1. Introduction

Small finite-sized particles suspended in a fluid flowing along a straight enclosed duct can migrate across streamlines due to inertia of the surrounding disturbed fluid. This phenomenon is known as inertial migration and the force acting on the particles to cause this is called inertial lift. It was first reported in experiments by Segré & Silberberg (Reference Segré and Silberberg1961), who observed that small particles suspended in a straight pipe with a circular cross-section focused to an annular ring located at ![]() $0.6$ times the radius of the pipe from the centre. In general, inertial migration results in focusing of particles onto a low-dimensional attractor of the particle–fluid system, such as points or closed curves within the two-dimensional duct cross-section. This process is often referred to as inertial particle focusing. In straight ducts with polygonal shaped cross-sections, such as rectangles and squares, the breaking of continuous rotational symmetry of a circular cross-section typically results in multiple isolated point attractors having discrete symmetry in the cross-section (Di Carlo et al. Reference Di Carlo, Edd, Humphry, Stone and Toner2009; Liu et al. Reference Liu, Hu, Jiang and Sun2015).

$0.6$ times the radius of the pipe from the centre. In general, inertial migration results in focusing of particles onto a low-dimensional attractor of the particle–fluid system, such as points or closed curves within the two-dimensional duct cross-section. This process is often referred to as inertial particle focusing. In straight ducts with polygonal shaped cross-sections, such as rectangles and squares, the breaking of continuous rotational symmetry of a circular cross-section typically results in multiple isolated point attractors having discrete symmetry in the cross-section (Di Carlo et al. Reference Di Carlo, Edd, Humphry, Stone and Toner2009; Liu et al. Reference Liu, Hu, Jiang and Sun2015).

The phenomenon of inertial particle focusing has found practical applications in various biomedical and industrial microfluidic technologies where passive techniques, that are minimally invasive, are desired to separate particles based on differing intrinsic properties (Martel & Toner Reference Martel and Toner2014; Zhang et al. Reference Zhang, Yan, Yuan, Alici, Nguyen, Ebrahimi Warkiani and Li2016). Current advances in inertial microfluidic particle separation technologies are primarily driven by experiments from which, through trial and error, one can optimise inertial microfluidic devices for specific applications. The ability to predict and optimise particle separation for different applications based on a foundational understanding of the underlying physics of inertial focusing behaviours is still a work in progress (Razavi Bazaz et al. Reference Razavi Bazaz, Mashhadian, Ehsani, Saha, Krüger and Ebrahimi Warkiani2020).

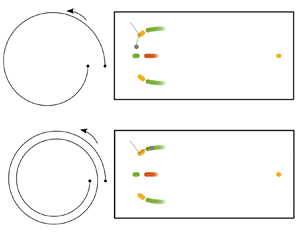

Microfluidic devices aimed at exploiting inertial particle focusing to separate particles by size often utilise curved duct geometries (Liu et al. Reference Liu, Petchakup, Tay, Li and Hou2019), e.g. typically consisting of a uniform rectangular cross-section extruded along a circular or spiral curve (see figure 1 for a schematic). Within curved ducts, in addition to primary fluid flow directed through each cross-section, the fluid flow develops a pair of counter-rotating vortices within the cross-section, known as Dean vortices (Dean Reference Dean1927; Dean & Hurst Reference Dean and Hurst1959). These cross-sectional vortices, induced by the curved geometry, break the flow symmetry across the width of the cross-section that is present in a straight duct (having the same cross-sectional shape). The interaction between Dean vortex drag and inertial lift force has three broad effects: (i) a reduction in the number of particle attractors within any given cross-section (i.e. compared with straight ducts), (ii) a pronounced dependence on particle size of the nature and/or location of particle attractors and (iii) a modest speed-up in cross-sectional particle migration. These features are advantageous for particle separation, thus explaining why curved ducts are typically preferred over straight ducts for applications requiring passive particle separation.

Figure 1. Schematic of the theoretical set-up. A particle of radius ![]() $a$ with centre located at

$a$ with centre located at ![]() $\boldsymbol {x}_p=\boldsymbol {x}(\theta _p,r_p,z_p)$ is suspended in an incompressible fluid flowing through a Archimedean spiral duct with changing bend radius,

$\boldsymbol {x}_p=\boldsymbol {x}(\theta _p,r_p,z_p)$ is suspended in an incompressible fluid flowing through a Archimedean spiral duct with changing bend radius, ![]() $R(\theta )$, and having a uniform rectangular cross-section of width

$R(\theta )$, and having a uniform rectangular cross-section of width ![]() $W$ and height

$W$ and height ![]() $H$. The enlarged view of the cross-section illustrates the local cross-sectional

$H$. The enlarged view of the cross-section illustrates the local cross-sectional ![]() $(r,z)$ co-ordinate system and the approximate streamlines of the secondary flow (grey closed curves) induced by the curvature of the duct. The edge labelled ‘inner wall’ is the side closer to the origin

$(r,z)$ co-ordinate system and the approximate streamlines of the secondary flow (grey closed curves) induced by the curvature of the duct. The edge labelled ‘inner wall’ is the side closer to the origin ![]() $(x,y,z)=(0,0,0)$ while the edge labelled ‘outer wall’ is the side further away from the origin. The black filled circle denotes the particle location while the coloured circles denote the particle equilibria: unstable node in red, stable nodes (point attractors) in green and saddle points in yellow.

$(x,y,z)=(0,0,0)$ while the edge labelled ‘outer wall’ is the side further away from the origin. The black filled circle denotes the particle location while the coloured circles denote the particle equilibria: unstable node in red, stable nodes (point attractors) in green and saddle points in yellow.

Mathematical models of particle migration have been developed using asymptotic methods to accurately estimate the forces driving particle migration in straight ducts (Hood, Lee & Roper Reference Hood, Lee and Roper2015) and constant curvature ducts (Harding, Stokes & Bertozzi Reference Harding, Stokes and Bertozzi2019) at low flow rates. Numerical simulations using the model of Harding et al. (Reference Harding, Stokes and Bertozzi2019) have shown that, for neutrally buoyant particles suspended in fluid flow through circular ducts (we use circular duct to refer to any duct geometry where a fixed cross-section is extruded along the arc of a circle) with rectangular cross-sections, the number, nature and location of the particle attractors varies with the radius of curvature (we utilise radius of curvature rather than bend radius here as it will be important to distinguish the two later when we discuss certain spiral geometries). The rich dynamical landscape, featuring a large variety of bifurcations, has been thoroughly explored by Ha et al. (Reference Ha, Harding, Bertozzi and Stokes2022) and Valani, Harding & Stokes (Reference Valani, Harding and Stokes2021, Reference Valani, Harding and Stokes2022). Within a spiral duct, the local radius of curvature, and hence also the particle attractors, continuously change as a particle advances through the duct. A natural question which arises is: What are the implications of continuous movement of particle attractors, with the potential to cross bifurcations, on inertial particle focusing and particle separation within spiral geometries? In this manuscript, we aim to address this question by systematically exploring the particle focusing dynamics in spiral ducts with slowly varying curvature that have uniform rectangular cross-sections.

Due to the horizontal and vertical symmetry of the rectangular cross-section, it is common to have multiple particle attractors in circular ducts with a large radius of curvature. The existence of multiple attractors make the underlying dynamical system multistable. In multistable systems, there are various mechanisms, called critical transitions, that may lead to switching of the system from one attractor to another under the influence of small perturbations. Critical transitions have become a major focus of research in climate change and ecology, where the transition from one state to another might be undesirable. Sometimes the terminology used is different in different fields and these critical transitions are often referred to as tipping points in climate science, while they are commonly known as regime shifts in ecology (Feudel, Pisarchik & Showalter Reference Feudel, Pisarchik and Showalter2018). There are several possible ways in which critical transitions can occur, however, there are two major types in deterministic dynamical systems (Feudel et al. Reference Feudel, Pisarchik and Showalter2018). Firstly, bifurcation-induced tipping, also known as B-tipping, takes place when a parameter of the dynamical system crosses a certain threshold value leading to a bifurcation in the system's attractor and resulting in tipping of the dynamical state away from the previous attractor. Secondly, rate-induced tipping, also known as R-tipping, takes place when a parameter is varied on a time scale different from that of the internal dynamics of the system; when the parameter's rate of change exceeds a critical threshold, then parts of the system are not able to successfully track an attractor, causing the dynamical state to tip away from that attractor towards another. In spiral ducts, the continuously changing radius of curvature can result in the emergence of both types of tipping phenomena as a result of bifurcations and continuous movement of particle attractors. This results in a complex dynamical landscape which we explore in detail by extending our studies (Harding et al. Reference Harding, Stokes and Bertozzi2019; Valani et al. Reference Valani, Harding and Stokes2022) of particle focusing and dynamics in circular ducts to spiral ducts with slowly varying curvature. We systematically explore the different dynamical behaviours and tipping phenomena as the system parameters are varied. Based on our observations, we also discuss how the observed dynamical features can be exploited for non-equilibrium particle separation in spiral ducts.

The paper is organised as follows. In § 2 we present the theoretical model and rationalise our choice of an Archimedean-like spiral duct geometry. We then briefly review the bifurcations that take place with radius of curvature in constant curvature ducts in § 3. In § 4 we present the results of the particle dynamics in spiral ducts when no bifurcations are present, while in § 5 we explore spiral ducts with bifurcations that result in a rich particle dynamics and tipping phenomena. We briefly explore the effects of flow rate on the particle dynamics in § 6. In § 7, we discuss novel non-equilibrium particle separation mechanisms. Our conclusions are given in § 8.

