Introduction

Degradation of the natural environment, with the climate crisis as the broadest and most fundamental threat, today cuts across the global automobile industry. Although this industry’s impact on the environment has been on the political agenda for at least half a century, transforming itself toward less environmentally damaging practices has proven extremely challenging. One of the most debated issues has been exhaust emissions from passenger cars. Whereas emissions of hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx) reached the political agenda in the 1960s, during the past three decades a growing concern regarding climate change has made carbon dioxide (CO2) emissions an additional challenge for automakers to address.Footnote 1 Decades ago, numerous automakers declared that action on climate change was imperative; at the same time, however, few companies have lived up to their rhetoric.Footnote 2 Increased discrepancy between “green” rhetoric and business practice has been identified as a general problem among large corporations since the 1980s and, according to some scholars, has presented a challenge almost as great as the neglect of environmental problems in the past.Footnote 3

Although the automobile industry has indeed served as the backbone of much business history scholarship—not least in the seminal works of Alfred D. Chandler—little research in business history to date has examined how environmental regulations and the environmental debate at-large challenged the automobile industry to transform toward sustainability from the 1960s onward.Footnote 4 As a result, there is a considerable gap in the literature offering insight into the historically shaped inertias and difficulties in transforming this industry with respect to the environment.Footnote 5 As argued by Adam Rome in his recent study of the chemical company DuPont, there is an overall need for detailed historical studies of corporate environmental performance, as a multiauthored history of corporate responsibility in the United States has only touched on the subject.Footnote 6 The same holds for virtually all other countries, including those in Europe.Footnote 7

In this context, Volvo Cars Corporation (hereafter Volvo) represents a captivating case study. When U.S. car manufacturers fiercely fought against new environmental regulations in the 1970s, and the American public regarded the automobile as the environmental “public enemy number one,”Footnote 8 Volvo stood out as a proactive company.Footnote 9 In 1972, the company adopted “environmental care” as the third core value in its business operations, alongside “quality” and “safety.” Volvo apparently embraced an emerging issue that, particularly, U.S. firms fought against. The person responsible for this early initiative was Volvo’s chief executive officer since 1971, Pehr G. Gyllenhammar. His initiative was well-timed. The United Nations organized the first Conference on the Human Environment in Stockholm in 1972,Footnote 10 and Sweden had already implemented a new environmental regulatory framework in 1969 and recently imposed new standards for exhaust emissions from automobiles.Footnote 11 In the United States, which at the time had grown into Volvo’s most important export market, the automobile industry had emerged as one of the most contested industries among environmentalists and the public.Footnote 12 A historic turn occurred in 1970 when the U.S. Congress passed the Clean Air Act (CAA) amendments, which challenged large shares of the global auto industry.Footnote 13 The amendments called for a 90 percent reduction of HC and CO emissions by 1975, relative to the emission levels of 1970 models. By 1976, a comparable 90 percent reduction in NOx emissions was to take place.Footnote 14 Congress pushed the federal deadlines several times (until 1980–1981) due to opposition by domestic car manufacturers, while California deterred implementation of the federal deadlines until 1977.Footnote 15

Volvo’s new “environmental care” core value soon materialized through leadership in controlling exhaust emissions. As demonstrated in previous research, the new requirements imposed by the 1970 CAA amendments instigated a race in research and development (R&D) efforts in the U.S. automobile industry as well as in the Japanese and European companies competing on the U.S. market, including Volvo.Footnote 16 By introducing the so-called three-way catalytic converter (TWC) on the California market in 1976, Volvo became the first automobile manufacturer to show that the CAA amendment’s standards were technically achievable, ahead of U.S. companies such as General Motors, Ford, and Chrysler.Footnote 17 Over the course of the 1970s, Volvo not only managed to lead the development of emission control technology but also strengthened its position as a market leader in safety standards.Footnote 18 A renewed strategic initiative was undertaken in the late 1980s to make the environment a cornerstone of the company, and it developed, according to previous studies, a unique company environmental profile.Footnote 19

However, despite Volvo’s early global leadership in exhaust emission control and safety standards, the company did not take the lead in addressing another evolving fundamental environmental problem: climate change and CO2 emissions. In 2009, Volvo was identified as the most fuel- and CO2-intensive company on the European market.Footnote 20 As it appears, Volvo’s environmental record has been contradictory since the 1970s. This article focuses on Volvo from the early 1970s to the 1990s. It seeks to understand the drivers behind the company’s proactive environmental strategies of the 1970s and why its early environmental leadership came to a halt, while identifying evolving obstacles and disincentives that help explain this development. This study also seeks to contribute historical perspectives to the question of why the growth of the automobile industry has been difficult to align with a shift toward environmental sustainability, through the lens of Volvo.

The automobile industry and exhaust emission regulation

For more than a century, the automobile industry has revolved around a dominant design based on a combustion engine, steel body, and mechanical power train. It is well established among scholars that this design has reached its limits in terms of environmental impact, especially in reducing CO2 emissions. Business and innovation scholars have highlighted some key inertial forces behind the unsustainable development of the automobile industry, whereby lock-ins and path dependencies have created great barriers to change. This occurred because the industry has been, and still is, interconnected with numerous technological systems and a complex of networks of co-specialized, interdependent, and complimentary assets.Footnote 21 As a result, single automobile firms have faced strong limitations to succeeding through radical or disruptive innovations, such as alternatives to the combustion engine.Footnote 22

Since the advent of the Fordist production organization, the low-cost production of automobiles on a massive scale has continued to be a paradigmatic feature of the global automobile industry. Automobile production has long been defined by cost-per-unit manufacturing, whereas consumption has been defined as the cost of cars as new, which discounts the lifetime costs of automobile use.Footnote 23 Developing cars that pollute less thus involves heavy investments in R&D, along with alterations to the automobiles’ key componentsFootnote 24 that usually increase the purchase price while only adding a few additional, direct consumer benefits.Footnote 25 However, consumers have rarely prioritized environmental factors over price and other functions when buying cars.Footnote 26 The weak willingness among consumers to pay a higher price for green products has constituted a critical problem for most green business initiatives in recent decades, even in several other sectors.Footnote 27

Against this background, it is no surprise that previous research has identified governmental regulations, and specifically mandatory emission standards, as the single most important driver behind the greening of the automobile industry.Footnote 28 At the same time, it has been shown that governmental regulation can be a double-edged sword because it can both break with or redirect current paths as well as reinforce them. Environmental regulations targeting the automobile industry have thus been a highly contested area since the 1960s.Footnote 29 The regulatory controversy over the regional and global environmental impact of the automobile industry has shifted in scope since the 1970s, evolving into the climate change debate as well as contradictory requirements between fuel efficiency and air pollutants such as NOx, and a range of other issues.Footnote 30

It is notable that the historiography on the environmental regulation of automobiles indicates different regulatory foci in Europe and in the United States. Scholars have typically argued that U.S. lawmakers have prioritized clean air over fuel consumption, while European lawmakers have generally prioritized fuel efficiency over clean air, especially since the energy crises of the 1970s.Footnote 31 Since the 1990s, the European and U.S. standards for exhaust pollutants have converged, although U.S. exhaust emission standards remain stricter. On the other hand, European standards for fuel efficiency and CO2 emissions are more stringent.Footnote 32

