1. Introduction

Viscoelastic fluid flows in non-uniform geometries consisting of contractions or expansions occur in physiological flows, e.g. arterial flows that may have such shape changes due to thrombus formation (Westein et al. Reference Westein, van der Meer, Kuijpers, Frimat, van den Berg and Heemskerk2013), and in various industrial applications (Pearson Reference Pearson1985). For such flows, one of the key interests is to understand the dependence of the pressure drop ![]() $\Delta p$ on the flow rate

$\Delta p$ on the flow rate ![]() $q$. It is well known that adding even small amounts of polymer molecules in a Newtonian solvent may drastically change the hydrodynamic features of the flow of the solution due to polymer stretching, which generates elastic stresses in addition to viscous stresses (Bird, Armstrong & Hassager Reference Bird, Armstrong and Hassager1987; Alves, Oliveira & Pinho Reference Alves, Oliveira and Pinho2021; Steinberg Reference Steinberg2021; Datta et al. Reference Datta2022).

$q$. It is well known that adding even small amounts of polymer molecules in a Newtonian solvent may drastically change the hydrodynamic features of the flow of the solution due to polymer stretching, which generates elastic stresses in addition to viscous stresses (Bird, Armstrong & Hassager Reference Bird, Armstrong and Hassager1987; Alves, Oliveira & Pinho Reference Alves, Oliveira and Pinho2021; Steinberg Reference Steinberg2021; Datta et al. Reference Datta2022).

Pressure-driven flows of viscoelastic fluids and the corresponding flow rate–pressure drop relation have been studied extensively in various geometries, mainly through numerical simulations (Szabo, Rallison & Hinch Reference Szabo, Rallison and Hinch1997; Alves, Oliveira & Pinho Reference Alves, Oliveira and Pinho2003; Binding, Phillips & Phillips Reference Binding, Phillips and Phillips2006; Alves & Poole Reference Alves and Poole2007; Zografos et al. Reference Zografos, Hartt, Hamersky, Oliveira, Alves and Poole2020; Varchanis et al. Reference Varchanis, Tsamopoulos, Shen and Haward2022) and experimental measurements (Rothstein & McKinley Reference Rothstein and McKinley1999, Reference Rothstein and McKinley2001; Sousa et al. Reference Sousa, Coelho, Oliveira and Alves2009; Ober et al. Reference Ober, Haward, Pipe, Soulages and McKinley2013; James & Roos Reference James and Roos2021). We refer the reader to overviews given recently by Boyko & Stone (Reference Boyko and Stone2022) and Hinch, Boyko & Stone (Reference Hinch, Boyko and Stone2024).

In particular, the abrupt contraction and contraction–expansion channels have received much attention (Rothstein & McKinley Reference Rothstein and McKinley1999; Alves et al. Reference Alves, Oliveira and Pinho2003; Binding et al. Reference Binding, Phillips and Phillips2006; Ferrás et al. Reference Ferrás, Afonso, Alves, Nóbrega and Pinho2020), and ![]() $4\,{:}\,1$ two-dimensional (2-D) and axisymmetric contraction flows have become benchmark flow problems in computational non-Newtonian fluid mechanics (Alves et al. Reference Alves, Oliveira and Pinho2021). Numerical simulations of viscoelastic fluid flow in these and other non-uniform geometries include a long downstream (exit) section to allow the stresses to reach their fully relaxed values (see, e.g. Debbaut, Marchal & Crochet Reference Debbaut, Marchal and Crochet1988; Alves et al. Reference Alves, Oliveira and Pinho2003). This is because, once perturbed from their fully relaxed values, the elastic stresses require a long distance for spatial relaxation to enable stable and converged numerical solutions. For higher Deborah (

$4\,{:}\,1$ two-dimensional (2-D) and axisymmetric contraction flows have become benchmark flow problems in computational non-Newtonian fluid mechanics (Alves et al. Reference Alves, Oliveira and Pinho2021). Numerical simulations of viscoelastic fluid flow in these and other non-uniform geometries include a long downstream (exit) section to allow the stresses to reach their fully relaxed values (see, e.g. Debbaut, Marchal & Crochet Reference Debbaut, Marchal and Crochet1988; Alves et al. Reference Alves, Oliveira and Pinho2003). This is because, once perturbed from their fully relaxed values, the elastic stresses require a long distance for spatial relaxation to enable stable and converged numerical solutions. For higher Deborah (![]() $De$) or Weissenberg (

$De$) or Weissenberg (![]() $Wi$) numbers (see definitions in § 2.1), a longer downstream section is required (Keiller Reference Keiller1993).

$Wi$) numbers (see definitions in § 2.1), a longer downstream section is required (Keiller Reference Keiller1993).

Therefore, understanding the spatial relaxation of elastic stresses, velocity and pressure is of both fundamental and practical importance, as that determines the size of the computational domain (Alves et al. Reference Alves, Oliveira and Pinho2003). However, despite extensive study of viscoelastic channel flows, the spatial relaxation of stresses and pressure in these geometries is not well understood. As a result, the length of the exit channel is currently set somewhat arbitrarily, thus motivating the development of theory. Furthermore, in many applications, it is necessary to determine the total pressure drop over the configuration for a given flow rate, thus requiring us to account for the pressure drop in the entry and exit channels. However, most studies to date focused on the non-uniform region or close vicinity of the abrupt contraction and reported a suitably non-dimensionalized so-called Couette correction (or excess pressure drop), rather than the total non-dimensional pressure drop in the entire configuration (see, e.g. Rothstein & McKinley Reference Rothstein and McKinley1999; Alves et al. Reference Alves, Oliveira and Pinho2003; Binding et al. Reference Binding, Phillips and Phillips2006), presumably due to the arbitrariness of the exit channel length in simulations.

One widely used approach to obtaining theoretical results in different viscoelastic fluid flow problems relies on considering the weakly viscoelastic limit by applying a perturbation expansion in powers of the Deborah or Weissenberg number, which are assumed to be small (see, e.g. Datt et al. Reference Datt, Natale, Hatzikiriakos and Elfring2017; Datt, Nasouri & Elfring Reference Datt, Nasouri and Elfring2018; Datt & Elfring Reference Datt and Elfring2019; Gkormpatsis et al. Reference Gkormpatsis, Gryparis, Housiadas and Beris2020; Dandekar & Ardekani Reference Dandekar and Ardekani2021; Housiadas, Binagia & Shaqfeh Reference Housiadas, Binagia and Shaqfeh2021; Su et al. Reference Su, Castillo, Pak, Zhu and Zenit2022). In particular, there have been many applications of such an expansion in conjunction with lubrication theory in studying thin films and tribology problems (Ro & Homsy Reference Ro and Homsy1995; Tichy Reference Tichy1996; Sawyer & Tichy Reference Sawyer and Tichy1998; Zhang, Matar & Craster Reference Zhang, Matar and Craster2002; Saprykin, Koopmans & Kalliadasis Reference Saprykin, Koopmans and Kalliadasis2007; Ahmed & Biancofiore Reference Ahmed and Biancofiore2021; Gamaniel, Dini & Biancofiore Reference Gamaniel, Dini and Biancofiore2021; Ahmed & Biancofiore Reference Ahmed and Biancofiore2023). Recently, we have applied lubrication theory and such an expansion in powers of ![]() $De$, developing a reduced-order model for the steady flow of an Oldroyd-B fluid in a slowly varying, arbitrarily shaped 2-D channel (Boyko & Stone Reference Boyko and Stone2022). We provided analytical expressions for the velocity and stress fields and the flow rate–pressure drop relation in the non-uniform region up to

$De$, developing a reduced-order model for the steady flow of an Oldroyd-B fluid in a slowly varying, arbitrarily shaped 2-D channel (Boyko & Stone Reference Boyko and Stone2022). We provided analytical expressions for the velocity and stress fields and the flow rate–pressure drop relation in the non-uniform region up to ![]() $O(De^2)$. We further exploited the reciprocal theorem (Boyko & Stone Reference Boyko and Stone2021, Reference Boyko and Stone2022) to obtain the flow rate–pressure drop relation at the next order,

$O(De^2)$. We further exploited the reciprocal theorem (Boyko & Stone Reference Boyko and Stone2021, Reference Boyko and Stone2022) to obtain the flow rate–pressure drop relation at the next order, ![]() $O(De^3)$. Housiadas & Beris (Reference Housiadas and Beris2023) extended the low-Deborah-number lubrication analysis of Boyko & Stone (Reference Boyko and Stone2022) to much higher asymptotic orders and provided analytical expressions for the pressure drop up to

$O(De^3)$. Housiadas & Beris (Reference Housiadas and Beris2023) extended the low-Deborah-number lubrication analysis of Boyko & Stone (Reference Boyko and Stone2022) to much higher asymptotic orders and provided analytical expressions for the pressure drop up to ![]() $O(De^8$).

$O(De^8$).

However, the low-Deborah-number analysis cannot accurately capture the behaviour at high ![]() $De$ numbers where there are significant elastic stresses. Another approach to simplifying the governing equations while capturing the underlying physics at non-small Deborah numbers is to consider the ultra-dilute limit (Remmelgas, Singh & Leal Reference Remmelgas, Singh and Leal1999; Moore & Shelley Reference Moore and Shelley2012; Li, Thomases & Guy Reference Li, Thomases and Guy2019; Mokhtari et al. Reference Mokhtari, Latché, Quintard and Davit2022),

$De$ numbers where there are significant elastic stresses. Another approach to simplifying the governing equations while capturing the underlying physics at non-small Deborah numbers is to consider the ultra-dilute limit (Remmelgas, Singh & Leal Reference Remmelgas, Singh and Leal1999; Moore & Shelley Reference Moore and Shelley2012; Li, Thomases & Guy Reference Li, Thomases and Guy2019; Mokhtari et al. Reference Mokhtari, Latché, Quintard and Davit2022), ![]() $\tilde {\beta }=\mu _{p}/\mu _{0} \ll 1$, where

$\tilde {\beta }=\mu _{p}/\mu _{0} \ll 1$, where ![]() $\mu _{p}$ is the polymer contribution to the total zero-shear-rate viscosity

$\mu _{p}$ is the polymer contribution to the total zero-shear-rate viscosity ![]() $\mu _{0}$ of the polymer solution. Physically, the ultra-dilute limit corresponds to a low concentration of polymer molecules in a Newtonian solvent, such that the viscosity of the polymer solution,

$\mu _{0}$ of the polymer solution. Physically, the ultra-dilute limit corresponds to a low concentration of polymer molecules in a Newtonian solvent, such that the viscosity of the polymer solution, ![]() $\mu _{0}$, is only slightly larger than the solvent viscosity,

$\mu _{0}$, is only slightly larger than the solvent viscosity, ![]() $\mu _{s}$ (Remmelgas et al. Reference Remmelgas, Singh and Leal1999; Mokhtari et al. Reference Mokhtari, Latché, Quintard and Davit2022). Furthermore, the limit

$\mu _{s}$ (Remmelgas et al. Reference Remmelgas, Singh and Leal1999; Mokhtari et al. Reference Mokhtari, Latché, Quintard and Davit2022). Furthermore, the limit ![]() $\tilde {\beta }=\mu _{p}/\mu _{0} \ll 1$ is closely related to the diluteness criterion of a constant shear-viscosity viscoelastic Boger fluid (Moore & Shelley Reference Moore and Shelley2012). In the ultra-dilute limit, the flow field approximated as Newtonian creates elastic stresses that are not coupled back to change the flow. These elastic stresses can then be used to find the correction to the velocity and pressure fields due to fluid viscoelasticity, even at high Deborah numbers. Previous studies used this approach to determine the structure of the stress distribution in the flow around a cylinder (Renardy Reference Renardy2000), a sphere (Moore & Shelley Reference Moore and Shelley2012) and arrays of cylinders (Mokhtari et al. Reference Mokhtari, Latché, Quintard and Davit2022), as well as in stagnation (Becherer, Van Saarloos & Morozov Reference Becherer, Van Saarloos and Morozov2009; Van Gorder, Vajravelu & Akyildiz Reference Van Gorder, Vajravelu and Akyildiz2009) and cross-slot (Remmelgas et al. Reference Remmelgas, Singh and Leal1999) flows.

