1. Introduction

Instability in stratified multiphase systems is a highly challenging phenomenon that continues to baffle researchers (Chandrasekhar Reference Chandrasekhar1961; Boomkamp & Miesen Reference Boomkamp and Miesen1996). Density and viscosity contrast, interfacial tension (IFT) and large velocity difference have been identified as key driving factors of interfacial instability (Barnea & Taitel Reference Barnea and Taitel1993; Govindarajan & Sahu Reference Govindarajan and Sahu2014). Depending on the mechanism, different types of instabilities are possible: Rayleigh–Taylor instability (Lewis Reference Lewis1950), Rayleigh–Plateau instability (Joseph Reference Joseph1873), Kelvin–Helmholtz (K–H) instability (Barnea & Taitel Reference Barnea and Taitel1993) and Saffman–Taylor instability (Saffman & Taylor Reference Saffman and Taylor1958). Pertinent to our study, for a coflowing multiphase system of two Newtonian, inviscid (![]() $\mu _{1,2} = 0$) and density stratified layers (

$\mu _{1,2} = 0$) and density stratified layers (![]() $\rho _{1} \neq \rho _{2}$) with different velocities (

$\rho _{1} \neq \rho _{2}$) with different velocities (![]() $u_{1} \neq u_{2}$) and a finite IFT (

$u_{1} \neq u_{2}$) and a finite IFT (![]() $\sigma$), K–H instability (Chandrasekhar Reference Chandrasekhar1961) would be present if

$\sigma$), K–H instability (Chandrasekhar Reference Chandrasekhar1961) would be present if ![]() $( u_{1} - u_{2} )^{2} > 2({( \rho _{1} + \rho _{2} )}/{\rho _{1}\rho _{2}} )\sqrt {\sigma g(\rho _{1} - \rho _{2})}$, where

$( u_{1} - u_{2} )^{2} > 2({( \rho _{1} + \rho _{2} )}/{\rho _{1}\rho _{2}} )\sqrt {\sigma g(\rho _{1} - \rho _{2})}$, where ![]() $\mu$,

$\mu$, ![]() $\rho$,

$\rho$, ![]() $u$ and

$u$ and ![]() $\sigma$ are symbols used for dynamic viscosity, density, velocity and IFT, respectively. On the other hand, an otherwise stable Poiseuille/Couette flow can exhibit long-wave instability

$\sigma$ are symbols used for dynamic viscosity, density, velocity and IFT, respectively. On the other hand, an otherwise stable Poiseuille/Couette flow can exhibit long-wave instability ![]() $(\lambda > \sqrt {{\mu }/{\rho \dot {\gamma }}})$ due to viscosity stratification even with negligible inertia (Yih Reference Yih1967), where

$(\lambda > \sqrt {{\mu }/{\rho \dot {\gamma }}})$ due to viscosity stratification even with negligible inertia (Yih Reference Yih1967), where ![]() $\lambda$ and

$\lambda$ and ![]() $\dot {\gamma }$ are symbols used for wavelength and strain rate, respectively. Such instability in multilayer viscous systems has been widely investigated theoretically for shear flow, Poiseuille and core–annular flow configurations (Hinch Reference Hinch1984; Hooper Reference Hooper1985; Hooper & Boyd Reference Hooper and Boyd1987; Hu & Joseph Reference Hu and Joseph1989; Joseph et al. Reference Joseph, Bai, Chen and Renardy1997; Govindarajan & Sahu Reference Govindarajan and Sahu2014). The literature reports a growth rate in semibounded flow (Hooper Reference Hooper1985) with a wall on one side

$\dot {\gamma }$ are symbols used for wavelength and strain rate, respectively. Such instability in multilayer viscous systems has been widely investigated theoretically for shear flow, Poiseuille and core–annular flow configurations (Hinch Reference Hinch1984; Hooper Reference Hooper1985; Hooper & Boyd Reference Hooper and Boyd1987; Hu & Joseph Reference Hu and Joseph1989; Joseph et al. Reference Joseph, Bai, Chen and Renardy1997; Govindarajan & Sahu Reference Govindarajan and Sahu2014). The literature reports a growth rate in semibounded flow (Hooper Reference Hooper1985) with a wall on one side ![]() ${\sim } O (k^{{4}/{3}})$ compared with bounded flows (Yih Reference Yih1967) with walls on both sides

${\sim } O (k^{{4}/{3}})$ compared with bounded flows (Yih Reference Yih1967) with walls on both sides ![]() ${\sim } O (k^{2})$, indicating the stabilizing effect of confinement for long waves with wavenumber,

${\sim } O (k^{2})$, indicating the stabilizing effect of confinement for long waves with wavenumber, ![]() $k \ll 1$. There have been experimental investigations to study the effect of viscosity stratification on instability (Charles & Lilleleht Reference Charles and Lilleleht1965; Kao & Park Reference Kao and Park1970; Khomami & Su Reference Khomami and Su2000). It has also been shown that coflows with a high IFT (

$k \ll 1$. There have been experimental investigations to study the effect of viscosity stratification on instability (Charles & Lilleleht Reference Charles and Lilleleht1965; Kao & Park Reference Kao and Park1970; Khomami & Su Reference Khomami and Su2000). It has also been shown that coflows with a high IFT (![]() $\sigma \approx 30$ mPa-s) operating at a higher Reynolds number (

$\sigma \approx 30$ mPa-s) operating at a higher Reynolds number (![]() $Re = 30$) could lead to bulk mode instability (Kao & Park Reference Kao and Park1970). On the other hand, coflows with a lower IFT (

$Re = 30$) could lead to bulk mode instability (Kao & Park Reference Kao and Park1970). On the other hand, coflows with a lower IFT (![]() $\sigma \approx 10$ mPa-s) exhibit interfacial mode instability, validating the theoretical prediction that lower IFT indeed increases the instability growth rate (Khomami & Su Reference Khomami and Su2000).

$\sigma \approx 10$ mPa-s) exhibit interfacial mode instability, validating the theoretical prediction that lower IFT indeed increases the instability growth rate (Khomami & Su Reference Khomami and Su2000).

Instability in superposed multilayer flows of non-Newtonian fluids has drawn significant attention in the last few decades due to its prevalence in chemical process industries wherein the understanding of instability serves as the window for maintaining a stable interface during the co-extrusion process (Ganpule & Khomami Reference Ganpule and Khomami1999). A few theoretical studies have been conducted with Newtonian and non-Newtonian multilayer flows, wherein non-Newtonian phases are inelastic shear thinning following the power-law model, and Carreau model (Su & Khomani Reference Su and Khomani1991), viscoelastic following the Oldroyd-B model and second-order fluid model (Su & Khomami Reference Su and Khomami1992) or viscoplastic following the Bingham fluid model (Hormozi, Wielage-Burchard & Frigaard Reference Hormozi, Wielage-Burchard and Frigaard2011). These theoretical investigations have revealed that, in such flow configurations, the elasticity jump across the interface alone can initiate instability even in the absence of viscosity contrast and the relative contribution of elasticity stratification (Su & Khomami Reference Su and Khomami1992) is of the same order as that of the viscosity contrast. On the other hand, the shear-thinning nature of fluids acts as an extra production term in disturbance energy analysis (Chekila et al. Reference Chekila, Nouar, Plaut and Nemdili2011; Lashgari et al. Reference Lashgari, Pralits, Giannetti and Brandt2012). However, the propagation of these instabilities along the axial direction is still unclear in the literature. Earlier experiments conducted on a slit die geometry with non-Newtonian fluids indicate an increase in instability with the jump in normal stress across the interface (Su & Khomami Reference Su and Khomami1992; Wilson & Khomami Reference Wilson and Khomami1992). Further, prior works have revealed that, as less viscous and elastic fluid occupies more of the conduit, the interface becomes more unstable (Yiantsios & Higgins Reference Yiantsios and Higgins1988; Su & Khomami Reference Su and Khomami1992; Khomami & Su Reference Khomami and Su2000). The literature suggests that the highest instability growth rate occurs at a non-dimensional wavenumber ![]() ${\sim } O (1)$ with all the lengths non-dimensionalized with the thickness of the fluid layer of higher viscosity. Further, previous studies reveal the encapsulation effect of superposed viscous layers wherein low-viscosity fluid tends to encapsulate the high-viscosity fluid, and the rate of encapsulation increases with increasing viscosity contrast (Lee & White Reference Lee and White1974). A review of the literature shows that most of these experimental studies are conducted on a macro-scale. However, interfacial instabilities involving viscoelastic fluids inside microfluidic confinements, where interfacial effects become predominant, are not well understood.

${\sim } O (1)$ with all the lengths non-dimensionalized with the thickness of the fluid layer of higher viscosity. Further, previous studies reveal the encapsulation effect of superposed viscous layers wherein low-viscosity fluid tends to encapsulate the high-viscosity fluid, and the rate of encapsulation increases with increasing viscosity contrast (Lee & White Reference Lee and White1974). A review of the literature shows that most of these experimental studies are conducted on a macro-scale. However, interfacial instabilities involving viscoelastic fluids inside microfluidic confinements, where interfacial effects become predominant, are not well understood.

Interfacial instability in coflowing fluids inside microfluidic confinement has been investigated in the context of monodispersed droplet generation (Guillot et al. Reference Guillot, Colin, Utada and Ajdari2007; Utada et al. Reference Utada, Fernandez-Nieves, Gordillo and Weitz2008). However, instability in the stratified flow of parallel streams has been rarely investigated (Hu & Cubaud Reference Hu and Cubaud2018; Hazra, Mitra & Sen Reference Hazra, Mitra and Sen2022b; Kaneelil et al. Reference Kaneelil, Pahlavan, Herrada, LeRoy, Stengel, Warner, Galea and Stone2022). Such systems have shown immense potential in the manipulation and sorting of particles, droplets and cells in microfluidics applications (Tsai et al. Reference Tsai, Wexler, Wan and Stone2011; Jayaprakash, Banerjee & Sen Reference Jayaprakash, Banerjee and Sen2016; Hazra et al. Reference Hazra, Jayaprakash, Pandian, Raj, Mitra and Sen2019), and interfacial instability would act as a deterrent to such processes (Deng et al. Reference Deng, Wang, Ju, Xie and Chu2016; Hazra et al. Reference Hazra, Mitra and Sen2022b). On the other hand, interfacial instability is conducive to some applications such as rapid on-chip droplet generation and cell encapsulation. Despite the above developments, axial propagation and the characterization of the growth or decay of interfacial disturbances in confined microsystems have not been investigated well. The literature suggests that contrast in viscosity, density and elasticity, IFT, the ratio of fluid depths and inertia are key factors of interfacial instability in stratified multiphase systems (Khomami & Su Reference Khomami and Su2000; Hu & Cubaud Reference Hu and Cubaud2018, Reference Hu and Cubaud2020). However, an in-depth study of instability in a microfluidic stratified two-phase system from a general viscoelastic perspective is missing in the literature.

