DISCUSSION POINTS

-

• Innovations in the field of photovoltaic (PV) have proliferated in the last two decades, however similar price improvements in battery technology has lagged despite substantial investment in this area; how might we envision the design of off-grid systems to adaptively take advantage of battery storage if/when these prices start to fall?

-

• The US took an all-inclusive approach to electrification, despite the unfavorable economics of reaching sparsely distributed homes far from urban centers; are there areas of the earth not yet electrified where it may make more sense to make islanded energy systems the ultimate goal?

Introduction and background

Access to modern energy services, such as heating for water, building climate control, and an on-demand 24/7 electrical grid, is central to provision of high quality social services (health, education, treated public water supplies), to economic growth (irrigation for agriculture, mechanized mills and food processing centers, industrial facilities), and to attainment of improved quality of life (indoor lighting and plumbing, small business development). The clear connection between electricity delivery and improved living conditions Reference Benka1 has led to a wide range of international initiatives and targets for improved energy access, such as the Millennium Development Goals, 2 the United Nation's Sustainable Energy for All Initiative, the Lighting Africa effort led by the World Bank and the International Finance Corporation, 3–5 and the U.S. Power Africa Initiative. The desire of the international community to balance global economic growth against concerns of accelerated CO2 emissions has brought solar technologies into the forefront for meeting this growth in energy demand. This manuscript discusses the historical and potential future roles for small-to-medium scale solar thermal technologies in addressing the challenge of leveling energy access standards across countries with widely variable economic resources and consumer needs.

Energy delivery challenge

Currently, 1.1 billion people remain unelectrified globally; over half reside on the Africa continent and nearly 30% live in India, the single largest underserved market, 6 although these numbers may be underestimated, given the widely varying definitions of ‘electrification’. Currently no standard threshold exists in energy (or power) consumed by (or available to) a household to constitute ‘electrified’, 7 and therefore while the North American 99% electrification rate does imply that nearly all households have as much power as they require at all times, the statistics on other continents may refer to households with a single light bulb, a 4 W solar panel, Reference Fehrenbacher8,Reference Markham9 or a defunct grid connection. For instance, under the India Rajiv Gandhi Grameen Vidyutikaran Yojana (RGGVY) rural electrification scheme, put in place in 2005, any village with more than 10% households and all public places connected to the electrical grid is considered ‘electrified’ regardless of the number of kilowatt-hours delivered 10,11 ; in fact, many such villages in Bihar receive 5 or fewer hours of active connection, while urban connections may achieve 24 h availability. 12 One effort to overcome the challenges in defining and modeling complex energy access scenarios has been the proposal of a multitiered multiattribute matrix ranking access from tier 0 through tier 5 according to progress along dimensions of capacity, availability, affordability, etc for both electricity and cooking energy. Reference Angelou and Bhatia13 Weighting between the tiers is a possible means of developing an energy access index. In practice, the use and availability of diverse forms of energy (e.g., kerosene, coal, or biomass for lighting, heating, or cooking) are only poorly studied, and global statistics comparable to those for electrification are lacking.

Energy-poor communities tend to be rural, often in areas with difficult or mountainous terrain, and the institutions (health clinics, schools, police stations, community centers) serving these communities also tend to lack access to electricity. Studies have identified, in particular, high grid connection fees, low population density, low income levels (corresponding to lower demand), and poor/aging transmission and distribution infrastructure as key challenges inhibiting grid extension projects in these areas. Reference Barnes14 In flat terrain, grid extension typically costs over 10k USD per km; in mountainous terrain, the cost can exceed 20k USD per km. Reference Foster, Ghassemi and Cota15 Because of the aforementioned difficulties in quantification of unelectrified communities, estimates of unelectrified rural institutions may serve as a reasonable lower bound for understanding the magnitude of the remaining challenge: as of 2013 over 80,000 health clinics and 250,000 schools remained in this category. Reference Kazem, Alkurwi, Mohmmed, Salam and Alwaeli16