$\tilde {\beta }=\mu _{p}/\mu _{0} \ll 1$ is closely related to the diluteness criterion of a constant shear-viscosity viscoelastic Boger fluid (Moore & Shelley Reference Moore and Shelley2012). In the ultra-dilute limit, the flow field approximated as Newtonian creates elastic stresses that are not coupled back to change the flow. These elastic stresses can then be used to find the correction to the velocity and pressure fields due to fluid viscoelasticity, even at high Deborah numbers. Previous studies used this approach to determine the structure of the stress distribution in the flow around a cylinder (Renardy Reference Renardy2000), a sphere (Moore & Shelley Reference Moore and Shelley2012) and arrays of cylinders (Mokhtari et al. Reference Mokhtari, Latché, Quintard and Davit2022), as well as in stagnation (Becherer, Van Saarloos & Morozov Reference Becherer, Van Saarloos and Morozov2009; Van Gorder, Vajravelu & Akyildiz Reference Van Gorder, Vajravelu and Akyildiz2009) and cross-slot (Remmelgas et al. Reference Remmelgas, Singh and Leal1999) flows.

In this work, we continue our theoretical studies (Boyko & Stone Reference Boyko and Stone2022; Hinch et al. Reference Hinch, Boyko and Stone2024) of the pressure-driven flow of the Oldroyd-B fluid in slowly varying, arbitrarily shaped, narrow channels. In contrast to Boyko & Stone (Reference Boyko and Stone2022), who focused only on the flow through a non-uniform channel in the low-Deborah-number limit, and Hinch et al. (Reference Hinch, Boyko and Stone2024), who studied numerically the flow through a contraction, expansion and constriction for order-one Deborah numbers, and also provided an asymptotic description at high Deborah numbers, the current work examines the ultra-dilute limit and arbitrary values of the Deborah number. Specifically, we analyse the flow of the Oldroyd-B fluid in a contracting geometry and the relaxation of the elastic stresses and pressure in the exit channel. We apply the lubrication approximation and use a one-way coupling between the velocity and polymer stresses to derive semi-analytical expressions for the conformation tensor in the contraction and the exit channel for arbitrary values of the Deborah number in the ultra-dilute limit. These semi-analytical expressions allow us to calculate the pressure drop and elucidate the relaxation of the elastic stresses and pressure in the exit channel for all ![]() $De$. We provide analytical expressions for the conformation tensor and the pressure drop in the high-Deborah-number limit, which are consistent with recent results of Hinch et al. (Reference Hinch, Boyko and Stone2024), thus complementing our previous low-Deborah-number lubrication analysis (Boyko & Stone Reference Boyko and Stone2022). Furthermore, we analyse the viscoelastic boundary layer near the walls at high Deborah numbers and derive the boundary-layer asymptotic solutions. Given the well-known lack of accuracy and convergence difficulties associated with the high-Weissenberg-number problem in numerical simulations (Owens & Phillips Reference Owens and Phillips2002; Alves et al. Reference Alves, Oliveira and Pinho2021), our analytical and semi-analytical results for the ultra-dilute limit, valid at high Deborah numbers, are of fundamental importance as they may serve to validate simulation predictions or be compared with experimental measurements to understand more about the applicability of model constitutive equations.

$De$. We provide analytical expressions for the conformation tensor and the pressure drop in the high-Deborah-number limit, which are consistent with recent results of Hinch et al. (Reference Hinch, Boyko and Stone2024), thus complementing our previous low-Deborah-number lubrication analysis (Boyko & Stone Reference Boyko and Stone2022). Furthermore, we analyse the viscoelastic boundary layer near the walls at high Deborah numbers and derive the boundary-layer asymptotic solutions. Given the well-known lack of accuracy and convergence difficulties associated with the high-Weissenberg-number problem in numerical simulations (Owens & Phillips Reference Owens and Phillips2002; Alves et al. Reference Alves, Oliveira and Pinho2021), our analytical and semi-analytical results for the ultra-dilute limit, valid at high Deborah numbers, are of fundamental importance as they may serve to validate simulation predictions or be compared with experimental measurements to understand more about the applicability of model constitutive equations.

2. Problem formulation and governing equations

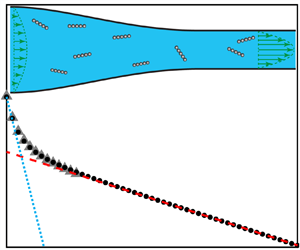

We analyse the incompressible steady flow of a viscoelastic fluid in a slowly varying and symmetric 2-D contraction of height ![]() $2h(z)$ and length

$2h(z)$ and length ![]() $\ell$, where

$\ell$, where ![]() $h(z)\ll \ell$, as illustrated in figure 1. Upstream of the contraction inlet (

$h(z)\ll \ell$, as illustrated in figure 1. Upstream of the contraction inlet (![]() $z=0$) there is an entry channel of height

$z=0$) there is an entry channel of height ![]() $2h_{0}$ and length

$2h_{0}$ and length ![]() $\ell _{0}$, and downstream of the contraction outlet (

$\ell _{0}$, and downstream of the contraction outlet (![]() $z=\ell$) there is an exit channel of height

$z=\ell$) there is an exit channel of height ![]() $2h_{\ell }$ and length

$2h_{\ell }$ and length ![]() $\ell _{\ell }$. The fluid flow has velocity

$\ell _{\ell }$. The fluid flow has velocity ![]() $\boldsymbol {u}$ and pressure distribution

$\boldsymbol {u}$ and pressure distribution ![]() $p$, which are induced by an imposed flow rate

$p$, which are induced by an imposed flow rate ![]() $q$ (per unit depth). Our primary interest is to determine the pressure drop

$q$ (per unit depth). Our primary interest is to determine the pressure drop ![]() $\Delta p$ over the contraction region and the spatial relaxation of pressure and elastic stresses in the exit channel. For our analysis, we shall employ two different systems of coordinates. The first is Cartesian coordinates

$\Delta p$ over the contraction region and the spatial relaxation of pressure and elastic stresses in the exit channel. For our analysis, we shall employ two different systems of coordinates. The first is Cartesian coordinates ![]() $(z,y)$ and

$(z,y)$ and ![]() $(z_{\ell },y)$, where the

$(z_{\ell },y)$, where the ![]() $z$ and

$z$ and ![]() $z_{\ell }=z-\ell$ axes lie along the symmetry midplane of the channel (dashed-dotted line) and

$z_{\ell }=z-\ell$ axes lie along the symmetry midplane of the channel (dashed-dotted line) and ![]() $y$ is in the direction of the shortest dimension. The second one is orthogonal curvilinear coordinates

$y$ is in the direction of the shortest dimension. The second one is orthogonal curvilinear coordinates ![]() $(\xi,\eta )$ defined in § 2.3.

$(\xi,\eta )$ defined in § 2.3.

Figure 1. Schematic illustration of the 2-D configuration consisting of a slowly varying and symmetric contraction of height ![]() $2h(z)$ and length

$2h(z)$ and length ![]() $\ell$ (

$\ell$ (![]() $h\ll \ell$). The contraction is connected to two long straight channels of height

$h\ll \ell$). The contraction is connected to two long straight channels of height ![]() $2h_{0}$ and

$2h_{0}$ and ![]() $2h_{\ell }$, respectively, up- and downstream and contains a viscoelastic fluid steadily driven by the imposed flow rate

$2h_{\ell }$, respectively, up- and downstream and contains a viscoelastic fluid steadily driven by the imposed flow rate ![]() $q$.

$q$.

We consider low-Reynolds-number flows so that the fluid motion is governed by the continuity equation and Cauchy momentum equations in the absence of inertia

To describe the viscoelastic behaviour of the fluid, we use the Oldroyd-B constitutive model (Oldroyd Reference Oldroyd1950), which represents the most simple combination of viscous and elastic stresses and is used widely to describe the flow of viscoelastic Boger fluids, characterized by a constant shear viscosity. The Oldroyd-B equation can be derived from microscopic principles by modelling polymer molecules as elastic dumbbells, which follow a linear Hooke's law for the restoring force as they are advected and stretched by the flow. The corresponding stress tensor ![]() $\boldsymbol {\sigma }$ is

$\boldsymbol {\sigma }$ is

where the first term on the right-hand side of (2.2) is the pressure contribution, the second term is the viscous stress contribution of a Newtonian solvent with a constant viscosity ![]() $\mu _{s}$, where

$\mu _{s}$, where ![]() $\boldsymbol{\mathsf{E}}=(\boldsymbol {\nabla }\boldsymbol {u}+(\boldsymbol {\nabla }\boldsymbol {u})^{\mathrm {T}})/2$ is the rate-of-strain tensor, and the last term,

$\boldsymbol{\mathsf{E}}=(\boldsymbol {\nabla }\boldsymbol {u}+(\boldsymbol {\nabla }\boldsymbol {u})^{\mathrm {T}})/2$ is the rate-of-strain tensor, and the last term, ![]() $\boldsymbol {\tau }_{p}$, is the polymer contribution. We note that

$\boldsymbol {\tau }_{p}$, is the polymer contribution. We note that ![]() $\boldsymbol{\mathsf{I}}$ in (2.2) is the identity tensor and T is the transpose operator on a tensor.

$\boldsymbol{\mathsf{I}}$ in (2.2) is the identity tensor and T is the transpose operator on a tensor.

For the Oldroyd-B model, the polymer contribution to the stress tensor ![]() $\boldsymbol {\tau }_{p}$ can be expressed in terms of the (symmetric) conformation tensor (or the deformation of the microstructure)

$\boldsymbol {\tau }_{p}$ can be expressed in terms of the (symmetric) conformation tensor (or the deformation of the microstructure) ![]() $\boldsymbol{\mathsf{A}}$ as (Bird et al. Reference Bird, Armstrong and Hassager1987; Larson Reference Larson1988; Morozov & Spagnolie Reference Morozov and Spagnolie2015)

$\boldsymbol{\mathsf{A}}$ as (Bird et al. Reference Bird, Armstrong and Hassager1987; Larson Reference Larson1988; Morozov & Spagnolie Reference Morozov and Spagnolie2015)

where ![]() $G$ is the elastic modulus,

$G$ is the elastic modulus, ![]() $\lambda$ is the relaxation time and

$\lambda$ is the relaxation time and ![]() $\mu _{p}=G \lambda$ is the polymer contribution to the shear viscosity at zero shear rate. It is also convenient to introduce the total zero-shear-rate viscosity

$\mu _{p}=G \lambda$ is the polymer contribution to the shear viscosity at zero shear rate. It is also convenient to introduce the total zero-shear-rate viscosity ![]() $\mu _0=\mu _s+\mu _p$.

$\mu _0=\mu _s+\mu _p$.