In the present work, we investigate the interfacial instability in microfluidic coflow combinations of Newtonian–Newtonian fluid (N–N) Fluorinert™ FC40 – SiO-1000 and Newtonian–viscoelastic fluids (N–VE) FC40 – polyethylene oxide (PEO) 1.7 %, FC40 – PEO 3 %, FC40 – PEO 4 % and FC40 – PEO 5 %. We theoretically obtain interface location, stream widths, velocity profiles and shear stress variation for the above-mentioned combinations. We perform linear stability analysis and develop analytical expressions for complex wave speed and the dispersion relation, ![]() $(k$ vs

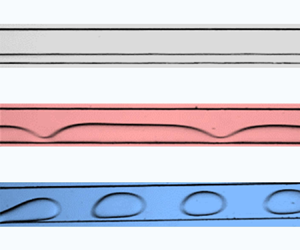

$(k$ vs ![]() $\omega _r)$. We categorize the behaviour of the systems into two regimes: a stable regime with a flat interface and an unstable regime with either waviness (unstable waviness) along the interface or droplets (unstable droplet) emerging from the low-viscosity fluid, as shown in figure 1(a) and presented in supplementary movie S1 available at https://doi.org/10.1017/jfm.2024.993. We present the regimes in a comprehensive regime plot in terms of the capillary numbers of the phases and explain the transitions among these regimes by decoupling the physics into viscous and elastic stratification components, which allows us to understand the competing effects leading to a variety of interfacial phenomena. In order to uncover the physical characteristics of the observed instabilities, we delineate the axial variation of amplitude

$\omega _r)$. We categorize the behaviour of the systems into two regimes: a stable regime with a flat interface and an unstable regime with either waviness (unstable waviness) along the interface or droplets (unstable droplet) emerging from the low-viscosity fluid, as shown in figure 1(a) and presented in supplementary movie S1 available at https://doi.org/10.1017/jfm.2024.993. We present the regimes in a comprehensive regime plot in terms of the capillary numbers of the phases and explain the transitions among these regimes by decoupling the physics into viscous and elastic stratification components, which allows us to understand the competing effects leading to a variety of interfacial phenomena. In order to uncover the physical characteristics of the observed instabilities, we delineate the axial variation of amplitude ![]() $(A)$ and wavelength

$(A)$ and wavelength ![]() $(\lambda )$. We also investigate the mechanism of droplet generation and pinch-off time, which are of particular interest in microfluidics. The possibility to alter the viscous and elastic stratification components in our experiments could potentially allow for control of the transition between the unstable-waviness and unstable-droplet regimes. Our study has the potential to improve the present understanding of interfacial instability in microfluidic coflow systems and identify hydrodynamic conditions for seamless microfluidic operations.

$(\lambda )$. We also investigate the mechanism of droplet generation and pinch-off time, which are of particular interest in microfluidics. The possibility to alter the viscous and elastic stratification components in our experiments could potentially allow for control of the transition between the unstable-waviness and unstable-droplet regimes. Our study has the potential to improve the present understanding of interfacial instability in microfluidic coflow systems and identify hydrodynamic conditions for seamless microfluidic operations.

Figure 1. Schematic description of the three distinct flow regimes and the experimental set-up. (a) Various flow configurations (flow is from left to right) observed in the experiments: (i) stable immiscible coflow configuration is shown with FC40 and PEO or SiO-1000 infused into the microchannel of dimensions ![]() $L\ (27~{\rm mm}) \times W (300\ \mathrm {\mu } {\rm m})$ as phase 1 (P1) and phase 2 (P2) with flow widths

$L\ (27~{\rm mm}) \times W (300\ \mathrm {\mu } {\rm m})$ as phase 1 (P1) and phase 2 (P2) with flow widths ![]() $W_{1}$ and

$W_{1}$ and ![]() $W_{2}$, respectively; (ii) part of the channel showing the unstable-waviness regime, where

$W_{2}$, respectively; (ii) part of the channel showing the unstable-waviness regime, where ![]() $\tilde {\lambda }$ and

$\tilde {\lambda }$ and ![]() $\tilde {A}$ are the dimensional wavelength and amplitude of the interfacial wave, respectively; and (iii) part of the channel showing the unstable-droplet regime. (b) Schematic diagram of the set-up and device. (i) Schematic of the experimental set-up showing microscope, high-speed camera and the pumps. (ii) Schematic of the microfluidic device.

$\tilde {A}$ are the dimensional wavelength and amplitude of the interfacial wave, respectively; and (iii) part of the channel showing the unstable-droplet regime. (b) Schematic diagram of the set-up and device. (i) Schematic of the experimental set-up showing microscope, high-speed camera and the pumps. (ii) Schematic of the microfluidic device.

2. Experiments

A schematic of the experimental set-up and the microchannel device used in the present study are depicted in figure 1(b). The device as shown in figures 1(b-ii) and 1(a) comprises two inlet channels leading to an expanded channel. The expanded channel is of rectangular cross-section and is 300 ![]() $\mathrm {\mu }$m wide (

$\mathrm {\mu }$m wide (![]() $W$), 100

$W$), 100 ![]() $\mathrm {\mu }$m deep and 27 mm long (

$\mathrm {\mu }$m deep and 27 mm long (![]() $L$). The device is fabricated in polydimethylsiloxane (PDMS) using standard soft lithography (Sajeesh, Doble & Sen Reference Sajeesh, Doble and Sen2014) (Appendix A). We expose the PDMS microchannel and a glass slide to oxygen plasma for 3 min at 30 W radio frequency (RF) power. Immediately after plasma exposure, the microchannel device is bonded onto the glass slide. After mild heating at 50

$L$). The device is fabricated in polydimethylsiloxane (PDMS) using standard soft lithography (Sajeesh, Doble & Sen Reference Sajeesh, Doble and Sen2014) (Appendix A). We expose the PDMS microchannel and a glass slide to oxygen plasma for 3 min at 30 W radio frequency (RF) power. Immediately after plasma exposure, the microchannel device is bonded onto the glass slide. After mild heating at 50 ![]() $^\circ$C for 5 min, the channel is flushed with PEO for 30 min to render hydrophilic channel surfaces. Polyethylene oxide (molecular wt. 1 MDa), silicone oil 1000 (SiO-1000), FC40 oil and Abil Em 90 surfactant were procured from Sigma-Aldrich, USA. The PEO at 1.7 %–5 % w/w is added to deionized (DI) water to obtain the non-Newtonian aqueous solutions, whose shear-thinning nature would depend on the polymer concentration. Abil Em 90 is mixed with FC40 at 5 % w/w. Viscosities of the fluids are measured using Anton Paar Rheometer MCR 72 with 50 mm of cone diameter at 25

$^\circ$C for 5 min, the channel is flushed with PEO for 30 min to render hydrophilic channel surfaces. Polyethylene oxide (molecular wt. 1 MDa), silicone oil 1000 (SiO-1000), FC40 oil and Abil Em 90 surfactant were procured from Sigma-Aldrich, USA. The PEO at 1.7 %–5 % w/w is added to deionized (DI) water to obtain the non-Newtonian aqueous solutions, whose shear-thinning nature would depend on the polymer concentration. Abil Em 90 is mixed with FC40 at 5 % w/w. Viscosities of the fluids are measured using Anton Paar Rheometer MCR 72 with 50 mm of cone diameter at 25 ![]() $^\circ$C and verified with the existing literature. Interfacial tension is measured using a droplet size analyser (DSA 25, Krüss GmbH, Germany). The measured properties of the fluids are summarized in table 1 and the viscosity variations are shown in Appendix B.

$^\circ$C and verified with the existing literature. Interfacial tension is measured using a droplet size analyser (DSA 25, Krüss GmbH, Germany). The measured properties of the fluids are summarized in table 1 and the viscosity variations are shown in Appendix B.

Table 1. Various properties of different fluids used in the experiments. Symbols ![]() $\mu$,

$\mu$, ![]() $\tau$,

$\tau$, ![]() $\gamma$ and

$\gamma$ and ![]() $m$ refer to viscosity, relaxation time (Ebagninin, Benchabane & Bekkour Reference Ebagninin, Benchabane and Bekkour2009), IFT with respect to FC40 and viscosity ratio with respect to FC40, respectively.

$m$ refer to viscosity, relaxation time (Ebagninin, Benchabane & Bekkour Reference Ebagninin, Benchabane and Bekkour2009), IFT with respect to FC40 and viscosity ratio with respect to FC40, respectively.

Each measurement is repeated at least thrice and the standard deviation is found to be within ![]() $\pm$3 %. Fluorinert™ FC40 (Newtonian, N) is used as the first coflow stream (P1), and SiO-1000 (Newtonian, N) or PEO (viscoelastic, VE) is used as the second coflow stream (P2). The coflow (N–N or N–VE) combinations FC40 – SiO-1000, FC40 – PEO 1.7 %, FC40 – PEO 3 %, FC40 – PEO 4 % and FC40 – PEO 5 % will be noted henceforth as P1–P2.

$\pm$3 %. Fluorinert™ FC40 (Newtonian, N) is used as the first coflow stream (P1), and SiO-1000 (Newtonian, N) or PEO (viscoelastic, VE) is used as the second coflow stream (P2). The coflow (N–N or N–VE) combinations FC40 – SiO-1000, FC40 – PEO 1.7 %, FC40 – PEO 3 %, FC40 – PEO 4 % and FC40 – PEO 5 % will be noted henceforth as P1–P2.

The working fluids are infused into the channels using high-performance syringe pumps (Cetoni GmbH, Germany) as shown in figure 1(b). The fluidic connections between the syringe pump and the device is established using polytetrafluoroethylene tubing (Fisher Scientific, USA). The phenomena (figure 1a) are observed and captured using an inverted microscope (Olympus IX73) coupled with a high-speed monochrome camera (FASTCAM SA3 model, Photron USA, Inc.) operating at 1000 to 6000 fps, interfaced with a computer system via Photron Fastcam Viewer software.