One complicating factor documented in the literature concerning governmental regulations and the automobile industry has been the development of dissimilar regulatory requirements on different markets, which have required different technologies for regulatory compliance. Daniel Esty and Damien Geradin have suggested that these conditions have obstructed product development and the implementation of exhaust emission control technologies.Footnote 33 One stream of literature has stressed the efforts by European automobile industry lobby associations to influence the design of European technical standards in order to protect against U.S., and later Japanese, competitors, although with little evidence regarding whether and how these associations were successful in their efforts.Footnote 34

Whereas government environmental regulation targeting automobiles took its incipient steps in both the United States and Europe, including Sweden, in the 1950s and 1960s, the United States already moved much faster on emission standards in the 1970s with the 1970 CAA amendments.Footnote 35 In the European Union (EEC at the time), it was not until 1989 that its member states reached an agreement on a common standard with a stringency similar to that of the CAA amendments, almost twenty years later. One greatly complicating factor in the European context was that individual countries, such as Sweden, faced obstacles to implementing a stricter and thus deviant emission control standard in relation to their European trade partners, as this would cause conflicts over nontariff barriers to trade. Across industries, various national governmental standards and goals for safety, emissions, and fuel efficiency emerged, which reflected regional and national concerns for consumer protection, along with concerns over energy conservation and energy security, particularly after the early 1970s, on both sides of the Atlantic.Footnote 36

According to David Vogel and others, in the 1970s and 1980s, automakers with substantial exports to the United States, such as German and Swedish companies, had incentives to lobby their own governments to harmonize domestic regulations with U.S. standards. This occurred because these firms had invested heavily in the catalytic converter technology to comply with CAA amendments’ standards, which took full effect in the early 1980s. Scholars have thus suggested that these automobile firms preferred regulatory harmonization between the European and U.S. markets to achieve scale economies. In theoretical terms, the existence of different product standards on different markets typically increases transaction costs and generates diseconomies of scale, whereas harmonizing standards across markets can increase economies of scale for advanced emissions technology.Footnote 37 This in turn meant that Italian and French firms, with marginal exports to the United States, would have been much more reluctant to adopt U.S. standards in Europe.Footnote 38

Besides regulatory pressure, the impact of the OPEC oil embargos in 1973 and 1978 has attracted research attention, not least among historians. It is well established in this line of research that the oil crises of the 1970s forced automobile firms to consider fuel efficiency and alternative fuels,Footnote 39 as well as electrification. Governments typically supported the automobile industry’s efforts to develop alternative-fueled vehicles and alternative fuel production. A handful of studies have explored such initiatives and why they never achieved real market success.Footnote 40 In the big picture, however, the combustion engine fueled by gasoline and diesel continued to overrule any alternative well into the 2010s, when the electric automobile company Tesla challenged the conventional automobile industry to seriously invest in electrification. An electric transition is still in the future, however. In 2019, battery electric and plug-in hybrid vehicles made up just 3.5 percent of new sales in Europe and just over 2 percent in the United States.Footnote 41

Volvo Cars: A Brief Background

Volvo was started in 1926 as a subsidiary of the Swedish multinational ball bearing company Svenska Kullagerfabriken (SKF), which introduced Volvo on the Stockholm exchange in 1935.Footnote 42 Volvo’s first important step was to diversify into truck manufacturing in the 1930s, which contributed to the company’s production growth in its first decade of operations.Footnote 43 Before World War II, Volvo’s passenger car production never reached any substantial commercial achievement. It was only in 1944, when Volvo introduced the PV 444 model, marketed as “the people’s car” in Sweden, that the company achieved its first market success with passenger cars.Footnote 44 It was not until 1953 that passenger cars surpassed trucks as Volvo’s primary source of revenue.Footnote 45

Although, from the 1950s, car ownership was growing in Sweden at a higher rate than in the rest of Europe, the domestic market was still comparatively small, which drove Volvo to enter the U.S. market in 1955. Within a decade, the company managed to obtain a position as the second most important foreign automobile manufacturer on the California market, after German Volkswagen.Footnote 46 Volvo’s car production increased more than threefold in the 1960s, mostly due to Volvo’s success in the United States.Footnote 47 As the company’s growth strategy was based on overseas exports, a large part of its production capacity was built up around and adapted to U.S. requirements.Footnote 48

Early on, Volvo adopted “quality” and “safety” as the company’s “core values.”Footnote 49 These core values served as a compass for allocating R&D investments in production, product technology, and brand building. From the 1950s, “safety” was given strategic priority under the leadership of Gunnar Engellau, who envisioned that safety could give Volvo a competitive advantage, not least in the United States.Footnote 50 The company incorporated scientific “car safety” into its R&D strategies in the 1950s, resulting in one of Volvo’s key innovations, the three-point seatbelt, which was approved in the United States in 1961 by the Society of Automotive Engineers (SAE).Footnote 51

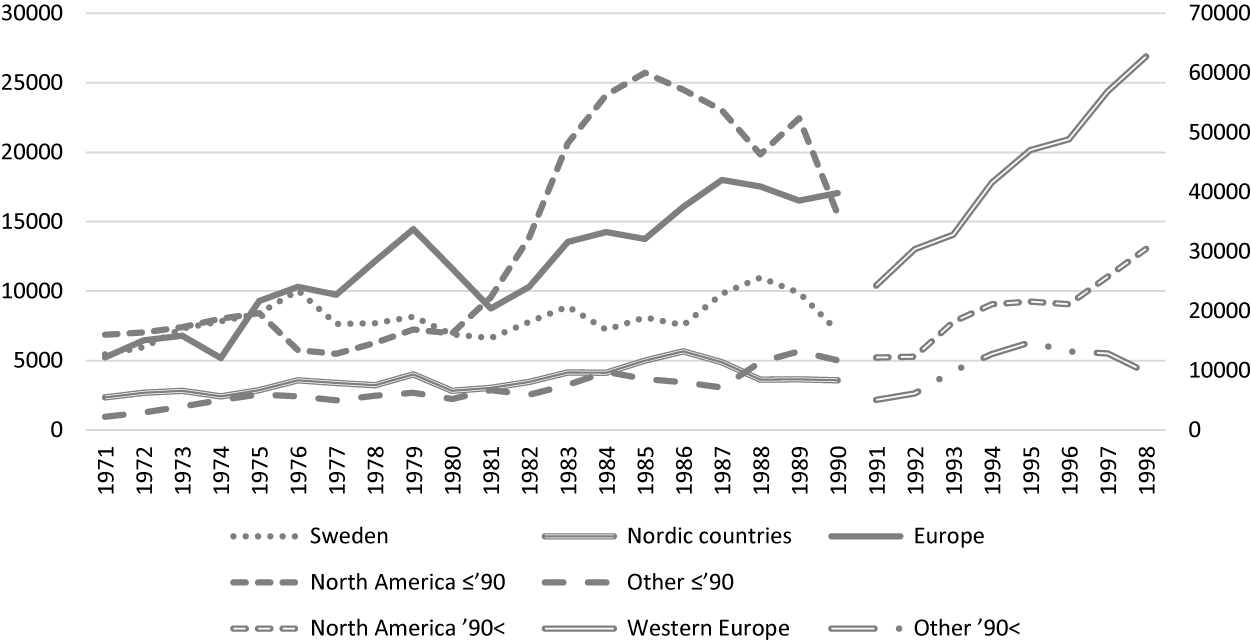

In the early 1970s, Volvo’s most important market was the United States, followed by Sweden and Britain. However, as demonstrated in Figure 1, there was a decline in exports to the United States during the oil crisis, both because the U.S. market was weakened and competition from Japanese manufacturers increased. Volvo’s exports to the United States then recovered, and in the early 1980s began strongly growing, for the first time exceeding one hundred thousand cars. Volvo’s strong growth in the United States was helped by the devaluations of the Swedish krona in the 1980s and the strong dollar.Footnote 52

Figure 1 Volvo passenger car sales on different markets, in million SEK, 1995 prices.