The evolution equation for the deformation of the microstructure ![]() $\boldsymbol{\mathsf{A}}$ of the Oldroyd-B model fluid is given at steady state as (Bird et al. Reference Bird, Armstrong and Hassager1987; Larson Reference Larson1988; Morozov & Spagnolie Reference Morozov and Spagnolie2015)

$\boldsymbol{\mathsf{A}}$ of the Oldroyd-B model fluid is given at steady state as (Bird et al. Reference Bird, Armstrong and Hassager1987; Larson Reference Larson1988; Morozov & Spagnolie Reference Morozov and Spagnolie2015)

2.1. Scaling analysis and non-dimensionalization

We consider narrow configurations, in which ![]() $h(z)\ll \ell$,

$h(z)\ll \ell$, ![]() $h_{0}$ is the half-height at

$h_{0}$ is the half-height at ![]() $z=0$, and

$z=0$, and ![]() $u_{c}=q/2h_{0}$ is the characteristic velocity scale set by the cross-sectionally averaged velocity. We introduce non-dimensional variables based on lubrication theory (Tichy Reference Tichy1996; Zhang et al. Reference Zhang, Matar and Craster2002; Saprykin et al. Reference Saprykin, Koopmans and Kalliadasis2007; Ahmed & Biancofiore Reference Ahmed and Biancofiore2021; Boyko & Stone Reference Boyko and Stone2022)

$u_{c}=q/2h_{0}$ is the characteristic velocity scale set by the cross-sectionally averaged velocity. We introduce non-dimensional variables based on lubrication theory (Tichy Reference Tichy1996; Zhang et al. Reference Zhang, Matar and Craster2002; Saprykin et al. Reference Saprykin, Koopmans and Kalliadasis2007; Ahmed & Biancofiore Reference Ahmed and Biancofiore2021; Boyko & Stone Reference Boyko and Stone2022)

where we have introduced the aspect ratio of the configuration, which is assumed to be small

the contraction ratio

the viscosity ratios

and the Deborah and Weissenberg numbers

For lubrication flows through the narrow geometries that we consider, there is a difference between the Deborah and Weissenberg numbers because of the two distinct length scales. The Weissenberg number ![]() $Wi$ is the product of the relaxation time scale of the fluid,

$Wi$ is the product of the relaxation time scale of the fluid, ![]() $\lambda$, and the characteristic shear rate of the flow,

$\lambda$, and the characteristic shear rate of the flow, ![]() $u_{c}/h_{0}$. On the other hand, the Deborah number

$u_{c}/h_{0}$. On the other hand, the Deborah number ![]() $De$ is the ratio of the relaxation time,

$De$ is the ratio of the relaxation time, ![]() $\lambda$, to the residence time in the contraction region,

$\lambda$, to the residence time in the contraction region, ![]() $\ell /u_{c}$, or alternatively, the product of the relaxation time and the characteristic extensional rate of the flow (Tichy Reference Tichy1996; Zhang et al. Reference Zhang, Matar and Craster2002; Saprykin et al. Reference Saprykin, Koopmans and Kalliadasis2007; Ahmed & Biancofiore Reference Ahmed and Biancofiore2021). The Deborah and Weissenberg numbers are related through

$\ell /u_{c}$, or alternatively, the product of the relaxation time and the characteristic extensional rate of the flow (Tichy Reference Tichy1996; Zhang et al. Reference Zhang, Matar and Craster2002; Saprykin et al. Reference Saprykin, Koopmans and Kalliadasis2007; Ahmed & Biancofiore Reference Ahmed and Biancofiore2021). The Deborah and Weissenberg numbers are related through ![]() $De=\epsilon Wi$, and for narrow geometries with

$De=\epsilon Wi$, and for narrow geometries with ![]() $\epsilon \ll 1$,

$\epsilon \ll 1$, ![]() $De$ can be small while keeping

$De$ can be small while keeping ![]() $Wi =O(1)$.

$Wi =O(1)$.

Similar to our previous study (Boyko & Stone Reference Boyko and Stone2022), we non-dimensionalize the pressure using the total zero-shear-rate viscosity ![]() $\mu _{0}=\mu _{s}+\mu _{p}$. However, for convenience, we non-dimensionalize the height based on the entry height rather than the exit height. In addition, unlike our previous study, we do not scale the deformation of the microstructure with

$\mu _{0}=\mu _{s}+\mu _{p}$. However, for convenience, we non-dimensionalize the height based on the entry height rather than the exit height. In addition, unlike our previous study, we do not scale the deformation of the microstructure with ![]() $De^{-1}$. Our current scaling is consistent with a fully developed unidirectional flow of an Oldroyd-B fluid in a straight channel, which yields

$De^{-1}$. Our current scaling is consistent with a fully developed unidirectional flow of an Oldroyd-B fluid in a straight channel, which yields ![]() $\tilde {A}_{zz}=O(De^2)$,

$\tilde {A}_{zz}=O(De^2)$, ![]() $\tilde {A}_{zy}=O(De)$ and

$\tilde {A}_{zy}=O(De)$ and ![]() $\tilde {A}_{yy}=O(1)$; see (2.10d)–(2.10f) and (2.16). This scaling is convenient when considering arbitrary and large values of the Deborah number.

$\tilde {A}_{yy}=O(1)$; see (2.10d)–(2.10f) and (2.16). This scaling is convenient when considering arbitrary and large values of the Deborah number.

Note that, in both Hinch et al. (Reference Hinch, Boyko and Stone2024) and here, the channel height is ![]() $2h$, but the total flow rate per unit depth in the former is

$2h$, but the total flow rate per unit depth in the former is ![]() $2q$, whereas in this work it is

$2q$, whereas in this work it is ![]() $q$ as in Boyko & Stone (Reference Boyko and Stone2022). All results are compatible because the variables used for the non-dimensionalization are the same, i.e. the expressions for the characteristic velocity, characteristic pressure and the Deborah number are the same.

$q$ as in Boyko & Stone (Reference Boyko and Stone2022). All results are compatible because the variables used for the non-dimensionalization are the same, i.e. the expressions for the characteristic velocity, characteristic pressure and the Deborah number are the same.

2.2. Dimensionless lubrication equations in Cartesian coordinates

Using the non-dimensionalization (2.5)–(2.9a,b), to the leading order in ![]() $\epsilon$, the governing equations (2.1)–(2.4) take the form

$\epsilon$, the governing equations (2.1)–(2.4) take the form

\begin{gather}\frac{\partial P}{\partial Z}=(1-\tilde{\beta})\frac{\partial^{2}U_{z}}{\partial Y^{2}}+\frac{\tilde{\beta}}{De}\left(\frac{\partial\tilde{A}_{zz}}{\partial Z}+\frac{\partial\tilde{A}_{zy}}{\partial Y}\right), \end{gather}

\begin{gather}\frac{\partial P}{\partial Z}=(1-\tilde{\beta})\frac{\partial^{2}U_{z}}{\partial Y^{2}}+\frac{\tilde{\beta}}{De}\left(\frac{\partial\tilde{A}_{zz}}{\partial Z}+\frac{\partial\tilde{A}_{zy}}{\partial Y}\right), \end{gather}

From (2.10c), it follows that ![]() $P=P(Z)$, i.e. the pressure is independent of

$P=P(Z)$, i.e. the pressure is independent of ![]() $Y$ up to

$Y$ up to ![]() $O(\epsilon ^2)$, consistent with the classical lubrication approximation. We note that the scaled

$O(\epsilon ^2)$, consistent with the classical lubrication approximation. We note that the scaled ![]() $\tilde {A}_{zz}$ on the right-hand side of (2.10d) relaxes to

$\tilde {A}_{zz}$ on the right-hand side of (2.10d) relaxes to ![]() $\epsilon ^2$, which is neglected at the leading order in

$\epsilon ^2$, which is neglected at the leading order in ![]() $\epsilon$.

$\epsilon$.

2.3. Orthogonal curvilinear coordinates for a slowly varying geometry

For our theoretical analysis, it is convenient to transform the geometry of the contraction from the Cartesian coordinates (![]() $Z,Y$) to curvilinear coordinates (

$Z,Y$) to curvilinear coordinates (![]() $\xi,\eta$), as illustrated in figure 2, with the mapping (Hinch et al. Reference Hinch, Boyko and Stone2024)

$\xi,\eta$), as illustrated in figure 2, with the mapping (Hinch et al. Reference Hinch, Boyko and Stone2024)

As shown in Appendix A, the curvilinear coordinates (![]() $\xi,\eta$) are orthogonal with a relative error of

$\xi,\eta$) are orthogonal with a relative error of ![]() $O(\epsilon ^{4})$, i.e.

$O(\epsilon ^{4})$, i.e. ![]() $\boldsymbol {\nabla }\xi \boldsymbol {\cdot }\boldsymbol {\nabla }\eta =O(\epsilon ^{4})$.

$\boldsymbol {\nabla }\xi \boldsymbol {\cdot }\boldsymbol {\nabla }\eta =O(\epsilon ^{4})$.

Figure 2. Schematic illustration of the orthogonal curvilinear coordinates (![]() $\xi,\eta$) for a slowly varying geometry. The coordinate

$\xi,\eta$) for a slowly varying geometry. The coordinate ![]() $\xi$ is constant along vertical grid lines, and

$\xi$ is constant along vertical grid lines, and ![]() $\eta$, defined in (2.11a,b), is constant along the curves going from left to right.

$\eta$, defined in (2.11a,b), is constant along the curves going from left to right.

Hereafter, we use ![]() $\boldsymbol {u}=u\boldsymbol {e}_{\xi }+\upsilon \boldsymbol {e}_{\eta }$ and

$\boldsymbol {u}=u\boldsymbol {e}_{\xi }+\upsilon \boldsymbol {e}_{\eta }$ and ![]() $\boldsymbol{\mathsf{A}}=A_{11}\boldsymbol {e}_{\xi }\boldsymbol {e}_{\xi }+A_{12}(\boldsymbol {e}_{\xi } \boldsymbol {e}_{\eta }+\boldsymbol {e}_{\eta }\boldsymbol {e}_{\xi })+A_{22} \boldsymbol {e}_{\eta }\boldsymbol {e}_{\eta }$ to denote, respectively, the components of velocity and deformation of the microstructure in curvilinear coordinates (

$\boldsymbol{\mathsf{A}}=A_{11}\boldsymbol {e}_{\xi }\boldsymbol {e}_{\xi }+A_{12}(\boldsymbol {e}_{\xi } \boldsymbol {e}_{\eta }+\boldsymbol {e}_{\eta }\boldsymbol {e}_{\xi })+A_{22} \boldsymbol {e}_{\eta }\boldsymbol {e}_{\eta }$ to denote, respectively, the components of velocity and deformation of the microstructure in curvilinear coordinates (![]() $\xi,\eta$). The corresponding non-dimensional velocity components in different coordinates are related through (see Appendix A)

$\xi,\eta$). The corresponding non-dimensional velocity components in different coordinates are related through (see Appendix A)

Similarly, the scaled conformation tensor components in different coordinates are related through (see Appendix A)

Finally, we note that, since there is only a ![]() $O(\epsilon ^{2})$ difference between the

$O(\epsilon ^{2})$ difference between the ![]() $\xi$- and

$\xi$- and ![]() $z$-directions, for convenience, we continue to use

$z$-directions, for convenience, we continue to use ![]() $Z$ rather than

$Z$ rather than ![]() $\xi$ in curvilinear coordinates.

$\xi$ in curvilinear coordinates.

2.4. Dimensionless lubrication equations in orthogonal curvilinear coordinates

Using the mapping (2.11a,b), the governing equations (2.10) take the form in curvilinear coordinates (Hinch et al. Reference Hinch, Boyko and Stone2024)

\begin{gather}\frac{\mathrm{d}P}{\mathrm{d}Z}=(1-\tilde{\beta})\frac{1}{H^{2}}\frac{\partial^{2}U}{\partial\eta^{2}}+\frac{\tilde{\beta}}{De}\left(\frac{1}{H}\frac{\partial(H\tilde{A}_{11})}{\partial Z}+\frac{1}{H}\frac{\partial\tilde{A}_{12}}{\partial\eta}\right), \end{gather}

\begin{gather}\frac{\mathrm{d}P}{\mathrm{d}Z}=(1-\tilde{\beta})\frac{1}{H^{2}}\frac{\partial^{2}U}{\partial\eta^{2}}+\frac{\tilde{\beta}}{De}\left(\frac{1}{H}\frac{\partial(H\tilde{A}_{11})}{\partial Z}+\frac{1}{H}\frac{\partial\tilde{A}_{12}}{\partial\eta}\right), \end{gather}The corresponding boundary conditions on the velocity are

which represent, respectively, the no-slip and no-penetration boundary conditions along the channel walls, the symmetry boundary condition at the centreline and the integral mass conservation along the channel. In addition, we assume a fully developed unidirectional Poiseuille flow in the straight entry channel and the corresponding deformation of the microstructure

with ![]() $H \equiv 1$ at the entrance. We also assume that, far downstream in the exit channel, the deformation of the microstructure attains a fully relaxed value, given by (2.16) with

$H \equiv 1$ at the entrance. We also assume that, far downstream in the exit channel, the deformation of the microstructure attains a fully relaxed value, given by (2.16) with ![]() $H \equiv H_{\ell }$.

$H \equiv H_{\ell }$.