In an effort to overcome these disparities in service availability, countries across sub-Saharan Africa have set ambitious electrification targets, e.g., 22% by 2022 in Uganda, 17 35% by 2020 in Lesotho, 18,19 40% by 2024 in Kenya, 3 75% by 2035 in Tanzania. 20 However, it is widely recognized that meeting these goals will require considering nontraditional (i.e., other than grid extension) options for electrifying rural communities, and many of these countries have specifically committed to the inclusion of community-scale renewable energy systems in their growth portfolios. 3,17 Correspondingly, in November 2014, the Government of India introduced the Deendayal Upadhyaya Gram Jyoti Yojana initiative, aimed at enhancing the rural distribution and transmission infrastructure and development of off-grid and microgrid networks, and the related Jawaharlal Nehru National Solar Mission scheme announced in 2010 that it specifically targets 2000 MW of off-grid solar power by 2022. 21,22 Solar thermal, or concentrating solar power (CSP) systems are unique in utilizing thermal energy storage (TES) as an alternative to electrical storage via batteries, and may be appropriate for integration with some community-scale systems, making this a relevant, timely topic for reflection and consideration in this review.

Technological and market context

Any discussion of the role of CSP technologies within the energy access market requires a definition of both the extent and timing of demand and an understanding of competing generation and storage solutions and their costs, summarized briefly here. As noted above, grid extension is generally understood to be uneconomical for serving certain isolated rural communities, and thus this section focuses on alternate technologies that can be deployed in an ‘islanded’ configuration.

Fossil fuel (usually diesel-powered) generators and solar PV panels are the two technologies typically considered for such applications, although biomass solutions have become more widely used in India in past decades as well (wind and hydro are deployed on a more limited case by case basis depending on local resources). Generators that operate from widely available fuel energy sources are appealing for their load following ability, low capital cost, and high availability (capacity factor > 0.95), however, volatile and rising fuel costs, combined with the tendency for plants to be operated at part-load levels where efficiencies are low, lead to high O&M and overall levelized electricity costs (typically 0.55 up to 3.33 USD/kW h (Refs. Reference Kazem, Alkurwi, Mohmmed, Salam and Alwaeli16, Reference Szabó, Bódis, Huld and Moner-Girona23 and Reference NORPLAN24) for countries without highly subsidized domestic oil supplies). Further use of diesel power exacerbates CO2 and particulate emissions associated with growth in energy demand. Biomass-based generation offsets some concerns and price prohibitions of diesel generation [prices projected under 0.29 USD/kW h by the International Renewable Energy Agency in 2012 (Ref. 25)] but is victim to fluctuating prices in fuel stocks and is in direct competition with food supplies, and has not gained substantial traction in the commercial market to date. PV panels with load following DC–AC inverters mitigate point of use pollution concerns and have negligible O&M costs but require a substantial capital investment; the 75% decrease in PV module prices from 2009 to 2014 (Ref. 26) places levelized costs for community-scale systems with limited storage around 0.27–0.80 USD/kW h (Refs. Reference Kazem, Alkurwi, Mohmmed, Salam and Alwaeli16 and Reference Szabó, Bódis, Huld and Moner-Girona23) (installed price, which includes PV panels, batteries, and labor; variance due to regional pricing and range of solar resource availability). In contrast, however, household solar home systems (SHS), typically very small per-home capacity and sold as ready-to-install packages (one time fee) or through a “pay-as-you-go” fee-for-service model (monthly fee), experience prices from 0.85 to upwards of 2.5 USD/kW h (Refs. Reference Simonet27 and Reference Jenkins28) if fees are calculated on a per-kW h basis. While in many cases, solar PV may still be the most cost-effective option for electricity provision, especially during daylight hours, the ability to supply all or a high fraction of demand (including nighttime and during cloudy weather) necessitates the use of energy storage via batteries, which are relatively expensive (see section “Applications, economics, and analysis” below). Meeting other energy needs (hot water, air conditioning, etc.) remains uneconomical using PV technology. Reference Orosz, Quoilin and Hemond29

