1. Introduction

Pulsatile turbulent pipe flows are widely encountered in engineering applications and biological systems, such as the turbomachinery and blood flow in aortic arteries. The oscillating nature of the pulsatile flow leads to a high-level fluctuation of the wall friction. Understanding the variation of the wall shear stress is of great practical significance to, e.g. pipeline leak detections (Colombo, Lee & Karney Reference Colombo, Lee and Karney2009) and blood-vessel problems (Cunningham & Gotlieb Reference Cunningham and Gotlieb2005), which require precise knowledge of flow dynamic behaviours. This paper is concerned with the wall shear stresses in pulsatile turbulent pipe flows and the corresponding fluid dynamics.

The pulsation process consists of continuous accelerating and decelerating phases. In the past decades, several researchers have focused on the flow responses in the accelerating turbulent pipe or channel flow, in which the flow rate varies in a step- or ramp-changing manner (Maruyama, Kuribayashi & Mizushina Reference Maruyama, Kuribayashi and Mizushina1976; Greenblatt & Moss Reference Greenblatt and Moss1999; He & Jackson Reference He and Jackson2000; Greenblatt & Moss Reference Greenblatt and Moss2004). It is well established, in both scenarios, that the flow initially evolves in a laminar-like way, accompanied by the streamwise stretching of the near-wall streaks (stage 1). Then, the elongated streaks break up, leading to the formation and subsequent merging of turbulent spots (stage 2). Finally, the turbulence reaches its new fully developed state (stage 3) (He, Ariyaratne & Vardy Reference He, Ariyaratne and Vardy2011; Jung & Chung Reference Jung and Chung2012; Seddighi et al. Reference Seddighi, He, Vardy and Orlandi2014; He & Seddighi Reference He and Seddighi2015; He, Seddighi & He Reference He, Seddighi and He2016). Specifically, this three-stage flow evolution resembles closely the bypass transition in the boundary layer induced by the free stream turbulence (He & Seddighi Reference He and Seddighi2013). Mathur et al. (Reference Mathur, Gorji, He, Seddighi, Vardy, O'Donoghue and Pokrajac2018) interpreted this process in a different way by regarding the preexisting turbulence as a perturbation that leads to the instability of the temporally developing laminar boundary layer from the wall. In any case, the laminar-like flow behaviours at the early stage allow an unsteady friction model to be established to predict the wall shear stress. Based on the assumption that the turbulence in stage 1 is nearly ‘frozen’, He & Ariyaratne (Reference He and Ariyaratne2011) derived a laminar-flow formulation to describe the wall shear stress at that stage. The acquired results are in good agreement with experimental or computational outcomes as further consolidated by He et al. (Reference He, Ariyaratne and Vardy2011). He & Seddighi (Reference He and Seddighi2015) and Jung & Kim (Reference Jung and Kim2017) discussed the effects of the ratio of the final to initial Reynolds number and the effects of the acceleration rate on the transition, respectively. They both showed that the turbulence evolves progressively for a low ratio and low acceleration rate, which is in contrast to the aforementioned bypass transition. Guerrero, Lambert & Chin (Reference Guerrero, Lambert and Chin2021) investigated the transient dynamics of the accelerating turbulent pipe flow in detail. By using the FIK identity, which is an exact expression developed by Fukagata, Iwamoto & Kasagi (Reference Fukagata, Iwamoto and Kasagi2002) to quantify the friction coefficient for wall-bounded flows, they were able to quantify the different contributions to the wall friction during the transient. Moreover, Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018a) showed that the flow responses during the accelerating phase of the pulsatile flow are similar to those in the first two stages of the uniformly accelerating flow. As for the decelerating flow which is characterized by a decay of the preexisting turbulence (Mathur Reference Mathur2016), Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018c) also demonstrated its laminar similarity to the accelerating flow at the initial stage.

Different from the one-way flow excursion reviewed above, the pulsatile turbulent flow exhibits strong wave–turbulence interactions due to the shear wave generated near the wall. The laminar Stokes thickness ![]() $l_{s}^{+}=l_{s}\bar {u}_{\tau }/\nu, l_{s} =\sqrt {2\nu /\omega }$, where

$l_{s}^{+}=l_{s}\bar {u}_{\tau }/\nu, l_{s} =\sqrt {2\nu /\omega }$, where ![]() $\nu$ and

$\nu$ and ![]() $\omega$ are the kinematic viscosity and the angular pulsatile frequency, respectively, is generally used to characterize the wall-normal length scale of such a near-wall shear wave. In the present paper, the superscript

$\omega$ are the kinematic viscosity and the angular pulsatile frequency, respectively, is generally used to characterize the wall-normal length scale of such a near-wall shear wave. In the present paper, the superscript ![]() $+$ denotes normalization using the mean friction velocity

$+$ denotes normalization using the mean friction velocity ![]() $\bar {u}_\tau$ and the kinematic viscosity

$\bar {u}_\tau$ and the kinematic viscosity ![]() $\nu$. To take into account the diffusion effect of turbulence, Scotti & Piomelli (Reference Scotti and Piomelli2001) proposed a turbulent Stokes thickness

$\nu$. To take into account the diffusion effect of turbulence, Scotti & Piomelli (Reference Scotti and Piomelli2001) proposed a turbulent Stokes thickness ![]() $l_{t}$, based on the eddy-viscosity theory, as the scaling parameter. There have been several experimental studies that focused on the pulsatile flows (Gerrard Reference Gerrard1971; Ronneberger & Ahrens Reference Ronneberger and Ahrens1977; Ramaprian & Tu Reference Ramaprian and Tu1980, Reference Ramaprian and Tu1983; Tu & Ramaprian Reference Tu and Ramaprian1983; Shemer & Kit Reference Shemer and Kit1984; Shemer, Wygnanski & Kit Reference Shemer, Wygnanski and Kit1985; Mao & Hanratty Reference Mao and Hanratty1986; Tardu & Binder Reference Tardu and Binder1993; Tardu, Binder & Blackwelder Reference Tardu, Binder and Blackwelder1994; Lodahl, Sumer & Fredsøe Reference Lodahl, Sumer and Fredsøe1998; He & Jackson Reference He and Jackson2009), covering a wide range of pulsation parameters. The wave–turbulence interactions exhibit a strong frequency dependence. When the pulsation frequency is high (

$l_{t}$, based on the eddy-viscosity theory, as the scaling parameter. There have been several experimental studies that focused on the pulsatile flows (Gerrard Reference Gerrard1971; Ronneberger & Ahrens Reference Ronneberger and Ahrens1977; Ramaprian & Tu Reference Ramaprian and Tu1980, Reference Ramaprian and Tu1983; Tu & Ramaprian Reference Tu and Ramaprian1983; Shemer & Kit Reference Shemer and Kit1984; Shemer, Wygnanski & Kit Reference Shemer, Wygnanski and Kit1985; Mao & Hanratty Reference Mao and Hanratty1986; Tardu & Binder Reference Tardu and Binder1993; Tardu, Binder & Blackwelder Reference Tardu, Binder and Blackwelder1994; Lodahl, Sumer & Fredsøe Reference Lodahl, Sumer and Fredsøe1998; He & Jackson Reference He and Jackson2009), covering a wide range of pulsation parameters. The wave–turbulence interactions exhibit a strong frequency dependence. When the pulsation frequency is high (![]() $0.02\lesssim \omega ^+ \lesssim 0.04$), the Stokes thickness is small such that the shear wave is only confined to the very narrow near-wall region. In this case, the inner shear wave and outer turbulence are weakly coupled (quasi-laminar state). There is a

$0.02\lesssim \omega ^+ \lesssim 0.04$), the Stokes thickness is small such that the shear wave is only confined to the very narrow near-wall region. In this case, the inner shear wave and outer turbulence are weakly coupled (quasi-laminar state). There is a ![]() $45^\circ$ phase lag between the centreline velocity and the wall shear stress, which coincides with the laminar Stokes solution. When the frequency falls in a low-frequency range (

$45^\circ$ phase lag between the centreline velocity and the wall shear stress, which coincides with the laminar Stokes solution. When the frequency falls in a low-frequency range (![]() $\omega ^+\lesssim 0.005$), the flow variation is slow enough to allow the turbulence to react and settle down. Hence, the instantaneous flow field resembles that of the steady flow at the corresponding Reynolds number (quasi-steady state). Generally speaking, if the pulsation amplitude is not large enough to induce a reversal flow, the time-averaged flow quantities remain nearly unchanged from their values in the steady flow (Brereton, Reynolds & Jayaraman Reference Brereton, Reynolds and Jayaraman1990). However, Tu & Ramaprian (Reference Tu and Ramaprian1983) showed a deviation of the mean velocity profile from the steady one when the frequency is close to or larger than the turbulent bursting frequency in the turbulent pipe flow, i.e. a very-high frequency range (

$\omega ^+\lesssim 0.005$), the flow variation is slow enough to allow the turbulence to react and settle down. Hence, the instantaneous flow field resembles that of the steady flow at the corresponding Reynolds number (quasi-steady state). Generally speaking, if the pulsation amplitude is not large enough to induce a reversal flow, the time-averaged flow quantities remain nearly unchanged from their values in the steady flow (Brereton, Reynolds & Jayaraman Reference Brereton, Reynolds and Jayaraman1990). However, Tu & Ramaprian (Reference Tu and Ramaprian1983) showed a deviation of the mean velocity profile from the steady one when the frequency is close to or larger than the turbulent bursting frequency in the turbulent pipe flow, i.e. a very-high frequency range (![]() $\omega ^+\gtrsim 0.04$). This can be possibly attributed to a resonance effect with the closeness between the pulsation frequency and the characteristic frequency of the near-wall coherent structure. In contrast, Tardu et al. (Reference Tardu, Binder and Blackwelder1994) and Scotti & Piomelli (Reference Scotti and Piomelli2001) did not report such a deviation in turbulent channel flows with different pulsation parameters. This might be due to the dependency of the bursting frequency on the Reynolds number and geometry such that a resonance condition is not easily satisfied. Sundstrom, Mulu & Cervantes (Reference Sundstrom, Mulu and Cervantes2016) performed experimental research on a double-frequency pulsatile turbulent pipe flow and showed that the time-averaged flow quantities are also unaffected by the double-frequency pulsation. For a large-amplitude oscillation (usually refers to a situation when the oscillatory to mean velocity ratio

