibility parameter

$Wi=4$. The extensibility parameter ![]() $L^2$ is fixed and equal to

$L^2$ is fixed and equal to ![]() $3600$. The

$3600$. The ![]() $\bullet$, blue symbols indicate the DNS data of Kim et al. (Reference Kim, Moin and Moser1987).

$\bullet$, blue symbols indicate the DNS data of Kim et al. (Reference Kim, Moin and Moser1987).

For viscoelastic flows, ![]() $DR \%$ increases monotonically with

$DR \%$ increases monotonically with ![]() $Wi$ in the range of

$Wi$ in the range of ![]() $Wi={O}(1)$ and start to saturate at

$Wi={O}(1)$ and start to saturate at ![]() $Wi>10$. The maximum drag reduction is close to

$Wi>10$. The maximum drag reduction is close to ![]() $40\,\%$ at

$40\,\%$ at ![]() $Wi=16$. Figure 10(b) shows the mean streamwise velocity profiles in wall units. It can be seen that increasing

$Wi=16$. Figure 10(b) shows the mean streamwise velocity profiles in wall units. It can be seen that increasing ![]() $Wi$ the velocity profiles collapse in the viscous sublayer, however, shift upward in the buffer region (thickening of the buffer layer) and are parallel to the Newtonian profile. Note that we do not reach Virk's maximum drag-reduction (MDR) asymptote (Virk Reference Virk1975), which is out of scope of the present study. The shift in the velocity profile is consistent with results in the literature (Xi & Graham Reference Xi and Graham2010; Shahmardi et al. Reference Shahmardi, Zade, Ardekani, Poole, Lundell, Rosti and Brandt2019).

$Wi$ the velocity profiles collapse in the viscous sublayer, however, shift upward in the buffer region (thickening of the buffer layer) and are parallel to the Newtonian profile. Note that we do not reach Virk's maximum drag-reduction (MDR) asymptote (Virk Reference Virk1975), which is out of scope of the present study. The shift in the velocity profile is consistent with results in the literature (Xi & Graham Reference Xi and Graham2010; Shahmardi et al. Reference Shahmardi, Zade, Ardekani, Poole, Lundell, Rosti and Brandt2019).

We next consider the EVP flow. The drag-reduction values and the corresponding mean streamwise velocity profiles for ![]() $Wi=4, \beta =0.9, L^2=3600$ and

$Wi=4, \beta =0.9, L^2=3600$ and ![]() $Bi=0$, 2.8, 5.6, 11.2 and

$Bi=0$, 2.8, 5.6, 11.2 and ![]() $22.4$ are shown in figure 11. Similarly to the viscoplastic flow, the

$22.4$ are shown in figure 11. Similarly to the viscoplastic flow, the ![]() $DR \%$ increases with

$DR \%$ increases with ![]() $Bi$ in the turbulent regime. Unlike pure viscoelastic case, plasticity enhances the

$Bi$ in the turbulent regime. Unlike pure viscoelastic case, plasticity enhances the ![]() $DR$ going from low-drag reduction (LDR,

$DR$ going from low-drag reduction (LDR, ![]() $DR\lesssim 40$) at

$DR\lesssim 40$) at ![]() $0 \le Bi < 5.6$ to high drag-reduction (HDR,

$0 \le Bi < 5.6$ to high drag-reduction (HDR, ![]() ${40< DR\lesssim 60}$) at

${40< DR\lesssim 60}$) at ![]() $Bi=5.6$. Moreover, the laminar regime delays to larger

$Bi=5.6$. Moreover, the laminar regime delays to larger ![]() $Bi>5.6$, which may be attributed to the dramatic effects due to the polymer dynamics. Unlike the viscoplastic case,

$Bi>5.6$, which may be attributed to the dramatic effects due to the polymer dynamics. Unlike the viscoplastic case, ![]() $DR \%$ only slightly decreases in the laminar case as shown also earlier in figure 7. The change of mean streamwise velocity profile with