Historical role of solar thermal technologies in rural service delivery

Small-to-medium scale solar thermal technology overview

Solar thermal systems encompass a wide range of technologies that all broadly rely on mechanical systems to collect sunlight as heat, typically via a system of concentrating optics and/or mirrors [then referred to as CST, or concentrating solar thermal (CST), systems]. Either by reflection or refraction, incident direct normal irradiance (DNI) is concentrated onto a receiver area (either a focal point or focal line) thereby inducing a temperature rise of the receiver surface [also known as the heat collection element (HCE)], which heats up a process, frequently via a heat transfer fluid (HTF) flowing through it. Reference Goswami30 Thermal energy collected in the HTF is used for heating applications (industrial processes, space heating, etc.), cooling applications (absorption chillers, ice making), or for extracting mechanical work using a heat engine [steam Rankine cycle, organic Rankine cycle (ORC), or Stirling], the latter usage being typically referred to as CSP. Importantly, between collection and conversion, thermal energy can be stored in a technically straightforward, scaleable, and inexpensive way in comparison to chemical storage of electricity in batteries. The use of TES rather than batteries in islanded systems has potential cost and maintenance advantages for load following applications under conditions of variable insolation. While several CSP and TES technologies are available at the utility (multi-MW) scale, Reference Lovegrove and Stein31–Reference Stekli, Irwin and Pitchumani34 Table 1 contains an overview of the types of solar thermal technologies typically used in or considered for rural energy delivery applications (electricity production and noncooking thermal applications). For this study, we restrict our analysis to systems sized up to 1 MWe (electricity applications) or 1 MWth (thermal applications), a size range we designate as ‘micro-CSP’ (a term first coined by commercial player Sopogy, which exited the ‘micro-CSP’ market in 2013 after a decade of operation and over 30 installations Reference Deign35 ). It should be noted that this cutoff is arbitrary but corresponds roughly to the smallest size potentially considered as viable for utility-scale generation (e.g., the 1 MWe Saguaro Power Plant in Arizona, USA 36 ) as well as the size above which technologies utilized tend to be more proven (higher technology readiness level), e.g., turbines developed for use in coal power plants, and operational revenues are high enough to justify numerous on-site staff (a resource that would be too costly for most smaller rural applications that may demand a higher level of automation).

Table 1. Small-to-medium scale concentrating solar technologies.

Multifaceted applications of concentrating solar systems

The range of solar concentrators in Table 1 provides opportunities to meet community needs for hot water or steam generation for process heat, 37–93 thermal energy for air-conditioning using absorption technologies, 94–116 and generation of electricity using a heat engine. 36,Reference Ragheb117–174 Figure 1 shows typical block diagrams of these processes. It is significant to note that a subset of these processes requires cooling (either air cooling or water cooling) and may therefore present additional demands on the environment in which they are installed; while water demands are not discussed in detail in this manuscript (due to a lack of published information on this topic), one must recognize the importance of considering this variable for installations in drought-prone or water-limited areas.

Figure 1. Configurations of typical heat-driven applications of solar thermal technologies.

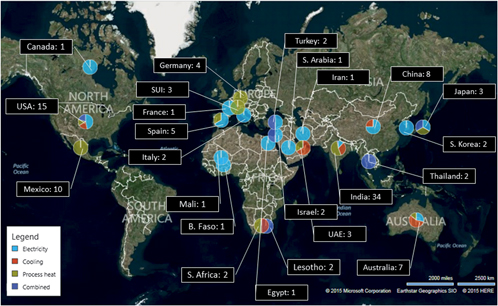

An inventory of historical, commercial, precommercial pilot, and research solar thermal installations described in the literature is provided as Appendix A (Tables A-1–A-4). This list includes solar thermal projects identified under 1 MW capacity (excepting those installed as the first phase of a multi-MW project); we have included projects with grid-ties or first-world applications in addition to those explicitly deployed for distributed applications, as such installations may be considered relevant demonstrations for decentralized energy distribution. Absolute project numbers are shown in Table 2 and Fig. 2, while an overview of applications by geography is provided as Fig. 3.

Table 2. Number of solar thermal projects identified, by application type.

Figure 2. Micro-CSP projects by type and capacity (kW).