3. Theoretical analysis

We consider a coflow of Newtonian and viscoelastic fluids through a rectangular microchannel, as shown in figure 1. One part of the channel is filled with a Newtonian fluid, indicated as phase 1 (P1), and the other part is occupied by a viscoelastic fluid, which is phase 2 (P2). We use the subscript‘1’ for the Newtonian fluid and ‘2’ for the viscoelastic fluid. We perform a linear stability analysis by considering the continuity equation, Navier–Stokes equation, and the Oldroyd-B model. For phase 1, for Newtonian fluid, the dimensional continuity and Navier–Stokes equations become

The Newtonian fluid velocity field is defined as ![]() $\tilde {\boldsymbol {u}}_1=\tilde {u}_1 \boldsymbol {e}_x+\tilde {v}_1\boldsymbol {e}_y$, where the pressure, viscosity and density of the fluid are denoted by

$\tilde {\boldsymbol {u}}_1=\tilde {u}_1 \boldsymbol {e}_x+\tilde {v}_1\boldsymbol {e}_y$, where the pressure, viscosity and density of the fluid are denoted by ![]() $\tilde {p}_1$,

$\tilde {p}_1$, ![]() $\mu _1$ and

$\mu _1$ and ![]() $\rho _1$, respectively. Here, tildes over

$\rho _1$, respectively. Here, tildes over ![]() $x, y, t$ and flow variables indicate the dimensional quantities. For phase 2, in the case of viscoelastic fluid, the continuity and Navier–Stokes equations along with the Oldroyd-B model give

$x, y, t$ and flow variables indicate the dimensional quantities. For phase 2, in the case of viscoelastic fluid, the continuity and Navier–Stokes equations along with the Oldroyd-B model give

where the viscoelastic fluid velocity field is defined as ![]() $\tilde {\boldsymbol {u}}_2=\tilde {u}_2 \boldsymbol {e}_x+\tilde {v}_2 \boldsymbol {e}_y$, and the pressure, solvent viscosity and density of the fluid are

$\tilde {\boldsymbol {u}}_2=\tilde {u}_2 \boldsymbol {e}_x+\tilde {v}_2 \boldsymbol {e}_y$, and the pressure, solvent viscosity and density of the fluid are ![]() $\tilde {p}_2$,

$\tilde {p}_2$, ![]() $\mu _{2s}$ and

$\mu _{2s}$ and ![]() $\rho _2$, respectively. Additionally,

$\rho _2$, respectively. Additionally, ![]() $\tilde {\boldsymbol {\sigma }}$ is a second-rank tensor that describes the polymer effect of the viscoelastic fluid, expressed as

$\tilde {\boldsymbol {\sigma }}$ is a second-rank tensor that describes the polymer effect of the viscoelastic fluid, expressed as

Here, ![]() $\tau$ is the relaxation time and

$\tau$ is the relaxation time and ![]() $\mu _{2p}$ is the polymer viscosity. We denote the components of the polymeric stress tensor in the fluid as

$\mu _{2p}$ is the polymer viscosity. We denote the components of the polymeric stress tensor in the fluid as ![]() $\tilde {\sigma }_{xx}$,

$\tilde {\sigma }_{xx}$, ![]() $\tilde {\sigma }_{yy}$ and

$\tilde {\sigma }_{yy}$ and ![]() $\tilde {\sigma }_{xy}$. The solvent viscous stress components are represented as

$\tilde {\sigma }_{xy}$. The solvent viscous stress components are represented as ![]() $\tilde {\sigma }_{xx,s}$,

$\tilde {\sigma }_{xx,s}$, ![]() $\tilde {\sigma }_{yy,s}$ and

$\tilde {\sigma }_{yy,s}$ and ![]() $\tilde {\sigma }_{xy,s}$. We consider the following general boundary conditions: (i) zero normal velocity and no-slip condition at the top and bottom walls, which can be represented as

$\tilde {\sigma }_{xy,s}$. We consider the following general boundary conditions: (i) zero normal velocity and no-slip condition at the top and bottom walls, which can be represented as

(ii) Continuity of velocity at the interface gives

(iii) Continuity of shear stress at the interface (at ![]() $y=0$) is expressed as

$y=0$) is expressed as

On the left-hand side of (3.9), ![]() $\tilde {\sigma }_{xy,s}$ represents the solvent component, while

$\tilde {\sigma }_{xy,s}$ represents the solvent component, while ![]() $\tilde {\sigma }_{xy}$ denotes the polymer component of the shear stress in phase 2. Here, phase 2 is considered to be a viscoelastic fluid, so

$\tilde {\sigma }_{xy}$ denotes the polymer component of the shear stress in phase 2. Here, phase 2 is considered to be a viscoelastic fluid, so ![]() $\{\tilde {\sigma }_{xy}\}_2$ is not zero. Since phase 1 is considered to be a Newtonian fluid,

$\{\tilde {\sigma }_{xy}\}_2$ is not zero. Since phase 1 is considered to be a Newtonian fluid, ![]() $\{\tilde {\sigma }_{xy}\}_1$ becomes zero. (iv) Continuity of normal stress at the interface (at

$\{\tilde {\sigma }_{xy}\}_1$ becomes zero. (iv) Continuity of normal stress at the interface (at ![]() $y=0$) gives

$y=0$) gives

Here, ![]() $\gamma$ and

$\gamma$ and ![]() $\tilde {A}$ denote the IFT and the deviation of the interface from its mean position, respectively. In the first term on the left-hand side of (3.10),

$\tilde {A}$ denote the IFT and the deviation of the interface from its mean position, respectively. In the first term on the left-hand side of (3.10), ![]() $\tilde {\sigma }_{yy,s}$ represents the solvent contribution, while

$\tilde {\sigma }_{yy,s}$ represents the solvent contribution, while ![]() $\tilde {\sigma }_{yy}$ indicates the polymer contribution to the normal stress in phase 2. Here, phase 2 is considered to be a viscoelastic fluid, so

$\tilde {\sigma }_{yy}$ indicates the polymer contribution to the normal stress in phase 2. Here, phase 2 is considered to be a viscoelastic fluid, so ![]() $\{\tilde {\sigma }_{yy}\}_2$ is not zero. Since phase 1 is considered to be a Newtonian fluid,

$\{\tilde {\sigma }_{yy}\}_2$ is not zero. Since phase 1 is considered to be a Newtonian fluid, ![]() $\{\tilde {\sigma }_{yy}\}_1$ becomes zero. The second term accounts for the normal stress of the Newtonian fluid in phase 1.

$\{\tilde {\sigma }_{yy}\}_1$ becomes zero. The second term accounts for the normal stress of the Newtonian fluid in phase 1.

We non-dimensionalize the above equations by considering

where ![]() $W_2$ is the width of the viscoelastic fluid layer and

$W_2$ is the width of the viscoelastic fluid layer and ![]() $U_0$ is the average velocity of the flow through the microchannel. Similarly, the dimensionless fluid velocity, pressure and viscoelastic stress tensor can be expressed as

$U_0$ is the average velocity of the flow through the microchannel. Similarly, the dimensionless fluid velocity, pressure and viscoelastic stress tensor can be expressed as

Using (3.11) and (3.12), the dimensionless continuity (3.1) and Navier–Stokes equation (3.2) for Newtonian fluid can be written as

Here, ![]() $r$ is the density ratio between the Newtonian fluid and the viscoelastic fluid, defined as

$r$ is the density ratio between the Newtonian fluid and the viscoelastic fluid, defined as ![]() $r=\rho _1/\rho _2$ and

$r=\rho _1/\rho _2$ and ![]() $R_1$ is the Reynolds number for the Newtonian fluid, given by

$R_1$ is the Reynolds number for the Newtonian fluid, given by ![]() ${R_1=U_0 \rho _1 W_2/\mu _1}$. Similarly, for the viscoelastic fluid, the dimensionless continuity (3.3) and Navier–Stokes equations (3.4) can be expressed as

${R_1=U_0 \rho _1 W_2/\mu _1}$. Similarly, for the viscoelastic fluid, the dimensionless continuity (3.3) and Navier–Stokes equations (3.4) can be expressed as

where (3.5) becomes

Here, ![]() $Wi$ is the Weissenberg number,

$Wi$ is the Weissenberg number, ![]() $Wi=\tau U_0/W_2$. The Reynolds number corresponding to the solvent and the polymer viscosity are considered as

$Wi=\tau U_0/W_2$. The Reynolds number corresponding to the solvent and the polymer viscosity are considered as ![]() $R_{2s}$ and

$R_{2s}$ and ![]() $R_{2p}$, where,

$R_{2p}$, where, ![]() $R_{2s}=U_0 \rho _2 W_2/\mu _{2s}$ and

$R_{2s}=U_0 \rho _2 W_2/\mu _{2s}$ and ![]() $R_{2p}=U_0 \rho _2 W_2/\mu _{2p}$.

$R_{2p}=U_0 \rho _2 W_2/\mu _{2p}$.

Following the conventional formulation for a normal mode of instability (Yih Reference Yih1967), the motion of fluid is resolved into the primary motion and the perturbation component. The perturbed forms of the velocity, pressure and viscoelastic stress fields are considered as

respectively, where ![]() $U, P$ and

$U, P$ and ![]() $\bar {\boldsymbol {\sigma }}$ are the primary flow velocity, pressure and viscoelastic stress. The primary flow has only an

$\bar {\boldsymbol {\sigma }}$ are the primary flow velocity, pressure and viscoelastic stress. The primary flow has only an ![]() $x$ component of velocity (

$x$ component of velocity (![]() $y$ component of fluid velocity

$y$ component of fluid velocity ![]() $V=0$) and it is independent of

$V=0$) and it is independent of ![]() $x$ and

$x$ and ![]() $t$ (Yih Reference Yih1967). Here,

$t$ (Yih Reference Yih1967). Here, ![]() ${u}'$,

${u}'$, ![]() ${v}'$,

${v}'$, ![]() ${p}'$,

${p}'$, ![]() $\boldsymbol {\sigma }'$ are the first-order perturbation field variables. We substitute the perturbed fluid field (3.18a–d) in (3.13)–(3.17). Then, we separate the primary and first-order perturbed equation and neglect the higher-order perturbations (Yih Reference Yih1967; Li Reference Li1969).

$\boldsymbol {\sigma }'$ are the first-order perturbation field variables. We substitute the perturbed fluid field (3.18a–d) in (3.13)–(3.17). Then, we separate the primary and first-order perturbed equation and neglect the higher-order perturbations (Yih Reference Yih1967; Li Reference Li1969).