2. Theoretical formalism

2.1. Mathematical model

Harding et al. (Reference Harding, Stokes and Bertozzi2019) developed an asymptotic model to calculate the forces acting on a neutrally buoyant spherical particle suspended in fluid flowing through a constant curvature duct at sufficiently small flow rates. By balancing these leading-order forces with viscous Stokes’ drag they constructed a first-order quasi-steady model for the trajectory of the particle. In this work, we adapt their model and apply it to spiral ducts with slowly varying curvature. By slowly varying curvature we mean that the background fluid flow through any cross-section of the spiral duct does not differ significantly from that through a circular duct with identical curvature. We expect the quasi-steady approximation of inertial migration to remain valid for such spiral ducts when approximating the background flow accordingly. The quality of this approximation will be demonstrated in § 2.3. Below, we briefly review the model of Harding et al. (Reference Harding, Stokes and Bertozzi2019); further details may be obtained from that paper.

As shown in figure 1, consider a neutrally buoyant spherical particle of radius ![]() $a$ suspended in fluid flowing through a spiral duct with a uniform rectangular cross-section. This specific example illustrates an Archimedean spiral for which the bend radius,

$a$ suspended in fluid flowing through a spiral duct with a uniform rectangular cross-section. This specific example illustrates an Archimedean spiral for which the bend radius, ![]() $R(\theta )$, varies with the azimuthal angle,

$R(\theta )$, varies with the azimuthal angle, ![]() $\theta$. The rectangular cross-section has width

$\theta$. The rectangular cross-section has width ![]() $W$ and height

$W$ and height ![]() $H$. We note that our model neglects the effects of any inlets and outlets, i.e. we analyse the dynamics of a particle assuming that the flow is fully developed throughout the duct. In a circular duct (with constant bend radius

$H$. We note that our model neglects the effects of any inlets and outlets, i.e. we analyse the dynamics of a particle assuming that the flow is fully developed throughout the duct. In a circular duct (with constant bend radius ![]() $R(\theta )=R$), and in the absence of the particle, a constant pressure gradient along the duct drives a steady incompressible fluid flow (Dean Reference Dean1927; Dean & Hurst Reference Dean and Hurst1959) which has been studied extensively for ducts with a rectangular cross-section (Winters Reference Winters1987; Yamamoto et al. Reference Yamamoto, Wu, Hyakutake and Yanase2004; Harding & Stokes Reference Harding and Stokes2018). In addition to the axial component of the fluid flow, the curvature induces a secondary flow within the cross-section consisting of a counter-rotating vortex pair. The presence of a particle in the duct disturbs this background flow and one can define disturbance pressure and velocity fields by taking the difference between the fields in the presence and absence of the particle. The resulting dimensionless dynamical equations for the disturbance pressure field

$R(\theta )=R$), and in the absence of the particle, a constant pressure gradient along the duct drives a steady incompressible fluid flow (Dean Reference Dean1927; Dean & Hurst Reference Dean and Hurst1959) which has been studied extensively for ducts with a rectangular cross-section (Winters Reference Winters1987; Yamamoto et al. Reference Yamamoto, Wu, Hyakutake and Yanase2004; Harding & Stokes Reference Harding and Stokes2018). In addition to the axial component of the fluid flow, the curvature induces a secondary flow within the cross-section consisting of a counter-rotating vortex pair. The presence of a particle in the duct disturbs this background flow and one can define disturbance pressure and velocity fields by taking the difference between the fields in the presence and absence of the particle. The resulting dimensionless dynamical equations for the disturbance pressure field ![]() $q$ and disturbance fluid velocity field

$q$ and disturbance fluid velocity field ![]() $\boldsymbol {v}$ in a rotating frame (moving with the particle) are given by

$\boldsymbol {v}$ in a rotating frame (moving with the particle) are given by

\begin{align} \left.\begin{gathered} - \boldsymbol{\nabla} q + \nabla^2\boldsymbol{v}=Re_p ((\boldsymbol{v}+\bar{\boldsymbol{u}}-\varTheta (\boldsymbol{e}_{z}\times \boldsymbol{x}))\boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{v}+\boldsymbol{v}\boldsymbol{\cdot}\boldsymbol{\nabla} \bar{\boldsymbol{u}} +\varTheta(\boldsymbol{e}_z\times\boldsymbol{v})) \quad \text{on}\ \boldsymbol{x} \in \mathcal{F}, \\ \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{v} = 0 \quad \text{on}\ \boldsymbol{x} \in \mathcal{F},\\ \boldsymbol{v}=\boldsymbol{0} \quad \text{on}\ \boldsymbol{x} \in \partial \mathcal{D},\\ \boldsymbol{v}={-}\bar{\boldsymbol{u}}+\varTheta(\boldsymbol{e}_z\times\boldsymbol{x})+ \boldsymbol{\varOmega}_p\times (\boldsymbol{x}-\boldsymbol{x}_p) \quad \text{on}\ \boldsymbol{x} \in \partial \mathcal{F} \setminus \partial \mathcal{D}. \end{gathered}\right\} \end{align}

\begin{align} \left.\begin{gathered} - \boldsymbol{\nabla} q + \nabla^2\boldsymbol{v}=Re_p ((\boldsymbol{v}+\bar{\boldsymbol{u}}-\varTheta (\boldsymbol{e}_{z}\times \boldsymbol{x}))\boldsymbol{\cdot} \boldsymbol{\nabla} \boldsymbol{v}+\boldsymbol{v}\boldsymbol{\cdot}\boldsymbol{\nabla} \bar{\boldsymbol{u}} +\varTheta(\boldsymbol{e}_z\times\boldsymbol{v})) \quad \text{on}\ \boldsymbol{x} \in \mathcal{F}, \\ \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{v} = 0 \quad \text{on}\ \boldsymbol{x} \in \mathcal{F},\\ \boldsymbol{v}=\boldsymbol{0} \quad \text{on}\ \boldsymbol{x} \in \partial \mathcal{D},\\ \boldsymbol{v}={-}\bar{\boldsymbol{u}}+\varTheta(\boldsymbol{e}_z\times\boldsymbol{x})+ \boldsymbol{\varOmega}_p\times (\boldsymbol{x}-\boldsymbol{x}_p) \quad \text{on}\ \boldsymbol{x} \in \partial \mathcal{F} \setminus \partial \mathcal{D}. \end{gathered}\right\} \end{align}

Here, ![]() $\bar {\boldsymbol {u}}$ is the background fluid flow velocity in the absence of the particle,

$\bar {\boldsymbol {u}}$ is the background fluid flow velocity in the absence of the particle, ![]() $\boldsymbol {\varOmega }_p$ is the particle spin and

$\boldsymbol {\varOmega }_p$ is the particle spin and ![]() $\boldsymbol {e}_{z}$ is the unit vector in the vertical

$\boldsymbol {e}_{z}$ is the unit vector in the vertical ![]() $z$ direction; all quantities are in a reference frame which is rotating about the

$z$ direction; all quantities are in a reference frame which is rotating about the ![]() $z$ axis at a rate

$z$ axis at a rate ![]() $\varTheta :=\partial \theta _p/\partial t$ which is assumed to be (nearly) constant. The domain

$\varTheta :=\partial \theta _p/\partial t$ which is assumed to be (nearly) constant. The domain ![]() $\mathcal {D}$ denotes the interior of the duct,

$\mathcal {D}$ denotes the interior of the duct, ![]() $\partial \mathcal {D}$ denotes the boundaries of the duct,

$\partial \mathcal {D}$ denotes the boundaries of the duct, ![]() $\mathcal {F}:=\{\boldsymbol {x}\in \mathcal {D}:|\boldsymbol {x}-\boldsymbol {x}_p|\geq 1\}$ is the dimensionless fluid domain in the presence of the particle and

$\mathcal {F}:=\{\boldsymbol {x}\in \mathcal {D}:|\boldsymbol {x}-\boldsymbol {x}_p|\geq 1\}$ is the dimensionless fluid domain in the presence of the particle and ![]() $\partial \mathcal {F} \setminus \partial \mathcal {D}=\{\boldsymbol {x}:|\boldsymbol {x}-\boldsymbol {x}_p|=1\}$ is the surface (boundary) of the particle. The dimensionless parameter

$\partial \mathcal {F} \setminus \partial \mathcal {D}=\{\boldsymbol {x}:|\boldsymbol {x}-\boldsymbol {x}_p|=1\}$ is the surface (boundary) of the particle. The dimensionless parameter ![]() $Re_p$ in (2.1) is the particle Reynolds number defined as

$Re_p$ in (2.1) is the particle Reynolds number defined as ![]() $Re_p=Re\,(a/l)^2$, where

$Re_p=Re\,(a/l)^2$, where ![]() $Re=\rho U_m l/\mu$ is the flow Reynolds number,

$Re=\rho U_m l/\mu$ is the flow Reynolds number, ![]() $\rho$ is the particle/fluid density,

$\rho$ is the particle/fluid density, ![]() $\mu$ is the fluid's dynamic viscosity,

$\mu$ is the fluid's dynamic viscosity, ![]() $l=\min \{W,H\}$ is the characteristic length scale associated with the duct cross-section and