Figure 3. Small-to-medium scale solar thermal projects by location and application type.

Several patterns emerge when considering these projects as a portfolio. Although the first solar thermal power plant was successfully demonstrated in Egypt in 1913 (Ref. 175), one must note that commercialization in this market is relatively young, with Scheffler dishes and parabolic trough collectors (PTCs) emerging in the mid-1980s and most other micro-CSP systems being developed in the past 10–15 years; hence, the majority of projects implemented in this field have been commissioned since the year 2000. At the same time, fluctuations in global energy markets (especially in the price of fossil fuels) have created a destabilized demand for solar energy that has resulted in the bankruptcy of many enterprises and rapid turnover in commercial availability of different technologies.

Despite these fluctuations, solar thermal installations used for heat in commercial processes have proven to be economically feasible across a wide range of applications (laundries, dairies, boiler pre-heating, etc.) and scales (10s to 100s of kWth) in competitive first-world and even urban markets as evidenced by their rapid expansion and commercial success. These combined characteristics suggest that CST technologies may be well-suited to drive economic growth as well in communities without access to traditional high-volume energy sources (electricity grid, affordable/subsidized fossil fuel delivery), under appropriate solar resource and application demand conditions. Similarly, solar-driven cooling applications have to date been used primarily by commercial entities as a cost-saving measure to offset heating, ventilation, and air conditioning (HVAC) costs, with the notable exception of the 351 kWth system installed at the institutional not-for-profit Muni Seva Ashram College of Nursing hospital in Gujarat, India for similar purposes. In developing markets, the high costs associated with building cooling (regardless of technology type) and the challenges associated with implementing building codes (e.g., ASHRAE 90.1) to ensure human health and safety with respect to indoor temperatures has impeded the scope of CST cooling markets. As the critical importance of human comfort levels in health care and educational outcomes becomes more widely recognized, systems such as the one supporting the Muni Seva hospital will provide a comparable example for a cost-effective cooling method that may be deployed to support institutional improvements in regions with good solar resources.

When considering a rural community as a unit, however, it is clear that, while important, neither process heating nor cooling interventions are adequate for achieving energy-access parity with systems similar to those in place in Europe and North America. Especially in sparsely populated regions currently considered as the most promising candidates for decentralized energy services, electricity delivery—to homes, institutions, and businesses—will also be critical to reaching energy access goals: for home and exterior security lighting, ventilation, refrigeration, cell-phone charging, irrigation, and powering tools/machines utilized in small businesses. Unlike micro-CST systems for processing heat and cooling applications, micro-CSP systems have not yet been proven economically competitive in existing markets where electricity prices are benchmarked by coal and natural gas generation. For communities sited outside project grid extension territories, however, this metric is unlikely to carry over, and it is thus important to evaluate the potential for use of micro-CSP within the context of this differentiated energy market.

Micro-CSP for distributed electricity generation

In this review, available published resources were surveyed to gather information on commissioned micro-CSP projects (systems up to 1 MW output capacity as noted above). A total of 124 projects in 25 countries were identified (Fig. 3), and while this inventory may not be comprehensive, it represents the most centralized database available to date. Micro-CSP projects specifically targeting electricity generation (exclusively or as part of a cogeneration or tri-generation scheme also providing heating and/or cooling products) are disadvantaged in comparison to micro-CST applications, in that poor prospects for economic returns in grid-tied markets have restricted development to niche applications and R&D efforts. Indeed, over 50% of the systems identified in Appendix A (Tables A-3 and A-4) are explicitly listed as demonstration or R&D facilities, while fewer than 10% are considered commercial endeavors (some systems of this nature are explicitly supported by government subsidy for noncommercial uses, and for others information is simply not available). As stated above, however, micro-CSP systems may prove a more competitive option within decentralized energy applications where electricity prices are dictated more commonly by the fuel costs of distributed generators rather than by utility-scale coal plants (the economics are discussed in more detail in the subsequent section). It is thus relevant to understand what progress has already been made in the development of micro-CSP and specifically what results have been achieved in piloting (or deploying) micro-CSP for electricity generation in these target markets. Data for power generation applications were collated from Appendix A by electrical nameplate capacity (presented in Fig. 2). It is particularly noteworthy that systems have been tested and/or deployed at all orders of magnitude to theoretically match the demand profiles of a wide range of rural communities, despite the fact that generally efficiencies and specific (per-unit) costs (levelized electricity cost) are known to improve as plant capacity scales.