3.1. The primary flow

The continuity equation (3.13) corresponding to the primary motion of Newtonian fluid is simplified as

From (3.14), the ![]() $x$-momentum equation becomes

$x$-momentum equation becomes

and the ![]() $y$-momentum equation reduces to

$y$-momentum equation reduces to ![]() $\partial {P}_1/\partial {y}=0$. Similarly, for the primary motion of viscoelastic fluid, the continuity equation becomes

$\partial {P}_1/\partial {y}=0$. Similarly, for the primary motion of viscoelastic fluid, the continuity equation becomes

The ![]() $x$-momentum equation simplifies to

$x$-momentum equation simplifies to

and the ![]() $y$-momentum equation becomes

$y$-momentum equation becomes

Here, ![]() $\bar {\sigma }_{xx}, \bar {\sigma }_{xy}, \bar {\sigma }_{yx}$ and

$\bar {\sigma }_{xx}, \bar {\sigma }_{xy}, \bar {\sigma }_{yx}$ and ![]() $\bar {\sigma }_{yy}$ are the components of viscoelastic stress tensor

$\bar {\sigma }_{yy}$ are the components of viscoelastic stress tensor ![]() $\bar {\boldsymbol {\sigma }}$ due to the primary flow, where

$\bar {\boldsymbol {\sigma }}$ due to the primary flow, where ![]() $\bar {\sigma }_{xy}=\bar {\sigma }_{yx}$. In order to find these stress components, we consider (3.17). For primary motion, (3.17) reduces to

$\bar {\sigma }_{xy}=\bar {\sigma }_{yx}$. In order to find these stress components, we consider (3.17). For primary motion, (3.17) reduces to

By following Li (Reference Li1969), simplification of the (3.24)–(3.26) gives the primary viscoelastic stress components as

Using (3.27), (3.24) and (3.25) reduce to

Using (3.27)–(3.29), the ![]() $x$ and

$x$ and ![]() $y$ momentum equations ((3.22) and (3.23)) for viscoelastic fluid become

$y$ momentum equations ((3.22) and (3.23)) for viscoelastic fluid become

Here, ![]() $\bar {\sigma }_{yy}=0$,

$\bar {\sigma }_{yy}=0$, ![]() $\partial {P_1}/\partial {y=0}$,

$\partial {P_1}/\partial {y=0}$, ![]() $\partial {P_2}/\partial {y=0}$, therefore, we consider

$\partial {P_2}/\partial {y=0}$, therefore, we consider ![]() $P_1=P_2=P$ (Yih Reference Yih1967; Li Reference Li1969). The equations governing the primary flow for Newtonian (3.20) and viscoelastic fluid (3.30) can be represented as

$P_1=P_2=P$ (Yih Reference Yih1967; Li Reference Li1969). The equations governing the primary flow for Newtonian (3.20) and viscoelastic fluid (3.30) can be represented as

and

respectively. Here,

and ![]() $\mu _{2}=\mu _{2s}+\mu _{2p}$. The

$\mu _{2}=\mu _{2s}+\mu _{2p}$. The ![]() $y$ coordinates of the top and bottom walls of the channel are represented by

$y$ coordinates of the top and bottom walls of the channel are represented by ![]() $y=1$ and

$y=1$ and ![]() $y=-n$, respectively, where

$y=-n$, respectively, where ![]() $n=W_1/W_2$. We solve (3.32) and (3.33) using boundary conditions (i) at

$n=W_1/W_2$. We solve (3.32) and (3.33) using boundary conditions (i) at ![]() $y=1$,

$y=1$, ![]() $U_2=0$, (ii) at

$U_2=0$, (ii) at ![]() $y=-n$,

$y=-n$, ![]() $U_1=0$, (iii) at

$U_1=0$, (iii) at ![]() $y=0$, continuity of velocity gives

$y=0$, continuity of velocity gives ![]() $U_1=U_2$ and (iv) at

$U_1=U_2$ and (iv) at ![]() $y=0$, continuity of shear stress gives

$y=0$, continuity of shear stress gives ![]() $m (\partial U_1/\partial y)= (\partial U_2/\partial y)$. Here,

$m (\partial U_1/\partial y)= (\partial U_2/\partial y)$. Here, ![]() $m$ is the viscosity ratio between the Newtonian and viscoelastic fluids,

$m$ is the viscosity ratio between the Newtonian and viscoelastic fluids, ![]() $m=\mu _1/\mu _2$. The primary flow velocity of the Newtonian and viscoelastic fluid becomes

$m=\mu _1/\mu _2$. The primary flow velocity of the Newtonian and viscoelastic fluid becomes

Here, the coefficients ![]() $A_1,A_2,a_1,a_2$ and

$A_1,A_2,a_1,a_2$ and ![]() $b$ are obtained as

$b$ are obtained as

\begin{equation} \left.\begin{array}{@{}c@{}} A_1=\dfrac{A_2}{m},\quad A_2={-}\dfrac{R_2 K}{2}, \\ a_1=\dfrac{K R_2 (m-n^2)}{2 m (m+n)},\quad a_2=m a_1, \\ b=\dfrac{K R_2 ( n + n^2) }{2 (m + n)}. \end{array}\right\} \end{equation}

\begin{equation} \left.\begin{array}{@{}c@{}} A_1=\dfrac{A_2}{m},\quad A_2={-}\dfrac{R_2 K}{2}, \\ a_1=\dfrac{K R_2 (m-n^2)}{2 m (m+n)},\quad a_2=m a_1, \\ b=\dfrac{K R_2 ( n + n^2) }{2 (m + n)}. \end{array}\right\} \end{equation}

Here, ![]() $n=W_1/W_2$ and

$n=W_1/W_2$ and ![]() $r=\rho _1/\rho _2$. We find an expression for

$r=\rho _1/\rho _2$. We find an expression for ![]() $K$ and

$K$ and ![]() $W_2$ from flow rate, given in Appendix C. Therefore,

$W_2$ from flow rate, given in Appendix C. Therefore, ![]() $R_2= (m/r)R_1$. Using the velocity profile of viscoelastic fluid (3.36) the primary viscoelastic stresses ((3.28) and (3.29)) can be obtained as

$R_2= (m/r)R_1$. Using the velocity profile of viscoelastic fluid (3.36) the primary viscoelastic stresses ((3.28) and (3.29)) can be obtained as

Here, ![]() $U'_2=2 A_2 y+ a_2$. Together, (3.35)–(3.39) give the flow field corresponding to the primary motion of N–VE coflow in a microchannel under a pressure gradient.

$U'_2=2 A_2 y+ a_2$. Together, (3.35)–(3.39) give the flow field corresponding to the primary motion of N–VE coflow in a microchannel under a pressure gradient.

3.2. The perturbation motion and governing equations of stability

Upon substituting the perturbed forms of the fields into the governing equations for a Newtonian fluid ((3.13) and (3.14)) and simplifying, we get the first-order perturbed continuity equation as

The ![]() $x$-momentum equation for Newtonian phase is

$x$-momentum equation for Newtonian phase is

The ![]() $y$-momentum equation reduces to

$y$-momentum equation reduces to

Similarly, perturbations in the governing equations of a viscoelastic fluid ((3.15) and (3.16)) give the first-order perturbed continuity, ![]() $x$ and

$x$ and ![]() $y$ momentum equations as

$y$ momentum equations as

respectively. Here, ![]() $\sigma '_{xx}$,

$\sigma '_{xx}$, ![]() $\sigma '_{xy}$ and

$\sigma '_{xy}$ and ![]() $\sigma '_{yy}$ are perturbed viscoelastic stress components. From (3.17) these components can be represented as

$\sigma '_{yy}$ are perturbed viscoelastic stress components. From (3.17) these components can be represented as

\begin{align} &{\sigma}'_{xx}+ Wi \left[\frac{\partial \sigma'_{xx}}{\partial t} +U_2 \frac{\partial{{\sigma}'_{xx}}}{\partial {x}}+v'\frac{\partial \bar{\sigma}_{xx}}{\partial y}-2{\bar{\sigma}_{xx}}\frac{\partial{{u}'_{2}}}{\partial {x}} -2 {\bar{\sigma}_{xy}}\frac{\partial{{u}'_{2}}}{\partial {y}}-2 {{\sigma}'_{xy}}\frac{\partial{{U}_{2}}}{\partial {y}}\right]\nonumber\\ &\quad =\frac{2}{R_{2p}}\frac{\partial u'_2}{\partial x}, \end{align}

\begin{align} &{\sigma}'_{xx}+ Wi \left[\frac{\partial \sigma'_{xx}}{\partial t} +U_2 \frac{\partial{{\sigma}'_{xx}}}{\partial {x}}+v'\frac{\partial \bar{\sigma}_{xx}}{\partial y}-2{\bar{\sigma}_{xx}}\frac{\partial{{u}'_{2}}}{\partial {x}} -2 {\bar{\sigma}_{xy}}\frac{\partial{{u}'_{2}}}{\partial {y}}-2 {{\sigma}'_{xy}}\frac{\partial{{U}_{2}}}{\partial {y}}\right]\nonumber\\ &\quad =\frac{2}{R_{2p}}\frac{\partial u'_2}{\partial x}, \end{align} \begin{align} & {\sigma}'_{xy}+ Wi \left[\frac{\partial \sigma'_{xy}}{\partial t} +U_2 \frac{\partial{{\sigma}'_{xy}}}{\partial {x}}+v'\frac{\partial \bar{\sigma}_{xy}}{\partial y}-{\bar{\sigma}_{xx}}\frac{\partial{{v}'_{2}}}{\partial {x}} -{{\sigma}'_{yy}}\frac{\partial{{U}_{2}}}{\partial {y}}\right]\nonumber\\ &\quad =\frac{1}{R_{2p}}\left[\frac{\partial u'_2}{\partial y}+\frac{\partial v'_2}{\partial x}\right], \end{align}

\begin{align} & {\sigma}'_{xy}+ Wi \left[\frac{\partial \sigma'_{xy}}{\partial t} +U_2 \frac{\partial{{\sigma}'_{xy}}}{\partial {x}}+v'\frac{\partial \bar{\sigma}_{xy}}{\partial y}-{\bar{\sigma}_{xx}}\frac{\partial{{v}'_{2}}}{\partial {x}} -{{\sigma}'_{yy}}\frac{\partial{{U}_{2}}}{\partial {y}}\right]\nonumber\\ &\quad =\frac{1}{R_{2p}}\left[\frac{\partial u'_2}{\partial y}+\frac{\partial v'_2}{\partial x}\right], \end{align}

From (3.40) and (3.43), ![]() $u'$ and

$u'$ and ![]() $v'$ can be represented in terms of streamfunction

$v'$ can be represented in terms of streamfunction ![]() $\psi$. Thus,

$\psi$. Thus,

To perform the linear stability analysis, similar to Yih (Reference Yih1967), we consider the perturbation fields as a function of an exponential time factor and assume that they are spatially periodic. For both the Newtonian and viscoelastic phases, these fields can be expressed as follows:

Here, ![]() $k$ and

$k$ and ![]() $c$ represent the dimensionless wavenumber and complex wave speed, respectively, where

$c$ represent the dimensionless wavenumber and complex wave speed, respectively, where ![]() $c = c_r + \textrm {i} c_i$. These dimensionless quantities are defined as

$c = c_r + \textrm {i} c_i$. These dimensionless quantities are defined as ![]() $c = \tilde {c}/U_0$ and

$c = \tilde {c}/U_0$ and ![]() $k = \tilde {k} W_2$, with

$k = \tilde {k} W_2$, with ![]() $\tilde {k}$ and

$\tilde {k}$ and ![]() $\tilde {c}$ denoting the dimensional wavenumber and complex wave speed. The relationship between these dimensional quantities is given by

$\tilde {c}$ denoting the dimensional wavenumber and complex wave speed. The relationship between these dimensional quantities is given by ![]() $\tilde {c} = \tilde {\omega }/\tilde {k}$, in which

$\tilde {c} = \tilde {\omega }/\tilde {k}$, in which ![]() $\tilde {\omega }$ is the dimensional angular frequency. The stability or instability of the N–VE coflow is determined by the sign of

$\tilde {\omega }$ is the dimensional angular frequency. The stability or instability of the N–VE coflow is determined by the sign of ![]() $c_i$ (or

$c_i$ (or ![]() $\omega _i$) (Yih Reference Yih1967; Govindarajan & Sahu Reference Govindarajan and Sahu2014). Substituting (3.49) and (3.50) for the Newtonian fluid in (3.41) and (3.42) after further simplification gives