2.5. Pressure drop across the non-uniform region in the lubrication limit

In this subsection, we show that one can calculate the pressure drop without solving directly for the velocity field. To this end, we first integrate by parts the integral constraint (2.15d), repeatedly, using (2.15a) and (2.15c), e.g. (Hinch et al. Reference Hinch, Boyko and Stone2024)

\begin{align}

\frac{1}{H(Z)}&=\int_{0}^{1}U\,\mathrm{d}\eta=\underset{0}{\underbrace{\left.\eta

U\right|_{0}^{1}}}-\int_{0}^{1}\eta\frac{\partial

U}{\partial\eta}\mathrm{d}\eta=\underset{0}{\underbrace{\left.\frac{1}{2}(1-\eta^{2})\frac{\partial

U}{\partial\eta}\right|_{0}^{1}}}-\frac{1}{2}\int_{0}^{1}(1-\eta^{2})\frac{\partial^{2}U}{\partial\eta^{2}}\mathrm{d}\eta.\end{align}

\begin{align}

\frac{1}{H(Z)}&=\int_{0}^{1}U\,\mathrm{d}\eta=\underset{0}{\underbrace{\left.\eta

U\right|_{0}^{1}}}-\int_{0}^{1}\eta\frac{\partial

U}{\partial\eta}\mathrm{d}\eta=\underset{0}{\underbrace{\left.\frac{1}{2}(1-\eta^{2})\frac{\partial

U}{\partial\eta}\right|_{0}^{1}}}-\frac{1}{2}\int_{0}^{1}(1-\eta^{2})\frac{\partial^{2}U}{\partial\eta^{2}}\mathrm{d}\eta.\end{align}

Substituting the expression for ![]() $\partial ^{2}U/\partial \eta ^{2}$ from (2.14b) into (2.17), we obtain

$\partial ^{2}U/\partial \eta ^{2}$ from (2.14b) into (2.17), we obtain

\begin{equation} -\frac{1-\tilde{\beta}}{H(Z)^3}=\frac{1}{2}\int_{0}^{1}(1-\eta^{2})\left[\frac{\mathrm{d}P}{\mathrm{d}Z}-\frac{\tilde{\beta}}{De}\left(\frac{1}{H}\frac{\partial(H\tilde{A}_{11})}{\partial Z}+\frac{1}{H}\frac{\partial\tilde{A}_{12}}{\partial\eta}\right)\right]\mathrm{d}\eta,\end{equation}

\begin{equation} -\frac{1-\tilde{\beta}}{H(Z)^3}=\frac{1}{2}\int_{0}^{1}(1-\eta^{2})\left[\frac{\mathrm{d}P}{\mathrm{d}Z}-\frac{\tilde{\beta}}{De}\left(\frac{1}{H}\frac{\partial(H\tilde{A}_{11})}{\partial Z}+\frac{1}{H}\frac{\partial\tilde{A}_{12}}{\partial\eta}\right)\right]\mathrm{d}\eta,\end{equation}which can be rearranged to yield the pressure gradient

\begin{equation} \frac{\mathrm{d}P}{\mathrm{d}Z}={-}\frac{3(1-\tilde{\beta})}{H(Z)^{3}}+\frac{3 \tilde{\beta}}{2De}\int_{0}^{1}(1-\eta^{2})\left[\frac{1}{H(Z)}\frac{\partial(H(Z)\tilde{A}_{11})}{\partial Z}+\frac{1}{H(Z)}\frac{\partial\tilde{A}_{12}}{\partial\eta}\right]\mathrm{d}\eta.\end{equation}

\begin{equation} \frac{\mathrm{d}P}{\mathrm{d}Z}={-}\frac{3(1-\tilde{\beta})}{H(Z)^{3}}+\frac{3 \tilde{\beta}}{2De}\int_{0}^{1}(1-\eta^{2})\left[\frac{1}{H(Z)}\frac{\partial(H(Z)\tilde{A}_{11})}{\partial Z}+\frac{1}{H(Z)}\frac{\partial\tilde{A}_{12}}{\partial\eta}\right]\mathrm{d}\eta.\end{equation}

Integrating (2.19) with respect to ![]() $Z$ from 0 to 1 provides the pressure drop

$Z$ from 0 to 1 provides the pressure drop ![]() $\Delta P=P(0)-P(1)$ across the non-uniform region

$\Delta P=P(0)-P(1)$ across the non-uniform region

\begin{align} \Delta P&=3(1-\tilde{\beta})\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}} \nonumber\\ &\quad -\frac{3\tilde{\beta}}{2De}\int_{0}^{1}\int_{0}^{1}(1-\eta^{2})\left[\frac{1}{H(Z)} \frac{\partial(H(Z)\tilde{A}_{11})}{\partial Z}+\frac{1}{H(Z)}\frac{\partial\tilde{A}_{12}}{\partial\eta}\right]\mathrm{d}\eta\,\mathrm{d}Z. \end{align}

\begin{align} \Delta P&=3(1-\tilde{\beta})\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}} \nonumber\\ &\quad -\frac{3\tilde{\beta}}{2De}\int_{0}^{1}\int_{0}^{1}(1-\eta^{2})\left[\frac{1}{H(Z)} \frac{\partial(H(Z)\tilde{A}_{11})}{\partial Z}+\frac{1}{H(Z)}\frac{\partial\tilde{A}_{12}}{\partial\eta}\right]\mathrm{d}\eta\,\mathrm{d}Z. \end{align}Using integration by parts, (2.20) can be expressed as

\begin{align} \Delta P&= 3(1-\tilde{\beta})\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}+\frac{3 \tilde{\beta}}{2De}\int_{0}^{1}(1-\eta^{2})\left[\tilde{A}_{11}(0,\eta)-\tilde{A}_{11}(1,\eta)\right] \mathrm{d}\eta \nonumber\\ &\quad -\frac{3\tilde{\beta}}{2De}\int_{0}^{1}\left[\frac{H'(Z)}{H(Z)}\left(\int_{0}^{1}(1-\eta^{2})\tilde{A}_{11}\, \mathrm{d}\eta\right)\right]\mathrm{d}Z \nonumber\\ &\quad -\frac{3\tilde{\beta}}{De}\int_{0}^{1}\left[\frac{1}{H(Z)}\int_{0}^{1}\eta\tilde{A}_{12}\,\mathrm{d}\eta \right]\mathrm{d}Z, \end{align}

\begin{align} \Delta P&= 3(1-\tilde{\beta})\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}+\frac{3 \tilde{\beta}}{2De}\int_{0}^{1}(1-\eta^{2})\left[\tilde{A}_{11}(0,\eta)-\tilde{A}_{11}(1,\eta)\right] \mathrm{d}\eta \nonumber\\ &\quad -\frac{3\tilde{\beta}}{2De}\int_{0}^{1}\left[\frac{H'(Z)}{H(Z)}\left(\int_{0}^{1}(1-\eta^{2})\tilde{A}_{11}\, \mathrm{d}\eta\right)\right]\mathrm{d}Z \nonumber\\ &\quad -\frac{3\tilde{\beta}}{De}\int_{0}^{1}\left[\frac{1}{H(Z)}\int_{0}^{1}\eta\tilde{A}_{12}\,\mathrm{d}\eta \right]\mathrm{d}Z, \end{align}

where prime indicates a derivative with respect to ![]() $Z$.

$Z$.

Equation (2.21) resembles the result of an application of the reciprocal theorem previously derived for the pressure drop of the flow of an Oldroyd-B fluid in a slowly varying channel (Boyko & Stone Reference Boyko and Stone2021, Reference Boyko and Stone2022). The first term on the right-hand side of (2.21) represents the viscous contribution of the Newtonian solvent to the pressure drop. The second term represents the contribution of the elastic normal stress difference at the inlet and outlet of the non-uniform channel. The third term represents the contribution of the elastic normal stresses that arise due to the spatial variations in the channel shape, which is a contribution that is absent in a straight channel. Finally, the last term represents the elastic contribution due to shear stresses within the fluid domain of the non-uniform channel. It should be noted that we do not assume a priori the particular shape of the channel ![]() $H(Z)$ but rather consider a flow in a slowly varying channel of arbitrary shape

$H(Z)$ but rather consider a flow in a slowly varying channel of arbitrary shape ![]() $H(Z)$.

$H(Z)$.

3. Low- $\tilde {\beta }$ lubrication analysis in a slowly varying region

$\tilde {\beta }$ lubrication analysis in a slowly varying region

In the previous section, we obtained the dimensionless equations (2.14), which are governed by the two non-dimensional parameters, ![]() $\tilde {\beta }$ and

$\tilde {\beta }$ and ![]() $De$, in the lubrication limit (

$De$, in the lubrication limit (![]() $\epsilon \ll 1$). In this section, we derive analytical expressions for the velocity, conformation tensor and the

$\epsilon \ll 1$). In this section, we derive analytical expressions for the velocity, conformation tensor and the ![]() $q-\Delta p$ relation for the pressure-driven flow of a very dilute viscoelastic Oldroyd-B fluid,

$q-\Delta p$ relation for the pressure-driven flow of a very dilute viscoelastic Oldroyd-B fluid, ![]() $\tilde {\beta }=\mu _{p}/\mu _{0}\ll 1$ in a slowly varying channel of arbitrary shape

$\tilde {\beta }=\mu _{p}/\mu _{0}\ll 1$ in a slowly varying channel of arbitrary shape ![]() $H(Z)$.

$H(Z)$.

In contrast to our previous study that employed a low-Deborah-number lubrication analysis (Boyko & Stone Reference Boyko and Stone2022), in this work, we assume ![]() $De=O(1)$ and consider the ultra-dilute limit,

$De=O(1)$ and consider the ultra-dilute limit, ![]() $\tilde {\beta }\ll 1$ (see Remmelgas et al. Reference Remmelgas, Singh and Leal1999; Moore & Shelley Reference Moore and Shelley2012; Li et al. Reference Li, Thomases and Guy2019; Mokhtari et al. Reference Mokhtari, Latché, Quintard and Davit2022). To this end, we seek solutions of the form

$\tilde {\beta }\ll 1$ (see Remmelgas et al. Reference Remmelgas, Singh and Leal1999; Moore & Shelley Reference Moore and Shelley2012; Li et al. Reference Li, Thomases and Guy2019; Mokhtari et al. Reference Mokhtari, Latché, Quintard and Davit2022). To this end, we seek solutions of the form

\begin{equation} \left(\begin{array}{c} U\\ V\\ P\\ \tilde{A}_{11}\\ \tilde{A}_{12}\\ \tilde{A}_{22} \end{array}\right)=\left(\begin{array}{c} U_{0}\\ V_{0}\\ P_{0}\\ \tilde{A}_{11,0}\\ \tilde{A}_{12,0}\\ \tilde{A}_{22,0} \end{array}\right)+\tilde{\beta}\left(\begin{array}{c} U_{1}\\ V_{1}\\ P_{1}\\ \tilde{A}_{11,1}\\ \tilde{A}_{12,1}\\ \tilde{A}_{22,1} \end{array}\right)+O(\epsilon^{2},\tilde{\beta}^{2}).\end{equation}

\begin{equation} \left(\begin{array}{c} U\\ V\\ P\\ \tilde{A}_{11}\\ \tilde{A}_{12}\\ \tilde{A}_{22} \end{array}\right)=\left(\begin{array}{c} U_{0}\\ V_{0}\\ P_{0}\\ \tilde{A}_{11,0}\\ \tilde{A}_{12,0}\\ \tilde{A}_{22,0} \end{array}\right)+\tilde{\beta}\left(\begin{array}{c} U_{1}\\ V_{1}\\ P_{1}\\ \tilde{A}_{11,1}\\ \tilde{A}_{12,1}\\ \tilde{A}_{22,1} \end{array}\right)+O(\epsilon^{2},\tilde{\beta}^{2}).\end{equation}

The ultra-dilute limit represents a one-way coupling between the velocity and pressure fields and the deformation of the microstructure (polymer stresses or conformation tensor). At leading order, the velocity and pressure are Newtonian, and the deformation of the microstructure (i.e. polymer stresses) arises from this Newtonian flow. Accordingly, the velocity and pressure at ![]() $O(\tilde {\beta })$ arise due to leading-order polymer stresses. In the next subsections, we provide closed-form asymptotic expressions for the velocity field and conformation tensor components at

$O(\tilde {\beta })$ arise due to leading-order polymer stresses. In the next subsections, we provide closed-form asymptotic expressions for the velocity field and conformation tensor components at ![]() $O(\tilde {\beta }^{0})$ and the pressure drop up to

$O(\tilde {\beta }^{0})$ and the pressure drop up to ![]() $O(\tilde {\beta })$.

$O(\tilde {\beta })$.

We note that the viscosity ratio ![]() $\tilde {\beta }=\mu _{p}/\mu _{0}$ is related to the so-called concentration of the polymers

$\tilde {\beta }=\mu _{p}/\mu _{0}$ is related to the so-called concentration of the polymers ![]() $c=\mu _{p}/\mu _{s}$ through

$c=\mu _{p}/\mu _{s}$ through ![]() $\tilde {\beta }=c/(c+1)$. Thus, at the leading order, the limits

$\tilde {\beta }=c/(c+1)$. Thus, at the leading order, the limits ![]() $\tilde {\beta }\ll 1$ and

$\tilde {\beta }\ll 1$ and ![]() $c\ll 1$ are identical.