Source: Volvo Annual Reports

Note: Volvo changed its regional sales reporting during the 1990s, which means that there is less information on smaller regional markets. No information on sales is available during the time of Ford’s ownership. Sales in markets until 1990 (≤’90) are read of the left axis, while sales after the 1990 (’90<) are read of the right axis.

As Figure 1 also shows, Volvo’s sales on European markets increased as the American market declined in the 1970s. The European market recovered more quickly from the first oil embargo in 1973 than the American market did, and it had stronger protection against Japanese competition. A newborn orientation toward Europe was manifested when Pehr G. Gyllenhammar formed the European Roundtable of Industrialists (ERT) in 1982, which played an important role during the process leading up to the 1986 Single European Act.Footnote 53

As will be demonstrated later in this article, Volvo’s challenges connected to environmental regulations shifted from legal compliance on the U.S. market in the 1970s to the European market in the 1980s, in which regulations required different technologies for compliance within Europe, but also in relation to the United States until the early 1990s. With growing economic integration in Europe and the creation of the European Union in 1993, and Sweden joining the European Community in 1995, the European market overall grew in importance. At the same time, the U.S. market remained a priority for Volvo. Finally, in 1999, Ford Motor Company acquired a passenger cars division, placing the company in Ford’s Premier Automotive Group along with Jaguar, Aston Martin, and Land Rover. In 2010, Chinese Geely Holding Group bought Volvo from Ford.Footnote 54 Since then, China has been Volvo’s fastest growing market. By 2019, Volvo had grown substantially, selling 700,000 cars, 150,000 of them in China.Footnote 55

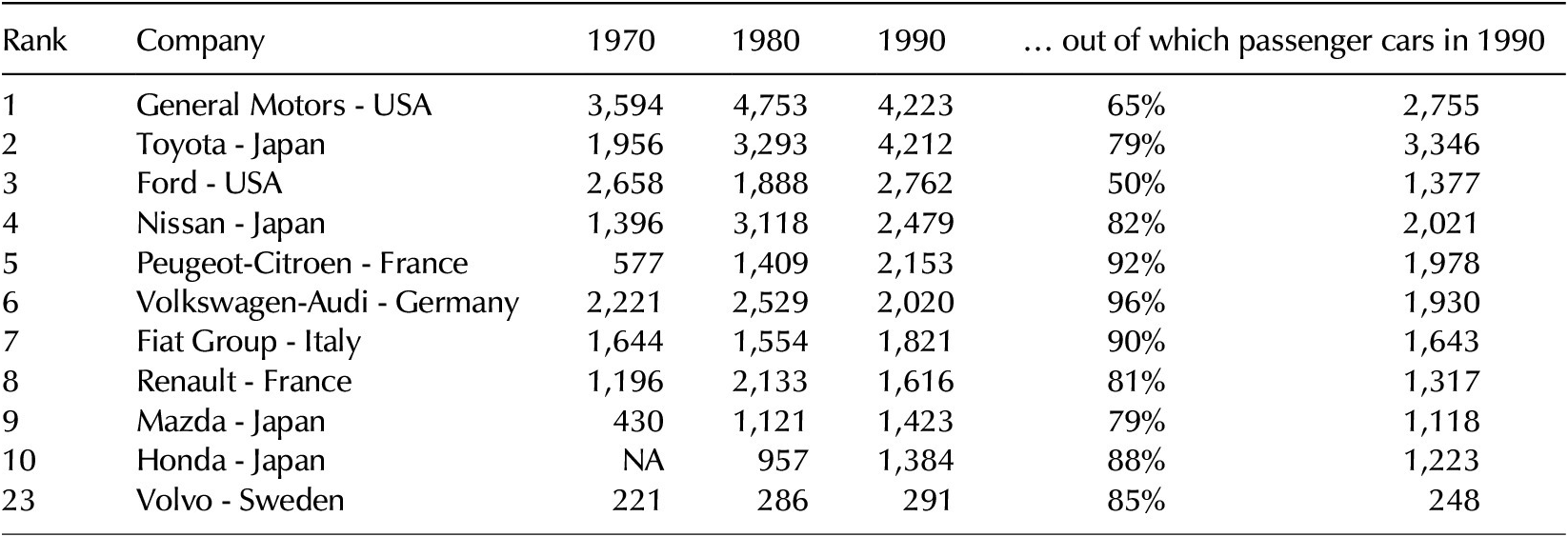

During the postwar period, Volvo developed into a large corporation in the Swedish, or Scandinavian, context. In 1950, the company had about 8,500 employees, but by the early 1980s this figure had expanded to 76,000.Footnote 56 However, as demonstrated in Table 1, Volvo was still a very small automobile manufacturer compared to U.S., Japanese, French, German, and Italian automobile manufacturers (see Table 1). As Berggren has noted, Volvo represented a paradox from an international perspective, as the company was a small-scale producer with a very strong belief in the merits of scale.Footnote 57

Table 1 Production of motor vehicles by the largest automobile manufacturers, in thousands of vehicles.* Ranked after production in 1990

Source: World Motor Vehicle Data, various years.

* Motor vehicles include both passenger cars and commercial vehicles.

Proactive Greening in the 1970s

The environmental issue developed into a top priority when Pehr G. Gyllenhammar took over Volvo’s leadership in 1971.Footnote 58 Overall, the 1960s was a period of environmental awaking in Swedish industry. In 1964, the Federation of Swedish Industry already initiated a new research institute to address research and technology development to tackle industrial pollution, an initiative that was signed by the country’s key industrial organizations.Footnote 59 The basic reason this occurred was Swedish industry had realized that stricter and more challenging governmental environmental policies would emerge. Sweden then established its Environmental Protection Agency in 1967 and implemented a new comprehensive environmental law in 1969, while Swedish scientists were the first to raise, on the international agenda, the issue of the long-range transport of acidic compounds causing “acid rain.”Footnote 60 In the early 1970s, Sweden also gained a reputation as an international leader in environmental protection when it initiated and hosted the United Nations Conference on the Human Environment, held in Stockholm in 1972; this was a milestone in the global cooperation on protecting the natural environment.Footnote 61 In advance of the Stockholm conference, the Federation of Swedish Industry, in collaboration with the International Chamber of Commerce, hosted the first World Industry Conference on the Human Environment in May 1972 in Gothenburg.Footnote 62