$l=\min \{W,H\}$ is the characteristic length scale associated with the duct cross-section and ![]() $U_m$ is a characteristic velocity scale chosen to be the maximum axial velocity of the background fluid flow. The variables in (2.1) have been scaled with physical parameters as in Harding et al. (Reference Harding, Stokes and Bertozzi2019): the particle radius

$U_m$ is a characteristic velocity scale chosen to be the maximum axial velocity of the background fluid flow. The variables in (2.1) have been scaled with physical parameters as in Harding et al. (Reference Harding, Stokes and Bertozzi2019): the particle radius ![]() $a$ for

$a$ for ![]() $\boldsymbol {x}$,

$\boldsymbol {x}$, ![]() $l/U_m$ for time

$l/U_m$ for time ![]() $t$,

$t$, ![]() $U_m a/l$ for the velocities

$U_m a/l$ for the velocities ![]() $\boldsymbol {v}$ and

$\boldsymbol {v}$ and ![]() $\bar {\boldsymbol {u}}$,

$\bar {\boldsymbol {u}}$, ![]() $U_m/l$ for the particle spin

$U_m/l$ for the particle spin ![]() $\boldsymbol {\varOmega }_p$ and the angular velocity

$\boldsymbol {\varOmega }_p$ and the angular velocity ![]() $\varTheta$, and

$\varTheta$, and ![]() $\mu U_m/l$ for the disturbance pressure

$\mu U_m/l$ for the disturbance pressure ![]() $q$.

$q$.

The disturbed fluid flow exerts force and torque on the spherical particle. The dimensionless force (scaled by ![]() $\rho U_m^2 a^4/l^2$) and torque (scaled by

$\rho U_m^2 a^4/l^2$) and torque (scaled by ![]() $\rho U_m^2 a^5/l^2$) acting on the particle in the rotating frame are given by

$\rho U_m^2 a^5/l^2$) acting on the particle in the rotating frame are given by

\begin{align} \boldsymbol{F}&={-}\frac{4{\rm \pi}}{3}\varTheta^2 (\boldsymbol{e}_z\times (\boldsymbol{e}_z\times \boldsymbol{x}_p))+ \int_{|\boldsymbol{x}-\boldsymbol{x}_p|<1} \bar{\boldsymbol{u}}\boldsymbol{\cdot} \boldsymbol{\nabla}\bar{\boldsymbol{u}}\,\text{d}V \nonumber\\ &\quad +\frac{1}{Re_p} \int_{|\boldsymbol{x}-\boldsymbol{x}_p|=1} (-\boldsymbol{n})\boldsymbol{\cdot} ({-}q\boldsymbol{I}+\boldsymbol{\nabla}\boldsymbol{v}+ \boldsymbol{\nabla}\boldsymbol{v}^{\rm T})\,\text{d}S, \end{align}

\begin{align} \boldsymbol{F}&={-}\frac{4{\rm \pi}}{3}\varTheta^2 (\boldsymbol{e}_z\times (\boldsymbol{e}_z\times \boldsymbol{x}_p))+ \int_{|\boldsymbol{x}-\boldsymbol{x}_p|<1} \bar{\boldsymbol{u}}\boldsymbol{\cdot} \boldsymbol{\nabla}\bar{\boldsymbol{u}}\,\text{d}V \nonumber\\ &\quad +\frac{1}{Re_p} \int_{|\boldsymbol{x}-\boldsymbol{x}_p|=1} (-\boldsymbol{n})\boldsymbol{\cdot} ({-}q\boldsymbol{I}+\boldsymbol{\nabla}\boldsymbol{v}+ \boldsymbol{\nabla}\boldsymbol{v}^{\rm T})\,\text{d}S, \end{align} \begin{align} \boldsymbol{T}&={-}\frac{8{\rm \pi}}{15}\varTheta (\boldsymbol{e}_z\times\boldsymbol{\varOmega}_p)+ \int_{|\boldsymbol{x}-\boldsymbol{x}_p|<1} (\boldsymbol{x}-\boldsymbol{x}_p)\times (\bar{\boldsymbol{u}}\boldsymbol{\cdot} \boldsymbol{\nabla}\bar{\boldsymbol{u}})\,\text{d}V \nonumber\\ &\quad +\frac{1}{Re_p} \int_{|\boldsymbol{x}-\boldsymbol{x}_p|=1} (\boldsymbol{x}-\boldsymbol{x}_p)\times((-\boldsymbol{n}) \boldsymbol{\cdot}({-}q\boldsymbol{I}+\boldsymbol{\nabla}\boldsymbol{v}+ \boldsymbol{\nabla}\boldsymbol{v}^{\rm T}))\,\text{d}S. \end{align}

\begin{align} \boldsymbol{T}&={-}\frac{8{\rm \pi}}{15}\varTheta (\boldsymbol{e}_z\times\boldsymbol{\varOmega}_p)+ \int_{|\boldsymbol{x}-\boldsymbol{x}_p|<1} (\boldsymbol{x}-\boldsymbol{x}_p)\times (\bar{\boldsymbol{u}}\boldsymbol{\cdot} \boldsymbol{\nabla}\bar{\boldsymbol{u}})\,\text{d}V \nonumber\\ &\quad +\frac{1}{Re_p} \int_{|\boldsymbol{x}-\boldsymbol{x}_p|=1} (\boldsymbol{x}-\boldsymbol{x}_p)\times((-\boldsymbol{n}) \boldsymbol{\cdot}({-}q\boldsymbol{I}+\boldsymbol{\nabla}\boldsymbol{v}+ \boldsymbol{\nabla}\boldsymbol{v}^{\rm T}))\,\text{d}S. \end{align}

Taking the particle Reynolds number as a small parameter and performing a perturbation expansion of the disturbance flow in powers of ![]() $Re_p$ we get

$Re_p$ we get

\begin{equation} \left.\begin{gathered} \boldsymbol{v} = \boldsymbol{v}_0+Re_p \boldsymbol{v}_1+{O}(Re^2_p), \\ q = q_0+Re_p q_1+{O}(Re^2_p). \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \boldsymbol{v} = \boldsymbol{v}_0+Re_p \boldsymbol{v}_1+{O}(Re^2_p), \\ q = q_0+Re_p q_1+{O}(Re^2_p). \end{gathered}\right\} \end{equation}

Substituting into (2.1) gives us a zeroth-order system for ![]() $q_0,\boldsymbol {v}_0$, and a first-order system for

$q_0,\boldsymbol {v}_0$, and a first-order system for ![]() $q_1,\boldsymbol {v}_1$. The zeroth-order system captures all the non-zero boundary conditions and the first-order system captures the most significant inertial contribution to the complete equations. Substituting the perturbation expansions in (2.2) results in the following equation for the leading-order cross-sectional force on the quasi-static particle:

$q_1,\boldsymbol {v}_1$. The zeroth-order system captures all the non-zero boundary conditions and the first-order system captures the most significant inertial contribution to the complete equations. Substituting the perturbation expansions in (2.2) results in the following equation for the leading-order cross-sectional force on the quasi-static particle:

Here, ![]() $\boldsymbol {F}_{-1}$ is the leading-order force consisting of drag from the background flow, with the subscript ‘s’ denoting the secondary (cross-sectional) component, while

$\boldsymbol {F}_{-1}$ is the leading-order force consisting of drag from the background flow, with the subscript ‘s’ denoting the secondary (cross-sectional) component, while ![]() $\boldsymbol {F}_0$ is the leading-order contribution of the inertial lift force. Then, using Stokes’ law, we balance the cross-sectional force in (2.5) with viscous Stokes’ drag and thus construct a first-order quasi-steady model for the trajectory of the particle giving the following dynamical equations of motion:

$\boldsymbol {F}_0$ is the leading-order contribution of the inertial lift force. Then, using Stokes’ law, we balance the cross-sectional force in (2.5) with viscous Stokes’ drag and thus construct a first-order quasi-steady model for the trajectory of the particle giving the following dynamical equations of motion:

where ![]() $\bar {u}_a$ is the axial component of the background fluid flow,

$\bar {u}_a$ is the axial component of the background fluid flow, ![]() $F_{s,r}=\boldsymbol {F}_s\boldsymbol {\cdot }\boldsymbol {e}_r$ and

$F_{s,r}=\boldsymbol {F}_s\boldsymbol {\cdot }\boldsymbol {e}_r$ and ![]() $F_{s,z}=\boldsymbol {F}_s\boldsymbol {\cdot }\boldsymbol {e}_z$ are the radial and the vertical components of the cross-sectional force, respectively, with corresponding drag coefficients

$F_{s,z}=\boldsymbol {F}_s\boldsymbol {\cdot }\boldsymbol {e}_z$ are the radial and the vertical components of the cross-sectional force, respectively, with corresponding drag coefficients ![]() $C_r$ and

$C_r$ and ![]() $C_z$ that vary with the particle's position in the cross-section. Thus, this model estimates the particle velocities within a circular duct with each of the forces implicitly depending on the radius of curvature (which coincides with the bend radius

$C_z$ that vary with the particle's position in the cross-section. Thus, this model estimates the particle velocities within a circular duct with each of the forces implicitly depending on the radius of curvature (which coincides with the bend radius ![]() $R$) in addition to the particle radius

$R$) in addition to the particle radius ![]() $a$. We note that our model does not include particle–particle interactions. Hence, the results presented in this manuscript are valid in the regime of low particle density where particle–particle interactions can be safely neglected.

