Researchers from South China University of Technology and the Chinese Academy of Sciences have developed a multifunctional, semitransparent, organic photovoltaic (ST-OPV) device that can generate electricity and at the same time block infrared (IR) light, which is responsible for heat generation. The ST-OPV would be capable of producing energy while reducing the overall consumption of electricity in a household or office. The heat rejection properties of the solar cell is comparable to commercial ones (NV-25, P-18ARL, and PR70). The work was reported in a recent issue of Joule (doi:10.1016/j.joule.2018.06.006).

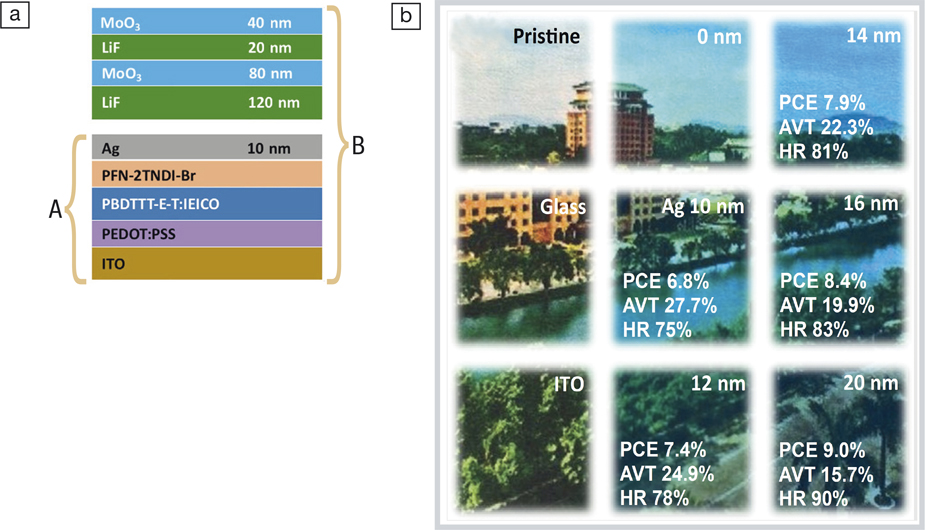

The amalgamation of power generation and heat insulation is carried out with a simple OPV structure of indium tin oxide (ITO)/PEDOT:PSS(p-type interlayer)/PBDTTT-E-T:IEICO(active layer)/PFN-2TNDI-Br(n-type interlayer)/Ag. Light enters from the ITO side. The absorbing polymer blends are promising candidates as the active layer in nonfullerene OPV and have weak absorption in the visible range. The 2,2′-((2Z,2′Z)-((5,5′-(4,4,9,9-tetrakis(4-hexylphenyl)-4,9-dihydro-s-indaceno[1,2-b:5,6-b′]dithiophene-2,7-diyl)bis(4-((2-ethylhexyl)-oxy)thiophene-5,2-diyl))bis(methanylylidene))bis(3-oxo-2,3-di-hydro-1H-indene-2,1-diylidene))dimalononitrile (IEICO) acceptor is of particular importance in the multifunctionality of the device, as the absorption edge of this material is extended to 900 nm, which helps to generate photocurrent while utilizing the near-IR (NIR) photons. Moving a step forward toward blocking NIR light, a four-layer distributed Bragg reflector (DBR structure) (LiF/MoO3) is deposited on top of the Ag electrode, which reflects the NIR photons back while maintaining transparency for visible wavelengths.

The transmittance and power-conversion efficiency (PCE) in these devices are optimized through varying the thickness of the Ag electrode, from 10 nm to 20 nm. The PCE (6.8–9%) of the ST-OPV device is found to be linearly dependent on the average visible transmittance (AVT) (28–17%). The thickness of the Ag electrode has a significant impact on the IR reflectivity as well. When the thickness of Ag increases from 10 nm to 20 nm, the IR rejection also increases from 75% to 90%, which is comparable to those of commercialized films for heat reduction such as NV-25, P-18ARL, and PR70. The PR70 solar film inspired the heat rejection design in this study as it utilizes a sophisticated photonic-crystal design with alternating thin films of high- and low-refractive-index materials forming a DBR.

The advanced engineering of materials and optimization of the optics result in 6.5% efficient solar cells and AVT of 25% with IR radiation rejection rate over 80%. According to estimated calculations by Hin-Lap Yip from South China University of Technology, in a 15 m2 window area in a 100 m2 house, the ST-OPV can cut down 30% of electricity cost per household. When the ST-OPV is combined with the heat rejection properties, then the electricity reduction could reach ∼50%. “Heat insulation is already a huge market, and [the introduction] of light harvesting will be a great added advantage,” Yip says.

Kui Zhao from Shaanxi Normal University, who was not involved in this study, says, “This study has demonstrated for the first time a dual-functional ST-OPV device. The device exhibits high performance with heat rejection properties comparable with those of commercial window films. This novel design concept is expected to open up a new approach to developing multifunctional yet efficient semitransparent organic solar cells.”

(a) Schematic of the semitransparent, organic photovoltaic (ST-OPV) device (A) and ST-OPV with Bragg reflector device (B). (b) The campus of the South China University of Technology viewed through different solar PV window films. The design of the film balances three key parameters: (1) power-conversion efficiency (PCE), (2) average visible transmittance (AVT), and (3) infrared rejection rate (HR). ITO is indium tin oxide. Credit: Prof. Hin-Lap Yip.

Enrique Gomez from The Pennsylvania State University, who was also not involved in this study, says, “This is a clever approach to manage the optical properties of polymer solar cells that further demonstrate their potential as semitransparent windows. Although a techno-economic analysis is still needed, I expect that this approach will bring semitransparent organic solar cells closer to commercialization as window materials.”