It was in this context that Gyllenhammar formed a strategy to raise Volvo’s environmental profile. One strategic decision was to make “environmental care” the company’s third brand value in 1972, joining “safety” and “quality.” In conjunction with the Stockholm conference in 1972, Volvo also declared its first environmental policy. The policy declaration contained a broad view on the company’s role in society and its responsibility toward the environment. Volvo stated that the automotive industry had been rightly accused of causing many disadvantages to human beings, including the damaging impact from air pollution, noise, and destruction of valuable landscape and city environments. Volvo also declared that it accepted its responsibility to find solutions, but—as would be argued by many business leaders in the future—the environmental requirements had to be considered against the costs.Footnote 63 At the time of the Stockholm conference, Gyllenhammar established contacts with Maurice Strong, Canadian general secretary of the Stockholm conference and later secretary of the United Nations Environment Programme (UNEP).Footnote 64 A delegation of the UN group was invited by Gyllenhammar for a one day session in Gothenburg to discuss the automotive industry.Footnote 65In 1973, Gyllenhammar was already involved in UNEP’s planning of an international conference concerning the automobile industry’s environmental challenges.Footnote 66

As an automobile producer, Volvo was exposed not only to Swedish environmental regulations but also to any exhaust emission standards imposed on its export markets. Although the Swedish Environmental Protection Act of 1969 enforced strict requirements on plant emissions, particularly with respect to paint chemicals in Volvo’s case, the new Swedish law did not require new standards for automobile exhaust emission control.Footnote 67 The major regulatory pressure on exhaust emissions came instead from the United States, and more specifically from the state of California, where automobile emissions had been seriously debated since at least the mid-1960s.

Political scientist Lennart J. Lundqvist has argued that Sweden was more focused on, and effective at, controlling emissions from stationary sources such as industrial plants in the 1970s, while the United States led in controlling mobile sources.Footnote 68 Before 1969, automobile emissions in Sweden had been separately and very loosely regulated by the Road Traffic Act of 1951. Then, in 1965, the Swedish Ministry of Transport formed a joint group of experts on automobile exhaust control, who delivered a proposal to the Swedish Government in 1968, which then issued an ordinance. The governmental ordinance specified limits for pollutants and testing methods applicable to cars beginning with model year 1971.Footnote 69 The method was based on the newly developed European test cycle. Pollutant limits set in Sweden in 1968 were stricter than European requirements but less strict than U.S. standards.Footnote 70 In 1970, Volvo, which had been involved in the joint group of experts, was already able to meet the exhaust emissions required by Swedish law through engine modifications.Footnote 71

The situation for Volvo changed dramatically in 1970, when the U.S. Congress passed the CAA amendments.Footnote 72 The amendments called for 90 percent emission reductions in HC and CO by 1975, relative to the emission levels of the 1970 models. By 1976, a comparable 90 percent reduction in NOx emissions was to take place.Footnote 73 This short time span meant that mere engine modifications were not sufficient for compliance but that automakers with sales on the U.S. market had to equip new cars with catalytic converters by 1975.Footnote 74 Therefore, the standards were technology forcing and sent shock waves across the industry. Basically, two business reactions took hold: actions to delay the American Environmental Protection Agency’s (EPA) implementation of the standards on the one hand, and actions to develop technology to comply with them on the other.

In 1972, International Harvester, Ford, Chrysler, General Motors, and Volvo filed for suspension, but the EPA denied their request. The companies then took the case to court and argued that the technology necessary to meet the requirement for the 1975 model would not be available before 1975. In 1973, the U.S. Court of Appeals for the District of Columbia remanded the decision to the EPA, who was instructed to hold hearings again in March 1973. The deadline for CO, HC, and NOx reductions was pushed forward one year (to 1976/1977), while less strict interim standards were implemented.Footnote 75 In 1975, the EPA once again pushed the standards for HC and CO to 1978, while the CAA standards for California were postponed until 1977.Footnote 76 As it happened, this dramatic process coincided with oil crises and Congress’s decision in 1975 to introduce corporate average fuel efficiency (CAFE) standards by 1978. The CAFE standards initiated a parallel investment race among General Motors, Ford, and Chrysler on the scale of the Apollo program.Footnote 77 By 1977, the U.S. manufacturers could still not comply with the CAA amendments of 1970, and Congress was forced to postpone the final deadline until 1980–1981 through the new CAA amendments of 1977, while NOx standards were relaxed. Otherwise, the U.S. automobile industry would have literally been prohibited by law from selling cars.Footnote 78 In this context it is important to mention that the introduction of unleaded gasoline across the United States was crucial, as lead destroys the catalysts’ abilities to abate harmful emissions. As General Motors announced early on that catalysts were necessary in order to comply with the CAA amendments’ standards, the U.S. EPA managed to mandate the introduction of unleaded gasoline.Footnote 79

The Invention of the Three-Way Catalytic Converter and the Oil Crisis

As mentioned, the amendments of 1970 were technology-forcing and spurred R&D efforts in the U.S. automobile industry and other companies with sales to the United States, including Volvo.Footnote 80 In 1970, Volvo already made a strategic decision to develop technologies for compliance as quickly as possible, rather than wait to see whether or not the new legal requirements would be postponed.Footnote 81 Volvo needed to be at the technological frontier, or it ran the risk of being denied access to the U.S. market and a quarter of its total sales.Footnote 82 The challenge was to find a solution that did not compromise consumer-based considerations such as drivability, performance, fuel efficiency, and price.Footnote 83 After Gyllenhammar took over Volvo’s leadership in 1972, funding for R&D was poured into the project.Footnote 84

In late 1972, Volvo and other manufacturers were mainly betting on systems containing two catalysts: one oxidation catalyst to reduce CO and HC emissions and one reduction catalyst, placed between the engine and the oxidation catalyst, to abate NOx. As the reduction of NOx required rich air-fuel mixtures while the oxidization of CO and HC required engines to run lean,Footnote 85 there were major challenges related to the control of the fuel mix and high fuel consumption, besides the need to install two catalysts instead of one.Footnote 86 At the beginning of 1973, Volvo’s engineers had a couple of solutions ready for implementation, but the best technology turned out to be a single three-way catalytic converter combined with the so-called Lambda sensor. At the time, catalytic converters were widely used in the processing industry, while Lambda sensors were used in industrial combustion plants. The Lambda sensor, developed by German Bosch, was a device that regulated the optimum amount of oxygen in combustion.Footnote 87 At an early stage, Stephen Wallman, who was in charge of Volvo’s R&D team, contacted Bosch and the American Engelhard Minerals and Chemical Corporation to suggest a collaboration. Engelhard had already developed a catalytic converter in 1964 to abate CO from the exhaust of gasoline- and propane-fueled vehicles in Swedish mines,Footnote 88 and worked closely with U.S. automakers and the EPA in the late 1960s and early 1970s.