$\omega ^+\gtrsim 0.04$). This can be possibly attributed to a resonance effect with the closeness between the pulsation frequency and the characteristic frequency of the near-wall coherent structure. In contrast, Tardu et al. (Reference Tardu, Binder and Blackwelder1994) and Scotti & Piomelli (Reference Scotti and Piomelli2001) did not report such a deviation in turbulent channel flows with different pulsation parameters. This might be due to the dependency of the bursting frequency on the Reynolds number and geometry such that a resonance condition is not easily satisfied. Sundstrom, Mulu & Cervantes (Reference Sundstrom, Mulu and Cervantes2016) performed experimental research on a double-frequency pulsatile turbulent pipe flow and showed that the time-averaged flow quantities are also unaffected by the double-frequency pulsation. For a large-amplitude oscillation (usually refers to a situation when the oscillatory to mean velocity ratio ![]() $A$ is larger than one), Manna, Vacca & Verzicco (Reference Manna, Vacca and Verzicco2012) reported a drag-reducing effect which manifests as an upward shift of the mean velocity profile in the logarithmic region. This is consistent with Mao & Hanratty (Reference Mao and Hanratty1994) and Manna & Vacca (Reference Manna and Vacca2005) in which a reduction of wall shear stresses was both reported.

$A$ is larger than one), Manna, Vacca & Verzicco (Reference Manna, Vacca and Verzicco2012) reported a drag-reducing effect which manifests as an upward shift of the mean velocity profile in the logarithmic region. This is consistent with Mao & Hanratty (Reference Mao and Hanratty1994) and Manna & Vacca (Reference Manna and Vacca2005) in which a reduction of wall shear stresses was both reported.

The laminar–turbulent transition is also an important phenomenon that occurs in pulsatile flows. Turbulence can be completely relaminarized in the pulsatile pipe flow with a non-zero mean flow under certain parameters (Lodahl et al. Reference Lodahl, Sumer and Fredsøe1998), and can also appear intermittently in a purely oscillatory flow (Feldmann & Wagner Reference Feldmann and Wagner2012), which belongs to a subcritical transition scenario (Feldmann & Wagner Reference Feldmann and Wagner2016b). Xu et al. (Reference Xu, Warnecke, Song, Ma and Hof2017) conducted an experimental study on the transition in a pulsatile pipe at amplitudes ![]() $A\le 0.7$. Based on the transition theory in the steady pipe flow (Hof et al. Reference Hof, Westerweel, Schneider and Eckhardt2006; Avila, Willis & Hof Reference Avila, Willis and Hof2010; Avila et al. Reference Avila, Moxey, De Lozar, Avila, Barkley and Hof2011), they summarized the effects of pulsation frequency and this was further elaborated by Xu & Avila (Reference Xu and Avila2018) with the aid of the direct numerical simulation (DNS). For a large-amplitude pulsation with

$A\le 0.7$. Based on the transition theory in the steady pipe flow (Hof et al. Reference Hof, Westerweel, Schneider and Eckhardt2006; Avila, Willis & Hof Reference Avila, Willis and Hof2010; Avila et al. Reference Avila, Moxey, De Lozar, Avila, Barkley and Hof2011), they summarized the effects of pulsation frequency and this was further elaborated by Xu & Avila (Reference Xu and Avila2018) with the aid of the direct numerical simulation (DNS). For a large-amplitude pulsation with ![]() $A> 0.7$, Xu, Song & Avila (Reference Xu, Song and Avila2021); Xu et al. (Reference Xu, Varshney, Ma, Song, Riedl, Avila and Hof2020) reported a helical instability mechanism that induces the burst of turbulence in a pulsatile pipe flow. In particular, this helical disturbance is triggered during the decelerating phase and disappears in the accelerating phase, indicating a strong phase asymmetry in the pulsatile pipe flow (Feldmann & Wagner Reference Feldmann and Wagner2016a). Further, Morón, Feldmann & Avila (Reference Morón, Feldmann and Avila2022) linked this helical instability to the linear stability of the corresponding laminar flow and discussed the effect of the pulsation wave form on the turbulence transition. Similarly, Feldmann, Morón & Avila (Reference Feldmann, Morón and Avila2020) investigated the spatio-temporal intermittency associated with a competition between the helical structures and puffs. This intermittency in the pulsatile pipe flow is qualitatively similar to the gas-liquid slug pipe flow reported by Padrino et al. (Reference Padrino, Srinil, Kurushina and Swailes2023).

$A> 0.7$, Xu, Song & Avila (Reference Xu, Song and Avila2021); Xu et al. (Reference Xu, Varshney, Ma, Song, Riedl, Avila and Hof2020) reported a helical instability mechanism that induces the burst of turbulence in a pulsatile pipe flow. In particular, this helical disturbance is triggered during the decelerating phase and disappears in the accelerating phase, indicating a strong phase asymmetry in the pulsatile pipe flow (Feldmann & Wagner Reference Feldmann and Wagner2016a). Further, Morón, Feldmann & Avila (Reference Morón, Feldmann and Avila2022) linked this helical instability to the linear stability of the corresponding laminar flow and discussed the effect of the pulsation wave form on the turbulence transition. Similarly, Feldmann, Morón & Avila (Reference Feldmann, Morón and Avila2020) investigated the spatio-temporal intermittency associated with a competition between the helical structures and puffs. This intermittency in the pulsatile pipe flow is qualitatively similar to the gas-liquid slug pipe flow reported by Padrino et al. (Reference Padrino, Srinil, Kurushina and Swailes2023).

A paradoxical phenomenon occurs in the intermediate frequency range (![]() $0.005\lesssim \omega ^+\lesssim 0.02$). In this frequency range, the amplitude of the oscillating wall shear stress in a turbulent flow (

$0.005\lesssim \omega ^+\lesssim 0.02$). In this frequency range, the amplitude of the oscillating wall shear stress in a turbulent flow (![]() $A_{\widetilde {\tau _{w}},t}$) is smaller than that in a laminar flow with the same pulsation conditions (

$A_{\widetilde {\tau _{w}},t}$) is smaller than that in a laminar flow with the same pulsation conditions (![]() $A_{\widetilde {\tau _{w}},s}$). This suggests a turbulence-induced drag reduction that is opposite to that in the steady flow where turbulence generally produces a larger drag than a laminar flow (Mao & Hanratty Reference Mao and Hanratty1986; Tardu et al. Reference Tardu, Binder and Blackwelder1994; Sundstrom & Cervantes Reference Sundstrom and Cervantes2018a). To deal with a non-closure problem in the governing equation, several researchers have established theoretical models for the Reynolds shear stress based on the concept of eddy viscosity. Most of these models in general fail to describe accurately the paradoxical phenomenon due to the inherent assumption that the Reynolds shear stress is in phase with the imposed oscillation (Weng, Boij & Hanifi Reference Weng, Boij and Hanifi2016; Weng, Boij & Hanifi Reference Weng, Boij and Hanifi2013). Weng et al. (Reference Weng, Boij and Hanifi2016) introduced the time dependency of the Reynolds shear stress into the standard eddy-viscosity model, which brings a phase lag between the Reynolds shear stress and the oscillating shear strain rate. This improved model is shown to be able to predict correctly the paradoxical phenomenon. However, a detailed explanation on why and how the turbulence reduces the wall shear stress is still lacking. Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018b) provided a new interpretation of this paradoxical phenomenon by decomposing the total wall shear stress into the contributions from the oscillating pressure gradient (

$A_{\widetilde {\tau _{w}},s}$). This suggests a turbulence-induced drag reduction that is opposite to that in the steady flow where turbulence generally produces a larger drag than a laminar flow (Mao & Hanratty Reference Mao and Hanratty1986; Tardu et al. Reference Tardu, Binder and Blackwelder1994; Sundstrom & Cervantes Reference Sundstrom and Cervantes2018a). To deal with a non-closure problem in the governing equation, several researchers have established theoretical models for the Reynolds shear stress based on the concept of eddy viscosity. Most of these models in general fail to describe accurately the paradoxical phenomenon due to the inherent assumption that the Reynolds shear stress is in phase with the imposed oscillation (Weng, Boij & Hanifi Reference Weng, Boij and Hanifi2016; Weng, Boij & Hanifi Reference Weng, Boij and Hanifi2013). Weng et al. (Reference Weng, Boij and Hanifi2016) introduced the time dependency of the Reynolds shear stress into the standard eddy-viscosity model, which brings a phase lag between the Reynolds shear stress and the oscillating shear strain rate. This improved model is shown to be able to predict correctly the paradoxical phenomenon. However, a detailed explanation on why and how the turbulence reduces the wall shear stress is still lacking. Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018b) provided a new interpretation of this paradoxical phenomenon by decomposing the total wall shear stress into the contributions from the oscillating pressure gradient (![]() $\tau _p$) and the Reynolds shear stress (

$\tau _p$) and the Reynolds shear stress (![]() $\tau _s$). It is shown that a phase shift between

$\tau _s$). It is shown that a phase shift between ![]() $\tau _p$ and

$\tau _p$ and ![]() $\tau _s$ results in a mutual cancellation that leads to the reduction of the total wall shear stress. Nevertheless, in their experimental study,

$\tau _s$ results in a mutual cancellation that leads to the reduction of the total wall shear stress. Nevertheless, in their experimental study, ![]() $\tau _s$ is calculated by subtracting

$\tau _s$ is calculated by subtracting ![]() $\tau _p$ from the measured total wall shear stress while

$\tau _p$ from the measured total wall shear stress while ![]() $\tau _p$ is calculated by the laminar Stokes solution. Hence, this interpretation still cannot explain the underlying mechanisms; for instance, it does not explain what causes the phase shift. Based on these, we choose to perform direct numerical simulations in turbulent pulsatile pipe flows, in the hope of extending the numerical database of pulsatile flows, elucidating the physical mechanisms that cause the paradoxical phenomenon and revealing the corresponding turbulence dynamics in detail.