$\omega _i$) (Yih Reference Yih1967; Govindarajan & Sahu Reference Govindarajan and Sahu2014). Substituting (3.49) and (3.50) for the Newtonian fluid in (3.41) and (3.42) after further simplification gives

Eliminating ![]() $f_1$ from (3.52) and (3.53) gives the Orr–Sommerfeld equation for the Newtonian phase as

$f_1$ from (3.52) and (3.53) gives the Orr–Sommerfeld equation for the Newtonian phase as

where ![]() $R_1=R_2 m^{-1} r$. Therefore (3.54) is the same as in Yih (Reference Yih1967). Similarly, substitution of (3.49) and (3.51) in the perturbed equations of the viscoelastic fluid (3.44) and (3.45) gives

$R_1=R_2 m^{-1} r$. Therefore (3.54) is the same as in Yih (Reference Yih1967). Similarly, substitution of (3.49) and (3.51) in the perturbed equations of the viscoelastic fluid (3.44) and (3.45) gives

By eliminating ![]() $f_2$ from (3.55) and (3.56), we obtain the Orr–Sommerfeld equation for the viscoelastic phase as

$f_2$ from (3.55) and (3.56), we obtain the Orr–Sommerfeld equation for the viscoelastic phase as

\begin{align} \phi^{iv}-2 k^2 \phi''+k^4 \phi&={\rm i} k R_{2s} \{ (U_2- c )(\phi''-k^2 \phi)-U''_2\phi\}\nonumber\\ &\quad -R_{2s}\{ {\rm i}k F'_1+ F''_2+k^2 F_2-{\rm i} k F'_3\}, \end{align}

\begin{align} \phi^{iv}-2 k^2 \phi''+k^4 \phi&={\rm i} k R_{2s} \{ (U_2- c )(\phi''-k^2 \phi)-U''_2\phi\}\nonumber\\ &\quad -R_{2s}\{ {\rm i}k F'_1+ F''_2+k^2 F_2-{\rm i} k F'_3\}, \end{align}

where ![]() $F_1$,

$F_1$, ![]() $F_2$ and

$F_2$ and ![]() $F_3$ are the amplitudes of the viscoelastic stress, which are a function of the polymer viscosity (

$F_3$ are the amplitudes of the viscoelastic stress, which are a function of the polymer viscosity (![]() $\mu _{2p}$) and the relaxation time

$\mu _{2p}$) and the relaxation time ![]() $(\tau )$. Substitution of (3.49) and (3.51) in (3.46)–(3.48) after further simplification gives

$(\tau )$. Substitution of (3.49) and (3.51) in (3.46)–(3.48) after further simplification gives

We use (3.58)–(3.60) to analyse the values of ![]() $F_1$,

$F_1$, ![]() $F_2$ and

$F_2$ and ![]() $F_3$ in the upcoming sections. Equations (3.57)–(3.60) constitute the governing equations for viscoelastic fluid

$F_3$ in the upcoming sections. Equations (3.57)–(3.60) constitute the governing equations for viscoelastic fluid ![]() $(\phi )$. For Newtonian fluid,

$(\phi )$. For Newtonian fluid, ![]() $\mu _{2p}= 0, \tau =0$, where

$\mu _{2p}= 0, \tau =0$, where ![]() $Wi\rightarrow 0$ and

$Wi\rightarrow 0$ and ![]() $R_{2p} \rightarrow \infty$, therefore

$R_{2p} \rightarrow \infty$, therefore ![]() $F_1$,

$F_1$, ![]() $F_2$ and

$F_2$ and ![]() $F_3$ become zero. Then, (3.57) becomes

$F_3$ become zero. Then, (3.57) becomes

which reproduces the Orr–Sommerfeld equation of Yih (Reference Yih1967) for a Newtonian fluid.

In order to solve the Orr–Sommerfeld equation, we consider following boundary conditions: (i) zero normal velocity and no-slip condition at the top and bottom walls, that can be represented as

(ii) Continuity of the velocity at the interface. The continuity of ![]() $v'$ at the interface

$v'$ at the interface ![]() $y=0$ gives

$y=0$ gives

Similar to Yih (Reference Yih1967), we consider the deviation of the interface from the mean position as ![]() $\eta$, where

$\eta$, where ![]() $y=\eta$. At

$y=\eta$. At ![]() $\eta$,

$\eta$, ![]() $v'$ becomes

$v'$ becomes

Therefore, ![]() $\eta$ is obtained as

$\eta$ is obtained as

Similarly, the continuity of ![]() $u'$ at the interface (Yih Reference Yih1967) demands

$u'$ at the interface (Yih Reference Yih1967) demands

which can be simplified as

(iii) Continuity of shear stress at the interface is expressed as

Similarly, (iv) continuity of normal stress at the interface gives

\begin{align} &{-}{\rm i}k R_{2s} \{c'

\phi'+a_2 \phi\}-\{\phi'''-k^2 \phi'\}+2k^2 \phi'\nonumber\\

&\quad +{\rm i}rkR_{2s} \{ c' \chi'+a_1 \chi\}+(r

R_{2s}/R_1)\{\chi'''-k^2 \chi'\} \nonumber\\ &\quad -2k^2(r

R_{2s}/R_1)\chi'-{\rm i}k R_{2s} F_1-R_{2s}F'_2 +{\rm i}k

R_{2s} F_3 ={\rm i} k^3 R_{2s} S (\phi/c').

\end{align}

\begin{align} &{-}{\rm i}k R_{2s} \{c'

\phi'+a_2 \phi\}-\{\phi'''-k^2 \phi'\}+2k^2 \phi'\nonumber\\

&\quad +{\rm i}rkR_{2s} \{ c' \chi'+a_1 \chi\}+(r

R_{2s}/R_1)\{\chi'''-k^2 \chi'\} \nonumber\\ &\quad -2k^2(r

R_{2s}/R_1)\chi'-{\rm i}k R_{2s} F_1-R_{2s}F'_2 +{\rm i}k

R_{2s} F_3 ={\rm i} k^3 R_{2s} S (\phi/c').

\end{align}

Here, ![]() $\gamma$ indicates the surface tension and

$\gamma$ indicates the surface tension and ![]() $S=\gamma /\rho _2 W_2 U_0^2$. The N–VE coflow equations (3.62)–(3.68) are similar to Yih (Reference Yih1967) given for a N–N coflow. However, (3.69) and (3.70) are different and specific to our study. For a Newtonian fluid,

$S=\gamma /\rho _2 W_2 U_0^2$. The N–VE coflow equations (3.62)–(3.68) are similar to Yih (Reference Yih1967) given for a N–N coflow. However, (3.69) and (3.70) are different and specific to our study. For a Newtonian fluid, ![]() $\mu _{2p}= 0, \tau =0$, where

$\mu _{2p}= 0, \tau =0$, where ![]() $Wi\rightarrow 0$ and

$Wi\rightarrow 0$ and ![]() $R_{2p} \rightarrow \infty$, therefore

$R_{2p} \rightarrow \infty$, therefore ![]() $F_1, F_2$ and

$F_1, F_2$ and ![]() $F_3$ become zero, which reproduces the same shear and normal stress boundary condition reported by Yih (Reference Yih1967) for a N–N coflow.

$F_3$ become zero, which reproduces the same shear and normal stress boundary condition reported by Yih (Reference Yih1967) for a N–N coflow.

3.3. Solution of the governing equations of stability

The governing equations of the stability analysis for a N–VE coflow considers the differential equations (3.54), (3.57), (3.62)–(3.64) and (3.68)–(3.70), which outline an eigenvalue problem. Moreover, (3.58), (3.59) and (3.60) give the viscoelastic stresses required for the governing equations. By following the method adopted by Yih (Reference Yih1967) for long-wave instability, we expand the eigenfunctions and eigenvalues in a power series of wavenumber ![]() $k$. Similar to Yih (Reference Yih1967) and Li (Reference Li1969), we consider a zeroth- and first-order approximation to get the eigenvalues.

$k$. Similar to Yih (Reference Yih1967) and Li (Reference Li1969), we consider a zeroth- and first-order approximation to get the eigenvalues.

In the zeroth approximation, we ignore all terms containing ![]() $k$ and its higher orders. Therefore, (3.54) and (3.57) reduce to the following:

$k$ and its higher orders. Therefore, (3.54) and (3.57) reduce to the following:

Here, the boundary conditions given by (3.62)–(3.64) and (3.68) remain the same. In the zeroth approximation, ![]() $\omega '$ is considered as

$\omega '$ is considered as ![]() $\omega '_0$. However, (3.69) and (3.70) reduce to

$\omega '_0$. However, (3.69) and (3.70) reduce to

Here, ![]() $m=r R_2/R_1=\mu _1/\mu _2$. Solving (3.71) and (3.72) using reduced boundary conditions gives

$m=r R_2/R_1=\mu _1/\mu _2$. Solving (3.71) and (3.72) using reduced boundary conditions gives

where

\begin{equation}

\left.\begin{array}{@{}c@{}} B_{10}=\dfrac{4 m+3 m n+n^3}{2

m n(1+n)},\quad B_{20}={-}\dfrac{m+3 n^2+4 n^3}{2 n^2

(1+n)}, \\ C_{10}=\dfrac{m + n^3}{m n^2 (1 + n)},\quad

C_{20}=m C_{10}, \\ D_{10}= \dfrac{ n^2-m}{2 m n^2 (1 +

n)}, \quad D_{20}=m D_{10}. \end{array}\right\}

\end{equation}

\begin{equation}

\left.\begin{array}{@{}c@{}} B_{10}=\dfrac{4 m+3 m n+n^3}{2

m n(1+n)},\quad B_{20}={-}\dfrac{m+3 n^2+4 n^3}{2 n^2

(1+n)}, \\ C_{10}=\dfrac{m + n^3}{m n^2 (1 + n)},\quad

C_{20}=m C_{10}, \\ D_{10}= \dfrac{ n^2-m}{2 m n^2 (1 +

n)}, \quad D_{20}=m D_{10}. \end{array}\right\}

\end{equation}

Using the above values, the eigenvalue ![]() $c'_0$ is calculated from (3.68), which gives

$c'_0$ is calculated from (3.68), which gives

The solution of the zeroth approximation is the same as given in Yih (Reference Yih1967) for N–N coflow.