$c\ll 1$ are identical.

3.1. Velocity, conformation and pressure drop at the leading order in  $\tilde {\beta }$

$\tilde {\beta }$

Substituting (3.1) into (2.14a)–(2.14b) and considering the leading order in ![]() $\tilde {\beta }$, the continuity and momentum equations take the form

$\tilde {\beta }$, the continuity and momentum equations take the form

subject to the boundary conditions

The solutions for the axial velocity ![]() $U_0$ and the pressure drop

$U_0$ and the pressure drop ![]() $\Delta P_{0}$ at the leading order are well known (see, e.g. Boyko & Stone Reference Boyko and Stone2022)

$\Delta P_{0}$ at the leading order are well known (see, e.g. Boyko & Stone Reference Boyko and Stone2022)

Substituting (3.4a) into the continuity equation (3.2a) and using (3.3b), yields

From (3.5), it follows that, in orthogonal curvilinear coordinates, the velocity in the ![]() $\eta$-direction is identically zero at

$\eta$-direction is identically zero at ![]() $O(\tilde {\beta }^{0})$, in contrast to the Cartesian coordinates where

$O(\tilde {\beta }^{0})$, in contrast to the Cartesian coordinates where ![]() $U_{y,0}=(3/2)H'(Z)Y(H(Z)^{2}-Y^{2})/H(Z)^{4}$. As we shall see, this fact significantly simplifies the theoretical analysis and allows us to derive closed-form expressions for the components of the conformation tensor.

$U_{y,0}=(3/2)H'(Z)Y(H(Z)^{2}-Y^{2})/H(Z)^{4}$. As we shall see, this fact significantly simplifies the theoretical analysis and allows us to derive closed-form expressions for the components of the conformation tensor.

Using (3.5), at leading order in ![]() $\tilde {\beta }$, the equations for the conformation tensor components, (2.14c)–(2.14e), simplify to

$\tilde {\beta }$, the equations for the conformation tensor components, (2.14c)–(2.14e), simplify to

subject to the boundary conditions

Equations (3.6) represent a set of one-way coupled first-order semi-linear partial differential equations that can be solved first for ![]() $\tilde {A}_{22,0}$, followed by

$\tilde {A}_{22,0}$, followed by ![]() $\tilde {A}_{12,0}$ and then for

$\tilde {A}_{12,0}$ and then for ![]() $\tilde {A}_{11,0}$.

$\tilde {A}_{11,0}$.

Solving (3.6) together with (3.7), we obtain closed-form expressions for ![]() $\tilde {A}_{22,0}$,

$\tilde {A}_{22,0}$, ![]() $\tilde {A}_{12,0}$ and

$\tilde {A}_{12,0}$ and ![]() $\tilde {A}_{11,0}$ for arbitrary values of

$\tilde {A}_{11,0}$ for arbitrary values of ![]() $De$ and the shape function

$De$ and the shape function ![]() $H(Z)$

$H(Z)$

\begin{gather} \frac{\tilde{A}_{22,0}}{H(Z)^{2}}=\exp(\,{f(DeU_{0}(Z,\eta))}) \left[1+\int_{0}^{Z}\exp({-f(DeU_{0}(\tilde{Z},\eta))}) \frac{1}{DeU_{0}(\tilde{Z},\eta)H(\tilde{Z})^2}\mathrm{d}\tilde{Z}\right], \end{gather}

\begin{gather} \frac{\tilde{A}_{22,0}}{H(Z)^{2}}=\exp(\,{f(DeU_{0}(Z,\eta))}) \left[1+\int_{0}^{Z}\exp({-f(DeU_{0}(\tilde{Z},\eta))}) \frac{1}{DeU_{0}(\tilde{Z},\eta)H(\tilde{Z})^2}\mathrm{d}\tilde{Z}\right], \end{gather} \begin{gather}\frac{\tilde{A}_{12,0}}{({-}3De\eta)}=\exp(\,{f(DeU_{0}(Z,\eta))}) \left[1\!+\!\int_{0}^{Z}\exp({-f(DeU_{0}(\tilde{Z},\eta))}) \frac{\tilde{A}_{22,0}(\tilde{Z},\eta)}{DeU_{0}(\tilde{Z},\eta)H(\tilde{Z})^2}\mathrm{d}\tilde{Z}\right], \end{gather}

\begin{gather}\frac{\tilde{A}_{12,0}}{({-}3De\eta)}=\exp(\,{f(DeU_{0}(Z,\eta))}) \left[1\!+\!\int_{0}^{Z}\exp({-f(DeU_{0}(\tilde{Z},\eta))}) \frac{\tilde{A}_{22,0}(\tilde{Z},\eta)}{DeU_{0}(\tilde{Z},\eta)H(\tilde{Z})^2}\mathrm{d}\tilde{Z}\right], \end{gather} \begin{align} &\frac{\tilde{A}_{11,0}}{18De^{2}\eta^{2}/H(Z)^2}\nonumber\\ &\quad =\exp(\,{f(DeU_{0}(Z,\eta))})\left[1+\int_{0}^{Z}\exp({-f(DeU_{0}(\tilde{Z},\eta))}) \frac{\tilde{A}_{12,0}(\tilde{Z},\eta)}{({-}3\eta De)DeU_{0}(\tilde{Z},\eta)}\mathrm{d}\tilde{Z}\right], \end{align}

\begin{align} &\frac{\tilde{A}_{11,0}}{18De^{2}\eta^{2}/H(Z)^2}\nonumber\\ &\quad =\exp(\,{f(DeU_{0}(Z,\eta))})\left[1+\int_{0}^{Z}\exp({-f(DeU_{0}(\tilde{Z},\eta))}) \frac{\tilde{A}_{12,0}(\tilde{Z},\eta)}{({-}3\eta De)DeU_{0}(\tilde{Z},\eta)}\mathrm{d}\tilde{Z}\right], \end{align}

where ![]() $f(DeU_{0}(Z,\eta ))$ is defined as

$f(DeU_{0}(Z,\eta ))$ is defined as

\begin{equation} f(DeU_{0}(Z,\eta))={-}\int_{0}^{Z}\frac{1}{De U_{0}(\tilde{Z},\eta)}\mathrm{d}\tilde{Z}={-}\int_{0}^{Z}\frac{2H(\tilde{Z})}{3De(1-\eta^{2})} \mathrm{d}\tilde{Z}.\end{equation}

\begin{equation} f(DeU_{0}(Z,\eta))={-}\int_{0}^{Z}\frac{1}{De U_{0}(\tilde{Z},\eta)}\mathrm{d}\tilde{Z}={-}\int_{0}^{Z}\frac{2H(\tilde{Z})}{3De(1-\eta^{2})} \mathrm{d}\tilde{Z}.\end{equation}

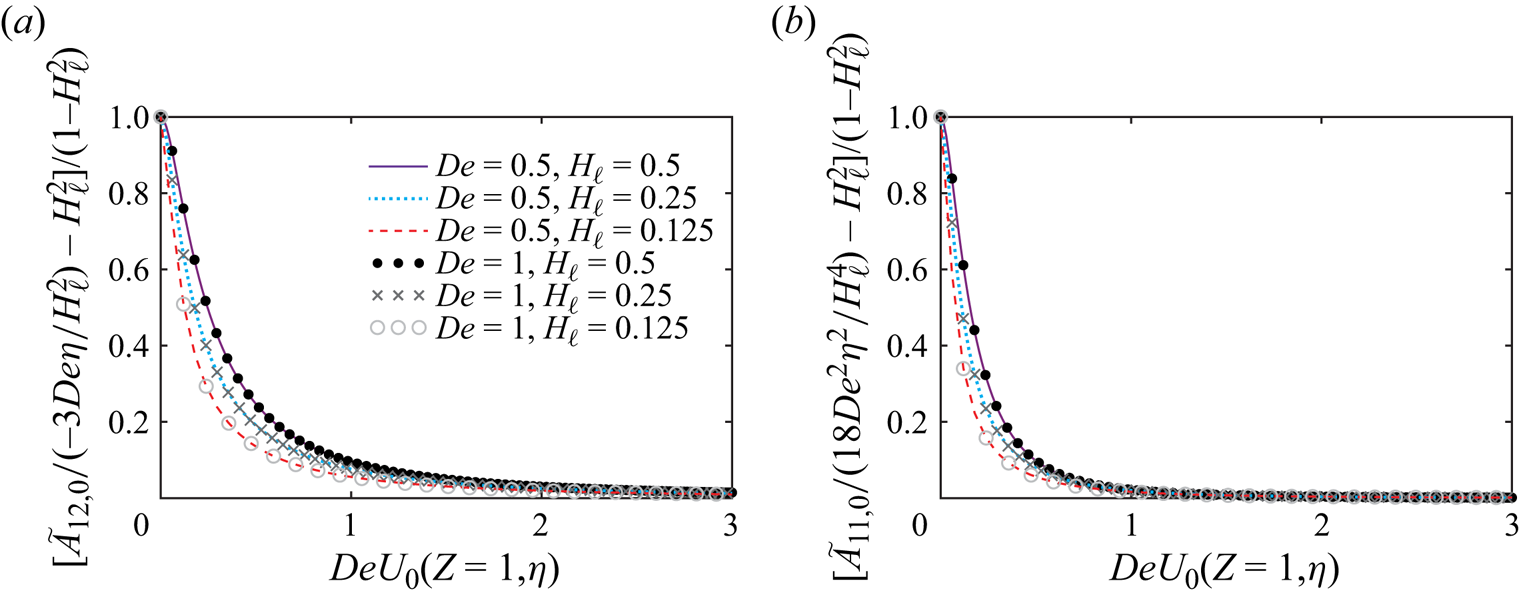

It is worth noting that the right-hand sides of (3.8)–(3.10) depend on the product ![]() $DeU_{0}(Z,\eta )$ and are not functions of

$DeU_{0}(Z,\eta )$ and are not functions of ![]() $De$ and

$De$ and ![]() $\eta$ separately. Furthermore, (3.8)–(3.10) clearly show that, while the distribution of

$\eta$ separately. Furthermore, (3.8)–(3.10) clearly show that, while the distribution of ![]() $\tilde {A}_{22,0}$ is set solely by the value at the beginning of the non-uniform region, the distribution of elastic shear and normal stresses,

$\tilde {A}_{22,0}$ is set solely by the value at the beginning of the non-uniform region, the distribution of elastic shear and normal stresses, ![]() $\tilde {A}_{12,0}$ and

$\tilde {A}_{12,0}$ and ![]() $\tilde {A}_{11,0}$, are coupled to the transverse normal stress

$\tilde {A}_{11,0}$, are coupled to the transverse normal stress ![]() $\tilde {A}_{22,0}$. In fact, the elastic normal stress

$\tilde {A}_{22,0}$. In fact, the elastic normal stress ![]() $\tilde {A}_{11,0}$ depends both on

$\tilde {A}_{11,0}$ depends both on ![]() $\tilde {A}_{12,0}$ and

$\tilde {A}_{12,0}$ and ![]() $\tilde {A}_{22,0}$.

$\tilde {A}_{22,0}$.

From (3.8)–(3.10), one might think that the conformation tensor components diverge at the wall (![]() $\eta =\pm 1$). However, using (3.6) and noting that

$\eta =\pm 1$). However, using (3.6) and noting that ![]() $U_{0}=\partial U_{0}/\partial Z=0$ at

$U_{0}=\partial U_{0}/\partial Z=0$ at ![]() $\eta =\pm 1$, it follows that, at the walls of the non-uniform channel,

$\eta =\pm 1$, it follows that, at the walls of the non-uniform channel,

In §§ 3.1.1 and 3.1.2, we provide explicit expressions for the conformation tensor components in the low- and high-![]() $De$ limits. We also note that the results shown in our figure 4(a,c) and the work of Hinch et al. (Reference Hinch, Boyko and Stone2024) suggest the existence of a viscoelastic boundary layer near the walls in the high-

$De$ limits. We also note that the results shown in our figure 4(a,c) and the work of Hinch et al. (Reference Hinch, Boyko and Stone2024) suggest the existence of a viscoelastic boundary layer near the walls in the high-![]() $De$ limit, which we analyse in § 3.1.3.