$\tau _p$ is calculated by the laminar Stokes solution. Hence, this interpretation still cannot explain the underlying mechanisms; for instance, it does not explain what causes the phase shift. Based on these, we choose to perform direct numerical simulations in turbulent pulsatile pipe flows, in the hope of extending the numerical database of pulsatile flows, elucidating the physical mechanisms that cause the paradoxical phenomenon and revealing the corresponding turbulence dynamics in detail.

This paper is organized as follows. A computational set-up is introduced in § 2. Some basic statistics and the properties of the varying wall shear stress are given in § 3. Section 4 explores the causes of the paradoxical phenomenon and § 5 discusses the hysteresis phenomenon of the wall shear stress. The effects of the pulsation amplitude are examined in § 6. Section 7 further examines the phase-wise variation of spectra and § 8 summarizes the main findings of this paper.

2. Computational set-up

For pulsatile flows, it is common to introduce a triple decomposition of the flow quantity ![]() $f(\boldsymbol {x},t)$ (Hussain & Reynolds Reference Hussain and Reynolds1970; Weng et al. Reference Weng, Boij and Hanifi2016; Sundstrom & Cervantes Reference Sundstrom and Cervantes2018b):

$f(\boldsymbol {x},t)$ (Hussain & Reynolds Reference Hussain and Reynolds1970; Weng et al. Reference Weng, Boij and Hanifi2016; Sundstrom & Cervantes Reference Sundstrom and Cervantes2018b):

where ![]() $\bar {f}$ and

$\bar {f}$ and ![]() $\langle\, f \rangle$ are the time-averaged and phase-averaged values,

$\langle\, f \rangle$ are the time-averaged and phase-averaged values, ![]() $\tilde {f}$ is the oscillating component,

$\tilde {f}$ is the oscillating component, ![]() $f'$ is the turbulent fluctuation and

$f'$ is the turbulent fluctuation and ![]() $\varphi$ is the phase. By further including the spatial average in statistically homogeneous directions, the time and phase averages can be defined as

$\varphi$ is the phase. By further including the spatial average in statistically homogeneous directions, the time and phase averages can be defined as

\begin{gather} \left\langle\, {f} \right\rangle(y,\varphi) = \lim_{M \to \infty } \frac{1}{{2{\rm \pi} ML}}\sum_{n = 1}^M {\int_0^L {\int_0^{2{\rm \pi} } {f\left(\boldsymbol{x},t + \frac{2{\rm \pi} n}{\omega}\right)} } } \,{\rm d}\kern 0.06em x\,{\rm d}\theta, \end{gather}

\begin{gather} \left\langle\, {f} \right\rangle(y,\varphi) = \lim_{M \to \infty } \frac{1}{{2{\rm \pi} ML}}\sum_{n = 1}^M {\int_0^L {\int_0^{2{\rm \pi} } {f\left(\boldsymbol{x},t + \frac{2{\rm \pi} n}{\omega}\right)} } } \,{\rm d}\kern 0.06em x\,{\rm d}\theta, \end{gather}

where ![]() $x$,

$x$, ![]() $y=R-r$ and

$y=R-r$ and ![]() $\theta$ denote the streamwise, wall-normal and azimuthal directions, respectively, with the corresponding velocity components being

$\theta$ denote the streamwise, wall-normal and azimuthal directions, respectively, with the corresponding velocity components being ![]() $u$,

$u$, ![]() $-v$ and

$-v$ and ![]() $w$. The pipe radius is

$w$. The pipe radius is ![]() $R$,

$R$, ![]() $L$ is the pipe length and

$L$ is the pipe length and ![]() $M$ is the total number of periods.

$M$ is the total number of periods.

In the present study, the pulsation is achieved by imposing a sinusoidally varying component to the constant streamwise pressure gradient that drives the steady turbulent pipe flow:

The constant mean pressure gradient ![]() $\partial \bar {p}/{\partial x}$ is set to aim for a steady turbulent flow of

$\partial \bar {p}/{\partial x}$ is set to aim for a steady turbulent flow of ![]() $Re_\tau =\bar {u}_\tau R/\nu =180$. Throughout the paper, the quantity

$Re_\tau =\bar {u}_\tau R/\nu =180$. Throughout the paper, the quantity ![]() $\varphi$ refers to a phase of the streamwise pressure gradient

$\varphi$ refers to a phase of the streamwise pressure gradient ![]() $\partial p/\partial x$. We use the ratio of the amplitude of the oscillating velocity to the mean velocity at the pipe centreline, i.e.

$\partial p/\partial x$. We use the ratio of the amplitude of the oscillating velocity to the mean velocity at the pipe centreline, i.e. ![]() $A=A_{\tilde {u}_{cl}}/\bar {u}_{cl}$, to characterize the pulsation amplitude. Using (2.1), the governing equation for the oscillating component of the streamwise velocity reads:

$A=A_{\tilde {u}_{cl}}/\bar {u}_{cl}$, to characterize the pulsation amplitude. Using (2.1), the governing equation for the oscillating component of the streamwise velocity reads:

\begin{equation} \frac{\partial \tilde{u}}{\partial t}={-}\frac{\partial \tilde{p}}{\partial x}+ \nu \frac{1}{r} \frac{\partial \tilde{u}}{\partial r} +\nu \frac{\partial ^2 \tilde{u} }{\partial r^2} \underbrace{-\frac{\partial r\widetilde{u'v'} }{r\partial r}}_{\wp}. \end{equation}

\begin{equation} \frac{\partial \tilde{u}}{\partial t}={-}\frac{\partial \tilde{p}}{\partial x}+ \nu \frac{1}{r} \frac{\partial \tilde{u}}{\partial r} +\nu \frac{\partial ^2 \tilde{u} }{\partial r^2} \underbrace{-\frac{\partial r\widetilde{u'v'} }{r\partial r}}_{\wp}. \end{equation}By evaluating (2.4) at the pipe centreline, we have

Hence, ![]() $\beta$ can be predetermined based on the desired pulsation amplitude

$\beta$ can be predetermined based on the desired pulsation amplitude ![]() $A$.

$A$.

To enable a direct comparison, the pulsation parameters selected in this paper, which are given in table 1, are similar to those of Weng et al. (Reference Weng, Boij and Hanifi2016) and Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018b) (figure 1a). Five frequencies are chosen for ![]() $A=0.1$ (Cases 1–5), and the resulting Womersley numbers

$A=0.1$ (Cases 1–5), and the resulting Womersley numbers ![]() $W=R\sqrt {\omega /\nu }$ ranges from 12.7 to 63.6. In addition, simulations of Cases 6 and 7 are performed at a higher amplitude of

$W=R\sqrt {\omega /\nu }$ ranges from 12.7 to 63.6. In addition, simulations of Cases 6 and 7 are performed at a higher amplitude of ![]() $A=0.4$ to evaluate the effect of pulsation amplitude. To provide a more comprehensive comparison with previous studies, each case is plotted in the

$A=0.4$ to evaluate the effect of pulsation amplitude. To provide a more comprehensive comparison with previous studies, each case is plotted in the ![]() $Re_b\unicode{x2013}Re_w$ plane (Lodahl et al. Reference Lodahl, Sumer and Fredsøe1998) together with available literature data (figure 1b). Here,

$Re_b\unicode{x2013}Re_w$ plane (Lodahl et al. Reference Lodahl, Sumer and Fredsøe1998) together with available literature data (figure 1b). Here, ![]() $Re_b=U_bD/\nu$ is the bulk Reynolds number based on the bulk velocity

$Re_b=U_bD/\nu$ is the bulk Reynolds number based on the bulk velocity ![]() $U_b$ and the pipe diameter

$U_b$ and the pipe diameter ![]() $D$, and

$D$, and ![]() $Re_w={A_{\tilde {u}_{cl}}}^2/\omega \nu$ is the oscillatory Reynolds number. It is clear that all cases fall in the turbulent regime, as demonstrated in figure 3 where the instantaneous streamwise velocity at the meridional plane for Case 7 is shown. Although there is a large coincidence in the parameter space between the current study and Cheng et al. (Reference Cheng, Jelly, Illingworth, Marusic and Ooi2020), we note that our goal is not to carry out an investigation in the unexplored parameter space but to further elucidate the mechanisms responsible for the aforementioned paradoxical phenomenon based on existing parameters in the literature. Further, all the simulation cases of Cheng et al. (Reference Cheng, Jelly, Illingworth, Marusic and Ooi2020) are conducted at the fixed

$Re_w={A_{\tilde {u}_{cl}}}^2/\omega \nu$ is the oscillatory Reynolds number. It is clear that all cases fall in the turbulent regime, as demonstrated in figure 3 where the instantaneous streamwise velocity at the meridional plane for Case 7 is shown. Although there is a large coincidence in the parameter space between the current study and Cheng et al. (Reference Cheng, Jelly, Illingworth, Marusic and Ooi2020), we note that our goal is not to carry out an investigation in the unexplored parameter space but to further elucidate the mechanisms responsible for the aforementioned paradoxical phenomenon based on existing parameters in the literature. Further, all the simulation cases of Cheng et al. (Reference Cheng, Jelly, Illingworth, Marusic and Ooi2020) are conducted at the fixed ![]() $\beta$ while the pulsation amplitude

$\beta$ while the pulsation amplitude ![]() $A$ is fixed in the present study. Therefore, our cases are in fact different from those of Cheng et al. (Reference Cheng, Jelly, Illingworth, Marusic and Ooi2020) according to (2.5). For each case, the pulsation is imposed at a single flow field of the steady turbulent pipe flow. After discarding the transient effect, the phase-averaged data are collected over more than 23 periods to obtain the final statistics.