$a$. We note that our model does not include particle–particle interactions. Hence, the results presented in this manuscript are valid in the regime of low particle density where particle–particle interactions can be safely neglected.

We are able to extend this quasi-steady model to spiral ducts with slowly varying curvature by considering ![]() $R$ as a function of

$R$ as a function of ![]() $\theta$ to describe the local radius of curvature (which must be distinguished from any notion of bend radius in non-circular duct geometries, see § 2.3 for more details). The radius of curvature is the appropriate quantity to determine local fluid behaviour as it is a well-defined geometrical construct which applies to any curve, whereas the notion of bend radius relies on having a well-defined origin (or other point of reference) which does not apply to generalised curves. Thus, while it is convenient to describe circular and Archimedean spiral ducts via a ‘bend radius’, we need to consider the radius of curvature when modelling the fluid.

$\theta$ to describe the local radius of curvature (which must be distinguished from any notion of bend radius in non-circular duct geometries, see § 2.3 for more details). The radius of curvature is the appropriate quantity to determine local fluid behaviour as it is a well-defined geometrical construct which applies to any curve, whereas the notion of bend radius relies on having a well-defined origin (or other point of reference) which does not apply to generalised curves. Thus, while it is convenient to describe circular and Archimedean spiral ducts via a ‘bend radius’, we need to consider the radius of curvature when modelling the fluid.

The circular duct model is solved numerically using a finite element method to compute the forces acting on the particle. We refer the reader to Harding et al. (Reference Harding, Stokes and Bertozzi2019) for additional details on the numerical framework. Once the relevant forces have been pre-computed at numerous sample points over the cross-section (and for numerous system parameter values), smooth interpolants of ![]() $C_r$,

$C_r$, ![]() $C_z$,

$C_z$, ![]() $F_{s,r}$,

$F_{s,r}$, ![]() $F_{s,z}$ are constructed and the particle dynamics is simulated using the MATLAB solver ode45.

$F_{s,z}$ are constructed and the particle dynamics is simulated using the MATLAB solver ode45.

For the results presented in this manuscript, we use the following non-dimensional scales for the system variables: dimensionless radius of curvature (or bend radius, as appropriate) ![]() $\tilde {R}=2R/H$, dimensionless particle size

$\tilde {R}=2R/H$, dimensionless particle size ![]() $\tilde {a}=2a/H$, dimensionless time

$\tilde {a}=2a/H$, dimensionless time ![]() $\tilde {t}=U_m t/H$ and cross-sectional co-ordinates

$\tilde {t}=U_m t/H$ and cross-sectional co-ordinates ![]() $\tilde {r}=2r/H$ and

$\tilde {r}=2r/H$ and ![]() $\tilde {z}=2z/H$.

$\tilde {z}=2z/H$.

2.2. Spiral duct geometry

Our illustrations thus far have utilised an Archimedean spiral, since these are readily recognised and understood. However, to extend the circular duct model to spiral ducts, it is convenient to instead consider an Archimedean-like spiral duct whose centreline is described by the parametric equation

where

with ![]() $\tilde {R}_{start},\tilde {R}_{end}$ denoting the radius of curvature at the start and end of the spiral duct, respectively, and

$\tilde {R}_{start},\tilde {R}_{end}$ denoting the radius of curvature at the start and end of the spiral duct, respectively, and ![]() $N_{turns}$ denoting the number of turns. This curve corresponds to the involute of a circle (having radius

$N_{turns}$ denoting the number of turns. This curve corresponds to the involute of a circle (having radius ![]() $\beta$) and, although visually similar, differs in several ways from a traditional Archimedean spiral described by

$\beta$) and, although visually similar, differs in several ways from a traditional Archimedean spiral described by

with ![]() $\tilde {R}(\theta )$ as in (2.8).

$\tilde {R}(\theta )$ as in (2.8).

For the traditional Archimedean spiral of (2.10), the radial distance from the origin, often referred to as the bend radius, varies linearly with respect to ![]() $\theta$. Accordingly,

$\theta$. Accordingly, ![]() $\tilde {R}_{start},\tilde {R}_{end},\tilde {R}(\theta )$ should be interpreted as bend radii in the context of the Archimedean spiral. However, it is important to note that the bend radius of an Archimedean spiral does not equal its radius of curvature, and it is the latter which is fundamental to describing/modelling the local fluid flow. In contrast, for the involute spiral of (2.7) it is the radius of curvature that varies linearly with respect to

$\tilde {R}_{start},\tilde {R}_{end},\tilde {R}(\theta )$ should be interpreted as bend radii in the context of the Archimedean spiral. However, it is important to note that the bend radius of an Archimedean spiral does not equal its radius of curvature, and it is the latter which is fundamental to describing/modelling the local fluid flow. In contrast, for the involute spiral of (2.7) it is the radius of curvature that varies linearly with respect to ![]() $\varphi$ and

$\varphi$ and ![]() $\tilde {R}_{start},\tilde {R}_{end},\tilde {R}(\varphi )$ can be interpreted as radii of curvature at the appropriate locations. The trade-off is that

$\tilde {R}_{start},\tilde {R}_{end},\tilde {R}(\varphi )$ can be interpreted as radii of curvature at the appropriate locations. The trade-off is that ![]() $\varphi$ no longer describes the polar angle.

$\varphi$ no longer describes the polar angle.

There are a number of additional differences between the two curves worth noting. The involute spiral has a closed-form arclength parametrisation whereas the Archimedean spiral does not. The principal unit normal of the involute spiral is ![]() $\boldsymbol {N}_I(\varphi )=[-\cos (\varphi ),-\sin (\phi )]$ and is directed from

$\boldsymbol {N}_I(\varphi )=[-\cos (\varphi ),-\sin (\phi )]$ and is directed from ![]() $\tilde {\boldsymbol {r}}_I(\varphi )$ to the point

$\tilde {\boldsymbol {r}}_I(\varphi )$ to the point ![]() $\beta [-\sin (\varphi ),\cos (\varphi )-1]$. The principal unit normal for the Archimedean spiral is more complex and, importantly, is not directed from

$\beta [-\sin (\varphi ),\cos (\varphi )-1]$. The principal unit normal for the Archimedean spiral is more complex and, importantly, is not directed from ![]() $\boldsymbol {\tilde {r}}_A(\theta )$ towards the origin. These differences between the two curves are subtle when

$\boldsymbol {\tilde {r}}_A(\theta )$ towards the origin. These differences between the two curves are subtle when ![]() $\beta$ is small, but they become important when considering how to update the value of

$\beta$ is small, but they become important when considering how to update the value of ![]() $\tilde {R}$ as a particle traverses a spiral duct having positive width. The simplest way one might describe the sidewalls in both spirals is to replace

$\tilde {R}$ as a particle traverses a spiral duct having positive width. The simplest way one might describe the sidewalls in both spirals is to replace ![]() $\tilde {R}({\cdot })$ with

$\tilde {R}({\cdot })$ with ![]() $\tilde {R}({\cdot })\pm \tilde {W}/2$ in each of (2.7) and (2.10). For the involute spiral this leads to a consistent width of

$\tilde {R}({\cdot })\pm \tilde {W}/2$ in each of (2.7) and (2.10). For the involute spiral this leads to a consistent width of ![]() $\tilde {W}$ as measured with respect to the principal unit normal of

$\tilde {W}$ as measured with respect to the principal unit normal of ![]() $\tilde {\boldsymbol {r}}_I(\varphi )$, but the same cannot be said for the Archimedean spiral. Moreover, when considering how to update

$\tilde {\boldsymbol {r}}_I(\varphi )$, but the same cannot be said for the Archimedean spiral. Moreover, when considering how to update ![]() $\tilde {R}$ as a particle traverses the involute spiral we have

$\tilde {R}$ as a particle traverses the involute spiral we have

where ![]() $s_I(\varphi )$ is the arclength along the involute spiral. The term

$s_I(\varphi )$ is the arclength along the involute spiral. The term ![]() $\textrm {d} s_I/\textrm {d}\tilde {t}$ is simply the velocity of the particle down the main axis (i.e. aligned with the tangent vector

$\textrm {d} s_I/\textrm {d}\tilde {t}$ is simply the velocity of the particle down the main axis (i.e. aligned with the tangent vector ![]() $\hat {\boldsymbol {T}}_I(\varphi )=[-\sin (\varphi ),\cos (\varphi )]$). For

$\hat {\boldsymbol {T}}_I(\varphi )=[-\sin (\varphi ),\cos (\varphi )]$). For ![]() $\textrm {d}\varphi /\textrm {d} s_I$ we note that

$\textrm {d}\varphi /\textrm {d} s_I$ we note that ![]() $\textrm {d} s_I/\textrm {d}\varphi =\tilde {R}(\varphi )+\tilde {r}_p$, where the addition of

$\textrm {d} s_I/\textrm {d}\varphi =\tilde {R}(\varphi )+\tilde {r}_p$, where the addition of ![]() $\tilde {r}_p$ accounts for the radial coordinate of the particle within the cross-section. For the Archimedean spiral, we similarly have

$\tilde {r}_p$ accounts for the radial coordinate of the particle within the cross-section. For the Archimedean spiral, we similarly have

where ![]() $s_A(\varphi )$ is the arclength along the Archimedean spiral. The term

