1. Introduction

The ability of a liquid to ‘wet’ a solid is described by the angle that the liquid makes with the solid when the interface is stationary – the static contact angle. For a liquid in contact with a smooth and chemically homogeneous and inert surface, this angle ![]() ${\theta }_{e}$ is unique and given by Young's equation. Real surfaces, which are often rough on a variety of length scales, are chemically heterogeneous and/or involve some type of irreversible work of adhesion, display a range of equilibrium contact angles: the maximum is the static advancing angle

${\theta }_{e}$ is unique and given by Young's equation. Real surfaces, which are often rough on a variety of length scales, are chemically heterogeneous and/or involve some type of irreversible work of adhesion, display a range of equilibrium contact angles: the maximum is the static advancing angle ![]() ${\theta }_{a}$, above which the interface will advance, and the minimum is the static receding angle

${\theta }_{a}$, above which the interface will advance, and the minimum is the static receding angle ![]() ${\theta }_{r}$, below which it will recede. The difference between these two angles is defined as the range of contact-angle hysteresis (CAH). The CAH,

${\theta }_{r}$, below which it will recede. The difference between these two angles is defined as the range of contact-angle hysteresis (CAH). The CAH, ![]() ${\theta }_{a}$ and

${\theta }_{a}$ and ![]() ${\theta }_{r}$ are critical wetting parameters that determine (for example) how easily drops can move over solid surfaces, under what conditions liquid films will smoothly coat surfaces, or whether gas injection will aid particle floatation. Technologies that depend on CAH angles include established processes such as industrial separation devices or the wetting behaviour of fabrics, through to more novel processes such as transparent self-cleaning surfaces for solar power generation or low-energy liquid fuel separation membranes (Cassie & Baxter Reference Cassie and Baxter1944; Wu et al. Reference Wu, Sugimura, Inoue and Takai2002; Feng et al. Reference Feng, Mai, Ma, Liu, Jiang and Zhu2004; Callies & Quéré Reference Callies and Quéré2005; Sun et al. Reference Sun, Feng, Gao and Jiang2005; Li et al. Reference Li, Ju, Xue, Ma, Feng, Gao and Jiang2013). For the design and optimisation of these processes, general and validated wetting theories are needed that can predict the CAH range. However, as highlighted via several recent works, such theories are not yet available, with fundamental questions remaining about the nature of the wetting process (Eral, ’t Mannetje & Oh Reference Eral, ’t Mannetje and Oh2013; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019; Erbil Reference Erbil2021; Butt et al. Reference Butt2022). The purpose of this study is to derive an energy conservation framework that can be applied to predict CAH angles.

${\theta }_{r}$ are critical wetting parameters that determine (for example) how easily drops can move over solid surfaces, under what conditions liquid films will smoothly coat surfaces, or whether gas injection will aid particle floatation. Technologies that depend on CAH angles include established processes such as industrial separation devices or the wetting behaviour of fabrics, through to more novel processes such as transparent self-cleaning surfaces for solar power generation or low-energy liquid fuel separation membranes (Cassie & Baxter Reference Cassie and Baxter1944; Wu et al. Reference Wu, Sugimura, Inoue and Takai2002; Feng et al. Reference Feng, Mai, Ma, Liu, Jiang and Zhu2004; Callies & Quéré Reference Callies and Quéré2005; Sun et al. Reference Sun, Feng, Gao and Jiang2005; Li et al. Reference Li, Ju, Xue, Ma, Feng, Gao and Jiang2013). For the design and optimisation of these processes, general and validated wetting theories are needed that can predict the CAH range. However, as highlighted via several recent works, such theories are not yet available, with fundamental questions remaining about the nature of the wetting process (Eral, ’t Mannetje & Oh Reference Eral, ’t Mannetje and Oh2013; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019; Erbil Reference Erbil2021; Butt et al. Reference Butt2022). The purpose of this study is to derive an energy conservation framework that can be applied to predict CAH angles.

The early energy-based wetting theories of Wenzel and Cassie remain influential in interpreting wetting phenomena. Considering the energy change that occurs as a liquid/gas interface advances a small distance over the surface of a rough solid, Wenzel (Reference Wenzel1936) proposed that the apparent contact angle is related to the roughness ![]() $r$ of the surface, defined as the total to projected surface area ratio (see § 4.1). In deriving this theory, Wenzel assumed that the liquid completely wets each surface undulation. Cassie & Baxter (Reference Cassie and Baxter1944) recognised that such ‘complete’ wetting did not necessarily occur, and derived an expression for the apparent contact angle on a partially wet surface in terms of the wetted and non-wetted liquid areas per projected solid area, being

$r$ of the surface, defined as the total to projected surface area ratio (see § 4.1). In deriving this theory, Wenzel assumed that the liquid completely wets each surface undulation. Cassie & Baxter (Reference Cassie and Baxter1944) recognised that such ‘complete’ wetting did not necessarily occur, and derived an expression for the apparent contact angle on a partially wet surface in terms of the wetted and non-wetted liquid areas per projected solid area, being ![]() $f_1$ and

$f_1$ and ![]() $f_2$, respectively (see § 4.1). The Wenzel and Cassie & Baxter equations are useful for understanding and interpreting experimental data; however, theories based solely on these concepts (e.g. Bico, Thiele & Quéré Reference Bico, Thiele and Quéré2002; Patankar Reference Patankar2003) are not predictive as the proportion of solid surface wetted by a liquid is not known a priori. Also, these theories give only one static contact angle for a rough structured surface, rather than the CAH range that is observed experimentally.

$f_2$, respectively (see § 4.1). The Wenzel and Cassie & Baxter equations are useful for understanding and interpreting experimental data; however, theories based solely on these concepts (e.g. Bico, Thiele & Quéré Reference Bico, Thiele and Quéré2002; Patankar Reference Patankar2003) are not predictive as the proportion of solid surface wetted by a liquid is not known a priori. Also, these theories give only one static contact angle for a rough structured surface, rather than the CAH range that is observed experimentally.

Another series of works is based on the thermodynamic concept of energy minimisation of an entire drop sitting on a rough surface. Johnson & Dettre (Reference Johnson and Dettre1964) computed the free energy of drops residing at the centre of concentric sinusoidal roughness rings, showing that the energy of the system oscillated as the drop volume increased and the interface advanced over each ring. They interpreted the amplitude of these energy oscillations as energy barriers that must be overcome by macroscopic vibrational energy to allow interface movement, implying that as the height of surface roughness decreases, the range of CAH should also decrease. This conclusion is contrary to experimental evidence, however, which shows that roughness-induced CAH depends strongly on surface topology (relative shape) rather than absolute roughness size, provided that gravitational and Laplace pressure effects can be neglected on the length scale of the roughness (Öner & McCarthy Reference Öner and McCarthy2000; Dorrer & Rühe Reference Dorrer and Rühe2008; Li et al. Reference Li, Xue, Lv, Huang, Lin and Duan2016; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019). Other studies have used similar static free-energy minimisation concepts to explain CAH for a variety of periodically shaped surfaces (Extrand Reference Extrand2002; Brandon et al. Reference Brandon, Haimovich, Yeger and Marmur2003; Marmur Reference Marmur2006, Reference Marmur2022); however, in general, the results do not qualitatively agree with observation. For example, Brandon et al. (Reference Brandon, Haimovich, Yeger and Marmur2003) used minimal surface energy modelling to show that the apparent contact-angle range for a drop on a doubly periodic undulating surface approached a single value (the Cassie angle) as the drop size to roughness ratio increased, again contradicting the above referenced experimental observations that show that the CAH range becomes quite constant at large droplet to roughness size ratios. A related question also remains about these analyses: is it really necessary to consider the energy of the entire flow system (most commonly a droplet) to calculate the CAH range, or is it instead a property associated with the three-phase contact line (TPCL) that can be applied to a wide variety of surrounding flow systems? This is an unresolved question that has garnered conflicting opinions (Extrand Reference Extrand2003; Gao & McCarthy Reference Gao and McCarthy2007a,Reference Gao and McCarthyb; McHale Reference McHale2007; Nosonovsky Reference Nosonovsky2007; Panchagnula & Vedantam Reference Panchagnula and Vedantam2007; Marmur Reference Marmur2022).

Other studies conclude that CAH is substantially a property of the TPCL region (Nosonovsky Reference Nosonovsky2007; Panchagnula & Vedantam Reference Panchagnula and Vedantam2007) and that CAH has its origin in the energy dissipation that occurs around the TPCL as it advances over the rough solid. Central to this concept is that the advancing and receding angles are defined as those measured while the interface is moving (albeit at a vanishingly slow velocity) rather than being determined solely by static thermodynamic states. An influential study in this vein is by Joanny & de Gennes (Reference Joanny and de Gennes1984), who proposed a model for CAH on a surface that contains a dilute number of ‘strong defects’ as a model for surface contamination or dilutely distributed surface roughness. The theory considered the ‘pinning’ and subsequent ‘depinning’ or ‘jumping’ of the contact line as it advanced over a surface, assuming that during each interface jump surface potential energy is dissipated to heat. Joanny & de Gennes (Reference Joanny and de Gennes1984) calculated this energy dissipation amount under ideal conditions and incorporated it into an equation for CAH relevant to dilute defect surfaces. More recent works have observed experimentally the pinning/depinning or ‘stick–slip’ behaviour of the fluid interface near the TPCL (Priest et al. Reference Priest, Albrecht, Sedev and Ralston2009; Forsberg et al. Reference Forsberg, Priest, Brinkmann, Sedev and Ralston2010; Schellenberger et al. Reference Schellenberger, Encinas, Vollmer and Butt2016; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019). Other studies have used a variety of energy conservation principles to extend the work of Joanny & de Gennes (Reference Joanny and de Gennes1984) to periodic surfaces (Raj et al. Reference Raj, Enright, Zhu, Adera and Wang2012; Butt et al. Reference Butt, Gao, Papadopoulos, Steffen, Kappl and Berger2017; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019) or interpreted measurements of CAH in terms of contact-line energy dissipation and interfacial ‘jumping’ dynamics (Priest, Sedev & Ralston Reference Priest, Sedev and Ralston2007, Reference Priest, Sedev and Ralston2013; Dorrer & Rühe Reference Dorrer and Rühe2008; Song et al. Reference Song, Liu, Sun, Jiao, Wang, Liu and Ye2022). Despite these successes, however, questions remain about this conceptual model of CAH; around what specific TPCL region should energy be conserved, how should the dissipation that occurs during the ‘stick–slip’ motion of the interface be calculated, and how can the energies of practical surfaces that may contain randomly shaped structures and/or micro-bubbles/droplets be included in such an analysis?