$A$ is fixed in the present study. Therefore, our cases are in fact different from those of Cheng et al. (Reference Cheng, Jelly, Illingworth, Marusic and Ooi2020) according to (2.5). For each case, the pulsation is imposed at a single flow field of the steady turbulent pipe flow. After discarding the transient effect, the phase-averaged data are collected over more than 23 periods to obtain the final statistics.

Table 1. Cases with different pulsation parameters, namely the pulsation amplitude ![]() $A$, the frequency

$A$, the frequency ![]() $\omega ^+$. Here,

$\omega ^+$. Here, ![]() $l_s^{+}$ is the laminar Stokes thickness;

$l_s^{+}$ is the laminar Stokes thickness; ![]() $W$ is the Womersley number;

$W$ is the Womersley number; ![]() $A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ is the amplitude of the wall shear stress normalized by its laminar Stokes value; and

$A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ is the amplitude of the wall shear stress normalized by its laminar Stokes value; and ![]() $Re_b=U_bD/\nu$ and

$Re_b=U_bD/\nu$ and ![]() $Re_w={A_{\tilde {u}_{cl}}}^2/\omega \nu$ are the bulk and oscillatory Reynolds numbers, respectively.

$Re_w={A_{\tilde {u}_{cl}}}^2/\omega \nu$ are the bulk and oscillatory Reynolds numbers, respectively.

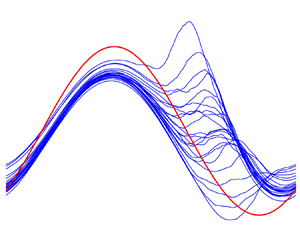

Figure 1. (a) Variation of the amplitude of the wall shear stress ![]() $A_{\widetilde {\tau _{w}},t}$ normalized by the laminar Stokes amplitude

$A_{\widetilde {\tau _{w}},t}$ normalized by the laminar Stokes amplitude ![]() $A_{\widetilde {\tau _{w}},s}$ with respect to the laminar Stokes thickness

$A_{\widetilde {\tau _{w}},s}$ with respect to the laminar Stokes thickness ![]() $l_s^+$. (b) Laminar–turbulent transition boundary (dash-dotted line, Lodahl et al. Reference Lodahl, Sumer and Fredsøe1998) and parameter combinations considered by previous studies. The critical Reynolds numbers

$l_s^+$. (b) Laminar–turbulent transition boundary (dash-dotted line, Lodahl et al. Reference Lodahl, Sumer and Fredsøe1998) and parameter combinations considered by previous studies. The critical Reynolds numbers ![]() $Re_{b,tr}$ and

$Re_{b,tr}$ and ![]() $Re_{w,tr}$ are denoted by the dashed lines.

$Re_{w,tr}$ are denoted by the dashed lines.

A cylindrical-coordinate spectral element–Fourier DNS solver Semtex is employed to conduct the simulations (Blackburn & Sherwin Reference Blackburn and Sherwin2004; Blackburn et al. Reference Blackburn, Lee, Albrecht and Singh2019). The computational mesh is the same as that of Liu et al. (Reference Liu, Zhu, Bao, Zhou and Han2022), where a ![]() $50\times 10$ two-dimensional spectral element mesh is deployed to discretize the meridional semi-plane. To represent the three-dimensional computational domain, 192 Fourier expansion planes are used in the azimuthal direction. The pipe length is set to be

$50\times 10$ two-dimensional spectral element mesh is deployed to discretize the meridional semi-plane. To represent the three-dimensional computational domain, 192 Fourier expansion planes are used in the azimuthal direction. The pipe length is set to be ![]() $L=6{\rm \pi} R$. To ensure that this mesh configuration is appropriate to resolve the precise turbulence dynamics, we choose Cases 3 and 7 to conduct the mesh independence test. The choice of these two cases is based on the fact that the former is the case for which the ratio

$L=6{\rm \pi} R$. To ensure that this mesh configuration is appropriate to resolve the precise turbulence dynamics, we choose Cases 3 and 7 to conduct the mesh independence test. The choice of these two cases is based on the fact that the former is the case for which the ratio ![]() $A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ reaches its minimum and the latter is a high-amplitude case in which the variation of turbulence dynamics is more intense. Details of the spatial grid resolution are given in table 2. The

$A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ reaches its minimum and the latter is a high-amplitude case in which the variation of turbulence dynamics is more intense. Details of the spatial grid resolution are given in table 2. The ![]() $hp$-refinement strategy for the spectral element method is employed. Our baseline grid resolutions are comparable with the regular and high resolutions reported by Zahtila et al. (Reference Zahtila, Lu, Chan and Ooi2023). Figure 2 shows the phase-averaged wall shear stress obtained from various grids. It can be found that all the curves for Case 3 overlap well and the kink variation trend in Case 7 can be observed for all test cases, indicating that our phase-averaged statistics are grid independent. Figure 1(a) compares the present results of

$hp$-refinement strategy for the spectral element method is employed. Our baseline grid resolutions are comparable with the regular and high resolutions reported by Zahtila et al. (Reference Zahtila, Lu, Chan and Ooi2023). Figure 2 shows the phase-averaged wall shear stress obtained from various grids. It can be found that all the curves for Case 3 overlap well and the kink variation trend in Case 7 can be observed for all test cases, indicating that our phase-averaged statistics are grid independent. Figure 1(a) compares the present results of ![]() $A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ for

$A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ for ![]() $A=0.1$ with previous studies. It is shown that the paradoxical phenomenon can be clearly reproduced and that the variation trend of

$A=0.1$ with previous studies. It is shown that the paradoxical phenomenon can be clearly reproduced and that the variation trend of ![]() $A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ with respect to

$A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ with respect to ![]() $l_s^+$ is also consistent with that in the literature. Note that the temporal variation of the wall shear stress is not necessarily a pure sine function; thus, here the amplitude corresponds to the amplitude of the fundamental mode calculated from the Fourier analysis. Quantitatively, a reasonable agreement can also be found except that the minimum of

$l_s^+$ is also consistent with that in the literature. Note that the temporal variation of the wall shear stress is not necessarily a pure sine function; thus, here the amplitude corresponds to the amplitude of the fundamental mode calculated from the Fourier analysis. Quantitatively, a reasonable agreement can also be found except that the minimum of ![]() $A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ is 0.65 at

$A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ is 0.65 at ![]() $l_s^+=14$, which is smaller compared with that of Weng et al. (Reference Weng, Boij and Hanifi2016) and Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018b) but in agreement with Tardu et al. (Reference Tardu, Binder and Blackwelder1994). This can probably be attributed to the different Reynolds numbers used in these studies. Moreover, the instantaneous fields in figure 3 exhibit visual smoothness, and no mesh imprints can be found. Hence, these results give us confidence in the accuracy of the DNS data used in this paper.

$l_s^+=14$, which is smaller compared with that of Weng et al. (Reference Weng, Boij and Hanifi2016) and Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018b) but in agreement with Tardu et al. (Reference Tardu, Binder and Blackwelder1994). This can probably be attributed to the different Reynolds numbers used in these studies. Moreover, the instantaneous fields in figure 3 exhibit visual smoothness, and no mesh imprints can be found. Hence, these results give us confidence in the accuracy of the DNS data used in this paper.

Table 2. Summary of the grid information. Here, ![]() $\Delta x^+$,

$\Delta x^+$, ![]() $\Delta y^+$ are the normalized streamwise, wall-normal grid resolutions;

$\Delta y^+$ are the normalized streamwise, wall-normal grid resolutions; ![]() $\Delta (r\theta )_{wall}^+$ is the normalized circumferential grid resolution at the wall;

$\Delta (r\theta )_{wall}^+$ is the normalized circumferential grid resolution at the wall; ![]() $P$ is the number of Lagrange knot points along the side of each element, corresponding to a polynomial order of

$P$ is the number of Lagrange knot points along the side of each element, corresponding to a polynomial order of ![]() $P-1$;

$P-1$; ![]() $N$ represents the number of Fourier expansion planes in the circumferential direction;

$N$ represents the number of Fourier expansion planes in the circumferential direction; ![]() $H$ denotes the number of elements in the streamwise direction, which is associated with the streamwise

$H$ denotes the number of elements in the streamwise direction, which is associated with the streamwise ![]() $h$-refinement strategy in the spectral element method.

$h$-refinement strategy in the spectral element method.

Figure 2. Comparisons of the phase-averaged wall shear stress ![]() $\langle \tau _w\rangle$ between different mesh-independence validation cases: (a) Case 3 (

$\langle \tau _w\rangle$ between different mesh-independence validation cases: (a) Case 3 (![]() $A=0.1$,

$A=0.1$, ![]() $l_s^+=14$); (b) Case 7 (

$l_s^+=14$); (b) Case 7 (![]() $A=0.4$,

$A=0.4$, ![]() $l_s^+=17$).

$l_s^+=17$).

Figure 3. Contours of the instantaneous inner-scaled streamwise velocity ![]() $u^{+}$ in the meridional plane for Case 7 (

$u^{+}$ in the meridional plane for Case 7 (![]() $A=0.4$,

$A=0.4$, ![]() $l_s^+=17$) at (a)

$l_s^+=17$) at (a) ![]() $\varphi \approx 0$, (b)

$\varphi \approx 0$, (b) ![]() $\varphi \approx {\rm \pi}/4$, (c)

$\varphi \approx {\rm \pi}/4$, (c) ![]() $\varphi \approx {\rm \pi}/2$, (d)

$\varphi \approx {\rm \pi}/2$, (d) ![]() $\varphi \approx 3{\rm \pi} /4$.