$s_A(\varphi )$ is the arclength along the Archimedean spiral. The term ![]() $\textrm {d} s_A/\textrm {d}\tilde {t}$ is again the particle velocity down the main axis; however, one must recognise that the tangent vector is given by the more complex expression

$\textrm {d} s_A/\textrm {d}\tilde {t}$ is again the particle velocity down the main axis; however, one must recognise that the tangent vector is given by the more complex expression

\begin{equation} \hat{\boldsymbol{T}}_A(\theta)=\frac{\tilde{R}(\theta)[-\sin(\theta),\cos(\theta)]+ \beta[\cos(\theta),\sin(\theta)]}{\sqrt{\tilde{R}(\theta)^2+\beta^2}}. \end{equation}

\begin{equation} \hat{\boldsymbol{T}}_A(\theta)=\frac{\tilde{R}(\theta)[-\sin(\theta),\cos(\theta)]+ \beta[\cos(\theta),\sin(\theta)]}{\sqrt{\tilde{R}(\theta)^2+\beta^2}}. \end{equation}

Moreover, for ![]() $\textrm {d}\theta /\textrm {d} s_A$ we note that

$\textrm {d}\theta /\textrm {d} s_A$ we note that ![]() $\textrm {d} s_A/\textrm {d}\theta =\sqrt {\tilde {R}(\theta )^2+\beta ^2}+\tilde {r}_p$. Upon accounting for these subtleties, one must still determine the radius of curvature of the Archimedean spiral to ensure the correct migration forces are sampled from our circular duct model. All together, these differences make the involute spiral much better suited to extending our curved duct model of inertial particle migration. We will use

$\textrm {d} s_A/\textrm {d}\theta =\sqrt {\tilde {R}(\theta )^2+\beta ^2}+\tilde {r}_p$. Upon accounting for these subtleties, one must still determine the radius of curvature of the Archimedean spiral to ensure the correct migration forces are sampled from our circular duct model. All together, these differences make the involute spiral much better suited to extending our curved duct model of inertial particle migration. We will use ![]() $\tilde {\boldsymbol {r}}(\varphi )=\tilde {\boldsymbol {r}}_I(\varphi )$ and

$\tilde {\boldsymbol {r}}(\varphi )=\tilde {\boldsymbol {r}}_I(\varphi )$ and ![]() $\tilde {R}=\tilde {R}(\varphi )$ going forwards, where

$\tilde {R}=\tilde {R}(\varphi )$ going forwards, where ![]() $\tilde {R},\tilde {R}_{start},\tilde {R}_{end}$ should always be interpreted as radii of curvature (with the exception of appendix where we compare results with an Archimedean spiral).

$\tilde {R},\tilde {R}_{start},\tilde {R}_{end}$ should always be interpreted as radii of curvature (with the exception of appendix where we compare results with an Archimedean spiral).

When designing a spiral duct, upper and lower bounds on the number of turns, ![]() ${N}_{turns}$, are determined by both geometrical and physical/practical constraints. From a purely geometrical point of view, the maximum number of turns,

${N}_{turns}$, are determined by both geometrical and physical/practical constraints. From a purely geometrical point of view, the maximum number of turns, ![]() $N_{\max }$, is constrained by the fact that the spiral duct, having non-zero width along the spiral curve, should not intersect itself. This means that, after one turn of the spiral,

$N_{\max }$, is constrained by the fact that the spiral duct, having non-zero width along the spiral curve, should not intersect itself. This means that, after one turn of the spiral, ![]() $\tilde {R}(\varphi )$ should change at least by the width of the cross-section, resulting in the constraint

$\tilde {R}(\varphi )$ should change at least by the width of the cross-section, resulting in the constraint ![]() $2{\rm \pi} \beta >\tilde {W}$, or equivalently

$2{\rm \pi} \beta >\tilde {W}$, or equivalently ![]() $N_{\max }<|\tilde {R}_{end}-\tilde {R}_{start}|/\tilde {W}$, where

$N_{\max }<|\tilde {R}_{end}-\tilde {R}_{start}|/\tilde {W}$, where ![]() $\tilde {W}=W/H$ is the aspect ratio of the rectangular cross-section. In addition to this geometrical constraint, there may be additional practical experimental/design constraints that further limit the maximum number of turns. For example, the required pressure difference to drive fluid flow through the duct increases with the length of the duct and there may be an upper limit on the pressure difference to preserve the structural integrity of a microfluidic device. The minimum number of turns

$\tilde {W}=W/H$ is the aspect ratio of the rectangular cross-section. In addition to this geometrical constraint, there may be additional practical experimental/design constraints that further limit the maximum number of turns. For example, the required pressure difference to drive fluid flow through the duct increases with the length of the duct and there may be an upper limit on the pressure difference to preserve the structural integrity of a microfluidic device. The minimum number of turns ![]() $N_{min}$ is constrained by two factors: (i) the maximum change in radius of curvature that can be considered reasonable in our slowly varying curvature model, and (ii) the time/length required for the particles (initially randomly distributed in the cross-section) to focus (sufficiently close) to their particle attractors. Both of these considerations are also influenced by the flow rate at which the device is expected to operate at.

$N_{min}$ is constrained by two factors: (i) the maximum change in radius of curvature that can be considered reasonable in our slowly varying curvature model, and (ii) the time/length required for the particles (initially randomly distributed in the cross-section) to focus (sufficiently close) to their particle attractors. Both of these considerations are also influenced by the flow rate at which the device is expected to operate at.

2.3. Numerical test for the slowly varying curvature approximation

Steady flow through an Archimedean spiral duct having a rectangular cross-section with large aspect ratio was considered in Harding & Stokes (Reference Harding and Stokes2018). (Non-rectangular cross-sections were also considered but in the context of this work only the rectangular cross-sections are of interest.) An approximation was developed via a regular perturbation expansion with respect to both the curvature parameter and the height-to-width ratio. It was found that the leading-order solution depended on the local curvature of the spiral but not its rate of change. First-order corrections with respect to both perturbation parameters were also considered, but these too did not introduce any non-trivial dependence on the rate of change of the spiral curvature. This provides strong evidence that spiral duct flow does not differ significantly from circular duct flow (when using the appropriate curvature parameter at any given point in the spiral). More specifically, it suggests that non-trivial dependence of the flow with respect to our ![]() $\beta$ parameter only occurs at order

$\beta$ parameter only occurs at order ![]() $O(\epsilon ^2)$ or smaller (relative to the magnitude of each leading-order component).

$O(\epsilon ^2)$ or smaller (relative to the magnitude of each leading-order component).

To test this further we conducted a numerical simulation of fluid flow through a relatively short spiral duct having a somewhat large value of ![]() $\beta$. Specifically, we considered a set-up with

$\beta$. Specifically, we considered a set-up with ![]() $\tilde {R}_{start}=100$,

$\tilde {R}_{start}=100$, ![]() $\tilde {R}_{end}=20$,

$\tilde {R}_{end}=20$, ![]() $N_{turns}=1/2$,

$N_{turns}=1/2$, ![]() $W=4$ and

$W=4$ and ![]() $H=2$, i.e. such that

$H=2$, i.e. such that ![]() $|\beta |=80/{\rm \pi} \approx 25.5$. We generated a structured mesh of this domain consisting of roughly 780 000 tetrahedra and then solved the Navier–Stokes equations using the finite element method with Taylor–Hood elements (utilising the FEniCS computing platform Logg, Mardal & Wells Reference Logg, Mardal and Wells2012; Alnaes et al. Reference Alnaes, Blechta, Hake, Johansson, Kehlet, Logg, Richardson, Ring, Rognes and Wells2015). At different cross-sections we then compared the velocity field with that which is obtained by solving the equations of steady flow through a circular duct (Harding Reference Harding2019, Reference Harding2022). At the cross-section of the spiral duct for which the radius of curvature is

$|\beta |=80/{\rm \pi} \approx 25.5$. We generated a structured mesh of this domain consisting of roughly 780 000 tetrahedra and then solved the Navier–Stokes equations using the finite element method with Taylor–Hood elements (utilising the FEniCS computing platform Logg, Mardal & Wells Reference Logg, Mardal and Wells2012; Alnaes et al. Reference Alnaes, Blechta, Hake, Johansson, Kehlet, Logg, Richardson, Ring, Rognes and Wells2015). At different cross-sections we then compared the velocity field with that which is obtained by solving the equations of steady flow through a circular duct (Harding Reference Harding2019, Reference Harding2022). At the cross-section of the spiral duct for which the radius of curvature is ![]() $50$, and with a flow Reynolds number of

$50$, and with a flow Reynolds number of ![]() $100$, we measured a relative

$100$, we measured a relative ![]() $L_2$ difference in the axial, radial and vertical velocity components of the circular and spiral duct flows as

$L_2$ difference in the axial, radial and vertical velocity components of the circular and spiral duct flows as ![]() $3.3\,\%$,

$3.3\,\%$, ![]() $5.5\,\%$ and

$5.5\,\%$ and ![]() $3.1\,\%$, respectively. The error decreased for smaller Reynolds numbers, for example with

$3.1\,\%$, respectively. The error decreased for smaller Reynolds numbers, for example with ![]() $Re=50$ we observe relative differences of

$Re=50$ we observe relative differences of ![]() $0.53\,\%$,

$0.53\,\%$, ![]() $0.99\,\%$ and

$0.99\,\%$ and ![]() $2.0\,\%$, respectively.