On a slightly different track, Joanny & de Gennes (Reference Joanny and de Gennes1984) also explored the influence of ‘weak’ surface defects on CAH, referring to smooth defects as those that cause the fluid interface near the solid to become distorted, but that do not result in the aforementioned ‘pinning’ and ‘depinning’ behaviour of the TPCL. Their conclusion was that isolated weak defects do not generally result in hysteresis; however, other works have extended this analysis to conclude that distributions of weak surface heterogeneities can cause CAH (Pomeau & Vannimenus Reference Pomeau and Vannimenus1985; Robbins & Joanny Reference Robbins and Joanny1987; Öpik Reference Öpik2000). In related work, Cox (Reference Cox1983) examined how an interface changes as it moves over a gently undulating sinusoidal periodic rough surface, showing that when the interface moved in the direction of roughness periodicity, TPCL ‘jumps’ occurred (i.e. ‘strong’ defects leading to CAH), but when advancing in other directions relative to the periodicity direction, the interface moved continuously (i.e. ‘weak’ defects producing no CAH). It should be noted that these theoretical studies predict the possible shapes that a fluid interface can take when passing over arrangements of surface heterogeneities, and from these, the range of CAH angles is inferred. In general, the link between CAH angles calculated via these interface topology methods and those calculated by energy conservation has not been established.

In reviewing this body of literature, key questions about wetting behaviour remain. Specifically, there is conjecture regarding how energy conservation, fluid interface distortion and the dynamics of interface ‘jumping’ determine CAH. Critically, there is no experimental consensus or fundamental analysis that shows how energy conservation should be applied to predict CAH – works that are based on energy conservation around entire droplets in general do not predict experimentally observed CAH trends, while studies that are based on energy changes around a moving TPCL lack rigour, leading to inconsistent formulations and application. Further, while many studies do view contact-line jumping as a source of CAH (‘strong’ defects), there is confusion over whether fluid interface distortion (‘weak’ defects) in isolation can produce CAH, and how studies that predict CAH angles via interface topology and dynamics can be mathematically related to CAH angles resulting from energy conservation.

This study addresses these questions. Specifically, we derive a rigorous energy conservation framework, which, when applied to the moving TPCL, can be used to predict CAH. We do this by first deriving a general multiphase mechanical energy balance (MMEB) equation (§ 2) that adds terms associated with the interfacial stresses acting between each of the material phases to the conventional single phase mechanical energy balance. We then apply this MMEB to a cylindrical control volume that is anchored to a TPCL as it moves across a rough solid surface at a vanishingly slow speed (§ 3), deriving an energy conservation equation that predicts CAH from knowledge of the interfacial dynamics occurring within the TPCL. Within § 4, we discuss under what physical conditions the theory is valid, apply the theory to the common Wenzel, Cassie–Baxter and ‘Fakir’ wetting regimes, and finally outline how the theory answers some of the open questions in the wetting field.

2. Macroscopic mechanical energy balance for immiscible multiphase mixtures

In this section, a macroscopic mechanical energy balance is derived for a moving control volume that contains a number of immiscible phases (see figure 1). The derivation is similar to that of Bird, Stewart & Lightfoot (Reference Bird, Stewart and Lightfoot2002, p. 221, § 7.8) except that interfacial tension acts at the interface between each pair of phases, and the balance is not specific to Newtonian liquids. (We do assume that each material has a symmetric stress tensor; however, for most homogeneous materials, this assumption appears to be valid (Kuiken Reference Kuiken1995; Dahler & Scriven Reference Dahler and Scriven1961).)

Figure 1. The macroscopic mechanical energy balance is performed on a moving control volume that contains multiple immiscible phases bounded by multiple interface types. Each interface type has an associated unit normal vector ![]() $\boldsymbol {n}_{{S},ij}$ that is directed into phase

$\boldsymbol {n}_{{S},ij}$ that is directed into phase ![]() $i$ (where

$i$ (where ![]() $i< j$). The velocity and outward unit normal of the control volume boundary are

$i< j$). The velocity and outward unit normal of the control volume boundary are ![]() ${\boldsymbol {v}}_{cv}$ and

${\boldsymbol {v}}_{cv}$ and ![]() $\boldsymbol {n}_{cv}$, respectively. In the indicated configuration, four material phases are present within the control volume, and they intersect along four different interface types.

$\boldsymbol {n}_{cv}$, respectively. In the indicated configuration, four material phases are present within the control volume, and they intersect along four different interface types.

The starting point is a momentum equation for a mixture of immiscible phases,

Here, ![]() $\boldsymbol {v}$ is the local phase velocity (assumed to vary continuously throughout),

$\boldsymbol {v}$ is the local phase velocity (assumed to vary continuously throughout), ![]() $\rho$ is the local phase density,

$\rho$ is the local phase density, ![]() $\mathsf {T}_{M}$ is the local total material stress at any point within any phase, and

$\mathsf {T}_{M}$ is the local total material stress at any point within any phase, and ![]() $\mathsf {T}_{S}$ is the local surface stress acting on the interfaces between phases. The functional form of the material stress tensor

$\mathsf {T}_{S}$ is the local surface stress acting on the interfaces between phases. The functional form of the material stress tensor ![]() $\mathsf {T}_{M}(\boldsymbol {x})$ is a property of the material type present at

$\mathsf {T}_{M}(\boldsymbol {x})$ is a property of the material type present at ![]() $\boldsymbol {x}$.

$\boldsymbol {x}$.

Formally, for (2.1) to be valid everywhere within ![]() ${V}_{cv}$, all terms appearing in the equation must be defined not only within each phase but also on the interfaces between phases. This includes terms such as

${V}_{cv}$, all terms appearing in the equation must be defined not only within each phase but also on the interfaces between phases. This includes terms such as ![]() ${\mathsf{T}}_{M}$ and

${\mathsf{T}}_{M}$ and ![]() $\rho$ that are associated with a particular material type. Such formal definitions could be made; however, as (2.1) is integrated over space in the following analysis, as long as any phase-specific terms are finite on each interface, their interface values do not affect the final energy balance. Hence we simply assume that the interface values for

$\rho$ that are associated with a particular material type. Such formal definitions could be made; however, as (2.1) is integrated over space in the following analysis, as long as any phase-specific terms are finite on each interface, their interface values do not affect the final energy balance. Hence we simply assume that the interface values for ![]() $\mathsf {T}_{M}(\boldsymbol {x})$ and

$\mathsf {T}_{M}(\boldsymbol {x})$ and ![]() $\rho$ are finite.

$\rho$ are finite.

The effects of interfacial tension on material movement are captured using a surface stress tensor ![]() ${\mathsf{T}}_{S}(\boldsymbol {x})$. The form of this tensor is taken from Lafaurie et al. (Reference Lafaurie, Nardone, Scardovelli, Zaleski and Zanetti1994), but generalised here to include interfaces between multiple phases:

${\mathsf{T}}_{S}(\boldsymbol {x})$. The form of this tensor is taken from Lafaurie et al. (Reference Lafaurie, Nardone, Scardovelli, Zaleski and Zanetti1994), but generalised here to include interfaces between multiple phases:

In this equation, ![]() ${\sigma }_{ij}$ is the constant surface energy per unit area (or interfacial tension) associated with the ‘

${\sigma }_{ij}$ is the constant surface energy per unit area (or interfacial tension) associated with the ‘![]() $ij$ interface’ (i.e. the interface between phases

$ij$ interface’ (i.e. the interface between phases ![]() $i$ and

$i$ and ![]() $j$),

$j$), ![]() $\boldsymbol{\mathsf{I}}$ is the identity tensor,

$\boldsymbol{\mathsf{I}}$ is the identity tensor, ![]() $\boldsymbol {n}_{{S},ij}$ is a unit vector directed normal to the

$\boldsymbol {n}_{{S},ij}$ is a unit vector directed normal to the ![]() $ij$ interface and into phase

$ij$ interface and into phase ![]() $i$, and

$i$, and ![]() ${\delta }_{{S},ij}$ is a ‘surface’ delta function that is non-zero only on the

${\delta }_{{S},ij}$ is a ‘surface’ delta function that is non-zero only on the ![]() $ij$ interface. The surface delta function is essentially a multidimensional analogue of the Dirac delta function and has been utilised extensively in the development of computational fluid dynamics methods (Brackbill, Kothe & Zemach Reference Brackbill, Kothe and Zemach1992; Lafaurie et al. Reference Lafaurie, Nardone, Scardovelli, Zaleski and Zanetti1994). In the present context, it has the property that

$ij$ interface. The surface delta function is essentially a multidimensional analogue of the Dirac delta function and has been utilised extensively in the development of computational fluid dynamics methods (Brackbill, Kothe & Zemach Reference Brackbill, Kothe and Zemach1992; Lafaurie et al. Reference Lafaurie, Nardone, Scardovelli, Zaleski and Zanetti1994). In the present context, it has the property that

where ![]() ${A}_{ij}$ is the total area of the

${A}_{ij}$ is the total area of the ![]() $ij$ interface existing within the control volume

$ij$ interface existing within the control volume ![]() ${V}_{cv}$. Further, under conditions where

${V}_{cv}$. Further, under conditions where ![]() $\boldsymbol {n}_{cv} \boldsymbol {\cdot } \boldsymbol {n}_{{S},ij}$ is uniform over a particular intersection between a surface

$\boldsymbol {n}_{cv} \boldsymbol {\cdot } \boldsymbol {n}_{{S},ij}$ is uniform over a particular intersection between a surface ![]() ${S}_{cv}$ and an interface defined by

${S}_{cv}$ and an interface defined by ![]() ${\delta }_{{S},ij}$, the surface integral of the surface delta function is given by

${\delta }_{{S},ij}$, the surface integral of the surface delta function is given by

where ![]() ${l}_{ij}$ represents the line length of the intersection between the two surfaces, and

${l}_{ij}$ represents the line length of the intersection between the two surfaces, and ![]() $\boldsymbol {n}_{cv}$ is a unit normal to the surface

$\boldsymbol {n}_{cv}$ is a unit normal to the surface ![]() ${S}_{cv}$. These properties of the surface delta function and others are discussed in more detail in Appendix A.