In Volvo’s test trials, the TWC and Lambda sensor demonstrated, in short, the highest emission control, performance levels, and fuel efficiency at a relatively small cost, besides offering the benefit of needing only one catalyst.Footnote 89 In the fall of 1976, more than a year before the contemporary deadline of the CAA amendments’ standards, Volvo introduced on the California market a Volvo 224 1977 model equipped with the TWC. In practice, this meant that Volvo had managed to meet the California standards ahead of the deadline.Footnote 90 Although other companies, such as BMW, Renault, Saab, Volkswagen, and Peugeot, had also been working on the use of three-way catalysts to meet the 1976 standards, while Honda and Daimler-Benz worked on other solutions, Volvo ultimately won the race.Footnote 91 The buyer of the first ten Volvo cars equipped with the new catalytic converter was the California Air Resources Board. The board used the car model to demonstrate to American manufacturers that it was possible to comply with the CAA requirements, and questioned them regarding their sluggishness. Chrysler, Volvo’s second customer, bought ten cars.Footnote 92 The second automaker to introduce the same catalytic converter was Swedish Saab, while Porsche became the third; after this, virtually all other companies on the U.S. market followed suit.Footnote 93 In 1977, the U.S. EPA awarded Volvo the National Environmental Industry Award for its achievement.Footnote 94

For Volvo’s image, being the automobile company that introduced the TWC on the U.S. market was a historic moment. While U.S. automobile manufacturers had fiercely fought new environmental regulation in the 1970s,Footnote 95 Volvo had changed the rules of the game and the bargaining power of the U.S. EPA.Footnote 96 U.S. lawmakers and the EPA actively used Volvo to showcase that it was actually possible to meet the original 1970 CAA amendments’ standards, despite the U.S. industry’s position that it could not be done.Footnote 97 For the U.S. EPA and the environmental movement, Volvo symbolized a David in the battle against Goliath.

In 1973, at the same time the car industry was seriously challenged by the CAA, the first OPEC oil embargo occurred. The oil crisis also coincided with the 1972 publication of the book Limits to Growth by the Club of Rome, which raised strong concerns about environmental limits to growth, although the notion of environmental “limits” was already on the agenda at the Stockholm conference in 1972.Footnote 98 Gyllenhammar was concerned by the “limits” debate and believed—at the time—that the ceasing of oil resources would pose a major threat to the auto industry and transport if no plausible alternatives were obtained.Footnote 99 Like governments and industries around the world, Volvo hence began to look for alternatives to possibly supplement or replace oil.Footnote 100

In 1974, Volvo started investigating options for alternative fuels, and negotiated with the Swedish Government to form a joint venture to develop methanol as a motor fuel. Gyllenhammar presented a plan for investment in methanol production to the minister of industry the same year. In 1975, the Swedish Methanol Development Company was established as a joint venture between Volvo and the Swedish state. The main objective was to secure methanol for civil society in cases of emergency, such as war. An advantage of methanol was its liquid form, which meant it could be stored and distributed within the existing gasoline distribution infrastructure. It was also important that it could be used in ordinary internal combustion engines through small modifications. In other words, as an alternative to gasoline, methanol could be smoothly linked to the internal combustion engine/oil trajectory within the established socio-technical systems.Footnote 101 Sweden, however, did not have the domestic natural resources needed for methanol production, such as natural gas, which was the reason why Gyllenhammar initiated discussions with the Norwegian state to get access to the fields of natural gas and oil in the Atlantic Ocean.Footnote 102 In 1978, Volvo started negotiations with the Norwegian state involving a fusion between Volvo and the state-owned oil company Statoil. The idea was to secure petroleum resources for Volvo, while Volvo helped to develop the engineering and mechanical industry in Norway.Footnote 103 In exchange for Volvo shares, the Norwegian state would give the company access to Norway’s continental shelf. However, Volvo’s shareholders ultimately voted against the deal, and the transaction between the Norwegian state and Volvo never became reality.Footnote 104

Different events coincided in the 1970s that created great concern regarding the future security of oil, but all in all, this did not lead Volvo to change course from fossil fuels and the combustion engine. The company had met the environmental requirements in the United States, and the company achieved goodwill for this. At the same time, Volvo made progress in the area of safety during the 1970s. In 1972, the company introduced the Volvo Experimental Safety Car (VESC), a concept car equipped with antilock brakes and airbags, along with other safety equipment.Footnote 105 In 1978, the U.S. National Highway Traffic Safety Administration (NHTSA) chose Volvo’s VESC concept-based 240 model as the benchmark for testing crash safety in the United States.Footnote 106 Volvo’s safety technologies formed the basis of safety policies not only in the United States but also in Sweden, which secured the company’s position as the spearhead of safety innovations.Footnote 107

Regulatory Roadblocks to Greening in the 1980s

Although Volvo spearheaded the development of exhaust emission control in the United States, the company was both unable and unwilling to take advantage of this technology in Sweden and elsewhere in Europe. The key issue was that vehicles equipped with a catalytic converter could only run on unleaded fuel. In the United States, the EPA demanded that gas stations provide unleaded gasoline, whereas no such decisions or agreements had been reached in Europe in the early 1980s. In practice, this meant that vehicles equipped with a catalytic converter could not be used until unleaded gasoline was provided. Of course, these circumstances applied to all carmakers with sales in Europe.

As will be explained below, Volvo did not pressure or even support the Swedish Government in setting the stringent U.S. standards before an agreement on the matter was reached within the EEC. Although scholars such as Perkins and Neumayer have argued that internationally oriented firms have incentives to maximize economies of scale for abatement technology by lobbying domestic governments to implement standards in parity with the standards on the firms’ primary export markets,Footnote 108 this is not what happened in the Volvo case.

Already, in December 1972, the Swedish Government decided to move closer to the CAA amendments’ standards.Footnote 109 Through this decision, the Swedish standards would diverge even more from the European ones in terms of stringency. Volvo argued that, although tighter standards were justified from an air quality perspective, severe problems would arise if the Swedish standards were disharmonious with those in the rest of Europe.Footnote 110 In 1979, when the Swedish Royal Commission on Exhaust Emissions discussed the possible introduction of U.S. standards requiring catalytic converters and unleaded gasoline in Sweden, Volvo strongly opposed this, even though the company already had the technology available.Footnote 111

Gyllenhammar launched a number of arguments. One of them, which was also supported by the labor unions, was the fact that if catalytic converters became mandatory in Sweden, Swedish motorists would not be able to drive their vehicles outside the country’s borders if neighboring countries did not provide unleaded gasoline. Another argument was that car prices would increase significantly. A more complex argument concerned trade relations: If Sweden imposed stricter standards than the rest of Europe, this would mean that, in practice, Sweden would raise technical barriers regarding other European automobile manufacturers. Gyllenhammar feared that this would lead to a situation in which other European countries retaliated by overall restricting imports from Swedish companies.Footnote 112

Due to the risk of disrupting the single market, the European Economic Community (EEC) Commission did indeed set upper and lower limits of lead in fuel in 1978, to take effect in 1981, which restricted all member states from introducing unleaded gasoline.Footnote 113 Although Sweden was not a member of the EEC, Sweden and Volvo still had to consider the EEC trade policies. Indeed, the expansion and harmonization of the common European market forced Volvo to be cautious of Swedish unilateral initiatives. The fact that Gyllenhammar was one of the driving industrial forces behind the European integration through his ERT initiative also reflected the fact that the European market had increased in significance.Footnote 114

In May 1984, the EEC Commission proposed that member states be allowed to mandate the availability of unleaded gasoline by 1986, and required an introduction of unleaded gasoline beginning in 1989 across the EEC.Footnote 115 In December 1985, Sweden finally made the decision to adopt U.S. standards by 1989, which required the use of the TWC technology.Footnote 116 The European Council, Commission, and Parliament decided upon similar standards for all new cars in 1989, effective from 1992, including the smaller cars that had been allowed more lax requirements by a council decision in 1985.Footnote 117 According to Vogel, difficulties in finding common ground for regulation in the EU mainly rested on the fact that there were differences in automobile production among the member states, as well as in their experiences with the American market and catalytic converters.Footnote 118

When the decision was finally made regarding strict emission requirements in Sweden, Volvo could finally make use of the TWC technology on the Swedish market. Volvo delivered cars with catalytic converters to Swedish customers as soon as unleaded gasoline was available in 1987, and in the last edition of the Volvo magazine Ratten in 1986, almost all the space was devoted to the catalytic converter.Footnote 119 A postscript to the 1986 annual report reported for the first time on Volvo’s past environmental achievements, especially highlighting the catalytic converter.Footnote 120 From this point on, Volvo also tried to reinforce an environmental image at home in order to portray the company as a reigning environmental pioneer.