$2.0\,\%$, respectively.

In a second computation we generated a structured mesh of a spiral duct with ![]() ${\tilde {R}_{start}=50}$,

${\tilde {R}_{start}=50}$, ![]() $\tilde {R}_{end}=300$,

$\tilde {R}_{end}=300$, ![]() $N_{turns}=1$ and other parameters as above, such that, now,

$N_{turns}=1$ and other parameters as above, such that, now, ![]() $|\beta |=125/{\rm \pi} \approx 40.8$. The same number of tetrahedra were used in this case. At the cross-section for which the radius of curvature is

$|\beta |=125/{\rm \pi} \approx 40.8$. The same number of tetrahedra were used in this case. At the cross-section for which the radius of curvature is ![]() $200$, and again with a flow Reynolds number of

$200$, and again with a flow Reynolds number of ![]() $100$, we measured a relative

$100$, we measured a relative ![]() $L_2$ difference in the three velocity components as

$L_2$ difference in the three velocity components as ![]() $0.25\,\%$,

$0.25\,\%$, ![]() $2.6\,\%$ and

$2.6\,\%$ and ![]() $0.46\,\%$. In this instance the difference did not decrease significantly when decreasing the Reynolds number, which suggests that the dominant error is due to the mesh resolution. A similar observation was made for other cross-sections (which are not too close or far from the ends where there are inlet/outlet effects). A precise analysis of the difference between circular and spiral duct flows is the subject of ongoing work, but together these results indicate that

$0.46\,\%$. In this instance the difference did not decrease significantly when decreasing the Reynolds number, which suggests that the dominant error is due to the mesh resolution. A similar observation was made for other cross-sections (which are not too close or far from the ends where there are inlet/outlet effects). A precise analysis of the difference between circular and spiral duct flows is the subject of ongoing work, but together these results indicate that ![]() $\beta =O(10)$ can be considered small enough that the spiral geometry is sufficiently slowly varying that the fluid flow through any given cross-section can be well approximated by circular duct flow with appropriately chosen curvature parameter, for Reynolds numbers up to

$\beta =O(10)$ can be considered small enough that the spiral geometry is sufficiently slowly varying that the fluid flow through any given cross-section can be well approximated by circular duct flow with appropriately chosen curvature parameter, for Reynolds numbers up to ![]() $O(100)$.

$O(100)$.

3. Bifurcations with respect to radius of curvature

We start by briefly reviewing the effect of radius of curvature on particle equilibria in circular duct geometries. We refer the interested reader to Harding et al. (Reference Harding, Stokes and Bertozzi2019) and Valani et al. (Reference Valani, Harding and Stokes2022) for a more detailed exploration of how various system parameters, such as radius of curvature, cross-sectional geometry and particle size, change the particle equilibria. Here, we provide an illustrative example of bifurcations with respect to changes in radius of curvature which will provide a foundation for the rest of the paper.

Figures 2(a) and 2(b) show bifurcation diagrams depicting the radial (![]() $\tilde {r}$) and vertical (

$\tilde {r}$) and vertical (![]() $\tilde {z}$) co-ordinates of particle equilibria (i.e. locations where the net force on the particle is zero), respectively, as a function of the radius of curvature

$\tilde {z}$) co-ordinates of particle equilibria (i.e. locations where the net force on the particle is zero), respectively, as a function of the radius of curvature ![]() $\tilde {R}$ for a small particle of radius

$\tilde {R}$ for a small particle of radius ![]() ${\tilde {a}=0.05}$ in a rectangular

${\tilde {a}=0.05}$ in a rectangular ![]() $2\times 1$ cross-section. The particle equilibria in the two-dimensional cross-section for

$2\times 1$ cross-section. The particle equilibria in the two-dimensional cross-section for ![]() $\tilde {R}=10\,000,3200,3000$ and

$\tilde {R}=10\,000,3200,3000$ and ![]() $1000$ are shown in (c). Note that, in the low flow-rate regime under consideration, the equilibria are independent of the flow Reynolds number. We see that, at relatively large radii of curvature, many particle equilibria are found in the cross-section, for example an unstable node near the centre of the duct, saddle points near the corners and stable nodes (point attractors) near the edges of the rectangular cross-section. A universal dynamical feature observed at relatively large radii of curvature is a slowing of migration along heteroclinic orbits which connect saddle points to stable nodes. These connected unstable/stable manifolds of saddle points/stable nodes effectively constitute a slow manifold. Several bifurcations take place as the radius of curvature is decreased. Firstly, near

$1000$ are shown in (c). Note that, in the low flow-rate regime under consideration, the equilibria are independent of the flow Reynolds number. We see that, at relatively large radii of curvature, many particle equilibria are found in the cross-section, for example an unstable node near the centre of the duct, saddle points near the corners and stable nodes (point attractors) near the edges of the rectangular cross-section. A universal dynamical feature observed at relatively large radii of curvature is a slowing of migration along heteroclinic orbits which connect saddle points to stable nodes. These connected unstable/stable manifolds of saddle points/stable nodes effectively constitute a slow manifold. Several bifurcations take place as the radius of curvature is decreased. Firstly, near ![]() $\tilde {R}\approx 7000$, a subcritical pitchfork bifurcation takes place near the outer wall where a stable node and two saddle points merge into a single saddle point. As the radius of curvature is further decreased, a pair of saddle-node bifurcations takes place near

$\tilde {R}\approx 7000$, a subcritical pitchfork bifurcation takes place near the outer wall where a stable node and two saddle points merge into a single saddle point. As the radius of curvature is further decreased, a pair of saddle-node bifurcations takes place near ![]() $\tilde {R}\approx 3000$ where saddle points near the inner wall annihilate with stable nodes near the top and bottom edges. Further decreasing the radius of curvature leads to two rapid bifurcations (see the inset of figure 2a). The stable node on the horizontal centreline (

$\tilde {R}\approx 3000$ where saddle points near the inner wall annihilate with stable nodes near the top and bottom edges. Further decreasing the radius of curvature leads to two rapid bifurcations (see the inset of figure 2a). The stable node on the horizontal centreline (![]() $\tilde {z}=0$) near the inner wall first undergoes a supercritical pitchfork bifurcation, producing two stable nodes in the vertical direction with a saddle point in between. The saddle point then merges with the unstable node in a saddle-node bifurcation while the two stable nodes transition to stable spirals. No further bifurcations take place as the radius of curvature is decreased even further, but the pair of stable spirals asymptotically migrate horizontally towards the vertical centreline (

$\tilde {z}=0$) near the inner wall first undergoes a supercritical pitchfork bifurcation, producing two stable nodes in the vertical direction with a saddle point in between. The saddle point then merges with the unstable node in a saddle-node bifurcation while the two stable nodes transition to stable spirals. No further bifurcations take place as the radius of curvature is decreased even further, but the pair of stable spirals asymptotically migrate horizontally towards the vertical centreline (![]() $\tilde {r}=0$) of the duct as

$\tilde {r}=0$) of the duct as ![]() $\tilde {R}\xrightarrow {}\tilde {W}$.

$\tilde {R}\xrightarrow {}\tilde {W}$.

Figure 2. A typical bifurcation diagram showing equilibria for a particle of dimensionless radius ![]() ${\tilde {a}=2a/H=0.05}$ in constant curvature ducts with a

${\tilde {a}=2a/H=0.05}$ in constant curvature ducts with a ![]() $2\times 1$ rectangular cross-section. (a) Horizontal dimensionless location

$2\times 1$ rectangular cross-section. (a) Horizontal dimensionless location ![]() $\tilde {r}=2r/H$ and (b) vertical dimensionless location

$\tilde {r}=2r/H$ and (b) vertical dimensionless location ![]() $\tilde {z}=2z/H$ of the particle equilibria as a function of the dimensionless radius of curvature

$\tilde {z}=2z/H$ of the particle equilibria as a function of the dimensionless radius of curvature ![]() $\tilde {R}=2R/H$. The inset in (a) shows details of bifurcations near

$\tilde {R}=2R/H$. The inset in (a) shows details of bifurcations near ![]() $\tilde {R}\approx 3000$. (c) Snapshots showing the particle equilibria in the two-dimensional cross-section at various

$\tilde {R}\approx 3000$. (c) Snapshots showing the particle equilibria in the two-dimensional cross-section at various ![]() $\tilde {R}$ values. These radii of curvature correspond to the vertical grey dashed lines in (a). For each panel, the size of the circle corresponds to particle size and the colour denotes the type of equilibria: unstable nodes in red, stable nodes/spirals (point attractor) in green/cyan and saddle points in yellow. The grey curves in (c) illustrate some trajectories of particles within the cross-section while the dashed rectangle indicates the location of the centre of the particle for which it will touch the walls of the duct.

$\tilde {R}$ values. These radii of curvature correspond to the vertical grey dashed lines in (a). For each panel, the size of the circle corresponds to particle size and the colour denotes the type of equilibria: unstable nodes in red, stable nodes/spirals (point attractor) in green/cyan and saddle points in yellow. The grey curves in (c) illustrate some trajectories of particles within the cross-section while the dashed rectangle indicates the location of the centre of the particle for which it will touch the walls of the duct.