${S}_{cv}$. These properties of the surface delta function and others are discussed in more detail in Appendix A.

Note that in general, interfacial stresses will act at each one of the immiscible material boundaries that exist within ![]() ${V}_{cv}$. Consequently, the sum in (2.2) cycles through all possible phase combinations under the condition that

${V}_{cv}$. Consequently, the sum in (2.2) cycles through all possible phase combinations under the condition that ![]() $i< j$; that is,

$i< j$; that is, ![]() $j=1\rightarrow m$ and

$j=1\rightarrow m$ and ![]() $i=1\rightarrow j$, where

$i=1\rightarrow j$, where ![]() $m$ is the total number of material phases present. Thus stresses from a possible

$m$ is the total number of material phases present. Thus stresses from a possible ![]() $(m-1)!$ interface types may be included in the momentum balance.

$(m-1)!$ interface types may be included in the momentum balance.

By using (2.2) to represent surface stresses, three assumptions about the system are implied. First, as the surface stress is a sum of contributions from each interface type, we have neglected any ‘line tension’ stresses that may occur at the intersection between interfaces. While no consensus regarding the existence of these stresses has been reached in the literature, most studies suggest that even if line tension does exist, it has a negligible effect on macroscopically measurable contact angles (Boruvka & Neumann Reference Boruvka and Neumann1977; Marmur Reference Marmur1997, Reference Marmur2006; Pompe, Fery & Herminghaus Reference Pompe, Fery and Herminghaus1999). Second, by assuming constant surface energies for each interface type, we have neglected any Marangoni forces that would exist if surfactants or thermal gradients were present within the control volume. Third, the assumption of constant surface energies also implies that the process of surface creation or destruction is reversible on a molecular scale. We discuss implications of this assumption in § 4.4.

With the immiscible multiphase momentum equation defined, we take the dot product of (2.1) with the local velocity ![]() $\boldsymbol {v}$ and then integrate the result over the volume

$\boldsymbol {v}$ and then integrate the result over the volume ![]() ${V}_{cv}$. Noting that both the stress tensors

${V}_{cv}$. Noting that both the stress tensors ![]() $\mathsf {T}_{M}$ and

$\mathsf {T}_{M}$ and ![]() $\mathsf {T}_{S}$ are symmetric, application of the Leibniz formula for differentiating a volume integral, the Gauss–Ostrogradskii theorem and the compressible continuity equation yields

$\mathsf {T}_{S}$ are symmetric, application of the Leibniz formula for differentiating a volume integral, the Gauss–Ostrogradskii theorem and the compressible continuity equation yields

\begin{align}

\frac{{\rm d}}{{\rm d}t} \int_{{V}_{cv}} \left (

\frac{1}{2}\, \rho v^2 + \rho \hat{\varPhi} \right ) {\rm

d}V &= \int_{{S}_{cv}} \boldsymbol{n}_{cv}

\boldsymbol{\cdot} \left [ \left ( \frac{1}{2}\,\rho v^2 +

\rho \hat{\varPhi} \right ) ( {\boldsymbol{v}}_{cv} -

\boldsymbol{v} ) \right ] {\rm d}S\nonumber\\ &\quad+

\int_{{S}_{cv}} \boldsymbol{n}_{cv} \boldsymbol{\cdot} [

{\mathsf{T}}_{M} \boldsymbol{\cdot} \boldsymbol{v} ] \,{\rm

d}S - \int_{{V}_{cv}} {\mathsf{T}}_{M}:\boldsymbol{\nabla}

\boldsymbol{v} \,{\rm d}V\nonumber\\ &\quad+

\int_{{S}_{cv}} \boldsymbol{n}_{cv} \boldsymbol{\cdot} [

{\mathsf{T}}_{S} \boldsymbol{\cdot} \boldsymbol{v} ] \,{\rm

d}S - \int_{{V}_{cv}} {\mathsf{T}}_{S}:\boldsymbol{\nabla}

\boldsymbol{v} \,{\rm d}V .

\end{align}

\begin{align}

\frac{{\rm d}}{{\rm d}t} \int_{{V}_{cv}} \left (

\frac{1}{2}\, \rho v^2 + \rho \hat{\varPhi} \right ) {\rm

d}V &= \int_{{S}_{cv}} \boldsymbol{n}_{cv}

\boldsymbol{\cdot} \left [ \left ( \frac{1}{2}\,\rho v^2 +

\rho \hat{\varPhi} \right ) ( {\boldsymbol{v}}_{cv} -

\boldsymbol{v} ) \right ] {\rm d}S\nonumber\\ &\quad+

\int_{{S}_{cv}} \boldsymbol{n}_{cv} \boldsymbol{\cdot} [

{\mathsf{T}}_{M} \boldsymbol{\cdot} \boldsymbol{v} ] \,{\rm

d}S - \int_{{V}_{cv}} {\mathsf{T}}_{M}:\boldsymbol{\nabla}

\boldsymbol{v} \,{\rm d}V\nonumber\\ &\quad+

\int_{{S}_{cv}} \boldsymbol{n}_{cv} \boldsymbol{\cdot} [

{\mathsf{T}}_{S} \boldsymbol{\cdot} \boldsymbol{v} ] \,{\rm

d}S - \int_{{V}_{cv}} {\mathsf{T}}_{S}:\boldsymbol{\nabla}

\boldsymbol{v} \,{\rm d}V .

\end{align}

Here, ![]() ${\boldsymbol {v}}_{cv}$ and

${\boldsymbol {v}}_{cv}$ and ![]() $\boldsymbol {n}_{cv}$ are the velocity and outwardly directed unit normal of the control volume boundary

$\boldsymbol {n}_{cv}$ are the velocity and outwardly directed unit normal of the control volume boundary ![]() ${S}_{cv}$, respectively,

${S}_{cv}$, respectively, ![]() $v$ is the magnitude of the local velocity

$v$ is the magnitude of the local velocity ![]() $\boldsymbol {v}$, and

$\boldsymbol {v}$, and ![]() $\hat {\varPhi }$ is a gravitational potential function satisfying

$\hat {\varPhi }$ is a gravitational potential function satisfying ![]() $\boldsymbol {g}=-\boldsymbol {\nabla }\hat {\varPhi }$.

$\boldsymbol {g}=-\boldsymbol {\nabla }\hat {\varPhi }$.

To simplify (2.5) further, we concentrate on the last two terms on the right-hand side, which relate to interfacial stresses. For the first of these, we substitute in the surface stress definition of (2.2) to find

\begin{equation} \int_{{S}_{cv}} \boldsymbol{n}_{cv} \boldsymbol{\cdot} [ {\mathsf{T}}_{S} \boldsymbol{\cdot} \boldsymbol{v} ]\, {\rm d}S = \sum_{i< j} {\sigma}_{ij} \int_{{S}_{cv}} {\delta}_{{S},ij}( \boldsymbol{\mathsf{I}} - \boldsymbol{n}_{{S},ij} \boldsymbol{n}_{{S},ij} ):\boldsymbol{v} \boldsymbol{n}_{cv} \,{\rm d}S. \end{equation}

\begin{equation} \int_{{S}_{cv}} \boldsymbol{n}_{cv} \boldsymbol{\cdot} [ {\mathsf{T}}_{S} \boldsymbol{\cdot} \boldsymbol{v} ]\, {\rm d}S = \sum_{i< j} {\sigma}_{ij} \int_{{S}_{cv}} {\delta}_{{S},ij}( \boldsymbol{\mathsf{I}} - \boldsymbol{n}_{{S},ij} \boldsymbol{n}_{{S},ij} ):\boldsymbol{v} \boldsymbol{n}_{cv} \,{\rm d}S. \end{equation}For the second term, we use the surface delta function transport equation derived in Appendix A:

Substituting ![]() $\mathsf {T}_{S}$ from (2.2) into the second interfacial stress term of (2.5), and then using the right-hand side of (2.7) to expand the double dot product gives

$\mathsf {T}_{S}$ from (2.2) into the second interfacial stress term of (2.5), and then using the right-hand side of (2.7) to expand the double dot product gives

\begin{align} \int_{{V}_{cv}} {\mathsf{T}}_{S}:\boldsymbol{\nabla} \boldsymbol{v} \,{\rm d}V & = \sum_{i< j} \int_{{V}_{cv}} {\sigma}_{ij} {\delta}_{{S},ij} ( \boldsymbol{\mathsf{I}} - \boldsymbol{n}_{\mathrm{S},ij} \boldsymbol{n}_{{S},ij} ):\boldsymbol{\nabla} \boldsymbol{v} \,{\rm d}V \nonumber\\ & = \sum_{i< j} \int_{{V}_{cv}} \frac{\partial ( {\sigma}_{ij} {\delta}_{{S},ij} )}{\partial t} + \boldsymbol{\nabla} \boldsymbol{\cdot} ( {\sigma}_{ij} {\delta}_{{S},ij} \boldsymbol{v} ) \,{\rm d}V . \end{align}

\begin{align} \int_{{V}_{cv}} {\mathsf{T}}_{S}:\boldsymbol{\nabla} \boldsymbol{v} \,{\rm d}V & = \sum_{i< j} \int_{{V}_{cv}} {\sigma}_{ij} {\delta}_{{S},ij} ( \boldsymbol{\mathsf{I}} - \boldsymbol{n}_{\mathrm{S},ij} \boldsymbol{n}_{{S},ij} ):\boldsymbol{\nabla} \boldsymbol{v} \,{\rm d}V \nonumber\\ & = \sum_{i< j} \int_{{V}_{cv}} \frac{\partial ( {\sigma}_{ij} {\delta}_{{S},ij} )}{\partial t} + \boldsymbol{\nabla} \boldsymbol{\cdot} ( {\sigma}_{ij} {\delta}_{{S},ij} \boldsymbol{v} ) \,{\rm d}V . \end{align}Using the scalar Leibniz theorem on the first term on the right-hand side of this equation and the Gauss–Ostrogradskii theorem on the second term yields