$De$ limit, which we analyse in § 3.1.3.

3.1.1. Conformation tensor in the low- $De$ limit

$De$ limit

For ![]() $De\ll 1$, we solve the equations iteratively for the conformation tensor components (3.6) to obtain

$De\ll 1$, we solve the equations iteratively for the conformation tensor components (3.6) to obtain

\begin{align} \tilde{A}_{22,0}&=1+\frac{3DeH'}{H^{2}}(1-\eta^{2})+\frac{9De^{2}[4H'^{2}-HH'']}{2H^{4}}(1-\eta^{2})^{2}\nonumber\\ &\quad+ \frac{27De^{3}[24H'^{3}-13HH'H''+H^{2}H''']}{4H^{6}}(1-\eta^{2})^{3}, \end{align}

\begin{align} \tilde{A}_{22,0}&=1+\frac{3DeH'}{H^{2}}(1-\eta^{2})+\frac{9De^{2}[4H'^{2}-HH'']}{2H^{4}}(1-\eta^{2})^{2}\nonumber\\ &\quad+ \frac{27De^{3}[24H'^{3}-13HH'H''+H^{2}H''']}{4H^{6}}(1-\eta^{2})^{3}, \end{align}

We note that the low-![]() $De$ results (3.13) are consistent with our previous work (Boyko & Stone Reference Boyko and Stone2022), in which we provided explicit expressions for

$De$ results (3.13) are consistent with our previous work (Boyko & Stone Reference Boyko and Stone2022), in which we provided explicit expressions for ![]() $\tilde {A}_{zz}$,

$\tilde {A}_{zz}$, ![]() $\tilde {A}_{zy}$ and

$\tilde {A}_{zy}$ and ![]() $\tilde {A}_{yy}$ up to

$\tilde {A}_{yy}$ up to ![]() $O(De^2)$ in Cartesian coordinates. For example, using (2.13c) and (3.13),

$O(De^2)$ in Cartesian coordinates. For example, using (2.13c) and (3.13), ![]() $\tilde {A}_{yy}$ can be expressed as

$\tilde {A}_{yy}$ can be expressed as ![]() $\tilde {A}_{yy}=1+3DeH'(Z)(H(Z)^2-3Y^2)/H(Z)^4+O(De^2)$, in agreement with (3.9a) in Boyko & Stone (Reference Boyko and Stone2022).

$\tilde {A}_{yy}=1+3DeH'(Z)(H(Z)^2-3Y^2)/H(Z)^4+O(De^2)$, in agreement with (3.9a) in Boyko & Stone (Reference Boyko and Stone2022).

3.1.2. Conformation tensor in the high- $De$ limit

$De$ limit

We here provide the closed-form expressions for the conformation tensor components in the high-![]() $De$ limit. We begin with the expression for

$De$ limit. We begin with the expression for ![]() $\tilde {A}_{22,0}$ and consider the core flow region.

$\tilde {A}_{22,0}$ and consider the core flow region.

For ![]() $De\gg 1$, except close to the wall, (3.6a) reduces to

$De\gg 1$, except close to the wall, (3.6a) reduces to

whose solution subject to (3.7c) is

Next, since ![]() $\tilde {A}_{12,0}$ scales as

$\tilde {A}_{12,0}$ scales as ![]() $O(De)$ while

$O(De)$ while ![]() $\tilde {A}_{22,0}$ is

$\tilde {A}_{22,0}$ is ![]() $O(1)$, within the core flow region in the high-

$O(1)$, within the core flow region in the high-![]() $De$ limit we obtain that the first term in (3.6b) dominates over all the remaining terms

$De$ limit we obtain that the first term in (3.6b) dominates over all the remaining terms

so that elastic shear stresses preserve their value from the entry channel through the non-uniform region

Finally, to determine ![]() $\tilde {A}_{11,0}$, we note that the third and fourth terms in (3.6c) scale as

$\tilde {A}_{11,0}$, we note that the third and fourth terms in (3.6c) scale as ![]() $O(De)$, while the first and second terms are

$O(De)$, while the first and second terms are ![]() $O(De^{2})$. Thus, for

$O(De^{2})$. Thus, for ![]() $De\gg 1$, we expect the first and second terms to balance each other while the remaining terms are negligible, so that

$De\gg 1$, we expect the first and second terms to balance each other while the remaining terms are negligible, so that

Solving (3.18) subject to (3.7a) yields

In fact, for ![]() $De\gg 1$, there is a purely passive response of the microstructure, similar to a material line element, transported and deformed by the flow without relaxing.

$De\gg 1$, there is a purely passive response of the microstructure, similar to a material line element, transported and deformed by the flow without relaxing.

The high-![]() $De$ results (3.15), (3.17) and (3.19) can be also directly obtained from the closed-form solutions (3.8)–(3.10) by noting that, for

$De$ results (3.15), (3.17) and (3.19) can be also directly obtained from the closed-form solutions (3.8)–(3.10) by noting that, for ![]() $De\gg 1$,

$De\gg 1$, ![]() $\exp ({\pm f(DeU_{0}(Z,\eta ))})\approx 1$, and neglecting the

$\exp ({\pm f(DeU_{0}(Z,\eta ))})\approx 1$, and neglecting the ![]() $O(De^{-1})$ terms.

$O(De^{-1})$ terms.

3.1.3. Boundary-layer analysis in the high- $De$ limit

$De$ limit

In the previous section, we obtained analytical expressions for the components of the conformation tensor in the high-![]() $De$ limit within the core flow region. However, these expressions do not hold near the walls, where a viscoelastic boundary layer of

$De$ limit within the core flow region. However, these expressions do not hold near the walls, where a viscoelastic boundary layer of ![]() $O(De^{-1})$ thickness exists (Hinch et al. Reference Hinch, Boyko and Stone2024). In this section, we analyse this boundary-layer region and provide boundary-layer equations and their closed-form solutions. To this end, we focus on the region

$O(De^{-1})$ thickness exists (Hinch et al. Reference Hinch, Boyko and Stone2024). In this section, we analyse this boundary-layer region and provide boundary-layer equations and their closed-form solutions. To this end, we focus on the region ![]() $\eta \in [0,1]$, and introduce the rescaled inner-region coordinate

$\eta \in [0,1]$, and introduce the rescaled inner-region coordinate

so that ![]() $De(1-\eta ^{2})=\zeta (2-\tilde {\eta })\approx 2\zeta$. Noting that, in the boundary layer,

$De(1-\eta ^{2})=\zeta (2-\tilde {\eta })\approx 2\zeta$. Noting that, in the boundary layer, ![]() $\tilde {A}_{22,0}=O(1)$,

$\tilde {A}_{22,0}=O(1)$, ![]() $\tilde {A}_{12,0}=O(De)$ and

$\tilde {A}_{12,0}=O(De)$ and ![]() $\tilde {A}_{11,0}=O(De^{2})$ (see (3.12)), to eliminate the dependence on

$\tilde {A}_{11,0}=O(De^{2})$ (see (3.12)), to eliminate the dependence on ![]() $De$ in the governing equations and boundary conditions (3.7), we rescale

$De$ in the governing equations and boundary conditions (3.7), we rescale ![]() $\tilde {A}_{22,0}$,

$\tilde {A}_{22,0}$, ![]() $\tilde {A}_{12,0}$ and

$\tilde {A}_{12,0}$ and ![]() $\tilde {A}_{11,0}$, which are functions of

$\tilde {A}_{11,0}$, which are functions of ![]() $Z$ and

$Z$ and ![]() $\zeta$, as

$\zeta$, as

Substituting (3.20) and (3.21a–c) into (3.6) and using (3.4a), we obtain the boundary-layer equations in the high-![]() $De$ limit

$De$ limit

subject to the inlet conditions

Solving (3.22) together with (3.23), we obtain closed-form expressions for ![]() $\mathcal {A}_{22}$,

$\mathcal {A}_{22}$, ![]() $\mathcal {A}_{12}$ and

$\mathcal {A}_{12}$ and ![]() $\mathcal {A}_{11}$ in the boundary-layer region

$\mathcal {A}_{11}$ in the boundary-layer region

\begin{gather} \mathcal{A}_{22}=\mathrm{e}^{\mathcal{F}(Z,\zeta)}\left[1+\int_{0}^{Z}\mathrm{e}^{-\mathcal{F}(\tilde{Z},\zeta)}\frac{1}{3\zeta H(\tilde{Z})}\mathrm{d}\tilde{Z}\right], \end{gather}

\begin{gather} \mathcal{A}_{22}=\mathrm{e}^{\mathcal{F}(Z,\zeta)}\left[1+\int_{0}^{Z}\mathrm{e}^{-\mathcal{F}(\tilde{Z},\zeta)}\frac{1}{3\zeta H(\tilde{Z})}\mathrm{d}\tilde{Z}\right], \end{gather} \begin{gather}\mathcal{A}_{12}=\mathrm{e}^{\mathcal{F}(Z,\zeta)}\left[1+\int_{0}^{Z}\mathrm{e}^{-\mathcal{F}(\tilde{Z},\zeta)}\frac{\mathcal{A}_{22}(\tilde{Z},\zeta)H(\tilde{Z})}{3\zeta}\mathrm{d}\tilde{Z}\right], \end{gather}

\begin{gather}\mathcal{A}_{12}=\mathrm{e}^{\mathcal{F}(Z,\zeta)}\left[1+\int_{0}^{Z}\mathrm{e}^{-\mathcal{F}(\tilde{Z},\zeta)}\frac{\mathcal{A}_{22}(\tilde{Z},\zeta)H(\tilde{Z})}{3\zeta}\mathrm{d}\tilde{Z}\right], \end{gather} \begin{gather}\mathcal{A}_{11}=\mathrm{e}^{\mathcal{F}(Z,\zeta)}\left[1+\int_{0}^{Z}\mathrm{e}^{-\mathcal{F}(\tilde{Z},\zeta)}\frac{\mathcal{A}_{12}(\tilde{Z},\zeta)H(\tilde{Z})}{3\zeta}\mathrm{d}\tilde{Z}\right], \end{gather}

\begin{gather}\mathcal{A}_{11}=\mathrm{e}^{\mathcal{F}(Z,\zeta)}\left[1+\int_{0}^{Z}\mathrm{e}^{-\mathcal{F}(\tilde{Z},\zeta)}\frac{\mathcal{A}_{12}(\tilde{Z},\zeta)H(\tilde{Z})}{3\zeta}\mathrm{d}\tilde{Z}\right], \end{gather}

where ![]() $\mathcal {F}(Z,\zeta )$ is defined as

$\mathcal {F}(Z,\zeta )$ is defined as

We note that solutions (3.24) satisfy the matching conditions between the inner and outer regions. Specifically, ![]() $\mathcal {A}_{22}|_{\zeta \rightarrow \infty }=[\tilde {A}_{22,0}^{core}/H(Z)^{2}]_{\eta =1}=1$,

$\mathcal {A}_{22}|_{\zeta \rightarrow \infty }=[\tilde {A}_{22,0}^{core}/H(Z)^{2}]_{\eta =1}=1$, ![]() $\mathcal {A}_{12}|_{\zeta \rightarrow \infty }=[\tilde {A}_{12,0}^{core}/(-3\eta De)]_{\eta =1}=1$ and

$\mathcal {A}_{12}|_{\zeta \rightarrow \infty }=[\tilde {A}_{12,0}^{core}/(-3\eta De)]_{\eta =1}=1$ and ![]() $\mathcal {A}_{11}|_{\zeta \rightarrow \infty }=[\tilde {A}_{11,0}^{core}/(18\eta ^{2}De^{2}/H(Z)^{2})]_{\eta =1}=1$.

$\mathcal {A}_{11}|_{\zeta \rightarrow \infty }=[\tilde {A}_{11,0}^{core}/(18\eta ^{2}De^{2}/H(Z)^{2})]_{\eta =1}=1$.