In the first approximation, we consider terms up to the first order of ![]() $k$. Therefore (3.54) and (3.57) become

$k$. Therefore (3.54) and (3.57) become

\begin{align} \phi^{iv}_1&={\rm i} k R_{2} \{ (U_2- c_0 )\phi''_0-2 A_2 \phi_0\}-4{\rm i}k \frac{R_2}{R_{2p}} Wi (U'_2 \phi''_0)'\nonumber\\ &\quad -{\rm i} k\frac{R_2}{ R_{2p}} Wi [ U''_2 \phi_0-2~U'_2 \phi'_0-(U_2-c_0) \phi'' ]''. \end{align}

\begin{align} \phi^{iv}_1&={\rm i} k R_{2} \{ (U_2- c_0 )\phi''_0-2 A_2 \phi_0\}-4{\rm i}k \frac{R_2}{R_{2p}} Wi (U'_2 \phi''_0)'\nonumber\\ &\quad -{\rm i} k\frac{R_2}{ R_{2p}} Wi [ U''_2 \phi_0-2~U'_2 \phi'_0-(U_2-c_0) \phi'' ]''. \end{align}

Here, in (3.80), the second and third terms on the right-hand side come from the viscoelastic stress tensor, obtained by simplifying ![]() $F_1$,

$F_1$, ![]() $F_2$ and

$F_2$ and ![]() $F_3$ in (3.58)–(3.60). The general solution of (3.79) and (3.80) can be written as

$F_3$ in (3.58)–(3.60). The general solution of (3.79) and (3.80) can be written as

Here, ![]() $h_1(y), h_2(y)$ and

$h_1(y), h_2(y)$ and ![]() $h_3(y)$ are obtained as

$h_3(y)$ are obtained as

The boundary conditions become

The continuity of shear stress at ![]() $y=0$ (i.e. (3.69)) becomes

$y=0$ (i.e. (3.69)) becomes

Here, ![]() $l_1=A_2-B_{20} a_2+c'_0 C_{20}$. From first approximation, at

$l_1=A_2-B_{20} a_2+c'_0 C_{20}$. From first approximation, at ![]() $y=0$, (3.70) is simplified to

$y=0$, (3.70) is simplified to

where ![]() $l_2=2(A_2 B_{20}-a_2 C_{20}- 3 c'_0 D_{20} )$. Solving (3.86)–(3.91) gives the coefficients

$l_2=2(A_2 B_{20}-a_2 C_{20}- 3 c'_0 D_{20} )$. Solving (3.86)–(3.91) gives the coefficients ![]() $B_{11},C_{11},D_{11},B_{21},C_{21}$ and

$B_{11},C_{11},D_{11},B_{21},C_{21}$ and ![]() $D_{21}$, whose expressions are given in Appendix C. Thus, the equation for the eigenvalue becomes

$D_{21}$, whose expressions are given in Appendix C. Thus, the equation for the eigenvalue becomes

The eigenvalue is obtained as

Here, the eigenvalue consists of two parts, ![]() $J_1$ is due to the viscosity of the fluid and

$J_1$ is due to the viscosity of the fluid and ![]() $J_2$ is due to elasticity of the fluid. We can also express (3.93) as

$J_2$ is due to elasticity of the fluid. We can also express (3.93) as ![]() $c_i=kR_2 J$, where

$c_i=kR_2 J$, where ![]() $J=J_1+J_2$. Also,

$J=J_1+J_2$. Also, ![]() $J_1$ can be expressed as

$J_1$ can be expressed as

In which

\begin{equation}

\left.\begin{array}{@{}c@{}} I_1 =r h_1({-}n)-\frac{1}{6}

n^3\{-(r-1)(c_0^{\prime} B_{20}+a_2)\}, \\ H_1 =r

h_1^{\prime}({-}n)+\frac{1}{2} n^2\{-(r-1)(c_0^{\prime}

B_{20}+a_2)\}. \end{array}\right\}

\end{equation}

\begin{equation}

\left.\begin{array}{@{}c@{}} I_1 =r h_1({-}n)-\frac{1}{6}

n^3\{-(r-1)(c_0^{\prime} B_{20}+a_2)\}, \\ H_1 =r

h_1^{\prime}({-}n)+\frac{1}{2} n^2\{-(r-1)(c_0^{\prime}

B_{20}+a_2)\}. \end{array}\right\}

\end{equation}

Similarly, ![]() $J_2$ becomes

$J_2$ becomes

\begin{align} J_2&=\frac{m^{{-}1} c_0^{\prime 2}}{a_1-a_2}Wi\left\{\frac{-3 l_1 m n^2 - l_2 m n^3 + 3 l_1 n^4 - l_2 n^4}{6 n^2 (1 + n) R_{2p}} \right. \nonumber\\ &\quad \left. -\,m(h'_3-2h_3)-\frac{m-n^2}{2(1+n)} (h_3-h'_3) \right\}. \end{align}

\begin{align} J_2&=\frac{m^{{-}1} c_0^{\prime 2}}{a_1-a_2}Wi\left\{\frac{-3 l_1 m n^2 - l_2 m n^3 + 3 l_1 n^4 - l_2 n^4}{6 n^2 (1 + n) R_{2p}} \right. \nonumber\\ &\quad \left. -\,m(h'_3-2h_3)-\frac{m-n^2}{2(1+n)} (h_3-h'_3) \right\}. \end{align}

For a Newtonian fluid, ![]() $\mu _{2p}= 0, \tau =0$, where

$\mu _{2p}= 0, \tau =0$, where ![]() $Wi\rightarrow 0$ and

$Wi\rightarrow 0$ and ![]() $R_{2p} \rightarrow \infty$, therefore

$R_{2p} \rightarrow \infty$, therefore ![]() $J_2$ becomes zero and

$J_2$ becomes zero and ![]() $J=J_1$. Then (3.93) becomes

$J=J_1$. Then (3.93) becomes

which reproduces the complex wave speed in a N–N coflow (Yih Reference Yih1967).

4. Results and discussion

In the experimental study, FC40 and SiO-1000 or PEO are infused into the microchannel as phase 1 (P1) and phase 2 (P2), respectively, to establish an immiscible N–N and N–VE coflow system (figure 1a). The flow rates of the FC40 and SiO-1000 phases are varied in the range 20–60 ![]() $\mathrm {\mu }$l min

$\mathrm {\mu }$l min![]() $^{-1}$ and 0.01–180

$^{-1}$ and 0.01–180 ![]() $\mathrm {\mu }$l min

$\mathrm {\mu }$l min![]() $^{-1}$, respectively. The flow rate of the PEO phase is kept in the range 0–17

$^{-1}$, respectively. The flow rate of the PEO phase is kept in the range 0–17 ![]() $\mathrm {\mu }$l min

$\mathrm {\mu }$l min![]() $^{-1}$, such that the shear-thinning effects are insignificant (see Appendix B for the viscosity vs shear rate plot), which goes well with our theoretical model. With the above flow rate conditions,

$^{-1}$, such that the shear-thinning effects are insignificant (see Appendix B for the viscosity vs shear rate plot), which goes well with our theoretical model. With the above flow rate conditions, ![]() $R_{1} = ({\rho _{1}\ U_{0} W_{2}}/{\mu _{1}} ) \approx 70{-}400$, and

$R_{1} = ({\rho _{1}\ U_{0} W_{2}}/{\mu _{1}} ) \approx 70{-}400$, and ![]() $R_{2} = ( {\rho _{2}\ U_{0} W_{2}}/{\mu _{2}} ) \approx 10^{- 5} - 2$, where

$R_{2} = ( {\rho _{2}\ U_{0} W_{2}}/{\mu _{2}} ) \approx 10^{- 5} - 2$, where ![]() $R_1$ and

$R_1$ and ![]() $R_2$ are the Reynolds numbers for phases P1 and P2, respectively. The mean velocity corresponding to the total flow rate (

$R_2$ are the Reynolds numbers for phases P1 and P2, respectively. The mean velocity corresponding to the total flow rate (![]() $=Q_1+Q_2$) is represented by

$=Q_1+Q_2$) is represented by ![]() $U_0$. The mean velocities of phases P1 and P2 are determined as

$U_0$. The mean velocities of phases P1 and P2 are determined as ![]() $U_{01} = {Q_{1}}/{W_{1}H}$ and

$U_{01} = {Q_{1}}/{W_{1}H}$ and ![]() $U_{02} = {Q_{2}}/{W_{2}H}$, respectively. The capillary numbers (

$U_{02} = {Q_{2}}/{W_{2}H}$, respectively. The capillary numbers (![]() $Ca$) of the two phases are estimated to be

$Ca$) of the two phases are estimated to be ![]() ${Ca}_{1} = {\mu _{1}U_{01}}/{\gamma _{12}} \approx 0.001{-}0.1$ and

${Ca}_{1} = {\mu _{1}U_{01}}/{\gamma _{12}} \approx 0.001{-}0.1$ and ![]() ${Ca}_{2} = {\mu _{2}U_{02}}/{\gamma _{12}} \approx 0.001{-}10$, where

${Ca}_{2} = {\mu _{2}U_{02}}/{\gamma _{12}} \approx 0.001{-}10$, where ![]() $\gamma _{12}$ is the IFT between the two phases. The flow rate ratio (

$\gamma _{12}$ is the IFT between the two phases. The flow rate ratio (![]() $Q_{r}$) is defined as the ratio

$Q_{r}$) is defined as the ratio ![]() $( = {Q_{1}}/{Q_{2}} )$ of phase 1 (P1) flow rate to the phase 2 (P2) flow rate. Viscosity ratio (

$( = {Q_{1}}/{Q_{2}} )$ of phase 1 (P1) flow rate to the phase 2 (P2) flow rate. Viscosity ratio (![]() $m$) is defined as the ratio

$m$) is defined as the ratio ![]() $( = {\mu _{1}}/{\mu _{2}})$ of the viscosity of P1 phase to that of P2 phase.

$( = {\mu _{1}}/{\mu _{2}})$ of the viscosity of P1 phase to that of P2 phase.

We first characterize the coflow system for a range of ![]() $Q_{r}$ and

$Q_{r}$ and ![]() $m$ values using the analytical expressions given for the primary flow in § 3.1. Further, we study the variation of velocity fields, interface location and shear stress distribution, which are elaborated in § 4.1. Next, in § 4.2, we illustrate the flow regimes: stable (S) and unstable (U) – waviness and droplet, observed for the different coflow combinations. We also theoretically predict these regimes using the expression for complex wave speed (

$m$ values using the analytical expressions given for the primary flow in § 3.1. Further, we study the variation of velocity fields, interface location and shear stress distribution, which are elaborated in § 4.1. Next, in § 4.2, we illustrate the flow regimes: stable (S) and unstable (U) – waviness and droplet, observed for the different coflow combinations. We also theoretically predict these regimes using the expression for complex wave speed (![]() $c_i$) derived in § 3.3. In § 4.3, we initially discuss the difference in the dispersion relation in the case of N–N and the N–VE coflow case. Later we experimentally characterize the behaviour of the axial evolution of the unstable-waviness regime (amplitude

$c_i$) derived in § 3.3. In § 4.3, we initially discuss the difference in the dispersion relation in the case of N–N and the N–VE coflow case. Later we experimentally characterize the behaviour of the axial evolution of the unstable-waviness regime (amplitude ![]() $A$ and wavelength

$A$ and wavelength ![]() $\lambda$) for different coflow combinations. Finally, in § 4.4, we investigate the unstable-droplet regime, which is of particular interest in microfluidic applications.

$\lambda$) for different coflow combinations. Finally, in § 4.4, we investigate the unstable-droplet regime, which is of particular interest in microfluidic applications.