\begin{equation} \int_{{V}_{cv}} {\mathsf{T}}_{S}:\boldsymbol{\nabla} \boldsymbol{v} \,{\rm d}V =\sum_{i< j} \left \{ \frac{{\rm d}}{{\rm d}t} ( {\sigma}_{ij} {A}_{ij} ) - \int_{{S}_{cv}} \boldsymbol{n}_{cv} \boldsymbol{\cdot} [ {\sigma}_{ij} {\delta}_{{S},ij} ( {\boldsymbol{v}}_{cv} - \boldsymbol{v} ) ] \,{\rm d}S \right \}, \end{equation}

\begin{equation} \int_{{V}_{cv}} {\mathsf{T}}_{S}:\boldsymbol{\nabla} \boldsymbol{v} \,{\rm d}V =\sum_{i< j} \left \{ \frac{{\rm d}}{{\rm d}t} ( {\sigma}_{ij} {A}_{ij} ) - \int_{{S}_{cv}} \boldsymbol{n}_{cv} \boldsymbol{\cdot} [ {\sigma}_{ij} {\delta}_{{S},ij} ( {\boldsymbol{v}}_{cv} - \boldsymbol{v} ) ] \,{\rm d}S \right \}, \end{equation}

where (2.3) has been used to relate surface area to the volume integral of ![]() ${\delta }_{{S},ij}$.

${\delta }_{{S},ij}$.

Finally, substituting (2.6) and (2.9) back into (2.5) and simplifying the material stress surface integral gives the immiscible MMEB valid for compressible and incompressible materials:

\begin{align}

&\underbrace{\frac{{\rm

d}}{{\rm d}t} \left [ \int_{{V}_{cv}} \left (

\frac{1}{2}\,\rho v^2 + \rho \hat{\varPhi} \right ) {\rm

d}V + \sum_{i< j} {\sigma}_{ij} {A}_{ij} \right ]}_{rate\, of\,

change\, of\, kinetic, \,gravitational\, potential\, and\, interfacial\,

surface\, energy\, within\, {V}_{cv}} \nonumber\\ &\quad

=\underbrace{\int_{{S}_{cv}} \boldsymbol{n}_{cv}

\boldsymbol{\cdot} \left [ \left ( \frac{1}{2}\,\rho v^2 +

\rho \hat{\varPhi} + \sum_{i< j} {\sigma}_{ij}

{\delta}_{{S},ij} \right ) \left ( {\boldsymbol{v}}_{cv} -

\boldsymbol{v} \right ) \right ] {\rm d}S}_{rate\, at\, which\,

kinetic, \,gravitational \,potential \,and \,interfacial\, surface

\,energy \,are \,advected \,into \,{V}_{cv}}\nonumber\\ &\qquad +

\underbrace{\sum_{i< j} {\sigma}_{ij} \int_{{S}_{cv}}

{\delta}_{{S},ij} ( \boldsymbol{\mathsf{I}} - \boldsymbol{n}_{{S},ij}

\boldsymbol{n}_{{S},ij} ):\boldsymbol{v}

\boldsymbol{n}_{cv} \,{\rm d}S }_{rate\, of\, work\, done\, on\, the\,

contents\, of\, {V}_{cv}\, by\, interfacial\, tension\, acting\, at\,

{S}_{cv}}\nonumber\\ &\qquad + \underbrace{\int_{{S}_{cv}}

{\mathsf{T}}_{M}:\boldsymbol{v} \boldsymbol{n}_{cv} \,{\rm

d}S}_{rate\, of\, work\, done\, on\, the\, contents\, of\, {V}_{cv}\, by\,

material\, stresses\, acting\, at\, {S}_{cv}} -

\underbrace{\int_{{V}_{cv}} {\mathsf{T}}_{M}:\boldsymbol{\nabla}

\boldsymbol{v} \,{\rm d}V}_{rate\, at\, which\, energy\, dissipates\,

to\, heat\, via\, material\, stresses\, acting\, within\, {V}_{cv}}.

\end{align}

\begin{align}

&\underbrace{\frac{{\rm

d}}{{\rm d}t} \left [ \int_{{V}_{cv}} \left (

\frac{1}{2}\,\rho v^2 + \rho \hat{\varPhi} \right ) {\rm

d}V + \sum_{i< j} {\sigma}_{ij} {A}_{ij} \right ]}_{rate\, of\,

change\, of\, kinetic, \,gravitational\, potential\, and\, interfacial\,

surface\, energy\, within\, {V}_{cv}} \nonumber\\ &\quad

=\underbrace{\int_{{S}_{cv}} \boldsymbol{n}_{cv}

\boldsymbol{\cdot} \left [ \left ( \frac{1}{2}\,\rho v^2 +

\rho \hat{\varPhi} + \sum_{i< j} {\sigma}_{ij}

{\delta}_{{S},ij} \right ) \left ( {\boldsymbol{v}}_{cv} -

\boldsymbol{v} \right ) \right ] {\rm d}S}_{rate\, at\, which\,

kinetic, \,gravitational \,potential \,and \,interfacial\, surface

\,energy \,are \,advected \,into \,{V}_{cv}}\nonumber\\ &\qquad +

\underbrace{\sum_{i< j} {\sigma}_{ij} \int_{{S}_{cv}}

{\delta}_{{S},ij} ( \boldsymbol{\mathsf{I}} - \boldsymbol{n}_{{S},ij}

\boldsymbol{n}_{{S},ij} ):\boldsymbol{v}

\boldsymbol{n}_{cv} \,{\rm d}S }_{rate\, of\, work\, done\, on\, the\,

contents\, of\, {V}_{cv}\, by\, interfacial\, tension\, acting\, at\,

{S}_{cv}}\nonumber\\ &\qquad + \underbrace{\int_{{S}_{cv}}

{\mathsf{T}}_{M}:\boldsymbol{v} \boldsymbol{n}_{cv} \,{\rm

d}S}_{rate\, of\, work\, done\, on\, the\, contents\, of\, {V}_{cv}\, by\,

material\, stresses\, acting\, at\, {S}_{cv}} -

\underbrace{\int_{{V}_{cv}} {\mathsf{T}}_{M}:\boldsymbol{\nabla}

\boldsymbol{v} \,{\rm d}V}_{rate\, at\, which\, energy\, dissipates\,

to\, heat\, via\, material\, stresses\, acting\, within\, {V}_{cv}}.

\end{align}

Along with the usual terms found in the single-phase mechanical energy balance (Bird et al. Reference Bird, Stewart and Lightfoot2002, p. 81, § 3.3), the MMEB of (2.10) contains three interfacial stress terms: the first represents the rate of change of interfacial energy contained within the control volume; the second represents the rate at which interfacial energy is advected across the control volume surface; and the third represents the rate at which interfacial stresses perform work on the control volume at the control volume surface.

To the best of our knowledge, this MMEB equation has not been derived previously. James & Lowengrub (Reference James and Lowengrub2004), based on the work of Batchelor (Reference Batchelor1967, p. 132), give an equation that is similar but concerns the material derivative of an infinitesimal surface element, rather than the material derivative of the surface delta function. In a different context, Yue (Reference Yue2020, B11, p. 899) provides a mechanical energy conservation equation that includes surface potential energy, but is expressed in terms of phase field variables.

Equation (2.10) should serve as a useful generic tool for examining energy conservation in flowing systems that possess phase interfaces. For example, the equation could also be used to examine the behaviour of foams or emulsions, applied either locally around phase interfaces to look at structure stability, or globally to understand conservation of bubble/droplet collections. Within the remainder of the paper, we apply the MMEB to understand contact-angle behaviour for a liquid interface advancing over a rough solid.

3. Calculating the advancing contact angle on a rough solid surface

Here, we analyse the macroscopic contact angle of an interface between two immiscible fluids that slowly advances over a rough solid. The analysis uses the MMEB derived in § 2, applied to a small control volume (CV) that moves with the advancing TPCL across the surface of the solid. Using semi-quantitative models for material and interface behaviour, an order of magnitude analysis is performed to determine which terms within the energy balance are significant, and from this an expression for the advancing contact angle is found that is valid in the limit of an infinitely slowly moving interface.

3.1. Defining the physical system and moving CV geometry

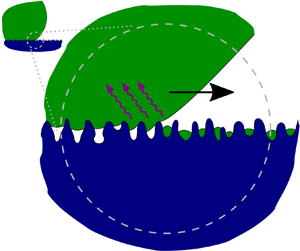

Figure 2 illustrates the physical system. Two fluid phases, labelled ![]() ${\bigcirc{\kern-6pt 1}}$ and

${\bigcirc{\kern-6pt 1}}$ and ![]() ${\bigcirc{\kern-6pt 2}}$, are bounded below by a solid phase, labelled

${\bigcirc{\kern-6pt 2}}$, are bounded below by a solid phase, labelled ![]() ${\bigcirc{\kern-9pt S}}$. The fluids may be either liquids or gases, but are completely insoluble with each other (immiscible) and with the solid, incompressible, and above a certain length scale

${\bigcirc{\kern-9pt S}}$. The fluids may be either liquids or gases, but are completely insoluble with each other (immiscible) and with the solid, incompressible, and above a certain length scale ![]() ${h}_{mol}$ (for molecular), act as continua. The implications of these assumptions are discussed further below and in § 4. The surface of the solid is rough, having undulations of a maximum characteristic size

${h}_{mol}$ (for molecular), act as continua. The implications of these assumptions are discussed further below and in § 4. The surface of the solid is rough, having undulations of a maximum characteristic size ![]() ${h}_{rough}$. (Two-dimensional roughness topologies such as long ridges or concentric rings are not covered by this theory as these shapes have one dimension that is infinitely long.) A hydrodynamic flow is occurring on a length scale of

${h}_{rough}$. (Two-dimensional roughness topologies such as long ridges or concentric rings are not covered by this theory as these shapes have one dimension that is infinitely long.) A hydrodynamic flow is occurring on a length scale of ![]() ${h}_{surround}$ that is much larger than

${h}_{surround}$ that is much larger than ![]() ${h}_{rough}$. This flow slowly drives the fluid interface to the right, hence phase

${h}_{rough}$. This flow slowly drives the fluid interface to the right, hence phase ![]() ${\bigcirc{\kern-6pt 1}}$ is slowly advancing over the solid, while phase

${\bigcirc{\kern-6pt 1}}$ is slowly advancing over the solid, while phase ![]() ${\bigcirc{\kern-6pt 2}}$ is slowly receding.