3.2. Pressure drop at the first order in  $\tilde {\beta }$

$\tilde {\beta }$

Equation (2.20) shows that the pressure drop depends on the elastic normal and shear stresses ![]() $\tilde {A}_{11}$ and

$\tilde {A}_{11}$ and ![]() $\tilde {A}_{12}$, and thus, generally, requires the solution of the nonlinear viscoelastic problem. However, in the ultra-dilute limit, corresponding to

$\tilde {A}_{12}$, and thus, generally, requires the solution of the nonlinear viscoelastic problem. However, in the ultra-dilute limit, corresponding to ![]() $\tilde {\beta }=\mu _{p}/\mu _{0}\ll 1$, we can determine the pressure drop at

$\tilde {\beta }=\mu _{p}/\mu _{0}\ll 1$, we can determine the pressure drop at ![]() $O(\tilde {\beta })$ for arbitrary values of

$O(\tilde {\beta })$ for arbitrary values of ![]() $De$ only with the knowledge of the velocity field and conformation tensor components at

$De$ only with the knowledge of the velocity field and conformation tensor components at ![]() $O(1)$. Specifically, substituting (3.1) into (2.20) yields at

$O(1)$. Specifically, substituting (3.1) into (2.20) yields at ![]() $O(\tilde {\beta })$ the pressure drop

$O(\tilde {\beta })$ the pressure drop ![]() $\Delta P_1$,

$\Delta P_1$,

\begin{align} \Delta P_1&={-}3\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}} \nonumber\\ &\quad -\frac{3}{2De}\int_{0}^{1}\int_{0}^{1}(1-\eta^{2})\left[\frac{1}{H(Z)}\frac{\partial(H(Z)\tilde{A}_{11,0})}{\partial Z}+\frac{1}{H(Z)}\frac{\partial\tilde{A}_{12,0}}{\partial\eta}\right]\mathrm{d}\eta\,\mathrm{d}Z, \end{align}

\begin{align} \Delta P_1&={-}3\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}} \nonumber\\ &\quad -\frac{3}{2De}\int_{0}^{1}\int_{0}^{1}(1-\eta^{2})\left[\frac{1}{H(Z)}\frac{\partial(H(Z)\tilde{A}_{11,0})}{\partial Z}+\frac{1}{H(Z)}\frac{\partial\tilde{A}_{12,0}}{\partial\eta}\right]\mathrm{d}\eta\,\mathrm{d}Z, \end{align}or alternatively

\begin{align} \Delta P_{1}&={-}3\int_{0}^{1}\frac{ \mathrm{d}Z}{H(Z)^{3}}+\frac{3}{2De}\int_{0}^{1}(1-\eta^{2}) \left[\tilde{A}_{11,0}(0,\eta)-\tilde{A}_{11,0}(1,\eta)\right]\mathrm{d}\eta \nonumber\\ &\quad -\frac{3}{2De}\int_{0}^{1}\left[\frac{H'(Z)}{H(Z)}\left(\int_{0}^{1}(1-\eta^{2})\tilde{A}_{11,0}\,\mathrm{d}\eta\right) \right]\mathrm{d}Z\nonumber\\ &\quad -\frac{3}{De}\int_{0}^{1}\left[\frac{1}{H(Z)}\int_{0}^{1}\eta\tilde{A}_{12,0}\,\mathrm{d}\eta\right]\mathrm{d}Z. \end{align}

\begin{align} \Delta P_{1}&={-}3\int_{0}^{1}\frac{ \mathrm{d}Z}{H(Z)^{3}}+\frac{3}{2De}\int_{0}^{1}(1-\eta^{2}) \left[\tilde{A}_{11,0}(0,\eta)-\tilde{A}_{11,0}(1,\eta)\right]\mathrm{d}\eta \nonumber\\ &\quad -\frac{3}{2De}\int_{0}^{1}\left[\frac{H'(Z)}{H(Z)}\left(\int_{0}^{1}(1-\eta^{2})\tilde{A}_{11,0}\,\mathrm{d}\eta\right) \right]\mathrm{d}Z\nonumber\\ &\quad -\frac{3}{De}\int_{0}^{1}\left[\frac{1}{H(Z)}\int_{0}^{1}\eta\tilde{A}_{12,0}\,\mathrm{d}\eta\right]\mathrm{d}Z. \end{align}

Thus, for a given flow rate ![]() $q$, the dimensionless pressure drop

$q$, the dimensionless pressure drop ![]() $\Delta P=\Delta p/(\mu _{0}q\ell /2h_{0}^{3})$, as a function of the shape function

$\Delta P=\Delta p/(\mu _{0}q\ell /2h_{0}^{3})$, as a function of the shape function ![]() $H(Z)$, the Deborah number

$H(Z)$, the Deborah number ![]() $De$ and the viscosity ratio

$De$ and the viscosity ratio ![]() $\tilde {\beta }\ll 1$, up to

$\tilde {\beta }\ll 1$, up to ![]() $O(\tilde {\beta })$, is given by

$O(\tilde {\beta })$, is given by

where the expressions for ![]() $\Delta P_{0}$ and

$\Delta P_{0}$ and ![]() $\Delta P_{1}$ are given in (3.4b) and (3.27), respectively.

$\Delta P_{1}$ are given in (3.4b) and (3.27), respectively.

Notably, in contrast to our previous results for the pressure drop obtained in the weakly viscoelastic and lubrication limits with ![]() $De\ll 1$ and

$De\ll 1$ and ![]() $\tilde {\beta }\in [0,1]$ (Boyko & Stone Reference Boyko and Stone2022), the current result (3.28) applies to the limit of

$\tilde {\beta }\in [0,1]$ (Boyko & Stone Reference Boyko and Stone2022), the current result (3.28) applies to the limit of ![]() $\tilde {\beta }\ll 1$, while allowing

$\tilde {\beta }\ll 1$, while allowing ![]() $De=O(1)$.

$De=O(1)$.

3.2.1. Pressure drop at  $O(\tilde {\beta })$ in the low-

$O(\tilde {\beta })$ in the low- $De$ limit

$De$ limit

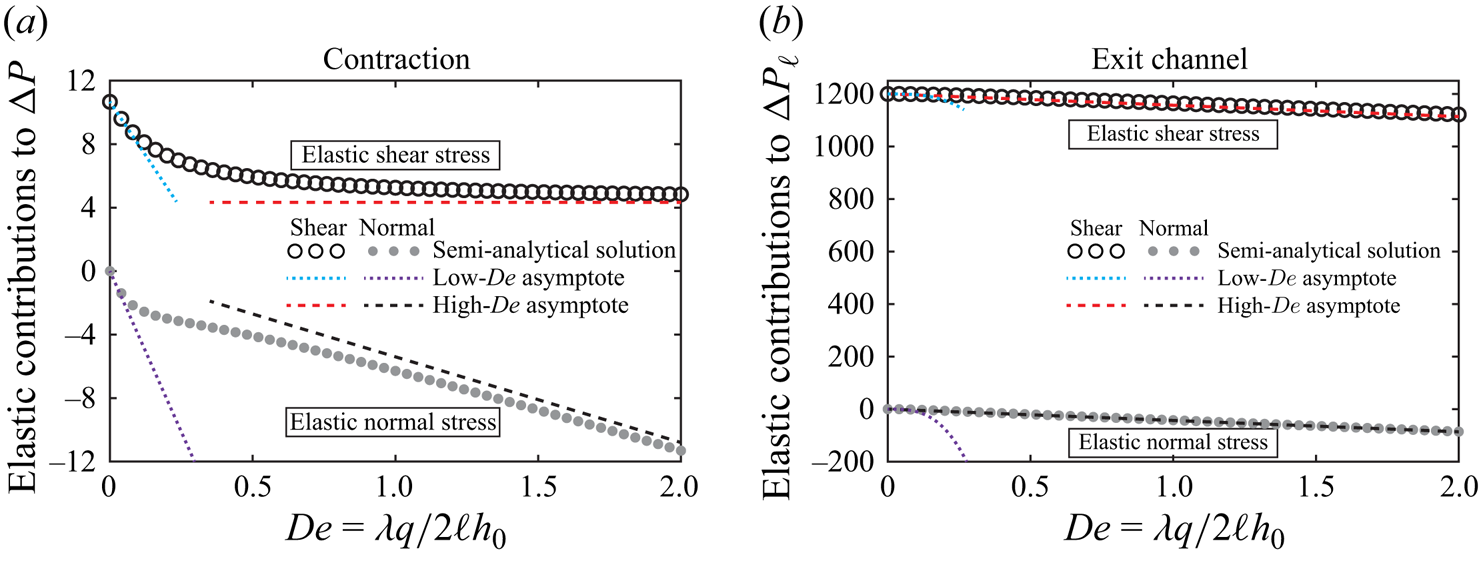

To calculate the pressure drop ![]() $\Delta P_{1}$ at low Deborah numbers in the non-uniform shape region, we use (3.13b)–(3.13c) and (3.27). The elastic normal stress (NS) contribution to the pressure drop at

$\Delta P_{1}$ at low Deborah numbers in the non-uniform shape region, we use (3.13b)–(3.13c) and (3.27). The elastic normal stress (NS) contribution to the pressure drop at ![]() $O(\tilde {\beta })$ is

$O(\tilde {\beta })$ is

\begin{align} \Delta P_{1}^{NS}&=\frac{3}{2De}\int_{0}^{1}(1\!-\!\eta^{2})\left[\tilde{A}_{11,0}\right]_{Z=1}^{Z=0}\, \mathrm{d}\eta -\frac{3}{2De}\int_{0}^{1}\left[\frac{H'(Z)}{H(Z)}\left(\int_{0}^{1} (1\!-\!\eta^{2})\tilde{A}_{11,0}\,\mathrm{d}\eta\right)\right]\mathrm{d}Z \nonumber\\ &= \frac{27}{10}De(1-H_{\ell}^{{-}4})\quad\mathrm{for}\ De\ll1, \end{align}

\begin{align} \Delta P_{1}^{NS}&=\frac{3}{2De}\int_{0}^{1}(1\!-\!\eta^{2})\left[\tilde{A}_{11,0}\right]_{Z=1}^{Z=0}\, \mathrm{d}\eta -\frac{3}{2De}\int_{0}^{1}\left[\frac{H'(Z)}{H(Z)}\left(\int_{0}^{1} (1\!-\!\eta^{2})\tilde{A}_{11,0}\,\mathrm{d}\eta\right)\right]\mathrm{d}Z \nonumber\\ &= \frac{27}{10}De(1-H_{\ell}^{{-}4})\quad\mathrm{for}\ De\ll1, \end{align}

where ![]() $[\tilde {A}_{11,0}]_{Z=1}^{Z=0}=\tilde {A}_{11,0}(0,\eta )-\tilde {A}_{11,0}(1,\eta )$.

$[\tilde {A}_{11,0}]_{Z=1}^{Z=0}=\tilde {A}_{11,0}(0,\eta )-\tilde {A}_{11,0}(1,\eta )$.

The elastic shear stress (SS) contribution to the pressure drop at ![]() $O(\tilde {\beta })$ is

$O(\tilde {\beta })$ is

\begin{align} \Delta P_{1}^{SS}&={-}\frac{3}{De}\int_{0}^{1}\left[\frac{1}{H(Z)}\int_{0}^{1}\eta\tilde{A}_{12,0}\, \mathrm{d}\eta\right]\mathrm{d}Z \nonumber\\ &= 3\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}+\frac{18}{10}De(1-H_{\ell}^{{-}4})\quad\mathrm{for}\ De\ll1. \end{align}

\begin{align} \Delta P_{1}^{SS}&={-}\frac{3}{De}\int_{0}^{1}\left[\frac{1}{H(Z)}\int_{0}^{1}\eta\tilde{A}_{12,0}\, \mathrm{d}\eta\right]\mathrm{d}Z \nonumber\\ &= 3\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}+\frac{18}{10}De(1-H_{\ell}^{{-}4})\quad\mathrm{for}\ De\ll1. \end{align}

Substituting (3.29) and (3.30) into (3.27) provides the pressure drop at ![]() $O(\tilde {\beta })$ in the low-

$O(\tilde {\beta })$ in the low-![]() $De$ limit up to

$De$ limit up to ![]() $O(De)$

$O(De)$

so that the total pressure drop across the non-uniform channel in the low-![]() $De$ limit, accounting for the leading-order effect of viscoelasticity, is

$De$ limit, accounting for the leading-order effect of viscoelasticity, is

\begin{align} \Delta

P&=\underset{\textit{Solvent stress}}{\underbrace{3(1-\tilde{\beta})\int_{0}^{1}

\frac{\mathrm{d}Z}{H(Z)^{3}}}}+\underset{\textit{Elastic shear stress}}{\underbrace{

3\tilde{\beta}\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}+\frac{18}{10}\tilde{\beta}

De(1-H_{\ell}^{{-}4})}}+\underset{\textit{Elastic normal stress}}{\underbrace{

\frac{27}{10}\tilde{\beta}De(1-H_{\ell}^{{-}4})}}

\nonumber\\

&=3\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}+\frac{9}{2}\tilde{\beta}De(1-H_{\ell}^{{-}4})+

O(De^2)\quad\mathrm{for}\ De\ll1,

\end{align}

\begin{align} \Delta

P&=\underset{\textit{Solvent stress}}{\underbrace{3(1-\tilde{\beta})\int_{0}^{1}

\frac{\mathrm{d}Z}{H(Z)^{3}}}}+\underset{\textit{Elastic shear stress}}{\underbrace{

3\tilde{\beta}\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}+\frac{18}{10}\tilde{\beta}

De(1-H_{\ell}^{{-}4})}}+\underset{\textit{Elastic normal stress}}{\underbrace{

\frac{27}{10}\tilde{\beta}De(1-H_{\ell}^{{-}4})}}

\nonumber\\

&=3\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}+\frac{9}{2}\tilde{\beta}De(1-H_{\ell}^{{-}4})+

O(De^2)\quad\mathrm{for}\ De\ll1,

\end{align}

in agreement with the results of our previous work (Boyko & Stone Reference Boyko and Stone2022). The three terms on the right-hand side of (3.32) represent, respectively, the Newtonian solvent stress contribution, the elastic shear stress contribution and the elastic normal stress contribution to the pressure drop.