For different particle sizes in the range ![]() $0<\tilde {a}\leq 0.2$, similar bifurcations take place but at different radii of curvature

$0<\tilde {a}\leq 0.2$, similar bifurcations take place but at different radii of curvature ![]() $\tilde {R}$. Harding et al. (Reference Harding, Stokes and Bertozzi2019) showed that, for circular ducts with rectangular cross-sections, the variations in particle equilibria with

$\tilde {R}$. Harding et al. (Reference Harding, Stokes and Bertozzi2019) showed that, for circular ducts with rectangular cross-sections, the variations in particle equilibria with ![]() $\tilde {R}$ for different-sized particles can be captured reasonably well by a single dimensionless ratio

$\tilde {R}$ for different-sized particles can be captured reasonably well by a single dimensionless ratio ![]() $\kappa =4/(\tilde {a}^3 \tilde {R})$, which describes the scaling of secondary flow drag relative to the inertial lift force. The bifurcation curves for different

$\kappa =4/(\tilde {a}^3 \tilde {R})$, which describes the scaling of secondary flow drag relative to the inertial lift force. The bifurcation curves for different ![]() $\tilde {a}$ when plotted as a function of

$\tilde {a}$ when plotted as a function of ![]() $\kappa$ collapse reasonably well onto a single curve.

$\kappa$ collapse reasonably well onto a single curve.

4. Spiral ducts with no bifurcations in particle equilibria

We start by analysing the dynamics of neutrally buoyant particles in spiral ducts when there are no bifurcations of particle equilibria over the entire range of radii of curvature within the spiral. Despite an absence of bifurcations, there can still be non-trivial dynamical effects due to the motion of stable nodes/spirals (point attractors) or due to changes in the size and dynamics along limit cycles (one-dimensional attractors). We treat cases where there is a vertically symmetric pair of stable nodes/spirals or limit cycles (![]() ${\pm }\tilde {z}$) in the duct cross-section as a single particle attractor (with respect to the horizontal

${\pm }\tilde {z}$) in the duct cross-section as a single particle attractor (with respect to the horizontal ![]() $\tilde {r}$ direction). We explore the case of a single point attractor in § 4.1, a single limit-cycle pair in § 4.2, while the presence of multiple particle attractors in the horizontal direction of the cross-section is explored in § 4.3.

$\tilde {r}$ direction). We explore the case of a single point attractor in § 4.1, a single limit-cycle pair in § 4.2, while the presence of multiple particle attractors in the horizontal direction of the cross-section is explored in § 4.3.

4.1. Spiral ducts with a single point attractor

We start by analysing the dynamics of particles in spiral ducts where there is a single particle attractor. In ducts with rectangular cross-sections, this regime arises at smaller radii of curvature, where secondary drag forces dominate inertial lift forces and one obtains either: (i) a single stable node near the inner wall of the curve duct (e.g. see ![]() $\tilde {R}=3000$ in figure 2c), or (ii) a vertically symmetric pair of stable nodes/spirals (e.g. see

$\tilde {R}=3000$ in figure 2c), or (ii) a vertically symmetric pair of stable nodes/spirals (e.g. see ![]() $\tilde {R}=1000$ in figure 2c).

$\tilde {R}=1000$ in figure 2c).

A typical example of particle focusing dynamics in an in-spiral duct (i.e. the particle travels in the direction of decreasing radius of curvature) consisting of a vertically symmetric pair of stable spirals at the same horizontal ![]() $\tilde {r}$ location, is shown in figure 3. Here, we compare the particle focusing dynamics for spirals having the same starting (

$\tilde {r}$ location, is shown in figure 3. Here, we compare the particle focusing dynamics for spirals having the same starting (![]() $\tilde {R}_{start}$) and ending (

$\tilde {R}_{start}$) and ending (![]() $\tilde {R}_{end}$) radii of curvature but a different number of turns (

$\tilde {R}_{end}$) radii of curvature but a different number of turns (![]() $N_{turns}$). Note that, even in the absence of bifurcations, the particle equilibria are not static throughout the spiral ducts; they move in response to the changing radius of curvature of each cross-section. We observe that, for the spiral having fewer turns, the combination of insufficient duct length and continuous movement of the point attractors inhibits complete particle focusing and a spread in the particle distribution is observed at the end of the spiral duct (see figure 3a). Alternatively, with more turns, one observes complete focusing of particles at the end of the spiral duct (see figure 3b). For cross-sections G through to H, the focused particle cluster tracks the moving attractors closely and there is a small ‘lag’ between the centre of the focused clusters and the centre of the attractors. Hence, in a typical spiral duct with a single horizontal attractor and sufficient turns, the particle focusing is similar to circular ducts whose radius of curvature coincides with the local radius of curvature at the end of the spiral; in both cases the particles focus in close proximity to the single attractor whose location is determined by the radius of curvature at the end of the spiral. Nevertheless, spiral duct geometries have an advantage over circular ducts since one can increase the duct length by having multiple non-intersecting turns (which is not practically possible in circular ducts, although circular ducts might be wrapped around in the form of a helix to obtain multiple turns while avoiding self-intersection, in which case the effects of torsion may become important and our present model may not be applicable). This becomes particularly useful at smaller radii of curvature where one turn of a circular duct is not sufficient for particle focusing (e.g. see figure 10a).

$N_{turns}$). Note that, even in the absence of bifurcations, the particle equilibria are not static throughout the spiral ducts; they move in response to the changing radius of curvature of each cross-section. We observe that, for the spiral having fewer turns, the combination of insufficient duct length and continuous movement of the point attractors inhibits complete particle focusing and a spread in the particle distribution is observed at the end of the spiral duct (see figure 3a). Alternatively, with more turns, one observes complete focusing of particles at the end of the spiral duct (see figure 3b). For cross-sections G through to H, the focused particle cluster tracks the moving attractors closely and there is a small ‘lag’ between the centre of the focused clusters and the centre of the attractors. Hence, in a typical spiral duct with a single horizontal attractor and sufficient turns, the particle focusing is similar to circular ducts whose radius of curvature coincides with the local radius of curvature at the end of the spiral; in both cases the particles focus in close proximity to the single attractor whose location is determined by the radius of curvature at the end of the spiral. Nevertheless, spiral duct geometries have an advantage over circular ducts since one can increase the duct length by having multiple non-intersecting turns (which is not practically possible in circular ducts, although circular ducts might be wrapped around in the form of a helix to obtain multiple turns while avoiding self-intersection, in which case the effects of torsion may become important and our present model may not be applicable). This becomes particularly useful at smaller radii of curvature where one turn of a circular duct is not sufficient for particle focusing (e.g. see figure 10a).

Figure 3. Particle focusing dynamics in an in-spiral duct with a ![]() $2\times 1$ rectangular cross-section that has a vertically symmetric pair of point attractors. The system parameters are

$2\times 1$ rectangular cross-section that has a vertically symmetric pair of point attractors. The system parameters are ![]() $R_{start}=300$,

$R_{start}=300$, ![]() $R_{end}=50$,

$R_{end}=50$, ![]() $Re=50$ and

$Re=50$ and ![]() $\tilde {a}=0.10$. Snapshots of the cross-section are shown at (A,E)

$\tilde {a}=0.10$. Snapshots of the cross-section are shown at (A,E) ![]() $\tilde {R}=300$, (B,F)

$\tilde {R}=300$, (B,F) ![]() $200$, (C,G)

$200$, (C,G) ![]() $100$ and (D,H)

$100$ and (D,H) ![]() $50$, for column (a)

$50$, for column (a) ![]() $N_{turns}=1$ and column (b)

$N_{turns}=1$ and column (b) ![]() $N_{turns}=4$, respectively. The coloured circles denote the type of particle equilibria with cyan for stable spirals (point attractors) and yellow for a saddle point. The grey circles denote the particle positions while the grey curves denote their trajectories. If the centre of a particle lies on the dashed rectangle, it will touch at least one wall of the duct.

$N_{turns}=4$, respectively. The coloured circles denote the type of particle equilibria with cyan for stable spirals (point attractors) and yellow for a saddle point. The grey circles denote the particle positions while the grey curves denote their trajectories. If the centre of a particle lies on the dashed rectangle, it will touch at least one wall of the duct.

4.2. Spiral ducts with a single limit-cycle pair

Next, we consider an in-spiral duct with square cross-section having a single one-dimensional attractor in the horizontal direction, as shown in figure 4. Specifically, we have a vertically symmetric pair of stable limit cycles (black curves) which persists throughout the entire length of the spiral. However, the decreasing radius of curvature throughout the in-spiral duct leads to a continuous change in the size of the limit cycle and the dynamics along it. The limit cycle is large in extent near the inlet of the spiral and shrinks progressively along the spiral, while the period to traverse the limit cycle simultaneously decreases. We make an interesting observation regarding the phase of the limit cycle occupied by particles based on their initial location in the cross-section. We find that most particles that do not start near the unstable spiral equilibria or along the horizontal centreline of the duct, aggregate around the same phase of the limit cycle (see Movie ![]() $1$). One of the key factors for this particle aggregation is that initially, the majority of particles are ‘squeezed’ along the horizontal centreline where their dynamics slow down. This results in aggregation of particles as they approach the stable limit cycles. This phenomenon is robust with respect to the number of turns, as can be seen in figure 4(a,b) respectively (compare Movies

$1$). One of the key factors for this particle aggregation is that initially, the majority of particles are ‘squeezed’ along the horizontal centreline where their dynamics slow down. This results in aggregation of particles as they approach the stable limit cycles. This phenomenon is robust with respect to the number of turns, as can be seen in figure 4(a,b) respectively (compare Movies ![]() $1$ and

$1$ and ![]() $2$), which allows the phase occupied by the majority of particles within the final cross-section to be manipulated by modifying the number of turns accordingly.