${\bigcirc{\kern-6pt 2}}$ is slowly receding.

Figure 2. The MMEB is performed over a cylindrical CV that is located at the intersection of the average solid surface and projected fluid interface planes, and moves forward over the solid at a speed of ![]() ${v}_{cv}$ and distance

${v}_{cv}$ and distance ![]() ${X}_{cv}$. (a,b) The region surrounding the CV and contact line on a macroscopic scale. (c) The same region on the scale of the CV and solid surface roughness. The symbols

${X}_{cv}$. (a,b) The region surrounding the CV and contact line on a macroscopic scale. (c) The same region on the scale of the CV and solid surface roughness. The symbols ![]() ${\bigcirc{\kern-6pt 1}}$,

${\bigcirc{\kern-6pt 1}}$, ![]() ${\bigcirc{\kern-6pt 2}}$ and

${\bigcirc{\kern-6pt 2}}$ and ![]() ${\bigcirc{\kern-9pt S}}$ indicate regions of phase-

${\bigcirc{\kern-9pt S}}$ indicate regions of phase-![]() $1$ fluid, phase-

$1$ fluid, phase-![]() $2$ fluid and solid, respectively.

$2$ fluid and solid, respectively.

The MMEB of (2.10) is applied to a moving CV as it advances at a constant velocity ![]() ${\boldsymbol {v}}_{cv}={v}_{cv}\boldsymbol {e}_{1}$ over a distance

${\boldsymbol {v}}_{cv}={v}_{cv}\boldsymbol {e}_{1}$ over a distance ![]() ${X}_{cv}$ along the solid surface. This is illustrated in figure 2(b). Note that

${X}_{cv}$ along the solid surface. This is illustrated in figure 2(b). Note that ![]() ${v}_{cv}$ is characteristic of the surrounding flow. The CV contains and is approximately centred on the TPCL, defined as the intersection between the advancing fluid interface and rough solid surface. The moving CV has the geometry of a cylinder with radius

${v}_{cv}$ is characteristic of the surrounding flow. The CV contains and is approximately centred on the TPCL, defined as the intersection between the advancing fluid interface and rough solid surface. The moving CV has the geometry of a cylinder with radius ![]() ${r}_{cv}$ and length

${r}_{cv}$ and length ![]() ${l}_{cv}$. The dimensions of the volume are smaller than those of the surrounding hydrodynamic flow (

${l}_{cv}$. The dimensions of the volume are smaller than those of the surrounding hydrodynamic flow (![]() ${h}_{surround}$), yet larger than those of the solid surface roughness (

${h}_{surround}$), yet larger than those of the solid surface roughness (![]() ${h}_{rough}$). Hence, noting the above description of the physical system and CV geometry, we effectively assume the separation of four length scales in our analysis:

${h}_{rough}$). Hence, noting the above description of the physical system and CV geometry, we effectively assume the separation of four length scales in our analysis:

Defining ![]() $\tau$ as the time taken for the CV to advance the entire distance

$\tau$ as the time taken for the CV to advance the entire distance ![]() ${X}_{cv}$, it follows that

${X}_{cv}$, it follows that ![]() ${X}_{cv}={v}_{cv}\tau$.

${X}_{cv}={v}_{cv}\tau$.

The precise centreline of the moving CV is defined to lie at the intersection between two averaged planes: the ‘average solid surface plane’ and the ‘projected fluid interface plane’. The locations of these planes are defined as those of the solid surface and fluid interfaces, respectively, averaged over distances of ![]() ${{O}({r}_{cv})}$ (where

${{O}({r}_{cv})}$ (where ![]() ${{O}(z)}$ means ‘order

${{O}(z)}$ means ‘order ![]() $z$’). As the solid surface roughness

$z$’). As the solid surface roughness ![]() ${h}_{rough}$ is of much smaller size than

${h}_{rough}$ is of much smaller size than ![]() ${r}_{cv}$, it follows that the average solid surface plane is perfectly flat on the length scale of the CV. The topology of the fluid interface is governed by the momentum and surface stress equations ((2.1) and (2.2), respectively), combined with boundary conditions specifying how the interface interacts with the solid surface. The specific boundary condition that we employ for the microscopic contact angle is Young's equation, expressed as

${r}_{cv}$, it follows that the average solid surface plane is perfectly flat on the length scale of the CV. The topology of the fluid interface is governed by the momentum and surface stress equations ((2.1) and (2.2), respectively), combined with boundary conditions specifying how the interface interacts with the solid surface. The specific boundary condition that we employ for the microscopic contact angle is Young's equation, expressed as

where ![]() $[ \boldsymbol {n}_{{{S},12}} ]_{{TPCL}}$ is the unit normal to the fluid interface at a point on the TPCL,

$[ \boldsymbol {n}_{{{S},12}} ]_{{TPCL}}$ is the unit normal to the fluid interface at a point on the TPCL, ![]() $\boldsymbol {n}_{w}$ is the outwardly directed wall normal at the same contact point, and

$\boldsymbol {n}_{w}$ is the outwardly directed wall normal at the same contact point, and ![]() ${\theta }_{e}$ is the equilibrium or ‘Young's’ angle. As (3.2) specifies a direct relationship between the fluid interface (

${\theta }_{e}$ is the equilibrium or ‘Young's’ angle. As (3.2) specifies a direct relationship between the fluid interface (![]() $\boldsymbol {n}_{{\text {S},12}}$) and solid (

$\boldsymbol {n}_{{\text {S},12}}$) and solid (![]() $\boldsymbol {n}_{w}$) normals along the TPCL, it follows that close to the rough solid surface, the fluid interface will have local curvatures that are characteristic of the solid roughness – that is, of

$\boldsymbol {n}_{w}$) normals along the TPCL, it follows that close to the rough solid surface, the fluid interface will have local curvatures that are characteristic of the solid roughness – that is, of ![]() ${{O}(1/{h}_{rough})}$ – and that these curvatures will exist within distances of

${{O}(1/{h}_{rough})}$ – and that these curvatures will exist within distances of ![]() ${{O}({h}_{rough})}$ from the TPCL. Conversely, further from the solid surface, the topology of the interface varies over the larger length scales of the surrounding flow (indeed, this can be used to define

${{O}({h}_{rough})}$ from the TPCL. Conversely, further from the solid surface, the topology of the interface varies over the larger length scales of the surrounding flow (indeed, this can be used to define ![]() ${h}_{surround}$), so the curvature of the interface there approaches

${h}_{surround}$), so the curvature of the interface there approaches ![]() ${{O}(1/{h}_{surround})}$. Hence, as

${{O}(1/{h}_{surround})}$. Hence, as ![]() ${h}_{rough} \ll {r}_{cv} \ll {h}_{surround}$ (see (3.1)), averaging the actual fluid interface over

${h}_{rough} \ll {r}_{cv} \ll {h}_{surround}$ (see (3.1)), averaging the actual fluid interface over ![]() ${{O}({r}_{cv})}$ produces a projected fluid interface plane that is perfectly flat on the length scales of the CV, and as the centreline of the CV is defined as the intersection between the projected fluid interface plane and average solid surface plane, on the scale of the CV, its geometry is that of a perfect cylinder, with a perfectly straight centreline.

${{O}({r}_{cv})}$ produces a projected fluid interface plane that is perfectly flat on the length scales of the CV, and as the centreline of the CV is defined as the intersection between the projected fluid interface plane and average solid surface plane, on the scale of the CV, its geometry is that of a perfect cylinder, with a perfectly straight centreline.

This description of the fluid interface topology and relationship to the geometry of the CV has implications when applying the MMEB. At distances of ![]() ${{O}({r}_{cv})}$ from the TPCL, the actual fluid interface and projected fluid interface will at all times be coincident and perfectly flat on these length scales. Hence, given that the projected fluid interface is used to define the centreline of the CV, the actual fluid interface will intersect the circumference of the CV (labelled as

${{O}({r}_{cv})}$ from the TPCL, the actual fluid interface and projected fluid interface will at all times be coincident and perfectly flat on these length scales. Hence, given that the projected fluid interface is used to define the centreline of the CV, the actual fluid interface will intersect the circumference of the CV (labelled as ![]() ${S}_{cv,cir}$ in figure 2b) in a perfectly normal direction. Similarly, along the ends of the CV (labelled as

${S}_{cv,cir}$ in figure 2b) in a perfectly normal direction. Similarly, along the ends of the CV (labelled as ![]() ${S}_{cv,end}$ in figure 2b) and at distances greater than

${S}_{cv,end}$ in figure 2b) and at distances greater than ![]() ${{O}({h}_{rough})}$ from the TPCL, the actual fluid interface will be flat, coincident with the projected fluid interface, and perfectly normal to the CV boundary. Closer to the TPCL, however, the interface will undulate with curvatures of

${{O}({h}_{rough})}$ from the TPCL, the actual fluid interface will be flat, coincident with the projected fluid interface, and perfectly normal to the CV boundary. Closer to the TPCL, however, the interface will undulate with curvatures of ![]() ${{O}(1/{h}_{rough})}$, crossing the CV boundary at angles that are not necessarily normal to

${{O}(1/{h}_{rough})}$, crossing the CV boundary at angles that are not necessarily normal to ![]() ${S}_{cv,end}$.

${S}_{cv,end}$.