3.2.2. Pressure drop at  $O(\tilde {\beta })$ in the high-

$O(\tilde {\beta })$ in the high- $De$ limit

$De$ limit

To calculate the pressure drop ![]() $\Delta P_{1}$ at high Deborah numbers in the non-uniform region, we use (3.17), (3.19) and (3.27). The elastic normal and shear stress contributions to the pressure drop at

$\Delta P_{1}$ at high Deborah numbers in the non-uniform region, we use (3.17), (3.19) and (3.27). The elastic normal and shear stress contributions to the pressure drop at ![]() $O(\tilde {\beta })$ are

$O(\tilde {\beta })$ are

Substituting (3.33) into (3.27) yields the pressure drop at ![]() $O(\tilde {\beta })$ in the high-

$O(\tilde {\beta })$ in the high-![]() $De$ limit

$De$ limit

so that the total pressure drop across the non-uniform channel in the high-![]() $De$ limit is

$De$ limit is

\begin{equation} \Delta

P=\underset{\textit{Solvent stress}}{\underbrace{3(1-\tilde{\beta})

\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}}}+\underset{\textit{Elastic shear stress}}{

\underbrace{3\tilde{\beta}\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)}}}+\underset{\textit{Elastic normal stress}}{

\underbrace{\frac{9}{5}\tilde{\beta}De(1-H_{\ell}^{{-}2})}}\quad\mathrm{for}\

De\gg1.\end{equation}

\begin{equation} \Delta

P=\underset{\textit{Solvent stress}}{\underbrace{3(1-\tilde{\beta})

\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)^{3}}}}+\underset{\textit{Elastic shear stress}}{

\underbrace{3\tilde{\beta}\int_{0}^{1}\frac{\mathrm{d}Z}{H(Z)}}}+\underset{\textit{Elastic normal stress}}{

\underbrace{\frac{9}{5}\tilde{\beta}De(1-H_{\ell}^{{-}2})}}\quad\mathrm{for}\

De\gg1.\end{equation}

Similar to the low-![]() $De$ limit, for the contraction geometry, the last term, corresponding to the elastic normal stress contribution, leads to a decrease in the pressure drop, which is linear in the Deborah number. As noted by Hinch et al. (Reference Hinch, Boyko and Stone2024), the tension in the streamlines at the end of the contraction pulls the flow through the contraction, thus requiring less pressure to push. Furthermore, at high Deborah numbers, the elastic shear stresses are lower than the fully relaxed value

$De$ limit, for the contraction geometry, the last term, corresponding to the elastic normal stress contribution, leads to a decrease in the pressure drop, which is linear in the Deborah number. As noted by Hinch et al. (Reference Hinch, Boyko and Stone2024), the tension in the streamlines at the end of the contraction pulls the flow through the contraction, thus requiring less pressure to push. Furthermore, at high Deborah numbers, the elastic shear stresses are lower than the fully relaxed value ![]() $\tilde {A}_{12}=-3De\eta /H_{\ell }^{2}$ due to insufficient time (distance) to approach their fully relaxed value in the contraction. Thus, the elastic shear stress contribution to the pressure drop,

$\tilde {A}_{12}=-3De\eta /H_{\ell }^{2}$ due to insufficient time (distance) to approach their fully relaxed value in the contraction. Thus, the elastic shear stress contribution to the pressure drop, ![]() $3\tilde {\beta }\int _{0}^{1}H(Z)^{-1}\,\mathrm {d}Z$, is smaller than the steady Poiseuille value of

$3\tilde {\beta }\int _{0}^{1}H(Z)^{-1}\,\mathrm {d}Z$, is smaller than the steady Poiseuille value of ![]() $3\tilde {\beta }\int _{0}^{1}H(Z)^{-3}\,\mathrm {d}Z$, further reducing the pressure drop. Finally, we note that the result (3.35) also holds for the expansion geometry

$3\tilde {\beta }\int _{0}^{1}H(Z)^{-3}\,\mathrm {d}Z$, further reducing the pressure drop. Finally, we note that the result (3.35) also holds for the expansion geometry ![]() $H_{\ell }>1$, in which the two physical mechanisms mentioned above lead to an increase in the pressure drop.

$H_{\ell }>1$, in which the two physical mechanisms mentioned above lead to an increase in the pressure drop.

4. Low- $\tilde {\beta }$ lubrication analysis in the exit channel

$\tilde {\beta }$ lubrication analysis in the exit channel

In this section, we analyse the spatial relaxation of the elastic stresses and the pressure drop in the uniform exit channel. From examining the expressions (3.8)–(3.10) for the conformation tensor, when there are no longer shape changes, we expect the elastic stresses and the pressure in the exit channel to relax exponentially, with a strong dependence on ![]() $De^{-1}$. Thus, for higher Deborah numbers, a longer downstream section is required (Keiller Reference Keiller1993) for polymer relaxation, consistent with previous numerical simulations using the Oldroyd-B model (Debbaut et al. Reference Debbaut, Marchal and Crochet1988; Alves et al. Reference Alves, Oliveira and Pinho2003).

$De^{-1}$. Thus, for higher Deborah numbers, a longer downstream section is required (Keiller Reference Keiller1993) for polymer relaxation, consistent with previous numerical simulations using the Oldroyd-B model (Debbaut et al. Reference Debbaut, Marchal and Crochet1988; Alves et al. Reference Alves, Oliveira and Pinho2003).

Following similar steps as in the previous section, in Appendix B, we derive closed-form expressions for the conformation tensor and the pressure drop in the uniform exit channel for arbitrary values of the Deborah number. Furthermore, we provide analytical expressions for the conformation tensor and the pressure drop in the low- and high-![]() $De$ limits. We summarize in table 1 the semi-analytical solutions and low- and high-

$De$ limits. We summarize in table 1 the semi-analytical solutions and low- and high-![]() $De$ asymptotic expressions for the deformation of the microstructure and the pressure drop of the Oldroyd-B fluid in a contraction and exit channel in the ultra-dilute limit derived in this work.

$De$ asymptotic expressions for the deformation of the microstructure and the pressure drop of the Oldroyd-B fluid in a contraction and exit channel in the ultra-dilute limit derived in this work.

Table 1. A summary of the semi-analytical solutions and low- and high-![]() $De$ asymptotic expressions for the deformation of the microstructure and the pressure drop of the Oldroyd-B fluid in a contraction and exit channel in the ultra-dilute limit.

$De$ asymptotic expressions for the deformation of the microstructure and the pressure drop of the Oldroyd-B fluid in a contraction and exit channel in the ultra-dilute limit.

In particular, we show that the total pressure drop in the exit channel can be expressed as

\begin{align} \Delta

P_{\ell}=\underset{\textit{Solvent stress}}{\underbrace{(1\!-\!\tilde{\beta})\frac{3L}{H_{\ell}^{3}}}}+\underset{\textit{Elastic normal stress}}{\underbrace{\frac{3\tilde{\beta}}{2De}\int_{0}^{1}(1\!-\!\eta^{2})\left[\tilde{A}_{11,0}\right]_{Z_{\ell}=L}^{Z_{\ell}=0}\,\mathrm{d}\eta}}

+\underset{\textit{Elastic shear stress}}{\underbrace{\frac{3\tilde{\beta}}{DeH_{\ell}}\int_{0}^{1}

\eta\left[\int_{L}^{0}\tilde{A}_{12,0}\,\mathrm{d}Z_{\ell}\right]\mathrm{d}\eta}},\end{align}

\begin{align} \Delta

P_{\ell}=\underset{\textit{Solvent stress}}{\underbrace{(1\!-\!\tilde{\beta})\frac{3L}{H_{\ell}^{3}}}}+\underset{\textit{Elastic normal stress}}{\underbrace{\frac{3\tilde{\beta}}{2De}\int_{0}^{1}(1\!-\!\eta^{2})\left[\tilde{A}_{11,0}\right]_{Z_{\ell}=L}^{Z_{\ell}=0}\,\mathrm{d}\eta}}

+\underset{\textit{Elastic shear stress}}{\underbrace{\frac{3\tilde{\beta}}{DeH_{\ell}}\int_{0}^{1}

\eta\left[\int_{L}^{0}\tilde{A}_{12,0}\,\mathrm{d}Z_{\ell}\right]\mathrm{d}\eta}},\end{align}

where ![]() $L=\ell _{\ell }/\ell$ is the dimensionless length,

$L=\ell _{\ell }/\ell$ is the dimensionless length, ![]() $H_{\ell }=H(Z=1)=h_{\ell }/h_{0}$ is the dimensionless height of the exit channel,

$H_{\ell }=H(Z=1)=h_{\ell }/h_{0}$ is the dimensionless height of the exit channel, ![]() $Z_{\ell }=Z-1$,

$Z_{\ell }=Z-1$, ![]() $\tilde {A}_{11,0}$ and

$\tilde {A}_{11,0}$ and ![]() $\tilde {A}_{12,0}$ are given in (B4) and (B5) and

$\tilde {A}_{12,0}$ are given in (B4) and (B5) and ![]() $[\tilde {A}_{11,0}]_{Z_{\ell }=L}^{Z_{\ell }=0}=\tilde {A}_{11,0}(Z_{\ell }=0,\eta )-\tilde {A}_{11,0}(Z_{\ell }=L,\eta )$.

$[\tilde {A}_{11,0}]_{Z_{\ell }=L}^{Z_{\ell }=0}=\tilde {A}_{11,0}(Z_{\ell }=0,\eta )-\tilde {A}_{11,0}(Z_{\ell }=L,\eta )$.

It should be noted that we can express the first-order contribution ![]() $\Delta P_{\ell, 1}$ in terms of the difference between the conformation tensor components at the beginning and end of the exit channel (see Appendix B and Hinch et al. Reference Hinch, Boyko and Stone2024)

$\Delta P_{\ell, 1}$ in terms of the difference between the conformation tensor components at the beginning and end of the exit channel (see Appendix B and Hinch et al. Reference Hinch, Boyko and Stone2024)

\begin{align} \Delta P_{\ell,1}&=\frac{3}{2De}\int_{0}^{1}(1-\eta^{2})\left[\tilde{A}_{11,0}\right]_{Z_{\ell}=L}^{Z_{\ell}=0}\, \mathrm{d}\eta -\frac{9}{2H_{\ell}^2}\int_{0}^{1}\eta(1-\eta^2)\left[\tilde{A}_{12,0}\right]_{Z_{\ell}=L}^{Z_{\ell}=0}\, \mathrm{d}\eta \nonumber\\ &\quad +\frac{27De}{2H_{\ell}^{4}}\int_{0}^{1}\eta^2(1-\eta^2)\left[\tilde{A}_{22,0}\right]_{Z_{\ell}=L}^{Z_{\ell}=0}\,\mathrm{d}\eta. \end{align}