$\varphi \approx 3{\rm \pi} /4$.

3. Fundamental characteristics of pulsatile flow

First, we present some basic properties of the pulsatile pipe flow. Figure 4(a) shows the oscillating component of the streamwise velocity at the pipe centreline ![]() $\tilde {u}_{cl}$. As expected, the oscillating amplitudes for high-frequency cases (Cases 2 and 3) are exactly

$\tilde {u}_{cl}$. As expected, the oscillating amplitudes for high-frequency cases (Cases 2 and 3) are exactly ![]() $A=0.1$, while they are slightly larger than 0.1 for low-frequency cases (Cases 4 and 5). This is due to the strong coupling of the near-wall shear layer and the central region for low-frequency cases (Weng et al. Reference Weng, Boij and Hanifi2016). A similar phenomenon can also be found for higher amplitude cases where the centreline velocity oscillates at an amplitude larger than 0.4 for Case 7. Figure 4(b,c) shows the wall-normal profiles of the normalized mean velocity

$A=0.1$, while they are slightly larger than 0.1 for low-frequency cases (Cases 4 and 5). This is due to the strong coupling of the near-wall shear layer and the central region for low-frequency cases (Weng et al. Reference Weng, Boij and Hanifi2016). A similar phenomenon can also be found for higher amplitude cases where the centreline velocity oscillates at an amplitude larger than 0.4 for Case 7. Figure 4(b,c) shows the wall-normal profiles of the normalized mean velocity ![]() $\bar {u}$ and the components of the Reynolds stress tensor. The mean velocity is insensitive to the frequency at a low amplitude of

$\bar {u}$ and the components of the Reynolds stress tensor. The mean velocity is insensitive to the frequency at a low amplitude of ![]() $A=0.1$, but an increase in amplitude leads to the elevation of

$A=0.1$, but an increase in amplitude leads to the elevation of ![]() $\bar {u}$ in the log region. This is consistent with previous studies (Scotti & Piomelli Reference Scotti and Piomelli2001; Manna et al. Reference Manna, Vacca and Verzicco2012). In addition, the mean velocity seems to be more sensitive to the frequency for high-amplitude cases. For the presented Reynolds stresses, all the curves collapse well except for that of

$\bar {u}$ in the log region. This is consistent with previous studies (Scotti & Piomelli Reference Scotti and Piomelli2001; Manna et al. Reference Manna, Vacca and Verzicco2012). In addition, the mean velocity seems to be more sensitive to the frequency for high-amplitude cases. For the presented Reynolds stresses, all the curves collapse well except for that of ![]() $\overline {u'u'}$. The increase of amplitude produces a larger magnitude of

$\overline {u'u'}$. The increase of amplitude produces a larger magnitude of ![]() $\overline {u'u'}$ beyond

$\overline {u'u'}$ beyond ![]() $y^+\approx 10$, and

$y^+\approx 10$, and ![]() $\overline {u'u'}$ is insensitive to the frequency for low-amplitude cases. Furthermore, the increase of

$\overline {u'u'}$ is insensitive to the frequency for low-amplitude cases. Furthermore, the increase of ![]() $\overline {u'u'}$ is accompanied by the wall-normal location of the maximum

$\overline {u'u'}$ is accompanied by the wall-normal location of the maximum ![]() $\overline {u'u'}$ moving away from the wall, which is similar to the situation where a transverse Stokes layer is generated by the wall oscillation (Quadrio & Sibilla Reference Quadrio and Sibilla2000; Liu et al. Reference Liu, Zhu, Bao, Zhou and Han2022).

$\overline {u'u'}$ moving away from the wall, which is similar to the situation where a transverse Stokes layer is generated by the wall oscillation (Quadrio & Sibilla Reference Quadrio and Sibilla2000; Liu et al. Reference Liu, Zhu, Bao, Zhou and Han2022).

Figure 4. (a) Time evolution of the oscillating component of the streamwise velocity ![]() $\tilde {u}_{cl}$ at the pipe centreline. (b) Wall-normal profiles of the mean streamwise velocity

$\tilde {u}_{cl}$ at the pipe centreline. (b) Wall-normal profiles of the mean streamwise velocity ![]() $\bar {u}^{+}$. (c) Wall-normal profiles of the components of the Reynolds stress tensor. Note that the curves for the steady pipe (no pulsation) overlap completely with those for Case 2 in panel (b,c).

$\bar {u}^{+}$. (c) Wall-normal profiles of the components of the Reynolds stress tensor. Note that the curves for the steady pipe (no pulsation) overlap completely with those for Case 2 in panel (b,c).

The near-wall flow dynamics is directly reflected by the wall shear stress. Figure 5 compares the phase-wise variation of the wall shear stress ![]() $\widetilde {\tau _w}$ (black solid lines) with their corresponding laminar Stokes values (dashed blue lines) for cases with

$\widetilde {\tau _w}$ (black solid lines) with their corresponding laminar Stokes values (dashed blue lines) for cases with ![]() $A=0.1$, with the latter calculated by evaluating the radial derivative of the laminar Stokes solution at the wall (see Manna et al. Reference Manna, Vacca and Verzicco2012):

$A=0.1$, with the latter calculated by evaluating the radial derivative of the laminar Stokes solution at the wall (see Manna et al. Reference Manna, Vacca and Verzicco2012):

\begin{equation} \tilde{u}(r,t) = A\,{\cdot}\, {\rm Re} \left[{\rm i}\left(\frac{{{{\rm J}_0}({{\rm i}^{3/2}}\sqrt 2 r/{l_s})}}{{{{\rm J}_0}({{\rm i}^{3/2}}\sqrt 2 R/{l_s})}} - 1\right){{\rm e}^{{\rm i}\omega (t - T/4)}}\right], \end{equation}

\begin{equation} \tilde{u}(r,t) = A\,{\cdot}\, {\rm Re} \left[{\rm i}\left(\frac{{{{\rm J}_0}({{\rm i}^{3/2}}\sqrt 2 r/{l_s})}}{{{{\rm J}_0}({{\rm i}^{3/2}}\sqrt 2 R/{l_s})}} - 1\right){{\rm e}^{{\rm i}\omega (t - T/4)}}\right], \end{equation}

where ![]() ${\rm J}_{0}$ is the Bessel function of the first kind of order zero, Re[

${\rm J}_{0}$ is the Bessel function of the first kind of order zero, Re[![]() $\,{\cdot}\,$] represents the real part of the argument,

$\,{\cdot}\,$] represents the real part of the argument, ![]() ${\rm i}$ is the imaginary unit and

${\rm i}$ is the imaginary unit and ![]() $T$ is the pulsation period. Also included is the corresponding fundamental mode obtained from the Fourier analysis (red solid lines), which allows us to evaluate qualitatively the extent of the nonlinear effect due to the turbulence. For a better presentation of the variation tendency, the data are duplicated and then spliced such that two periods are shown.

$T$ is the pulsation period. Also included is the corresponding fundamental mode obtained from the Fourier analysis (red solid lines), which allows us to evaluate qualitatively the extent of the nonlinear effect due to the turbulence. For a better presentation of the variation tendency, the data are duplicated and then spliced such that two periods are shown.

Figure 5. Phase-wise variations of the oscillating component of the wall shear stress ![]() $\widetilde {\tau _w}$ for

$\widetilde {\tau _w}$ for ![]() $A=0.1$ (the black lines), with the corresponding fundamental Fourier mode represented by the red solid lines. The blue dashed lines correspond to the laminar Stokes solution. The vertical arrows denote the phases where the phase-averaged wall shear stress

$A=0.1$ (the black lines), with the corresponding fundamental Fourier mode represented by the red solid lines. The blue dashed lines correspond to the laminar Stokes solution. The vertical arrows denote the phases where the phase-averaged wall shear stress ![]() $\langle \tau _w \rangle$ reaches its maximum or minimum. (a) Case 1; (b) Case 2; (c) Case 3; (d) Case 4; (e) Case 5.

$\langle \tau _w \rangle$ reaches its maximum or minimum. (a) Case 1; (b) Case 2; (c) Case 3; (d) Case 4; (e) Case 5.

For Case 1, the three curves overlap completely, indicating a quasi-laminar flow state. The phase-wise variation of the wall shear stress follows a purely sinusoidal pattern (figure 5a). A mild increase in frequency leads to the subtle departure from the laminar Stokes value and the decrease of ![]() $A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ from unity for Case 2 (figure 5b). For Case 3, it is clear that the amplitude of the wall shear stress is significantly smaller than its laminar value but they still synchronize in phase. The differences between the wall shear stress and its fundamental mode are subtle, suggesting that the phase symmetry still holds. Considerable changes occur for Case 4. As seen, the wall shear stress deviates significantly from its fundamental mode. The drag-increasing phase occupies for a longer portion of the cycle than the drag-decreasing phase. That is, a hysteresis occurs during the oscillation cycle, indicating the destruction of the phase symmetry. Interestingly, when approaching the maxima, the increasing rate decreases, leading to a stage of the high-level wall shear stress with a slow growth. Similar phenomena have also been reported experimentally by Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018b), where up to 500 cycles of measurements have been performed to obtain the phase-averaged wall shear stress at a higher amplitude and Reynolds number. Nevertheless, their data still suffer from fluctuations due to measurement uncertainties. Chen et al. (Reference Chen, Chan, Hutchins, Poon and Ooi2014) also reported the same tendency for similar pulsation parameters, but their data were obtained only from the final period. In the present study, the sufficient number of averaging periods and the spatial average in homogeneous directions ensure the smoothness of the phase-averaged statistics. In addition, the wall shear stress lags behind the laminar value, which does not occur in the former cases. This discrepancy and the physical meaning of this phase lag will be discussed in § 5. For the smallest frequency considered (Case 5), the deviations from the fundamental mode are still observable and the hysteresis is less evident but discernable. A phase lag with respect to the laminar value can also be observed. Theoretically, if the frequency is small enough to reach the quasi-steady state, all three curves should be in phase with the sinusoidally varying pressure gradient, and no hysteresis occurs. Hence, it can be inferred that as the frequency increases from zero, the aforementioned phase lag and hysteresis emerge initially and then disappear gradually.