In 1988, Volvo adopted a renewed environmental strategy, which, according to studies by the management scholar Sandra Rothenberg and coauthors, represented the “most comprehensive and proactive environmental strategy in industry” at the time.Footnote 121 However, this strategy did not embrace the issue of vehicle emissions; rather, it focused on controlling emissions from plants. The new strategy was a response to a public embarrassment when Volvo’s subsidiary companies had violated Swedish environmental regulation. In the wake of this scandal, Inge Horkeby, Volvo’s chief environmental manager from 1987 to 2015, recognized a need for a comprehensive environmental strategy throughout the whole Volvo Corporate Group. Volvo had rapidly diversified beginning in the late 1970s, and had acquired, among other businesses, a number of foodstuff companies managed under the holding company Provendor. When a sugar manufacturing company violated its environmental emission permit, severely damaging a water treatment plant along the southern Baltic Sea, it became a scandal in Swedish media. Gyllenhammar was highly annoyed by the situation and called together a new group, Task Force: Environment, consisting of all the chief executives of the various subsidiary companies within the Volvo Corporate Group.Footnote 122 Meanwhile, Volvo bought a twelve-page advertisement in British Time Magazine in 1989, portraying Gyllenhammar as “Volvo’s green voice,” who showed an “almost missionary zeal on green issues.”Footnote 123 Volvo additionally raised its green profile by instituting the Volvo Environmental Prize in 1989. Although the company boosted its “green” corporate communication in the late 1980s, this rhetoric was not reflected in the cars it planned to produce in the future.

Toward Premium Greening in the 1990s

The start of the 1990s was critical for Volvo in several ways. Sweden entered a deep economic crisis in 1990, which lasted through 1994, and a failed merger with French Renault in 1993 caused Gyllenhammar, who was then the chairman of Volvo, to resign.Footnote 124 By then, he had built an impressive reputation for himself and Volvo. For nine consecutive years prior to his resignation, he held the title of “Sweden’s most admired man.”Footnote 125 Gyllenhammar’s strategic thinking has been characterized as “focused on grand deals, alliances, and diversification,” with little interest for the automobile business as such.Footnote 126 The Renault deal was heavily criticized by top managers, engineers, and shareholders, who feared that state-owned Renault would gain too much control.Footnote 127

After the failed merger with Renault, Volvo was forced to rethink its image. As others in the automotive world, the company turned toward lean production with shorter lead times and higher levels of flexibility to catch small shifts in demand, while divesting its nonautomotive businesses.Footnote 128 Its targeted customers were now labeled “affluent progressives.”Footnote 129 These newly targeted consumers were the quickly growing class of well-educated, well-off, liberal intellectuals, who valued safety and were concerned about the environment. The former selling points, which had stressed high secondhand value and durability and had appealed to the consumer’s rationality, were now giving way to more emotionally laden aspects such as identity. Additional effort was put into design for a more visually pleasing experience, along with greater focus on driving pleasure and low-maintenance ownership. To accompany this change toward premium branding, Volvo further followed a hard rationalization plan and changed its corporate communication.Footnote 130 In 1994, Sören Gyll, the Volvo CEO since 1992, presented to the annual shareholder meeting an action plan that emphasized a clearer focus on strengthening the company’s global network. Within the network, the company’s brand should be more clearly communicated using Volvo’s core values: quality, safety, and environmental care.Footnote 131

In the late 1980s and early 1990s, the environmental debate changed its characteristics, and new targets were set for Swedish environmental policy. More laws and increasingly stringent requirements were added to existing environmental regulations. According to the Swedish Government, a more holistic approach was needed that would cover the environmental impact not only of production but also of the product itself, “from cradle to grave.” Life cycle analysis—evaluating the total environmental impact of material and energy flows in the production, use, and disposal of a product—arose as part of this development.Footnote 132 The 1980s also saw the emergence of the issue of ozone depletion, which resulted in the Montreal Protocol in 1987 and a phaseout of chlorofluorocarbons (CFCs).

In the 1990s, Volvo worked toward compliance with new Swedish regulatory requirements, for instance by developing a declaration of contents to make car recycling easier. The company also developed a CFC-free refrigerant, for which Volvo was awarded the Ozone Protection Award by the U.S. EPA.Footnote 133 In order to meet the requirements of the 1994 Swedish Producer Responsibility Act—a law that made manufacturers responsible for recycling their own products—Volvo also established improved methods for recycling.Footnote 134 In 1996, the Swedish Government enacted a special act regulating producers’ responsibilities with respect to discarded automobiles, demanding that by 2002, 85 percent of the weight of each automobile should be possible to recycle.Footnote 135 But overall, there was no regulatory push for lower exhaust emissions stemming from Swedish or European regulation in the 1990s. Instead, once again the initiative came from the state of California in the United States.

In 1990, the California Air Resources Board (CARB) issued the zero-emission vehicle (ZEV) mandate, along with other, less strict targets for low-emission vehicles. The mandate required that 2 percent of an automobile company’s sales be of the ZEV type by 1998, with the share increasing to 10 percent by 2003. Although this regulation was technology-neutral, only battery electric vehicles (BEV) could come close to zero emissions. CARB was inspired to require emission-free vehicles by GM’s unveiling of its Impact, a BEV prototype, which promised to substantially improve the performance of BEVs. CARB understood that the development of electric vehicles still needed time to be fully commercially viable, but the board also distrusted automobile manufacturers and decided to force the development. The U.S. “Big Three”—GM, Ford, and Chrysler—thus had to invest heavily in R&D for BEVs, but they fought the mandate through law and politics—a strategy reminiscent of the 1970s.Footnote 136

Aiming to comply with the new rules in California, Volvo developed the Environmental Concept Car (ECC), which was launched in 1992. The ECC was the first hybrid Volvo developed. It had a diesel-driven gas turbine, and its interior featured natural materials such as cork, along with low-weight materials such as aluminum in the car body, which would make it lightweight and easy to recycle.Footnote 137 Volvo’s ECC won international awards and gained international attention, which again strengthened its reputation as an environmentally conscious brand. The ECC represented the vision of a “catchall” solution in private motoring, indicating that it was possible to be a friend of the environment without sacrificing the comfort or safety that consumers were now used to.Footnote 138 However, most concept cars aiming for ZEV were never intended to be commercialized in the first place. According to Leif Fredrickson, who studied Ford and the ZEV mandate, green marketing was one way to influence regulatory development by projecting a public image as authoritative experts in environmental technologies. Ford was the most vocal opponent of the ZEV mandate, but at the same time developed the Ecostar, a BEV that was never meant to be mass-produced. With the Ecostar, Ford only wanted to project the image that the company was a leader in electric vehicle technology. In portraying itself as an authoritative leader in BEV technology Ford hoped to persuade the public to back its efforts to weaken the mandate, albeit under false pretenses.Footnote 139 Although Volvo did not develop its own line of hybrid or electrical engines for a long time, it certainly used marketing to convince its stakeholders of its environmental technology expertise.