The contact angle of phase ![]() ${\bigcirc{\kern-6pt 1}}$ on the macroscopic length scale is defined as

${\bigcirc{\kern-6pt 1}}$ on the macroscopic length scale is defined as ![]() $\theta$. It is the angle between the average solid surface plane and fluid interface plane, measured through phase

$\theta$. It is the angle between the average solid surface plane and fluid interface plane, measured through phase ![]() ${\bigcirc{\kern-6pt 1}}$. Equivalently, consistent with the above, it is the angle between the average solid surface plane and actual fluid interface measured at distances of

${\bigcirc{\kern-6pt 1}}$. Equivalently, consistent with the above, it is the angle between the average solid surface plane and actual fluid interface measured at distances of ![]() ${{O}({r}_{cv})}$ from the TPCL. The objective of our analysis is to determine the minimum macroscopic angle that just causes the fluid interface to advance continually over the solid surface, albeit at the vanishingly slow velocity

${{O}({r}_{cv})}$ from the TPCL. The objective of our analysis is to determine the minimum macroscopic angle that just causes the fluid interface to advance continually over the solid surface, albeit at the vanishingly slow velocity ![]() ${v}_{cv}$. An equivalent objective is to find the maximum macroscopic angle that just allows the fluid interface to remain stationary. Either definition represents the advancing angle of phase

${v}_{cv}$. An equivalent objective is to find the maximum macroscopic angle that just allows the fluid interface to remain stationary. Either definition represents the advancing angle of phase ![]() ${\bigcirc{\kern-6pt 1}}$ over solid

${\bigcirc{\kern-6pt 1}}$ over solid ![]() ${\bigcirc{\kern-9pt S}}$ in the presence of phase

${\bigcirc{\kern-9pt S}}$ in the presence of phase ![]() ${\bigcirc{\kern-6pt 2}}$ and is referred to as

${\bigcirc{\kern-6pt 2}}$ and is referred to as ![]() ${\theta }_{a}$ (for ‘advancing’). Formally,

${\theta }_{a}$ (for ‘advancing’). Formally, ![]() ${\theta }_{a}=\lim _{{v}_{cv}\rightarrow 0} \theta$.

${\theta }_{a}=\lim _{{v}_{cv}\rightarrow 0} \theta$.

Note that as phase ![]() ${\bigcirc{\kern-6pt 1}}$ advances over the solid, phase

${\bigcirc{\kern-6pt 1}}$ advances over the solid, phase ![]() ${\bigcirc{\kern-6pt 2}}$ recedes. Thus an equivalent objective is to find the receding angle of phase

${\bigcirc{\kern-6pt 2}}$ recedes. Thus an equivalent objective is to find the receding angle of phase ![]() ${\bigcirc{\kern-6pt 2}}$ (

${\bigcirc{\kern-6pt 2}}$ (![]() $\theta _{{{r},2}}={\rm \pi} -{\theta }_{a}$). Indeed, by swapping the physical properties between phases

$\theta _{{{r},2}}={\rm \pi} -{\theta }_{a}$). Indeed, by swapping the physical properties between phases ![]() ${\bigcirc{\kern-6pt 1}}$ and

${\bigcirc{\kern-6pt 1}}$ and ![]() ${\bigcirc{\kern-6pt 2}}$ (detailed in § 4.1), we can use the same analysis to determine the range of angles over which a fluid interface will remain stationary – that is, the range of CAH.

${\bigcirc{\kern-6pt 2}}$ (detailed in § 4.1), we can use the same analysis to determine the range of angles over which a fluid interface will remain stationary – that is, the range of CAH.

3.2. Describing material dynamics within the moving CV

As well as defining the physical system and CV geometry used in the MMEB, to be able to perform an order of magnitude analysis on its various terms, we need to describe quantitatively how the materials within the volume behave as a function of both space and time. Specifically, we need conceptual models for how the fluid velocities, pressures, interface topology and solid stresses vary as the CV advances.

Within the fluid phase, we assume that for the majority of the advancing time ![]() $\tau$, the TPCL and surrounding fluid both move continuously at the slow speeds of

$\tau$, the TPCL and surrounding fluid both move continuously at the slow speeds of ![]() ${{O}({v}_{cv})}$. We refer to the system as being in ‘equilibrium’ when this is the case, and define the velocity field existing during these times as

${{O}({v}_{cv})}$. We refer to the system as being in ‘equilibrium’ when this is the case, and define the velocity field existing during these times as ![]() $\tilde {\boldsymbol {v}}={{O}({v}_{cv})}$. However, at certain times during

$\tilde {\boldsymbol {v}}={{O}({v}_{cv})}$. However, at certain times during ![]() $\tau$, local areas of the TPCL will become pinned by particular surface defects, creating local interface deflections that become larger as the remainder of the TPCL continues to advance. Eventually, once the surrounding TPCL has advanced some distance of

$\tau$, local areas of the TPCL will become pinned by particular surface defects, creating local interface deflections that become larger as the remainder of the TPCL continues to advance. Eventually, once the surrounding TPCL has advanced some distance of ![]() ${{O}({h}_{rough})}$ from the pinning location, these contact-line sections will either detach from the surface defect and return to the main TPCL, or detach from the TPCL and form isolated bubbles/droplets of entrained fluid within the surface roughness. Either way, these detachment processes cause the local TPCL and surrounding fluid to move at much faster capillary-driven speeds than the continuous CV advance speed (

${{O}({h}_{rough})}$ from the pinning location, these contact-line sections will either detach from the surface defect and return to the main TPCL, or detach from the TPCL and form isolated bubbles/droplets of entrained fluid within the surface roughness. Either way, these detachment processes cause the local TPCL and surrounding fluid to move at much faster capillary-driven speeds than the continuous CV advance speed (![]() ${v}_{cv}$), causing a viscous dissipation of energy. This ‘stick–slip’ dissipative motion has been described previously as one cause of CAH (Joanny & de Gennes Reference Joanny and de Gennes1984; Raj et al. Reference Raj, Enright, Zhu, Adera and Wang2012; Butt et al. Reference Butt, Gao, Papadopoulos, Steffen, Kappl and Berger2017; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019) and as discussed in the Introduction has also been observed experimentally (Priest et al. Reference Priest, Albrecht, Sedev and Ralston2009; Forsberg et al. Reference Forsberg, Priest, Brinkmann, Sedev and Ralston2010; Schellenberger et al. Reference Schellenberger, Encinas, Vollmer and Butt2016; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019). In this study, we define the local interface and fluid speeds associated with these capillary-driven events as

${v}_{cv}$), causing a viscous dissipation of energy. This ‘stick–slip’ dissipative motion has been described previously as one cause of CAH (Joanny & de Gennes Reference Joanny and de Gennes1984; Raj et al. Reference Raj, Enright, Zhu, Adera and Wang2012; Butt et al. Reference Butt, Gao, Papadopoulos, Steffen, Kappl and Berger2017; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019) and as discussed in the Introduction has also been observed experimentally (Priest et al. Reference Priest, Albrecht, Sedev and Ralston2009; Forsberg et al. Reference Forsberg, Priest, Brinkmann, Sedev and Ralston2010; Schellenberger et al. Reference Schellenberger, Encinas, Vollmer and Butt2016; Jiang et al. Reference Jiang, Xu, Sarshar and Choi2019). In this study, we define the local interface and fluid speeds associated with these capillary-driven events as ![]() $\hat {\boldsymbol {v}}={{O}({v}_{cap})}$, and the total time during which there is a dissipation event occurring within the CV as

$\hat {\boldsymbol {v}}={{O}({v}_{cap})}$, and the total time during which there is a dissipation event occurring within the CV as ![]() ${\tau }_{cap}$. We further assume that the number of defects within the CV (

${\tau }_{cap}$. We further assume that the number of defects within the CV (![]() $N$) is small enough and the capillary velocity (

$N$) is small enough and the capillary velocity (![]() ${v}_{cap}$) large enough that only one dissipation event occurs within the CV at any one time. With these assumptions, and for convenience assuming that the analysis duration

${v}_{cap}$) large enough that only one dissipation event occurs within the CV at any one time. With these assumptions, and for convenience assuming that the analysis duration ![]() $\tau$ commences and finishes while the system is in equilibrium, we can split the total time over which the analysis is being conducted into a number of ‘dissipation events’ (

$\tau$ commences and finishes while the system is in equilibrium, we can split the total time over which the analysis is being conducted into a number of ‘dissipation events’ (![]() $N$) and ‘equilibrium stages’ (

$N$) and ‘equilibrium stages’ (![]() $N+1$), with the

$N+1$), with the ![]() $k$th dissipation event starting at

$k$th dissipation event starting at ![]() $\hat {t}_k$ and lasting for

$\hat {t}_k$ and lasting for ![]() ${\widehat {\Delta t}}_k$, and the

${\widehat {\Delta t}}_k$, and the ![]() $k$th equilibrium stage starting at

$k$th equilibrium stage starting at ![]() $\tilde {t}_k$ and lasting for

$\tilde {t}_k$ and lasting for ![]() $\widetilde {\Delta t}_k$. The schematic timeline of figure 3 illustrates this decomposition. The following relationships result:

$\widetilde {\Delta t}_k$. The schematic timeline of figure 3 illustrates this decomposition. The following relationships result:

\begin{equation} \left.\begin{gathered} {\tau}_{cap}=\sum_{k=1}^N {\widehat{\Delta t}}_k, \quad \tau=\sum_{k=1}^{N+1} \widetilde{\Delta t}_k + {\tau}_{cap}, \\ {\widehat{\Delta t}}_k = \tilde{t}_{k+1} - \hat{t}_k, \quad \widetilde{\Delta t}_k = \hat{t}_k - \tilde{t}_k, \\ \tilde{t}_1=0, \quad \tilde{t}_{N+1} + \widetilde{\Delta t}_{N+1} = \tau. \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} {\tau}_{cap}=\sum_{k=1}^N {\widehat{\Delta t}}_k, \quad \tau=\sum_{k=1}^{N+1} \widetilde{\Delta t}_k + {\tau}_{cap}, \\ {\widehat{\Delta t}}_k = \tilde{t}_{k+1} - \hat{t}_k, \quad \widetilde{\Delta t}_k = \hat{t}_k - \tilde{t}_k, \\ \tilde{t}_1=0, \quad \tilde{t}_{N+1} + \widetilde{\Delta t}_{N+1} = \tau. \end{gathered}\right\} \end{equation}

In terms of notation used in the remainder of the analysis, variables annotated with a ‘hat’ correspond to properties associated with individual dissipation events (where parts of the TPCL are moving at ![]() ${{O}({v}_{cap})}$), variables annotated with a ‘tilde’ correspond to properties associated with the system while in equilibrium (where the entire TPCL is moving at at most

${{O}({v}_{cap})}$), variables annotated with a ‘tilde’ correspond to properties associated with the system while in equilibrium (where the entire TPCL is moving at at most ![]() ${{O}({v}_{cv})}$), and variables annotated with a ‘bar’ correspond to the entire advancing period

${{O}({v}_{cv})}$), and variables annotated with a ‘bar’ correspond to the entire advancing period ![]() $\tau$. The decomposition of

$\tau$. The decomposition of ![]() $\tau$ into separate dissipation and equilibrium stages is a key concept used in the subsequent energy analysis.