4.1. Description of stratified coflow in a microchannel

The instabilities generated due to the viscosity stratification in coflowing fluids strongly depend on the interface location and local velocity variation (Govindarajan & Sahu Reference Govindarajan and Sahu2014). In order to describe the unstable regimes, we first analyse the primary flow (figure 1a) using the theoretical formulations given in § 3.1. This allows us to identify the reference interface location and determine the characteristic velocities for phases P1 and P2.

Initially, we analytically determine the interface location by calculating the low-viscosity (P1) and high-viscosity (P2) stream width (![]() $W_1$ and

$W_1$ and ![]() $W_2$), as detailed in Appendix C.1. The variation of width ratio

$W_2$), as detailed in Appendix C.1. The variation of width ratio ![]() $( {W_{2}}/{W})$ depends on the flow rate ratio (

$( {W_{2}}/{W})$ depends on the flow rate ratio (![]() $Q_{r}$) and the viscosity ratio (

$Q_{r}$) and the viscosity ratio (![]() $m$). We plot the variation of

$m$). We plot the variation of ![]() $W_2/W$ with

$W_2/W$ with ![]() $(Q_r m)^{-1}$ at different values of

$(Q_r m)^{-1}$ at different values of ![]() $m$ as shown in figure 2(a), where

$m$ as shown in figure 2(a), where ![]() $(Q_r m)^{-1}= (Q_2 \mu _2)/(Q_1 \mu _1)$. Here, the plots for different

$(Q_r m)^{-1}= (Q_2 \mu _2)/(Q_1 \mu _1)$. Here, the plots for different ![]() $m$ values collapse onto a single curve given by a theoretical fit:

$m$ values collapse onto a single curve given by a theoretical fit: ![]() $W_2/W \approx (1+1.67 (Q_r m)^{1/3})^{-1}$. We use this fit to determine the interfacial location (or fluid stream width ratio) and the local velocity variations. We observe that, with the increase in both flow rate and viscosity of phase P2 (while keeping the phase P1 flow rate and viscosity constant), the width of second phase or

$W_2/W \approx (1+1.67 (Q_r m)^{1/3})^{-1}$. We use this fit to determine the interfacial location (or fluid stream width ratio) and the local velocity variations. We observe that, with the increase in both flow rate and viscosity of phase P2 (while keeping the phase P1 flow rate and viscosity constant), the width of second phase or ![]() $W_2$ increases (Hu & Cubaud Reference Hu and Cubaud2018). Owing to the thin layer effect (Renardy & Joseph Reference Renardy and Joseph1985), at very high

$W_2$ increases (Hu & Cubaud Reference Hu and Cubaud2018). Owing to the thin layer effect (Renardy & Joseph Reference Renardy and Joseph1985), at very high ![]() $(Q_r m)^{-1}$ values, the phase 1 shrinks to a small stream width

$(Q_r m)^{-1}$ values, the phase 1 shrinks to a small stream width ![]() $W_1$ which can be obtained as

$W_1$ which can be obtained as ![]() $W_1=W-W_2$.

$W_1=W-W_2$.

Figure 2. Theoretical study of width ratios, velocity profiles and shear stress distribution. (a) Evolution of fluid stream width ratio ![]() $(W_2/W)$ against

$(W_2/W)$ against ![]() $(Q_r m)^{-1}=(Q_2/Q_1)(\mu _2/\mu _1)$ for various viscosity ratios (

$(Q_r m)^{-1}=(Q_2/Q_1)(\mu _2/\mu _1)$ for various viscosity ratios (![]() $m$), which is represented by a theoretical fit of the form

$m$), which is represented by a theoretical fit of the form ![]() $W_2/W \approx (1+1.67 (Q_r m)^{1/3})^{-1}$. (b) Velocity profile of coflow combinations at various

$W_2/W \approx (1+1.67 (Q_r m)^{1/3})^{-1}$. (b) Velocity profile of coflow combinations at various ![]() $m$ values for

$m$ values for ![]() $Q_r=4$ are shown, where phase 1, phase 2 and the interface location are indicated. (c) Interfacial shear stress (

$Q_r=4$ are shown, where phase 1, phase 2 and the interface location are indicated. (c) Interfacial shear stress (![]() $\bar {\sigma }_{xy}|_{y=0}$) variation with

$\bar {\sigma }_{xy}|_{y=0}$) variation with ![]() $Q_2/Q_1$ for various

$Q_2/Q_1$ for various ![]() $m$ values. The viscosity ratios

$m$ values. The viscosity ratios ![]() $(m=\mu _1/\mu _2)$ are considered as

$(m=\mu _1/\mu _2)$ are considered as ![]() $m=1/100$,

$m=1/100$, ![]() $1/200$,

$1/200$, ![]() $1/250$ and

$1/250$ and ![]() $1/500$.

$1/500$.

We obtain the flow velocity profiles for various coflow combination with different viscosity ratios at a fixed flow rate ratio (![]() $Q_{r} = 4.0$) from (3.35)–(3.37), as presented in figure 2(b). It is found that, with decreasing

$Q_{r} = 4.0$) from (3.35)–(3.37), as presented in figure 2(b). It is found that, with decreasing ![]() $m$, velocity profiles become more skewed, which can give rise to interfacial instability (Hu & Cubaud Reference Hu and Cubaud2018). As expected theoretically (Hazra et al. Reference Hazra, Mitra and Sen2022b), the maximum velocity occurs in P1 phase having a lower viscosity. Therefore, at a fixed flow rate of P2, with decreasing

$m$, velocity profiles become more skewed, which can give rise to interfacial instability (Hu & Cubaud Reference Hu and Cubaud2018). As expected theoretically (Hazra et al. Reference Hazra, Mitra and Sen2022b), the maximum velocity occurs in P1 phase having a lower viscosity. Therefore, at a fixed flow rate of P2, with decreasing ![]() $m$, the maximum velocity in P1 phase increases (Hazra et al. Reference Hazra, Mitra and Sen2022b). The variation of interfacial shear stress (

$m$, the maximum velocity in P1 phase increases (Hazra et al. Reference Hazra, Mitra and Sen2022b). The variation of interfacial shear stress (![]() $\bar {\sigma }_{xy}$) with varying flow rate ratio (

$\bar {\sigma }_{xy}$) with varying flow rate ratio (![]() $Q_{r}$) is depicted in figure 2(c). The interfacial shear stress at

$Q_{r}$) is depicted in figure 2(c). The interfacial shear stress at ![]() $y=0$ is calculated as

$y=0$ is calculated as ![]() $\bar {\sigma }_{xy}|_{y=0} \approx ({1}/{R_2}) ({\partial U_2}/{\partial y})=({r}/{R_1}) ({\partial U_1}/{\partial y})$. The results demonstrate that, for a fixed viscosity ratio (

$\bar {\sigma }_{xy}|_{y=0} \approx ({1}/{R_2}) ({\partial U_2}/{\partial y})=({r}/{R_1}) ({\partial U_1}/{\partial y})$. The results demonstrate that, for a fixed viscosity ratio (![]() $m$), the interfacial shear stress (

$m$), the interfacial shear stress (![]() $\bar {\sigma }_{xy}|_{y=0}$) increases with a decrease in the flow rate ratio (

$\bar {\sigma }_{xy}|_{y=0}$) increases with a decrease in the flow rate ratio (![]() $Q_{r}$). Additionally, for a fixed

$Q_{r}$). Additionally, for a fixed ![]() $Q_{r}$, a decrease in the viscosity ratio (

$Q_{r}$, a decrease in the viscosity ratio (![]() $m$) leads to an increase in

$m$) leads to an increase in ![]() $\bar {\sigma }_{xy}|_{y=0}$. This relationship between

$\bar {\sigma }_{xy}|_{y=0}$. This relationship between ![]() $\bar {\sigma }_{xy}$ and

$\bar {\sigma }_{xy}$ and ![]() $Q_{r}$ is crucial for understanding the transition between different flow regimes.

$Q_{r}$ is crucial for understanding the transition between different flow regimes.

4.2. Description of flow regimes

Viscous and elastic stratification give rise to different flow regimes in microfluidic confinements. However, understanding the individual effect of viscosity and elasticity on the total instability is challenging due to the coupled variation of viscosity and elasticity. We conduct experiments and use the formulations given in § 3.3 to explore the decoupled effects of viscous and elastic stratification. In this section, we describe the experimentally observed flow regimes and use the variation of complex wave speed ![]() $(c_i)$ to explain the transition between stable and unstable regimes. The earlier study (Yih Reference Yih1967) for the case of Poiseuille flow of coflowing Newtonian fluids reported only an unstable regime for a fluid density ratio

$(c_i)$ to explain the transition between stable and unstable regimes. The earlier study (Yih Reference Yih1967) for the case of Poiseuille flow of coflowing Newtonian fluids reported only an unstable regime for a fluid density ratio ![]() $r=1$ and stream width ratio

$r=1$ and stream width ratio ![]() $n=1$. However, we observe different flow morphologies: (i) a stable regime (S) with a straight interface, (ii) an unstable regime (U) with wavy interface or droplets (dripping) from low-viscosity fluid; for the case of coflowing Newtonian and viscoelastic fluids. The experimental images of the different regimes observed from a large set of experiments are shown in figure 3(a). The images are captured at a fixed axial location,

$n=1$. However, we observe different flow morphologies: (i) a stable regime (S) with a straight interface, (ii) an unstable regime (U) with wavy interface or droplets (dripping) from low-viscosity fluid; for the case of coflowing Newtonian and viscoelastic fluids. The experimental images of the different regimes observed from a large set of experiments are shown in figure 3(a). The images are captured at a fixed axial location, ![]() $\tilde {x} \approx 3$ mm with various coflow combinations (at a fixed

$\tilde {x} \approx 3$ mm with various coflow combinations (at a fixed ![]() $m$) by varying the flow rate (

$m$) by varying the flow rate (![]() $Q_{2}$) of the high-viscosity fluid, keeping the flow rate (

$Q_{2}$) of the high-viscosity fluid, keeping the flow rate (![]() $Q_{1}$) of the low-viscosity fluid fixed.

$Q_{1}$) of the low-viscosity fluid fixed.