Climate Change and Heavier Cars

Before 1995 Volvo did not treat human-induced climate change as an issue that the company had a responsibility to address, although there already was an awareness of the problem in the 1970s. At a seminar organized by the Swedish Commission of Transport Research in 1977, one of Volvo’s engineers gave a presentation that included a forecast regarding the relationship between CO2 emissions and CO2 concentration in the atmosphere and rising temperatures by the years 2000, 2050, and 2100.Footnote 140 Although most countries joined the UN Framework Convention on Climate Change in 1992, it was not until 1993 that the company began monitoring CO2 emissions from its production plants. It was 1995 when Volvo finally addressed climate change as a real threat in its environmental data report.Footnote 141 Improved fuel efficiency, rather than electrification or other alternatives, was seen as the most promising way to reduce the climate impact of Volvo’s cars.Footnote 142 However, at the same time, the company’s marked focus on large, heavy cars in the premium segments made this strategy difficult to pursue in practice.

In Sweden, the Swedish Road Administration changed the rules for company car taxation in 1997, excluding all cars using more than 0.86 liters per 10 kilometers. This dismissed many of Volvo’s models produced in Sweden, which was a blow to its green image. In 1997, Leif Johansson, newly appointed CEO of Volvo Corporate Group, made a promise to lower the company’s fuel intensity 25 percent by 2005, compared to 1990. This goal was only aimed at cars sold within the European Union, not the United States.Footnote 143 Lowering fuel and CO2 emissions from cars had never been Volvo’s first priority in its R&D programs. CO2 emissions—which is a proxy for fuel intensity—from Volvo’s cars dropped only 9 percent between 1970 and 1995.Footnote 144 The goal to reduce the fuel intensity of cars sold within the EU was later changed to 25 percent for the period 1995–2008, which followed from a voluntary agreement between members of the European Automobile Manufacturers Association (ACEA) and the European Commission.Footnote 145

Since 1978, when fuel use began being monitored in Sweden, Volvo and Saab were the most fuel-intensive brands on the Swedish market. From 1978 and throughout the 1990s, Volvo’s car fleet was 8 percent more fuel intensive than the average car.Footnote 146 Up to the late 2000s, Volvo was in fact the least fuel-efficient brand on the whole European market.Footnote 147 The company’s long-term R&D focus on spacious family cars, along with sporty cars and SUVs from the 1990s, drove Volvo to the top of the fuel intensity list on the European market.Footnote 148 Among Volvo’s top selling cars, the 144 DL (1973) used 1.20 liters per 10 kilometers, the 240 (1983) used 0.94 liters, the 850 (1993) used 0.87 liters, and the V70 140 (2003) used 0.91 liters.Footnote 149 Clearly, there were trade-offs between the company’s premium product range and fuel efficiency, while its high ambitions for safety standards also added weight. Volvo experienced little market pull from its major markets to develop technologies outside high-performance gasoline engines.Footnote 150 In 1997, close to half of all its cars were sold in the United States, Sweden, and the UK, where diesels made up only a tiny fraction of the market.Footnote 151 For other European companies such as Citroen, Peugeot, Renault, Fiat, and Volkswagen, the choice of diesel technology was easier as they had all but abandoned the U.S. market to Japanese competition in the 1990s.Footnote 152 Moreover, Volvo lacked the financial muscle to independently develop complex new hybrid-electric drivetrains after the failed Renault merger, whereas under Ford it relied on existing engineering practices.Footnote 153

Regional dynamics influencing technology choice might partly explain Volvo’s poor performance in fuel efficiency. Berggren et al. have argued that Japanese companies, particularly Toyota, started developing gasoline-electric hybrid engines in the 1990s as a response to rising concerns over CO2 emissions and urban air quality issues, along with projections of oil shortage and rising fuel prices. Toyota’s first hybrid Prius was introduced on the Japanese market in 1997 and in the United States in 2000. Hybrids enjoyed some success in the United States as fuel prices started to climb, but still only captured 1.6 percent of the market in 2006. In Europe, on the other hand, diesel technology became more popular for reaching fuel efficiency goals, after a series of innovations sprung out of the 1990s that improved performance, convenience, and, not least, emission control in diesels.Footnote 154

Although fuel efficiency, and hence CO2, remained a problem, Volvo followed the general trend of boosting green communication to stakeholders. Volvo’s environmental data, reported since 1991, demonstrate that environmental information and statistics became more detailed and extensive in 1995, with the number of pages doubling from 1994 to 1995. Since 1993, the reports have been signed by Volvo’s executives, and have since then stressed the competitive advantages of leaner production and a more holistic approach to business. Already, in 1995, Sören Gyll set the target for Volvo “to become, and to be considered, one of the world’s leading manufacturers in the environmental field by the year 2000.”Footnote 155 Leif Johansson claimed that, because of the increased market demand for “environmentally compatible products,” companies that could successfully implement environmental programs in their production schemes would gain competitive advantages.Footnote 156 Thus, following the general trend in multinational corporations, greenness moved closer to the core of Volvo’s communication. In 1998, the company introduced the S80 model, which was, according to Volvo, the first car in the world to have an environmental declaration of contents.Footnote 157 The S80 was indeed not a small car, however, coming in right below the premium segment. It used 0.94 liters per 10 kilometers, which was considered fuel efficient for a car in the family segment but was 10 percent above the average in Sweden.Footnote 158 Overall, Volvo leaned toward developing larger cars with more powerful engines. Despite the intensive debate on climate change and CO2 emissions, fuel intensity was still not an issue of great concern to the company. The introduction of the cross-country V70 was a clear sign that Volvo would follow the trend toward larger, more powerful cars.