$\tau$ into separate dissipation and equilibrium stages is a key concept used in the subsequent energy analysis.

Figure 3. The entire analysis time ![]() $\tau$ is split into a number

$\tau$ is split into a number ![]() $N$ of dissipation periods (indicated in blue) where a portion of the TPCL moves at velocities of

$N$ of dissipation periods (indicated in blue) where a portion of the TPCL moves at velocities of ![]() ${{O}({v}_{cap})}$, interspersed between

${{O}({v}_{cap})}$, interspersed between ![]() $N+1$ equilibrium stages where the entire TPCL moves at velocities of at most

$N+1$ equilibrium stages where the entire TPCL moves at velocities of at most ![]() ${{O}({v}_{cv})}$.

${{O}({v}_{cv})}$.

A number of mathematical constraints follow from the dynamic model of fluid movement described above. First, the analysis assumes that ![]() ${v}_{cv} \ll {v}_{cap}$. By assuming that the fluids are Newtonian with a stress defined by

${v}_{cv} \ll {v}_{cap}$. By assuming that the fluids are Newtonian with a stress defined by

an order of magnitude analysis on the augmented Navier–Stokes equations (as defined by (2.1) and (2.2)) shows that capillary-driven fluid velocities can be limited by either viscous dissipation (i.e. ![]() $Ca \sim 1$) or momentum acceleration/advection inertial terms (i.e.

$Ca \sim 1$) or momentum acceleration/advection inertial terms (i.e. ![]() ${We \sim 1}$) during any dissipation event. Hence a conservative estimate for the capillary-driven velocity scale is

${We \sim 1}$) during any dissipation event. Hence a conservative estimate for the capillary-driven velocity scale is

In this expression and subsequent order of magnitude analyses, properties such as ![]() $\sigma$,

$\sigma$, ![]() $\mu$ and

$\mu$ and ![]() $\rho$ are order of magnitude estimates only, which for most expressions can be taken as the maximum of the different phase properties existing within the CV. Equation (3.5) places a constraint on the maximum

$\rho$ are order of magnitude estimates only, which for most expressions can be taken as the maximum of the different phase properties existing within the CV. Equation (3.5) places a constraint on the maximum ![]() ${v}_{cv}$ that can be used, given that

${v}_{cv}$ that can be used, given that ![]() ${v}_{cv} \ll {v}_{cap}$.

${v}_{cv} \ll {v}_{cap}$.

Interestingly, (3.5) predicts that capillary velocities are limited by inertial terms (![]() $We \sim 1$) rather than viscous terms (

$We \sim 1$) rather than viscous terms (![]() $Ca \sim 1$) on most practical surfaces. To illustrate, for a water droplet within air advancing over a rough solid surface, the viscous limited velocity is

$Ca \sim 1$) on most practical surfaces. To illustrate, for a water droplet within air advancing over a rough solid surface, the viscous limited velocity is ![]() $\sigma /\mu \approx 72$ m s

$\sigma /\mu \approx 72$ m s![]() $^{-1}$, while for all surface roughness values

$^{-1}$, while for all surface roughness values ![]() ${h}_{rough} \gtrapprox {h}_{rough,crit} = \mu ^2/(\rho \sigma ) = 14$ nm, the inertially limited velocity (

${h}_{rough} \gtrapprox {h}_{rough,crit} = \mu ^2/(\rho \sigma ) = 14$ nm, the inertially limited velocity (![]() $\sqrt {\sigma /(\rho \,{h}_{rough})}$) is smaller and hence will determine

$\sqrt {\sigma /(\rho \,{h}_{rough})}$) is smaller and hence will determine ![]() ${v}_{cap}$. Indeed, for a more typical surface roughness

${v}_{cap}$. Indeed, for a more typical surface roughness ![]() ${h}_{rough}=10$

${h}_{rough}=10$ ![]() $\mathrm {\mu }$m, (3.5) gives

$\mathrm {\mu }$m, (3.5) gives ![]() ${v}_{cap} \approx 3$ m s

${v}_{cap} \approx 3$ m s![]() $^{-1}$. We consider the implications of this in more detail in § 4.3. Note that even though the local velocities existing during a dissipation event may be determined by a balance between capillary and inertial terms (

$^{-1}$. We consider the implications of this in more detail in § 4.3. Note that even though the local velocities existing during a dissipation event may be determined by a balance between capillary and inertial terms (![]() $We \sim 1$), the Reynolds number for the motion near the surface roughness is not large (

$We \sim 1$), the Reynolds number for the motion near the surface roughness is not large (![]() $Re \sim 20$ for the above

$Re \sim 20$ for the above ![]() ${h}_{rough}=10$

${h}_{rough}=10$ ![]() $\mathrm {\mu }$m system). This means that the size of the region where velocities are

$\mathrm {\mu }$m system). This means that the size of the region where velocities are ![]() ${{O}({v}_{cap})}$ during dissipation events is only of

${{O}({v}_{cap})}$ during dissipation events is only of ![]() ${{O}({h}_{rough})}$, and importantly, these high velocities will not exist at the circumference of the CV, located at approximately

${{O}({h}_{rough})}$, and importantly, these high velocities will not exist at the circumference of the CV, located at approximately ![]() ${r}_{cv}$ from the TPCL.

${r}_{cv}$ from the TPCL.

A second constraint required by the dynamic model of fluid movement outlined above is that ![]() ${\tau }_{cap} \ll \tau$. We first note that the time taken for each dissipation event can be estimated from the interface velocity and distance travelled during each event –

${\tau }_{cap} \ll \tau$. We first note that the time taken for each dissipation event can be estimated from the interface velocity and distance travelled during each event – ![]() $\widehat {\Delta t}_k={{O}({h}_{rough}/{v}_{cap})}$ – and that as there are

$\widehat {\Delta t}_k={{O}({h}_{rough}/{v}_{cap})}$ – and that as there are ![]() $N$ dissipation events occurring during

$N$ dissipation events occurring during ![]() $\tau$,

$\tau$, ![]() ${\tau }_{cap} = {{O}(N\,{h}_{rough}/{v}_{cap})}$. Recognising that the number of dissipation events occurring during the advance duration is

${\tau }_{cap} = {{O}(N\,{h}_{rough}/{v}_{cap})}$. Recognising that the number of dissipation events occurring during the advance duration is ![]() ${{O}({A}_{cv}/{h}_{rough}^2)}$ where

${{O}({A}_{cv}/{h}_{rough}^2)}$ where ![]() ${A}_{cv} = {X}_{cv} {l}_{cv}$, and that

${A}_{cv} = {X}_{cv} {l}_{cv}$, and that ![]() $\tau ={X}_{cv}/{v}_{cv}$, leads to

$\tau ={X}_{cv}/{v}_{cv}$, leads to

Equation (3.6) can always be satisfied provided that ![]() ${v}_{cv}$ is small enough, which is obviously the case when determining

${v}_{cv}$ is small enough, which is obviously the case when determining ![]() ${\theta }_{a}$ as this angle is derived in the limit of

${\theta }_{a}$ as this angle is derived in the limit of ![]() ${v}_{cv}\rightarrow 0$. If the energy balance is being applied to moving interfaces, however, (i.e.

${v}_{cv}\rightarrow 0$. If the energy balance is being applied to moving interfaces, however, (i.e. ![]() ${v}_{cv} \ne 0$), then (3.6) places a constraint on the maximum applicable

${v}_{cv} \ne 0$), then (3.6) places a constraint on the maximum applicable ![]() ${v}_{cv}$. This is discussed further in § 4.3.

${v}_{cv}$. This is discussed further in § 4.3.

Two final conceptual models concerning the continuous fluid movement occurring during the equilibrium stages of the flow have to be developed in order to apply the MMEB; these specify the velocity gradient and pressure, both of which relate to the fluid stress.

For the velocity gradient, we note that during equilibrium stages, the TPCL advances at a speed of ![]() ${{O}({v}_{cv})}$ over the solid, resulting in a velocity discontinuity at the solid surface if the conventional continuum no-slip fluid boundary condition is applied. Indeed, velocity profiles that satisfy the Navier–Stokes equations and that are consistent with both a moving TPCL and the no-slip boundary condition are available (Moffatt Reference Moffatt1964; Huh & Scriven Reference Huh and Scriven1971); however, these result in velocity gradients near that TPCL that increase as

${{O}({v}_{cv})}$ over the solid, resulting in a velocity discontinuity at the solid surface if the conventional continuum no-slip fluid boundary condition is applied. Indeed, velocity profiles that satisfy the Navier–Stokes equations and that are consistent with both a moving TPCL and the no-slip boundary condition are available (Moffatt Reference Moffatt1964; Huh & Scriven Reference Huh and Scriven1971); however, these result in velocity gradients near that TPCL that increase as ![]() $1/r$ (where

$1/r$ (where ![]() $r$ is the distance to the TPCL). We find that integrating these gradients over the region surrounding the TPCL in our energy balance results in an energy dissipation term for non-zero

$r$ is the distance to the TPCL). We find that integrating these gradients over the region surrounding the TPCL in our energy balance results in an energy dissipation term for non-zero ![]() ${v}_{cv}$ that diverges logarithmically in an unphysical fashion, as others have found (Huh & Scriven Reference Huh and Scriven1971). Proposed solutions to this problem, which we invoke here, all involve removing or limiting the stress (equivalently velocity gradients) within the fluid at small distances (

${v}_{cv}$ that diverges logarithmically in an unphysical fashion, as others have found (Huh & Scriven Reference Huh and Scriven1971). Proposed solutions to this problem, which we invoke here, all involve removing or limiting the stress (equivalently velocity gradients) within the fluid at small distances (![]() ${h}_{mol}$) from the TPCL. Various justifications for this limiting have been proposed (Huh & Scriven Reference Huh and Scriven1971; Joanny & de Gennes Reference Joanny and de Gennes1984; Petrov & Petrov Reference Petrov and Petrov1992), but most revolve around a breakdown of the Newtonian or continuum model of a fluid at the TPCL where individual molecules or particles within the fluid must ‘jump’ along the solid. The implications of this limit are discussed further in § 4.3. Putting these concepts together, we hence estimate the velocity gradients existing within the fluid during the equilibrium stages as

${h}_{mol}$) from the TPCL. Various justifications for this limiting have been proposed (Huh & Scriven Reference Huh and Scriven1971; Joanny & de Gennes Reference Joanny and de Gennes1984; Petrov & Petrov Reference Petrov and Petrov1992), but most revolve around a breakdown of the Newtonian or continuum model of a fluid at the TPCL where individual molecules or particles within the fluid must ‘jump’ along the solid. The implications of this limit are discussed further in § 4.3. Putting these concepts together, we hence estimate the velocity gradients existing within the fluid during the equilibrium stages as

where as discussed, ![]() ${h}_{mol}$ is a small length scale related to the molecular (or non-continuum) nature of the fluid.