$A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ from unity for Case 2 (figure 5b). For Case 3, it is clear that the amplitude of the wall shear stress is significantly smaller than its laminar value but they still synchronize in phase. The differences between the wall shear stress and its fundamental mode are subtle, suggesting that the phase symmetry still holds. Considerable changes occur for Case 4. As seen, the wall shear stress deviates significantly from its fundamental mode. The drag-increasing phase occupies for a longer portion of the cycle than the drag-decreasing phase. That is, a hysteresis occurs during the oscillation cycle, indicating the destruction of the phase symmetry. Interestingly, when approaching the maxima, the increasing rate decreases, leading to a stage of the high-level wall shear stress with a slow growth. Similar phenomena have also been reported experimentally by Sundstrom & Cervantes (Reference Sundstrom and Cervantes2018b), where up to 500 cycles of measurements have been performed to obtain the phase-averaged wall shear stress at a higher amplitude and Reynolds number. Nevertheless, their data still suffer from fluctuations due to measurement uncertainties. Chen et al. (Reference Chen, Chan, Hutchins, Poon and Ooi2014) also reported the same tendency for similar pulsation parameters, but their data were obtained only from the final period. In the present study, the sufficient number of averaging periods and the spatial average in homogeneous directions ensure the smoothness of the phase-averaged statistics. In addition, the wall shear stress lags behind the laminar value, which does not occur in the former cases. This discrepancy and the physical meaning of this phase lag will be discussed in § 5. For the smallest frequency considered (Case 5), the deviations from the fundamental mode are still observable and the hysteresis is less evident but discernable. A phase lag with respect to the laminar value can also be observed. Theoretically, if the frequency is small enough to reach the quasi-steady state, all three curves should be in phase with the sinusoidally varying pressure gradient, and no hysteresis occurs. Hence, it can be inferred that as the frequency increases from zero, the aforementioned phase lag and hysteresis emerge initially and then disappear gradually.

Figure 6 shows the phase-wise variation of the wall shear stress for cases with ![]() $A=0.4$. A reduction of the amplitudes compared with the corresponding laminar value is still observable. Specifically,

$A=0.4$. A reduction of the amplitudes compared with the corresponding laminar value is still observable. Specifically, ![]() $A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ increases from 0.65 to 0.8 as the amplitude increases from 0.1 to 0.4 for

$A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ increases from 0.65 to 0.8 as the amplitude increases from 0.1 to 0.4 for ![]() $l_s^+=14$, while it decreases from 0.86 to 0.59 for

$l_s^+=14$, while it decreases from 0.86 to 0.59 for ![]() $l_s^+=17$. For Case 6, a distinct deviation from the fundamental mode occurs when the wall shear stress reaches its minimum (negative peak of

$l_s^+=17$. For Case 6, a distinct deviation from the fundamental mode occurs when the wall shear stress reaches its minimum (negative peak of ![]() $\widetilde {\tau _w}$), which implies a strong nonlinear effect of turbulence at that phase. Same as that for

$\widetilde {\tau _w}$), which implies a strong nonlinear effect of turbulence at that phase. Same as that for ![]() $A=0.1$, the wall shear stress is still in phase with the laminar value. For Case 7, a distinct kink can be clearly observed at around the phase of

$A=0.1$, the wall shear stress is still in phase with the laminar value. For Case 7, a distinct kink can be clearly observed at around the phase of ![]() $t=3T/4$. We note that both Tu & Ramaprian (Reference Tu and Ramaprian1983) and Scotti & Piomelli (Reference Scotti and Piomelli2001) reported such a kink, but the causes are still unclear. Such a kink also implies special turbulence dynamics and will be discussed in detail in § 6. The fundamental mode lags behind the laminar value, consistent with that for

$t=3T/4$. We note that both Tu & Ramaprian (Reference Tu and Ramaprian1983) and Scotti & Piomelli (Reference Scotti and Piomelli2001) reported such a kink, but the causes are still unclear. Such a kink also implies special turbulence dynamics and will be discussed in detail in § 6. The fundamental mode lags behind the laminar value, consistent with that for ![]() $A=0.1$. It is worth noting that we only consider a higher amplitude at two intermediate frequencies. In fact, increasing the amplitude will not change the quasi-laminar state for high-frequency cases (e.g. Cases 1 and 2), hence their wall shear stresses are expected to still follow the laminar solution; while for a low-frequency case where the quasi-steady state is reached, a higher pulsation amplitude leads to a higher amplitude of the wall shear stress, but the variation trend would still follow a sinusoidal manner. Case 5 can be considered as a transition case for which the flow state is closer to the quasi-steady state. The hysteresis phenomenon at the frequency of Case 5 with a higher amplitude is probably not evident. Thus, behaviours of the wall shear stress for cases with high or low frequencies are somewhat predictable, which is the reason for considering only these two frequencies with a higher amplitude.

$A=0.1$. It is worth noting that we only consider a higher amplitude at two intermediate frequencies. In fact, increasing the amplitude will not change the quasi-laminar state for high-frequency cases (e.g. Cases 1 and 2), hence their wall shear stresses are expected to still follow the laminar solution; while for a low-frequency case where the quasi-steady state is reached, a higher pulsation amplitude leads to a higher amplitude of the wall shear stress, but the variation trend would still follow a sinusoidal manner. Case 5 can be considered as a transition case for which the flow state is closer to the quasi-steady state. The hysteresis phenomenon at the frequency of Case 5 with a higher amplitude is probably not evident. Thus, behaviours of the wall shear stress for cases with high or low frequencies are somewhat predictable, which is the reason for considering only these two frequencies with a higher amplitude.

Figure 6. Phase-wise variations of the oscillating component of the wall shear stress ![]() $\widetilde {\tau _w}$ for

$\widetilde {\tau _w}$ for ![]() $A=0.4$ (the black lines), with the corresponding fundamental Fourier mode represented by the red solid lines. The blue dashed lines correspond to the laminar Stokes solution. The vertical arrows denote the phases where the phase-averaged wall shear stress

$A=0.4$ (the black lines), with the corresponding fundamental Fourier mode represented by the red solid lines. The blue dashed lines correspond to the laminar Stokes solution. The vertical arrows denote the phases where the phase-averaged wall shear stress ![]() $\langle \tau _w \rangle$ reaches its maximum or minimum. (a) Case 6; (b) Case 7.

$\langle \tau _w \rangle$ reaches its maximum or minimum. (a) Case 6; (b) Case 7.

In this section, we provide a general description of the pulsatile pipe flow, with a focus on the phase-wise variation of the wall shear stress. Different combinations of the pulsation parameters lead to significantly different behaviours of ![]() $\widetilde {\tau _w}$. In the following sections, we aim to explore the causes of such differences and the corresponding flow dynamics based on (2.4) since

$\widetilde {\tau _w}$. In the following sections, we aim to explore the causes of such differences and the corresponding flow dynamics based on (2.4) since ![]() $\widetilde {\tau _w}$ correlates closely to

$\widetilde {\tau _w}$ correlates closely to ![]() $\tilde {u}$ near the wall.

$\tilde {u}$ near the wall.

4. Damping mechanisms of the oscillating wall shear stress

We focus on Case 3, for which the ratio ![]() $A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ reaches its minimum, to elucidate the mechanisms that lead to the amplitude reduction of the oscillating wall shear stress (

$A_{\widetilde {\tau _{w}},t}/A_{\widetilde {\tau _{w}},s}$ reaches its minimum, to elucidate the mechanisms that lead to the amplitude reduction of the oscillating wall shear stress (![]() $\widetilde {\tau _w}$) in the turbulent state compared with its corresponding laminar value.

$\widetilde {\tau _w}$) in the turbulent state compared with its corresponding laminar value.

The phase-wise variation of ![]() $\tilde {u}$ for Case 3 is shown in figure 7(b), together with its laminar value calculated from (3.1) shown in figure 7(a). As seen, the most dramatic difference resides in the near-wall region; namely, below

$\tilde {u}$ for Case 3 is shown in figure 7(b), together with its laminar value calculated from (3.1) shown in figure 7(a). As seen, the most dramatic difference resides in the near-wall region; namely, below ![]() $y^+\approx 20$, the laminar contour appears to be more distorted than that in the turbulent case in that region. By examining the contour values, it can be observed that the amplitude of the oscillating

$y^+\approx 20$, the laminar contour appears to be more distorted than that in the turbulent case in that region. By examining the contour values, it can be observed that the amplitude of the oscillating ![]() $\tilde {u}$ is smaller in the turbulent case, corresponding to the smaller amplitude of

$\tilde {u}$ is smaller in the turbulent case, corresponding to the smaller amplitude of ![]() $\widetilde {\tau _w}$ shown in figure 5(c). In the outer layer, the laminar and turbulent cases behave almost the same. According to (2.4), the key term that the laminar equation lacks is the weighted radial derivative of the Reynolds shear stress

$\widetilde {\tau _w}$ shown in figure 5(c). In the outer layer, the laminar and turbulent cases behave almost the same. According to (2.4), the key term that the laminar equation lacks is the weighted radial derivative of the Reynolds shear stress ![]() $\widetilde {u'v'}$ (Sundstrom & Cervantes Reference Sundstrom and Cervantes2018c), which we denote as