Figure 3. Description of experimentally observed distinct flow regimes via theoretical study depicting the variation of ![]() $J(=J_1+J_2), \ J_1$ (viscous stratification component), and

$J(=J_1+J_2), \ J_1$ (viscous stratification component), and ![]() $J_2$ (elastic stratification component) and a comprehensive regime plot. (a) Experimental images (pertaining to data points marked with

$J_2$ (elastic stratification component) and a comprehensive regime plot. (a) Experimental images (pertaining to data points marked with ![]() $\bigstar$ in c) different regimes: stable (grey), unstable waviness (red) and unstable droplet (blue) are shown in a tabular form for varying flow rate ratio (

$\bigstar$ in c) different regimes: stable (grey), unstable waviness (red) and unstable droplet (blue) are shown in a tabular form for varying flow rate ratio (![]() $Q_{r}$) and viscosity ratio (

$Q_{r}$) and viscosity ratio (![]() $m$). Scale measures 300

$m$). Scale measures 300 ![]() $\mathrm {\mu }$m. (b) Theoretical variation of

$\mathrm {\mu }$m. (b) Theoretical variation of ![]() $J$,

$J$, ![]() $J_1$, and

$J_1$, and ![]() $J_2$ corresponding to (a) for different fluid combinations with fixed

$J_2$ corresponding to (a) for different fluid combinations with fixed ![]() $Q_1$: (i) FC40-SiO 1000,

$Q_1$: (i) FC40-SiO 1000, ![]() $Q_1 = 45$

$Q_1 = 45$ ![]() $\mathrm {\mu }$l min

$\mathrm {\mu }$l min![]() $^{-1}$, (ii) FC40-PEO 3 %,

$^{-1}$, (ii) FC40-PEO 3 %, ![]() $Q_1 = 50$

$Q_1 = 50$ ![]() $\mathrm {\mu }$l min

$\mathrm {\mu }$l min![]() $^{-1}$, (iii) FC40-PEO 4 %,

$^{-1}$, (iii) FC40-PEO 4 %, ![]() $Q_1 = 45$

$Q_1 = 45$ ![]() $\mathrm {\mu }$l min

$\mathrm {\mu }$l min![]() $^{-1}$ and (iv) FC40-PEO 5 %,

$^{-1}$ and (iv) FC40-PEO 5 %, ![]() $Q_1 = 40$

$Q_1 = 40$ ![]() $\mathrm {\mu }$l min

$\mathrm {\mu }$l min![]() $^{-1}$. The colour bands represent the experimental stable (S), unstable-waviness (U-W) and unstable-droplet (U-D) regimes for a range of

$^{-1}$. The colour bands represent the experimental stable (S), unstable-waviness (U-W) and unstable-droplet (U-D) regimes for a range of ![]() $Q_2$. From theory, the critical values of

$Q_2$. From theory, the critical values of ![]() $Q_2$ and

$Q_2$ and ![]() $J$ for the transition from the stable (S) to the unstable (U) regime are indicated by

$J$ for the transition from the stable (S) to the unstable (U) regime are indicated by ![]() $Q_2^{c1}$ (black vertical dashed line) and

$Q_2^{c1}$ (black vertical dashed line) and ![]() $J^{c1}$ (black horizontal dashed line). The transition from the unstable-waviness to the unstable-droplet regime is marked by

$J^{c1}$ (black horizontal dashed line). The transition from the unstable-waviness to the unstable-droplet regime is marked by ![]() $Q_2^{c2}$ (green vertical dashed line) and

$Q_2^{c2}$ (green vertical dashed line) and ![]() $J^{c2}$ (green horizontal dashed line). (c) Regime plot showing stable coflow (grey), unstable-waviness (red) and unstable-droplet (blue) regimes for FC40-PEO 3 % (triangle symbol, double compound line), FC40-PEO 4 % (square symbol, dash-dot line), FC40-PEO 5 % (diamond symbol, dash-dot-dot line) and FC40-SiO 1000 (circle symbol, dash line) coflow combinations over a range of capillary numbers,

$J^{c2}$ (green horizontal dashed line). (c) Regime plot showing stable coflow (grey), unstable-waviness (red) and unstable-droplet (blue) regimes for FC40-PEO 3 % (triangle symbol, double compound line), FC40-PEO 4 % (square symbol, dash-dot line), FC40-PEO 5 % (diamond symbol, dash-dot-dot line) and FC40-SiO 1000 (circle symbol, dash line) coflow combinations over a range of capillary numbers, ![]() ${Ca}_{1}$ and

${Ca}_{1}$ and ![]() ${Ca}_{2}$. The subscript 1 and 2 are used for low-viscosity fluid (FC40) and the high-viscosity fluid, respectively. Different versions and colours of the corresponding symbols are used to indicate flow rates (

${Ca}_{2}$. The subscript 1 and 2 are used for low-viscosity fluid (FC40) and the high-viscosity fluid, respectively. Different versions and colours of the corresponding symbols are used to indicate flow rates (![]() $Q_{1}$,

$Q_{1}$, ![]() $Q_{2})$ over which the coflowing fluid combinations undergo various regime transitions, as shown in the legend. A more detailed version of the regime plot is provided in Appendix D.

$Q_{2})$ over which the coflowing fluid combinations undergo various regime transitions, as shown in the legend. A more detailed version of the regime plot is provided in Appendix D.

In general, our experiments (shown in figure 3a) show that instabilities are generated due to the viscosity and elasticity difference between the liquids in a coflow. In this situation, an increase in the flow rate of the high-viscosity fluid causes a transition from stable to convective and eventually to absolute instability (Guillot et al. Reference Guillot, Colin, Utada and Ajdari2007; Utada et al. Reference Utada, Fernandez-Nieves, Gordillo and Weitz2008; Hemachandran et al. Reference Hemachandran, Hoque, Laurell and Sen2021). Transition between the different regimes (stable and unstable) in microfluidic coflows can be understood further using the expression for the complex wave speed (![]() $c_{i}$) obtained from the temporal stability analysis given in § 3.3, where

$c_{i}$) obtained from the temporal stability analysis given in § 3.3, where ![]() $c_i=k R_2 J$ and

$c_i=k R_2 J$ and ![]() $J=J_1+J_2$. Generally in a temporal stability analysis, the stability of a system is determined by observing the time evolution of perturbations (Yih Reference Yih1967; Govindarajan & Sahu Reference Govindarajan and Sahu2014). By assuming the wavenumber to be real (

$J=J_1+J_2$. Generally in a temporal stability analysis, the stability of a system is determined by observing the time evolution of perturbations (Yih Reference Yih1967; Govindarajan & Sahu Reference Govindarajan and Sahu2014). By assuming the wavenumber to be real (![]() $k = k_r$), temporal instability is distinguished from spatial instability (Utada et al. Reference Utada, Fernandez-Nieves, Gordillo and Weitz2008). A zero value of the complex wave speed of the perturbations,

$k = k_r$), temporal instability is distinguished from spatial instability (Utada et al. Reference Utada, Fernandez-Nieves, Gordillo and Weitz2008). A zero value of the complex wave speed of the perturbations, ![]() $c_i$, indicates a neutrally stable case. However, if

$c_i$, indicates a neutrally stable case. However, if ![]() $c_i$ is negative (

$c_i$ is negative (![]() $c_i<0$), the disturbances diminish over time, indicating a flat interface in the stable regime. Conversely, if

$c_i<0$), the disturbances diminish over time, indicating a flat interface in the stable regime. Conversely, if ![]() $c_i$ is positive (

$c_i$ is positive (![]() $c_i >0$), the disturbances increase exponentially, indicating that the system is unstable. Since our theoretical analysis assumes the wavenumber to be real, we use the above mentioned

$c_i >0$), the disturbances increase exponentially, indicating that the system is unstable. Since our theoretical analysis assumes the wavenumber to be real, we use the above mentioned ![]() $c_i$ conditions to predict the regimes. The nature of the instability is found to be either convective or absolute. In order to differentiate between these two, a spatio-temporal analysis with the Briggs–Bers criterion is used in the literature (Guillot et al. Reference Guillot, Colin, Utada and Ajdari2007; Utada et al. Reference Utada, Fernandez-Nieves, Gordillo and Weitz2008). The complex wave speed,

$c_i$ conditions to predict the regimes. The nature of the instability is found to be either convective or absolute. In order to differentiate between these two, a spatio-temporal analysis with the Briggs–Bers criterion is used in the literature (Guillot et al. Reference Guillot, Colin, Utada and Ajdari2007; Utada et al. Reference Utada, Fernandez-Nieves, Gordillo and Weitz2008). The complex wave speed, ![]() $c_i$, and growth rate,

$c_i$, and growth rate, ![]() $\omega _i$, are related to the wavenumber,

$\omega _i$, are related to the wavenumber, ![]() $k$, by the equation

$k$, by the equation ![]() $\omega _i = k c_i$, where the values of

$\omega _i = k c_i$, where the values of ![]() $\omega _0$ and

$\omega _0$ and ![]() $k_0$ are obtained from

$k_0$ are obtained from ![]() $D(\omega _0, k_0)=0$ and

$D(\omega _0, k_0)=0$ and ![]() $v_{group}=\partial \omega / \partial k |_{\omega =\omega _0, k=k_0}$ (Huerre & Monkewitz Reference Huerre and Monkewitz1990; Sahu & Govindarajan Reference Sahu and Govindarajan2014). Finally, the regimes obey the following conditions with regards to the instability: (i) convectively unstable,

$v_{group}=\partial \omega / \partial k |_{\omega =\omega _0, k=k_0}$ (Huerre & Monkewitz Reference Huerre and Monkewitz1990; Sahu & Govindarajan Reference Sahu and Govindarajan2014). Finally, the regimes obey the following conditions with regards to the instability: (i) convectively unstable, ![]() $\omega _i>0, v_{group}>0$; (ii) absolutely unstable,

$\omega _i>0, v_{group}>0$; (ii) absolutely unstable, ![]() $\omega _i>0, v_{group}<0$.

$\omega _i>0, v_{group}<0$.

First, we investigate the effect of viscous stratification by considering the case of N–N coflows: FC40-SiO 1000 (![]() $m = 1/250$). As mentioned in the earlier § 3.3, the formulations for

$m = 1/250$). As mentioned in the earlier § 3.3, the formulations for ![]() $c_i$ reduces to (3.97) for the case of a FC40-SiO 1000 coflow, where the elastic stratification (Weissenberg number,

$c_i$ reduces to (3.97) for the case of a FC40-SiO 1000 coflow, where the elastic stratification (Weissenberg number, ![]() $Wi\approx 0$) effects become negligible (

$Wi\approx 0$) effects become negligible (![]() $J_2=0$,

$J_2=0$, ![]() $J=J_1$) and the instabilities are generated only due to the variation in the viscous stratification (

$J=J_1$) and the instabilities are generated only due to the variation in the viscous stratification (![]() $J_1$). Through (3.94)–(3.97), we obtain the variations in

$J_1$). Through (3.94)–(3.97), we obtain the variations in ![]() $J_1$,

$J_1$, ![]() $J_2$,

$J_2$, ![]() $J$ and

$J$ and ![]() $c_i$ for a wide range of values of

$c_i$ for a wide range of values of ![]() $r$ and

$r$ and ![]() $n$, and represent for the case of a FC40-SiO 1000 coflow having

$n$, and represent for the case of a FC40-SiO 1000 coflow having ![]() $m=1/250$ and

$m=1/250$ and ![]() $r=1.89$ via figure 3(b-i). As

$r=1.89$ via figure 3(b-i). As ![]() $Q_2$ increases, the viscosity stratification causes

$Q_2$ increases, the viscosity stratification causes ![]() $J_1$ to increase – flipping from a negative to a positive value. Further,

$J_1$ to increase – flipping from a negative to a positive value. Further, ![]() $J_1$ becomes maximum at a substantially high flow rate (

$J_1$ becomes maximum at a substantially high flow rate (![]() $Q_2$) as shown in figure 3(b-i). At the same time, the fluid stream width ratio (