This trend toward larger cars was manifested in the SUV, or Sport Utility Vehicle, and was pronounced primarily among U.S. consumers, who had long preferred big and powerful cars.Footnote 159 Concurrently, U.S. fuel efficiency standards have been less strict compared to, for instance, European, Japanese, and Chinese regulation.Footnote 160 The SUV also gained increased consumer attention in Sweden in the late 1990s, and has, since the mid-1980s, been the fastest growing vehicle category in North America. The SUV has been credited as the model segment that has kept the declining North American auto industry profitable, with its 25 percent market share in 2002.Footnote 161 Since the 2010s, SUVs have been the fastest growing market segment within the EU, reaching over 30 percent in 2018.Footnote 162

Volvo’s still strong dependency on the American market led them to develop SUV models and to introduce in 1997 an XC (cross-country) edition of its top seller V70, called the V70 XC AWD. In 1997, with the V70 AWD and the XC model, and for the first time since the 1980s, Volvo’s sales exceeded one hundred thousand units on the U.S. market alone.Footnote 163 The V70 XC was the first step toward a fully developed SUV. Thus, at the same time as the environment was on the agenda more than ever, with the Kyoto Protocol to control CO2 signed in 1997, Volvo launched cars in the most environmentally contested car segment.Footnote 164 For a brand that has had “environmental care” as a core value for several decades, the company’s investments in the SUV model appear to be an oxymoron. Volvo reported that the V70 XC used 10.9 liters per 10 kilometers,Footnote 165 which was not in line with the goal of decreasing fuel intensity 25 percent by 2008. The V70 XC, however, was first and foremost aimed at the American market, which stood for 25 percent of Volvo’s total sales in 1998.Footnote 166

It has indeed been argued that stagnant fuel economy standards, low gasoline prices, a lack of investment by automakers in fuel-efficient technologies, and the popularity of SUVs led of the fuel intensity of passenger cars to increase in the 1990s and 2000s.Footnote 167 Volvo’s investment in U.S.-style SUVs was an industry-wide trend, which points to a contradictory development in the entire car industry from the 1990s onward. SUVs became immensely popular among consumers, and virtually all automobile manufacturers followed suit, developing both SUVs and smaller, more fuel-efficient models, including hybrid-electric and full BEVs. As argued by Jones, the phenomenon of attaining the sustainability of one component within the global corporation that coexists with environmentally damaging activities has been a widespread strategy in the corporate world since the 1990s.Footnote 168

Although the automobile industry has paid attention to electric vehicles (EVs) for many decades, the market expansion of EVs is still a very recent phenomenon in Europe, driven by the 2020/2021 standards for CO2. In 2019, only 3.5 percent of new vehicles in Europe and just over 2 percent in the United States were equipped with battery electric or plug-in hybrid drivetrains.Footnote 169 It is not enough to mitigate the climate impact of large vehicles, however. As recently as 2020, the International Energy Agency (IEA) identified SUVs as the most important driver behind the increase in CO2 emissions for the period 2010–2018 after the power sector, but ahead of heavy industries including iron and steel, cement, and aluminum.Footnote 170 The jury is still out on whether an electrification of the automobile fleet will take hold and how encompassing it will be. In 2017, Volvo made headlines when it proclaimed the death of the internal combustion engine, saying that all its new models launched after 2019 would be electric or electric hybrids. However, as the Union of Concerned Scientists stated in 2018, Volvo defined its electrified vehicle as just about anything with an electric motor. This included vehicles utilizing 48V stop-start systems that are incapable of being propelled solely by their electric motor at any speed. The Alliance of Automobile Manufacturers, a trade group that represents manufacturers selling 70 percent of all new vehicles in the United States, used an equally loose definition of “electrification.”Footnote 171

Conclusions

Over the three decades covered by this article, it becomes clear that government regulatory pressure was the primary driver behind Volvo’s initiatives to innovate in exhaust emission control technologies. Volvo has actively and, in the case of the U.S. CAA amendments, proactively complied with government regulations, but never adopted a strategy to go beyond legal compliance for the sake of the environment. At the same time Volvo did successfully communicate its achievements to enhance the value of its brand as “green.” Premium and green branding emerged as complementary assets for Volvo in the 1990s, although the company lacked the initiative and capability to break with old trajectories in order to address climate change.

As this article has demonstrated, Volvo’s early dependency on the U.S. market drove the company to invent and introduce the three-way catalytic converter (TWC) on the California market in the 1970s. Coupled with the decision to adopt “environmental care” as one of its core values in 1972, Volvo emerged as a pioneering company in addressing environmental issues. The 1970s thus created a legacy whereby the Volvo brand came to be associated with responsibility for the environment as well as safety, with the company’s CEO, Gyllenhammar, acting as an activist by helping to raise the company’s environmental profile. The question is, what factors drove Volvo to lose its leading position in controlling vehicle emissions? At least three interrelated key factors can be identified that limited or affected the greening of Volvo after the 1970s.

The first complicating factor was Volvo’s market position. The fact that it was a small car producer made the company a niche manufacturer in the Western world, serving the segment of buyers valuing safety and comfort. After the 1970s, safety remained Volvo’s competitive strategy, while the company moved further into premium products in the 1990s. As Volvo’s “safety” strategy brought more weight to the car—such as robust constructions—it also meant a trade-off in terms of fuel consumption. At the same time, this was nothing that the customers in Volvo’s market segment worried about. The fact that the company aimed for the premium segment and launched its first SUV in 1997, the same year as the Kyoto Protocol was signed, highlights contradictions in the greening of capitalism. It was an industry-wide trend, whereby larger automobile firms developed both smaller and “clean” fuel-efficient car models alongside SUVs.

Second, the complexities of trade relations and national interests in constructing a European governance system of automobile emissions delayed action in Europe. In practice, automobile companies like Volvo were bounded to produce cars that were more polluting for the European market than for the U.S. market in the 1980s. Apart from the deterrable, additional costs of TWC systems when regulatory standards do not require advanced emission control, unleaded gasoline is the case in point. Volvo, or any other brand, could not produce cars equipped with TWC systems for the European market until unleaded gasoline was widely provided. It was not until 1989 that the EEC/EU countries required the availability of unleaded gasoline, something that the U.S. EPA had already required in the early 1970s.

Third, our study demonstrates that the barriers Volvo faced in addressing the evolving environmental issue largely existed outside its firm boundaries. There is little to suggest that Volvo’s loss of leadership on the environmental issue signifies any particular vice or flaw within the company itself. As has been stressed in recent business history studies by, for example, Geoffrey Jones and Adam Rome, the market realities have often worked against radical green initiatives in large, established corporations.Footnote 172 Our study of Volvo showcases how an early green pioneer in the 1970s never established an orientation to address climate change, the most critical problem of our time. We have identified a lack of regulatory pressure on the company’s primary markets, along with a lack of financial strength, as important reasons why Volvo did not develop new and less CO2-intensive technologies.

However, studying the case of Volvo does not catch all the factors that have driven or prevented the automobile industry from transforming toward lower exhaust (tailpipe) emissions, including climate gases. This study has only scratched the tip of the iceberg, and similar historical case studies of other automakers are needed to enable systematic comparisons. For example, this study has only touched upon some of the complexities associated with the creation of harmonized vehicle emission standards and how they forced firms to take action or put obstacles in place to prevent them from doing so, depending on their market position. Complexities regarding businesses’ impact and lobbying on the political process of vehicle emission standards in the United States and the EEC/EU are issues that were not covered in this study. The extent to which automobile firms have manipulated information on emissions and fuel efficiency performance, and the size of the trade-offs resulting from counteracting technical regulations on safety and emission control, are examples of other issues that beg for more research.

Finally, as this article indicates, Volvo chose to stay safe before going green, and the company played it safe in a dual sense. The first sense of “safe” was related to technical aspects of vehicle safety and “safety” branding, whereas the second sense can be called safe business decisions, involving sticking to conventional petroleum-based technologies, protecting its market position, and going premium after the 1990s.

Acknowledgements

The authors want to thank the three anonymous reviewers for helpful comments that improved the manuscript significantly. We would also like to thank William Childs for helpful comments at an early stage of this manuscript. Financial support from the Jan Wallander and Tom Hedelius Foundation is gratefully acknowledged.