$\widetilde {u'v'}$ (Sundstrom & Cervantes Reference Sundstrom and Cervantes2018c), which we denote as ![]() $\wp$. This term can be further decomposed into the derivative term

$\wp$. This term can be further decomposed into the derivative term ![]() $-\partial \widetilde {u'v'}/\partial r$ and the curvature term

$-\partial \widetilde {u'v'}/\partial r$ and the curvature term ![]() $-\widetilde {u'v'}/r$, for which the latter is generally negligible compared with the former in the near-wall region. Hence, we examine the phase-wise variation of

$-\widetilde {u'v'}/r$, for which the latter is generally negligible compared with the former in the near-wall region. Hence, we examine the phase-wise variation of ![]() $\widetilde {u'v'}$ in figure 7(c). Importantly, there is a phase lag between

$\widetilde {u'v'}$ in figure 7(c). Importantly, there is a phase lag between ![]() $\widetilde {u'v'}$ and

$\widetilde {u'v'}$ and ![]() $\tilde {u}$ such that the positive and negative peaks of

$\tilde {u}$ such that the positive and negative peaks of ![]() $\widetilde {u'v'}$ are reached when

$\widetilde {u'v'}$ are reached when ![]() $\vert \partial \tilde {u}/\partial t \rvert$ reaches its maximum (the regions between the blue and red contours). Evidently, the term

$\vert \partial \tilde {u}/\partial t \rvert$ reaches its maximum (the regions between the blue and red contours). Evidently, the term ![]() $\wp$ is prominent below the blue and red contours, as shown by the magenta contours in figure 7(c). For negative

$\wp$ is prominent below the blue and red contours, as shown by the magenta contours in figure 7(c). For negative ![]() $\widetilde {u'v'}$ (blue region, at

$\widetilde {u'v'}$ (blue region, at ![]() $t\approx T/4$), the radial derivative of

$t\approx T/4$), the radial derivative of ![]() $\widetilde {u'v'}$ near the wall is positive, hence the term

$\widetilde {u'v'}$ near the wall is positive, hence the term ![]() $\wp$ acts as a sink term that leads to a reduction of the positive acceleration

$\wp$ acts as a sink term that leads to a reduction of the positive acceleration ![]() $\partial \tilde {u}/\partial t$. Similarly, for positive

$\partial \tilde {u}/\partial t$. Similarly, for positive ![]() $\widetilde {u'v'}$ (red region, at

$\widetilde {u'v'}$ (red region, at ![]() $t\approx 3T/4$), the term

$t\approx 3T/4$), the term ![]() $\wp$ contributes positively to the negative

$\wp$ contributes positively to the negative ![]() $\partial \tilde {u}/\partial t$. Thus, in the turbulent case, the acceleration and deceleration of

$\partial \tilde {u}/\partial t$. Thus, in the turbulent case, the acceleration and deceleration of ![]() $\tilde {u}$ in the near-wall region are both damped by term

$\tilde {u}$ in the near-wall region are both damped by term ![]() $\wp$ compared with its laminar value, therefore causing the reduction of the amplitude of

$\wp$ compared with its laminar value, therefore causing the reduction of the amplitude of ![]() $\tilde {u}$ and then the wall shear stress. It is noted that in the near-wall region of a steady fully developed turbulent pipe flow,

$\tilde {u}$ and then the wall shear stress. It is noted that in the near-wall region of a steady fully developed turbulent pipe flow, ![]() $-{\rm d}\overline {u'v'}/{\rm d}r$ acts as a gain term in the

$-{\rm d}\overline {u'v'}/{\rm d}r$ acts as a gain term in the ![]() $\bar {u}$ transport equation and hence contributes positively to the mean velocity (

$\bar {u}$ transport equation and hence contributes positively to the mean velocity (![]() $-\overline {u'v'}/r$ is comparatively negligible) (Wu & Moin Reference Wu and Moin2008). Thus, the effect of turbulence is reversed by the imposed unsteadiness. It should also be noted that the temporal variation of

$-\overline {u'v'}/r$ is comparatively negligible) (Wu & Moin Reference Wu and Moin2008). Thus, the effect of turbulence is reversed by the imposed unsteadiness. It should also be noted that the temporal variation of ![]() $\widetilde {u'v'}$ is not strictly sinusoidal, i.e. the time span of the blue contour is not strictly the same as that of the red contour, and the same goes for the following contours. This coincides with the fact that the wall shear stress deviates slightly from its fundamental mode as shown in figure 5(c).

$\widetilde {u'v'}$ is not strictly sinusoidal, i.e. the time span of the blue contour is not strictly the same as that of the red contour, and the same goes for the following contours. This coincides with the fact that the wall shear stress deviates slightly from its fundamental mode as shown in figure 5(c).

Figure 7. Phase-wise variations of (a) the laminar Stokes velocity ![]() $\tilde {u}^{+}$, (b) the turbulent streamwise velocity

$\tilde {u}^{+}$, (b) the turbulent streamwise velocity ![]() $\tilde {u}^{+}$ and (c) the Reynolds shear stress

$\tilde {u}^{+}$ and (c) the Reynolds shear stress ![]() $\widetilde {u'v'}^{+}$ for Case 3 (

$\widetilde {u'v'}^{+}$ for Case 3 (![]() $A=0.1$,

$A=0.1$, ![]() $l_s^+=14$). The magenta contours in panel (c) represent the term

$l_s^+=14$). The magenta contours in panel (c) represent the term ![]() $\wp$, with the values (divided by

$\wp$, with the values (divided by ![]() $10^{-3}$) marked on the contour lines. The magenta dash-dotted straight line indicates the laminar Stokes thickness of

$10^{-3}$) marked on the contour lines. The magenta dash-dotted straight line indicates the laminar Stokes thickness of ![]() $l_s^{+}=14$.

$l_s^{+}=14$.

Apparently, it is the phase lag between ![]() $\tilde {u}$ and

$\tilde {u}$ and ![]() $\widetilde {u'v'}$ that causes the nearly antiphase variation between the term

$\widetilde {u'v'}$ that causes the nearly antiphase variation between the term ![]() $\wp$ and

$\wp$ and ![]() $\partial \tilde {u}/\partial t$, leading to the subsequent reduction of the amplitude of

$\partial \tilde {u}/\partial t$, leading to the subsequent reduction of the amplitude of ![]() $\widetilde {\tau _w}$. To further understand the origin of such a phase lag, we examine the phase-wise variations of

$\widetilde {\tau _w}$. To further understand the origin of such a phase lag, we examine the phase-wise variations of ![]() $\widetilde {u'u'}$,

$\widetilde {u'u'}$, ![]() $\widetilde {v'v'}$ and the production terms of

$\widetilde {v'v'}$ and the production terms of ![]() $\widetilde {u'u'}$ and

$\widetilde {u'u'}$ and ![]() $\widetilde {u'v'}$ (shown in figure 8):

$\widetilde {u'v'}$ (shown in figure 8):

\begin{gather} P_{\widetilde{u'u'}}=\underbrace{-\overline{u'v'}\frac{\partial \tilde{u} }{\partial r}}_{P_{uu,1}} \underbrace{ -\widetilde{u'v'}\frac{\partial \bar{u} }{\partial r}}_{P_{uu,2}} \underbrace{ -\left(\widetilde{u'v'}\frac{\partial \tilde{u} }{\partial r}-\overline{\widetilde{u'v'}\frac{\partial \tilde{u} }{\partial r}} \right)}_{P_{uu,3}}, \end{gather}

\begin{gather} P_{\widetilde{u'u'}}=\underbrace{-\overline{u'v'}\frac{\partial \tilde{u} }{\partial r}}_{P_{uu,1}} \underbrace{ -\widetilde{u'v'}\frac{\partial \bar{u} }{\partial r}}_{P_{uu,2}} \underbrace{ -\left(\widetilde{u'v'}\frac{\partial \tilde{u} }{\partial r}-\overline{\widetilde{u'v'}\frac{\partial \tilde{u} }{\partial r}} \right)}_{P_{uu,3}}, \end{gather} \begin{gather} P_{\widetilde{u'v'}}=\underbrace{-\overline{v'v'}\frac{\partial \tilde{u} }{\partial r}}_{P_{uv,1}} \underbrace{ -\widetilde{v'v'}\frac{\partial \bar{u} }{\partial r}}_{P_{uv,2}} \underbrace{ -\left(\widetilde{v'v'}\frac{\partial \tilde{u} }{\partial r}-\overline{\widetilde{v'v'}\frac{\partial \tilde{u} }{\partial r}} \right)}_{P_{uv,3}}. \end{gather}

\begin{gather} P_{\widetilde{u'v'}}=\underbrace{-\overline{v'v'}\frac{\partial \tilde{u} }{\partial r}}_{P_{uv,1}} \underbrace{ -\widetilde{v'v'}\frac{\partial \bar{u} }{\partial r}}_{P_{uv,2}} \underbrace{ -\left(\widetilde{v'v'}\frac{\partial \tilde{u} }{\partial r}-\overline{\widetilde{v'v'}\frac{\partial \tilde{u} }{\partial r}} \right)}_{P_{uv,3}}. \end{gather}

These quantities are closely correlated as ![]() $\widetilde {v'v'}$ dictates the production terms of

$\widetilde {v'v'}$ dictates the production terms of ![]() $\widetilde {u'v'}$;

$\widetilde {u'v'}$; ![]() $\widetilde {u'v'}$ dictates the production terms of

$\widetilde {u'v'}$ dictates the production terms of ![]() $\widetilde {u'u'}$, and the energy redistribution from

$\widetilde {u'u'}$, and the energy redistribution from ![]() $\widetilde {u'u'}$ directly feeds energy into

$\widetilde {u'u'}$ directly feeds energy into ![]() $\widetilde {v'v'}$. In addition, the laminar Stokes thickness

$\widetilde {v'v'}$. In addition, the laminar Stokes thickness ![]() $l_s^+=14$ (magenta dash-dotted line) is included to mark the edge of the laminar Stokes layer.