$2$), which allows the phase occupied by the majority of particles within the final cross-section to be manipulated by modifying the number of turns accordingly.

Figure 4. Particle focusing dynamics in a spiral duct with square cross-section having a vertically symmetric pair of limit-cycle attractors. (a,b) Particle dynamics for in-spiral ducts having (a) ![]() $N_{turns}=4$ (see supplementary Movie 1 available at https://doi.org/10.1017/jfm.2024.487) and (b)

$N_{turns}=4$ (see supplementary Movie 1 available at https://doi.org/10.1017/jfm.2024.487) and (b) ![]() $N_{turns}=5$ (see Movie 2). Cross-sectional images at the (A,C) start and (B,D) end of the spiral show particle equilibria (dark coloured circles with purple for unstable spirals and yellow for saddle points) along with particle positions (light coloured circles) whose colour is based on the phase angle

$N_{turns}=5$ (see Movie 2). Cross-sectional images at the (A,C) start and (B,D) end of the spiral show particle equilibria (dark coloured circles with purple for unstable spirals and yellow for saddle points) along with particle positions (light coloured circles) whose colour is based on the phase angle ![]() $\phi$ occupied by the particles along the limit cycle (black curves) at the end of the spiral. If the centre of a particle lies on the dashed square, it will touch at least one wall of the duct. The system parameters are fixed to

$\phi$ occupied by the particles along the limit cycle (black curves) at the end of the spiral. If the centre of a particle lies on the dashed square, it will touch at least one wall of the duct. The system parameters are fixed to ![]() $R_{start}=1250$,

$R_{start}=1250$, ![]() $R_{end}=500$,

$R_{end}=500$, ![]() $\tilde {a}=0.05$ and

$\tilde {a}=0.05$ and ![]() $Re=50$.

$Re=50$.

4.3. Spiral ducts with multiple particle attractors

Multiple point attractors with different horizontal locations can coexist in circular ducts with rectangular cross-sections. When this occurs, the cross-sectional domain can be partitioned based on the basin of attraction for each point attractor. This allows one to readily identify where a particle will converge based on its initial location. However, when spiral ducts contain multiple point attractors throughout (with no bifurcations), both the point attractors and the basins of attraction move in response to the continuously changing radius of curvature. This can lead to some particles finding themselves in a different basin of attraction to the one they started in and this thereby induces non-trivial focusing effects.

Figure 5(a,b) compares a particle's trajectory in two spiral duct geometries having different numbers of turns. The duct has a ![]() $2\times 1$ rectangular cross-section and the spiral is such that multiple point attractors persist throughout. Two horizontally distinct stable nodes are present, one on the horizontal centreline near the inner wall, and a vertically symmetric pair of stable nodes a bit further away from the inner wall. Two saddle points between the three stable node attractors separate their respective basins of attraction. In figure 5(a) we show the trajectory of a particle starting out near the top inner (left) corner of the cross-section, specifically within the basin of the upper stable node (with respect to the starting radius of curvature) but near the boundary of that basin. As the particle is carried through the spiral duct, within the cross-section it is initially attracted towards the upper saddle point within a neighbourhood of its stable manifold. By the time the particle reaches its shortest distance to the saddle point, it finds itself in the basin of the left-most stable node due to the upward motion of the saddle point (see yellow arrows). Conversely, with more turns of the spiral as shown in figure 5(b), a particle starting from the same initial position remains in the basin of attraction of the upper-most stable node throughout the spiral. Thus, this particle–fluid system exhibits rate-induced tipping (R-tipping) where, depending on the rate at which the radius of curvature changes (e.g. via manipulating

$2\times 1$ rectangular cross-section and the spiral is such that multiple point attractors persist throughout. Two horizontally distinct stable nodes are present, one on the horizontal centreline near the inner wall, and a vertically symmetric pair of stable nodes a bit further away from the inner wall. Two saddle points between the three stable node attractors separate their respective basins of attraction. In figure 5(a) we show the trajectory of a particle starting out near the top inner (left) corner of the cross-section, specifically within the basin of the upper stable node (with respect to the starting radius of curvature) but near the boundary of that basin. As the particle is carried through the spiral duct, within the cross-section it is initially attracted towards the upper saddle point within a neighbourhood of its stable manifold. By the time the particle reaches its shortest distance to the saddle point, it finds itself in the basin of the left-most stable node due to the upward motion of the saddle point (see yellow arrows). Conversely, with more turns of the spiral as shown in figure 5(b), a particle starting from the same initial position remains in the basin of attraction of the upper-most stable node throughout the spiral. Thus, this particle–fluid system exhibits rate-induced tipping (R-tipping) where, depending on the rate at which the radius of curvature changes (e.g. via manipulating ![]() $N_{turns}$), particles starting near a basin boundary can approach a stable node with a basin of attraction different from the one they started in. Similarly, rate-induced tipping occurs in a spiral duct with a tall

$N_{turns}$), particles starting near a basin boundary can approach a stable node with a basin of attraction different from the one they started in. Similarly, rate-induced tipping occurs in a spiral duct with a tall ![]() $1\times 2$ rectangular cross-section, as shown in figure 5(c,d).

$1\times 2$ rectangular cross-section, as shown in figure 5(c,d).

Figure 5. Rate-induced tipping (R-tipping) for small particles of (a,b) radius ![]() $\tilde {a}=0.05$ in an in-spiral duct with

$\tilde {a}=0.05$ in an in-spiral duct with ![]() $\tilde {R}_{start}=4500$,

$\tilde {R}_{start}=4500$, ![]() $\tilde {R}_{end}=3100$,

$\tilde {R}_{end}=3100$, ![]() $Re=50$ and a

$Re=50$ and a ![]() $2\times 1$ rectangular cross-section. Particles which start near a saddle point that separates the basins of attraction of adjacent stable node attractors can either fall in the basin of attraction of the left-most stable node for (a)

$2\times 1$ rectangular cross-section. Particles which start near a saddle point that separates the basins of attraction of adjacent stable node attractors can either fall in the basin of attraction of the left-most stable node for (a) ![]() $N_{turns}=1$, or one of the stable node pair to the right of this for (b)

$N_{turns}=1$, or one of the stable node pair to the right of this for (b) ![]() $N_{turns}=2$. Similar behaviour is observed in (c,d) an in-spiral duct with

$N_{turns}=2$. Similar behaviour is observed in (c,d) an in-spiral duct with ![]() $\tilde {R}_{start}=1000$,

$\tilde {R}_{start}=1000$, ![]() $\tilde {R}_{end}=500$,

$\tilde {R}_{end}=500$, ![]() $Re=50$ and a

$Re=50$ and a ![]() $1\times 2$ rectangular cross-section for larger particles of radius

$1\times 2$ rectangular cross-section for larger particles of radius ![]() $\tilde {a}=0.15$ with (c)

$\tilde {a}=0.15$ with (c) ![]() $N_{turns}=0.5$ and (d)

$N_{turns}=0.5$ and (d) ![]() $N_{turns}=1$. The cross-sections of the ducts show particle equilibria (coloured circles) and their motion as the radius of curvature changes through the spiral (coloured arrows) with unstable nodes in red, stable nodes (point attractors) in green and saddle points in yellow. The particle location at the end of each spiral duct (grey filled circle), its motion (grey arrows) and trajectory (black curve) are also shown. If the centre of a particle lies on the dashed rectangle it will touch at least one wall of the duct.

$N_{turns}=1$. The cross-sections of the ducts show particle equilibria (coloured circles) and their motion as the radius of curvature changes through the spiral (coloured arrows) with unstable nodes in red, stable nodes (point attractors) in green and saddle points in yellow. The particle location at the end of each spiral duct (grey filled circle), its motion (grey arrows) and trajectory (black curve) are also shown. If the centre of a particle lies on the dashed rectangle it will touch at least one wall of the duct.

We note that, since the saddle-point equilibria, which separate the basins of attraction, do not move significantly between the starting and ending cross-sections of the spirals shown in figure 5, the R-tipping phenomenon only affects a small fraction of particles with initial positions near the basin boundaries. Hence, we do not expect R-tipping by itself to have major consequences for inertial particle focusing and separation. However, if R-tipping occurs in combination with bifurcations in particle equilibria, then significant changes in focusing behaviour can occur, as will be discussed in § 5.2.

5. Spiral ducts with bifurcations in particle equilibria

Bifurcations of particle equilibria can take place as the radius of curvature changes along a spiral duct. When bifurcations take place at a critical radius of curvature (depending also on the particle size and cross-sectional shape), this results in abrupt changes to the particle dynamics and focusing behaviour. Moreover, since the dynamics of the system undergoes a topological change, the direction in which bifurcations are traversed, i.e. in-spiral or out-spiral, leads to significantly different focusing behaviours at the end of the spiral. In this section, we explore different types of particle dynamics and focusing behaviours in spiral ducts where bifurcations occur. We start by exploring the particle dynamics in spiral ducts with bifurcations at a single radius of curvature in § 5.1, followed by a similar exploration in spiral ducts with bifurcations at multiple radii of curvature in § 5.2.

5.1. Spiral ducts with bifurcations at a single radius of curvature