${h}_{mol}$ is a small length scale related to the molecular (or non-continuum) nature of the fluid.

For the continuous flow pressure variation, we perform an order of magnitude on the single-phase Navier–Stokes equations, recognising that pressure gradients may develop in response to viscous stress, momentum acceleration/advection and/or gravitational terms. This gives an expression for the pressure gradient in either fluid phase as

\begin{align} \widetilde{\boldsymbol{\nabla} p} & = {{O}(\rho\,\boldsymbol{\nabla} \boldsymbol{\cdot} \tilde{\boldsymbol{v}}\tilde{\boldsymbol{v}})} + {{O}(\mu\, \nabla^2 \tilde{\boldsymbol{v}})} + {{O}(\rho \boldsymbol{g})} \nonumber\\ & = {{O}\left(\frac{\rho {v}_{cv}^2}{\max(r,{h}_{mol})}\right)} + {{O}\left(\frac{\mu {v}_{cv}}{[ \max(r,{h}_{mol}) ]^2}\right)} + {{O}(\rho g)}, \end{align}

\begin{align} \widetilde{\boldsymbol{\nabla} p} & = {{O}(\rho\,\boldsymbol{\nabla} \boldsymbol{\cdot} \tilde{\boldsymbol{v}}\tilde{\boldsymbol{v}})} + {{O}(\mu\, \nabla^2 \tilde{\boldsymbol{v}})} + {{O}(\rho \boldsymbol{g})} \nonumber\\ & = {{O}\left(\frac{\rho {v}_{cv}^2}{\max(r,{h}_{mol})}\right)} + {{O}\left(\frac{\mu {v}_{cv}}{[ \max(r,{h}_{mol}) ]^2}\right)} + {{O}(\rho g)}, \end{align}

where again the fluid stress has been limited within a distance of ![]() ${h}_{mol}$ from the TPCL. Noting that the equilibrium stage fluid pressure

${h}_{mol}$ from the TPCL. Noting that the equilibrium stage fluid pressure ![]() $\tilde {p}$ is relative to some point in the surrounding fluid far from the TPCL, and that under these slow flow conditions there is a potential pressure jump over the fluid interface due to the surrounding interface curvature of

$\tilde {p}$ is relative to some point in the surrounding fluid far from the TPCL, and that under these slow flow conditions there is a potential pressure jump over the fluid interface due to the surrounding interface curvature of ![]() ${{O}(\sigma /{h}_{surround})}$, we model the pressure variation within the CV during the equilibrium stages as

${{O}(\sigma /{h}_{surround})}$, we model the pressure variation within the CV during the equilibrium stages as

where ![]() $p_0$ is some reference pressure located at a point away from the TPCL, but within the vicinity of the CV. All models describing the conceptual behaviour of the fluid phases during the equilibrium stages have now been defined.

$p_0$ is some reference pressure located at a point away from the TPCL, but within the vicinity of the CV. All models describing the conceptual behaviour of the fluid phases during the equilibrium stages have now been defined.

For the solid phase, to apply the MMEB, we need models that describe how the solid velocities and stresses vary as the TPCL advances over the rough surface. In this study, we invoke the simplest possible model by assuming that velocities within the solid are everywhere zero. With this assumption the energy balance becomes independent of solid phase stresses. On physical grounds, zero velocities can be justified within the solid by assuming that it is a yield-stress (or plastic) material that does not experience a stress exceeding its yield-stress during the analysis time. In reality, this is probably justifiable for most solids used in engineering applications, but for soft solids used in (e.g.) biomedical applications, energy dissipation within the solid phase may be significant. This is certainly an area for future work that could be incorporated into the presented mechanical energy balance framework, but it is not advanced here.

3.3. Applying the mechanical energy balance to the moving CV

With the physical system defined and semi-quantitative models for how the materials within the CV behave as it advances over the rough solid, we can now apply the MMEB to find the advancing contact angle.

3.3.1. Formulating the contact-angle mechanical energy balance

We start by deriving the most general form of the contact-angle energy balance by applying (2.10) to the moving CV and integrating it over a time period from ![]() $t_1$ to

$t_1$ to ![]() $t_2$, giving

$t_2$, giving

\begin{equation} T_0(t_1,t_2) = \sum_{i=1}^6 T_i(t_1,t_2), \end{equation}

\begin{equation} T_0(t_1,t_2) = \sum_{i=1}^6 T_i(t_1,t_2), \end{equation}where

$$\begin{gather}E(t) = \int_{{V}_{cv}} \left ( \frac{1}{2}\,\rho v^2 + \rho \hat{\varPhi} \right ) {\rm d}V + \sum_{i< j} {\sigma}_{ij} {A}_{ij}, \end{gather}$$

$$\begin{gather}E(t) = \int_{{V}_{cv}} \left ( \frac{1}{2}\,\rho v^2 + \rho \hat{\varPhi} \right ) {\rm d}V + \sum_{i< j} {\sigma}_{ij} {A}_{ij}, \end{gather}$$ $$\begin{gather}T_{1} (t_1,t_2) = \frac{1}{{A}_{cv}} \int^{t_2}_{t_1} \int_{{S}_{cv}} \sum_{i< j} {\sigma}_{ij} {\delta}_{{S},ij} \boldsymbol{n}_{cv} \boldsymbol{\cdot} {\boldsymbol{v}}_{cv} \, {\rm d}S \,{\rm d}t, \end{gather}$$

$$\begin{gather}T_{1} (t_1,t_2) = \frac{1}{{A}_{cv}} \int^{t_2}_{t_1} \int_{{S}_{cv}} \sum_{i< j} {\sigma}_{ij} {\delta}_{{S},ij} \boldsymbol{n}_{cv} \boldsymbol{\cdot} {\boldsymbol{v}}_{cv} \, {\rm d}S \,{\rm d}t, \end{gather}$$ $$\begin{gather}T_{4} (t_1,t_2) ={-} \frac{1}{{A}_{cv}} \int^{t_2}_{t_1} \int_{{S}_{cv}} \sum_{i< j} {\sigma}_{ij} \delta_{S,ij} \boldsymbol{n}_{{S},ij} \boldsymbol{n}_{{S},ij} : \boldsymbol{v} \boldsymbol{n}_{cv} \, {\rm d}S \,{\rm d}t, \end{gather}$$

$$\begin{gather}T_{4} (t_1,t_2) ={-} \frac{1}{{A}_{cv}} \int^{t_2}_{t_1} \int_{{S}_{cv}} \sum_{i< j} {\sigma}_{ij} \delta_{S,ij} \boldsymbol{n}_{{S},ij} \boldsymbol{n}_{{S},ij} : \boldsymbol{v} \boldsymbol{n}_{cv} \, {\rm d}S \,{\rm d}t, \end{gather}$$

In the derivation, use has been made of ![]() $\boldsymbol{\mathsf{I}} : \boldsymbol {v}\boldsymbol {n}_{cv} = \boldsymbol {n}_{cv} \boldsymbol {\cdot } \boldsymbol {v}$.

$\boldsymbol{\mathsf{I}} : \boldsymbol {v}\boldsymbol {n}_{cv} = \boldsymbol {n}_{cv} \boldsymbol {\cdot } \boldsymbol {v}$.

Next, defining the following notations that correspond to the entire, the ![]() $k$th equilibrium and the

$k$th equilibrium and the ![]() $k$th dissipation stages of the advance as

$k$th dissipation stages of the advance as

respectively for ![]() $i = 0$ to

$i = 0$ to ![]() $6$, (3.10) is applied over the entire advance period from time

$6$, (3.10) is applied over the entire advance period from time ![]() $0$ to

$0$ to ![]() $\tau$ to give

$\tau$ to give

\begin{equation} \bar{T}_0 = \sum_{i=1}^6 \bar{T}_i. \end{equation}

\begin{equation} \bar{T}_0 = \sum_{i=1}^6 \bar{T}_i. \end{equation}

Recognising that ![]() $\bar {T}_i$ for

$\bar {T}_i$ for ![]() $i = 1$ to

$i = 1$ to ![]() $6$ are all integrals over the total time period, using (3.3) these terms can be written as sums of the corresponding terms from the equilibrium and dissipation stages, giving

$6$ are all integrals over the total time period, using (3.3) these terms can be written as sums of the corresponding terms from the equilibrium and dissipation stages, giving

\begin{equation} \bar{T}_0 = \sum_{i=1}^6 \left ( \sum_{k=1}^{N+1} \tilde{T}_{i,k} + \sum_{k=1}^N \hat{T}_{i,k} \right ) = \sum_{i=1}^6 \sum_{k=1}^{N+1} \tilde{T}_{i,k} + \sum_{k=1}^N \sum_{i=1}^6 \hat{T}_{i,k}. \end{equation}