$l_s^+=14$ (magenta dash-dotted line) is included to mark the edge of the laminar Stokes layer.

Figure 8. Phase-wise variations of (a) the streamwise Reynolds normal stress ![]() $\widetilde {u'u'}^+$ and (b) the radial Reynolds normal stress

$\widetilde {u'u'}^+$ and (b) the radial Reynolds normal stress ![]() $\widetilde {v'v'}^+$ for Case 3 (

$\widetilde {v'v'}^+$ for Case 3 (![]() $A=0.1$,

$A=0.1$, ![]() $l_s^+=14$). Phase-wise variations of the production terms in (4.1) for Case 3 (

$l_s^+=14$). Phase-wise variations of the production terms in (4.1) for Case 3 (![]() $A=0.1$,

$A=0.1$, ![]() $l_s^+=14$): (c)

$l_s^+=14$): (c) ![]() $P_{uu,1}^+$, (e)

$P_{uu,1}^+$, (e) ![]() $P_{uu,2}^+$, (g)

$P_{uu,2}^+$, (g) ![]() $P_{uu,3}^+$, (d)

$P_{uu,3}^+$, (d) ![]() $P_{uv,1}^+$, (f)

$P_{uv,1}^+$, (f) ![]() $P_{uv,2}^+$, (h)

$P_{uv,2}^+$, (h) ![]() $P_{uv,3}^+$. The magenta dash-dotted lines indicate the laminar Stokes thickness of

$P_{uv,3}^+$. The magenta dash-dotted lines indicate the laminar Stokes thickness of ![]() $l_s^{+}=14$.

$l_s^{+}=14$.

The phase-wise variation of ![]() $\widetilde {u'u'}$ is well correlated with

$\widetilde {u'u'}$ is well correlated with ![]() $\tilde {u}$, with the latter leading by a small phase margin. Since the streamwise velocity fluctuation is directly linked to the near-wall streak, this phase lag reflects the inertial effect of the turbulence structure. Here, the contour only gives the information regarding the intensity of near-wall streaks. It will be shown later by the spectrum analysis that the increase of

$\tilde {u}$, with the latter leading by a small phase margin. Since the streamwise velocity fluctuation is directly linked to the near-wall streak, this phase lag reflects the inertial effect of the turbulence structure. Here, the contour only gives the information regarding the intensity of near-wall streaks. It will be shown later by the spectrum analysis that the increase of ![]() $\widetilde {u'u'}$ is also accompanied by the elongation of near-wall streaks. The shear-strain-oscillated production

$\widetilde {u'u'}$ is also accompanied by the elongation of near-wall streaks. The shear-strain-oscillated production ![]() $P_{uu,1}$ leads

$P_{uu,1}$ leads ![]() $\widetilde {u'u'}$ in phase and the wall-normal location of the maximum coincides with that of

$\widetilde {u'u'}$ in phase and the wall-normal location of the maximum coincides with that of ![]() $\widetilde {u'u'}$. The Reynolds-stress-oscillated production

$\widetilde {u'u'}$. The Reynolds-stress-oscillated production ![]() $P_{uu,2}$ peaks inside the Stokes layer, and its magnitude is larger than

$P_{uu,2}$ peaks inside the Stokes layer, and its magnitude is larger than ![]() $P_{uu,1}$. Thus, the main portion of the near-wall streak is dominated by the oscillating shear strain rate through

$P_{uu,1}$. Thus, the main portion of the near-wall streak is dominated by the oscillating shear strain rate through ![]() $P_{uu,1}$, with the phase lag corresponding to the delayed development of the streak. Here,

$P_{uu,1}$, with the phase lag corresponding to the delayed development of the streak. Here, ![]() $P_{uu,2}$ is in phase with

$P_{uu,2}$ is in phase with ![]() $\widetilde {u'v'}$ and therefore responsible for the distortion of

$\widetilde {u'v'}$ and therefore responsible for the distortion of ![]() $\widetilde {u'u'}$ contour within the Stokes layer. The phase-wise variation of

$\widetilde {u'u'}$ contour within the Stokes layer. The phase-wise variation of ![]() $\widetilde {v'v'}$ further lags behind

$\widetilde {v'v'}$ further lags behind ![]() $\widetilde {u'u'}$; it reaches a positive (negative) peak during the deceleration (acceleration) phase of

$\widetilde {u'u'}$; it reaches a positive (negative) peak during the deceleration (acceleration) phase of ![]() $\tilde {u}$. The production terms

$\tilde {u}$. The production terms ![]() $P_{uv,1}$ and

$P_{uv,1}$ and ![]() $P_{uv,2}$ both peak outside the Stokes layer, but

$P_{uv,2}$ both peak outside the Stokes layer, but ![]() $P_{uv,2}$ is more correlated with

$P_{uv,2}$ is more correlated with ![]() $\widetilde {u'v'}$ and its magnitude is larger than

$\widetilde {u'v'}$ and its magnitude is larger than ![]() $P_{uv,1}$. Thus, it can be inferred that the variation of

$P_{uv,1}$. Thus, it can be inferred that the variation of ![]() $\widetilde {u'v'}$ is dominated by

$\widetilde {u'v'}$ is dominated by ![]() $\widetilde {v'v'}$ rather than the oscillating shear strain rate, but the existence of

$\widetilde {v'v'}$ rather than the oscillating shear strain rate, but the existence of ![]() $P_{uv,1}$ makes the

$P_{uv,1}$ makes the ![]() $\widetilde {u'v'}$ lead

$\widetilde {u'v'}$ lead ![]() $\widetilde {v'v'}$ by a small phase margin. The phase lag between

$\widetilde {v'v'}$ by a small phase margin. The phase lag between ![]() $\widetilde {v'v'}$ and

$\widetilde {v'v'}$ and ![]() $\widetilde {u'u'}$ indicates the energy redistribution from

$\widetilde {u'u'}$ indicates the energy redistribution from ![]() $\widetilde {u'u'}$ to

$\widetilde {u'u'}$ to ![]() $\widetilde {v'v'}$ (the same goes for

$\widetilde {v'v'}$ (the same goes for ![]() $\widetilde {w'w'}$, not shown here. The variation of

$\widetilde {w'w'}$, not shown here. The variation of ![]() $\widetilde {w'w'}$ is in phase with

$\widetilde {w'w'}$ is in phase with ![]() $\widetilde {v'v'}$). Moreover, the magnitude of

$\widetilde {v'v'}$). Moreover, the magnitude of ![]() $\widetilde {u'u'}$ is one order of magnitude larger than

$\widetilde {u'u'}$ is one order of magnitude larger than ![]() $\widetilde {v'v'}$ and

$\widetilde {v'v'}$ and ![]() $\widetilde {w'w'}$. The reduction of the energy of

$\widetilde {w'w'}$. The reduction of the energy of ![]() $\widetilde {u'u'}$ does not match the total energy gain of

$\widetilde {u'u'}$ does not match the total energy gain of ![]() $\widetilde {v'v'}$ and

$\widetilde {v'v'}$ and ![]() $\widetilde {w'w'}$, which implies that there must be significant dissipation of the turbulent kinetic energy (TKE) during the deceleration phase of

$\widetilde {w'w'}$, which implies that there must be significant dissipation of the turbulent kinetic energy (TKE) during the deceleration phase of ![]() $\tilde {u}$ as confirmed in figure 9. It should be noted that the nonlinear production terms

$\tilde {u}$ as confirmed in figure 9. It should be noted that the nonlinear production terms ![]() $P_{uu,3}$ and

$P_{uu,3}$ and ![]() $P_{uv,3}$ are both negligible compared with the other linear production terms.

$P_{uv,3}$ are both negligible compared with the other linear production terms.

Figure 9. Phase-wise variation of the dissipation rate ![]() $\widetilde {\varepsilon ^+}$ of the TKE

$\widetilde {\varepsilon ^+}$ of the TKE ![]() $k=\overline {u'_{i}u'_{i}}$ (

$k=\overline {u'_{i}u'_{i}}$ (![]() $i=1,2,3$) for Case 3 (

$i=1,2,3$) for Case 3 (![]() $A=0.1$,

$A=0.1$, ![]() $l_s^+=14$). Note that the time-averaged dissipation rate

$l_s^+=14$). Note that the time-averaged dissipation rate ![]() $\overline {\varepsilon ^+}$ is negative, thus a negative value of the oscillating component indicates the enhanced dissipation rate. For the definition of

$\overline {\varepsilon ^+}$ is negative, thus a negative value of the oscillating component indicates the enhanced dissipation rate. For the definition of ![]() $\widetilde {\varepsilon ^+}$, we refer the reader to Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) for further details.

$\widetilde {\varepsilon ^+}$, we refer the reader to Eggels et al. (Reference Eggels, Unger, Weiss, Westerweel, Adrian, Friedrich and Nieuwstadt1994) for further details.

Based on the information given, we can summarize the flow evolution with a schematic in figure 10. There are two circulations representing the time evolution of ![]() $\widetilde {u'u'}$ and the bulk velocity

$\widetilde {u'u'}$ and the bulk velocity ![]() $U_b$, respectively. The inside of the

$U_b$, respectively. The inside of the ![]() $U_b$ loop corresponds roughly to the inner Stokes layer, while the outside is associated with the region outside the Stokes layer. As shown in figure 8(a), the majority of

$U_b$ loop corresponds roughly to the inner Stokes layer, while the outside is associated with the region outside the Stokes layer. As shown in figure 8(a), the majority of ![]() $\widetilde {u'u'}$ contours are outside the Stokes layer, hence here the