$DR \%$ only slightly decreases in the laminar case as shown also earlier in figure 7. The change of mean streamwise velocity profile with ![]() $Bi$ is more significant than in figure 10(a) and more similar to figure 10(b) for

$Bi$ is more significant than in figure 10(a) and more similar to figure 10(b) for ![]() $Bi\le 5.6$, i.e. the velocity profile collapse in the viscous sublayer, and shift upward in the buffer and log-law layer approaching Virk's asymptote. In contrast, for

$Bi\le 5.6$, i.e. the velocity profile collapse in the viscous sublayer, and shift upward in the buffer and log-law layer approaching Virk's asymptote. In contrast, for ![]() $Bi>5.6$ the flow fully laminarises and becomes similar to the case in figure 10(a), with the zero-shear region at the centreline.

$Bi>5.6$ the flow fully laminarises and becomes similar to the case in figure 10(a), with the zero-shear region at the centreline.

Next, we analyse the wall-normal distribution of the Reynolds stress components ![]() $\overline {u'u'}$ and

$\overline {u'u'}$ and ![]() $\overline {v'v'}$, shown in figure 12 together with the Newtonian case by Kim et al. (Reference Kim, Moin and Moser1987) (blue symbol). The profiles are normalised with

$\overline {v'v'}$, shown in figure 12 together with the Newtonian case by Kim et al. (Reference Kim, Moin and Moser1987) (blue symbol). The profiles are normalised with ![]() $u_\tau ^2$. The results for the viscoelastic case (a,b) show that the

$u_\tau ^2$. The results for the viscoelastic case (a,b) show that the ![]() $\overline {u'u'}$ increases while

$\overline {u'u'}$ increases while ![]() $\overline {v'v'}$ decreases with

$\overline {v'v'}$ decreases with ![]() $Wi$. In general, the shape of the profiles is similar to the corresponding Newtonian one, but the magnitude changes with

$Wi$. In general, the shape of the profiles is similar to the corresponding Newtonian one, but the magnitude changes with ![]() $Wi$. Moreover, all the peaks move towards the channel centre, in agreement with the thickening of the buffer layer observed in the mean velocity profile. A similar behaviour has been noticed in the literature for drag-reducing turbulent viscoelastic flows (White & Mungal Reference White and Mungal2008; Dallas, Vassilicos & Hewitt Reference Dallas, Vassilicos and Hewitt2010). The VP case (

$Wi$. Moreover, all the peaks move towards the channel centre, in agreement with the thickening of the buffer layer observed in the mean velocity profile. A similar behaviour has been noticed in the literature for drag-reducing turbulent viscoelastic flows (White & Mungal Reference White and Mungal2008; Dallas, Vassilicos & Hewitt Reference Dallas, Vassilicos and Hewitt2010). The VP case (![]() $Wi=0.01$) is depicted in (c,d) to examine the effects of the Bingham number in the range

$Wi=0.01$) is depicted in (c,d) to examine the effects of the Bingham number in the range ![]() $0\le Bi \le 2.8$. We clearly observe that the peak of the streamwise component

$0\le Bi \le 2.8$. We clearly observe that the peak of the streamwise component ![]() $\overline {u'u'}$ increases with

$\overline {u'u'}$ increases with ![]() $Bi$, while it decreases for

$Bi$, while it decreases for ![]() $\overline {v'v'}$. A similar trend is observed for the EVP case (

$\overline {v'v'}$. A similar trend is observed for the EVP case (![]() $Wi=4$) as depicted in (e,f).

$Wi=4$) as depicted in (e,f).

Although the overall trends are similar, the combined effects of elasticity and plasticity in the EVP flows result in larger deviations from the Newtonian flow than for the two limiting cases, particularly for the peak in the ![]() $\overline {u'u'}$ profile. It is also interesting to note that in the EVP flow the peak moves non-monotonically, unlike in the VE and VP cases: it first moves away from the wall as

$\overline {u'u'}$ profile. It is also interesting to note that in the EVP flow the peak moves non-monotonically, unlike in the VE and VP cases: it first moves away from the wall as ![]() $Bi$ increases (