Another important consideration in micro-CSP is the power cycle used to convert heat to electricity, e.g., a steam Rankine, organic Rankine, Stirling, or Brayton cycle, as these technologies themselves may be more or less available, efficient, or affordable at different scales. It is clear from Tables A-3 and A-4 that no market-driven consensus has yet been reached on the optimal technologies to use for either solar collectors or for heat-to-electrical conversion; Figs. 4 and 5 highlight the cases where some pattern emerges from analysis of all projects together. To date, parabolic dishes and Stirling engines (typically coupled to take advantage of the high concentration ratios directly at the engine receiver) have tended to be favored in the <10 kWe range, however, a number of different solar collector types (primarily the PTC) have also been coupled with ORC engines at this small scale and no definitive economic winner has yet emerged. In the 10–99 kWe range, parabolic troughs and dishes are dominant, coupled with many different cycle configurations customized for the application (with ORC representing about 50% of projects). Above 1 MWe, the ORC and traditional steam Rankine cycle become the frequent choices of heat engine (likely for cost reasons, as these components are used in other power plants at this scale and are thus available commercially), and PTCs become the more frequent collector choice likely due to and the commercial availability at this scale and relative ease of scalability. In the range of 100 s of kWe, however, one finds a variety of system configurations, coupling different cycles and solar collector types. At this scale the temperatures that can be achieved in the solar fields are higher, while total area required is small enough to retain feasibility of solar field assembly out of many types and sizes of solar modules; as such, the economic viability of particular projects may be much more dependent on the local supply chain, experience in labor markets, or other locally driven variables than in the technologies selected for the plant.

Figure 4. Cycle technologies selected for heat-to-electrical conversion in micro-CSP projects: counts provided for the number of each engine type for four size categories (under 10, 10–99.9, 100–999 kWe, and 1 MWe). Except for the last category which contains systems at only one size (1 MW), other categories aggregate systems over the indicated size range. (Absent bar indicates zero systems with that combination of characteristics.)

Figure 5. Solar collector technologies selected for heat-to-electrical conversion in micro-CSP projects. FPC = flat plate collector; CPC = compound parabolic concentrator; PD = paraboloid dish; PT = power tower; PTC = parabolic trough collector; LF = linear Fresnel.

Key demonstrations for decentralized applications

In looking to assess the feasibility and potential of micro-CST/CSP for distributed applications, it is informative to look both at projects already conducted in the target locations (rural communities with limited energy access via centralized pathways) and those installed as R&D facilities but with the explicit intention of evaluating the technology for use in decentralized communities (as opposed to R&D intended eventually to enable utility-scale installations). While heating and cooling applications are also potentially important energy needs in decentralized communities, it is clear from the assembled plant inventory that such projects tend to be driven by industrial, rather than community demands; in contrast, power-producing and cogeneration projects tend to support both community needs and those of closely sited industrial activities. As such this section will focus primarily on electricity and cogeneration, briefly highlighting a few projects (data from Appendix A) that exemplify the potential of micro-CSP for these decentralized applications.

Two examples constructed in developed nations bracket the range of project sizes that would be expected to serve remote, off-grid communities. At the small end of the range is the 6 kWe Solar PTC-ORC system constructed at Commonwealth Scientific and Industrial Research Organisation (CSIRO) (the Australian national science and research agency) in 2006 (Ref. Reference Kohlenbach, Mcevoy, Stein, Burton, Wong, Lovegrove, Burgess, Joe and Coventry131); in publications describing the system and results, researchers indicate that “eventual applications are envisaged for both distributed generation (i.e., sited in appropriate locations in suburban communities) and remote power and energy”. This end-goal guided system design and consideration of the economics governing system competitiveness as it was explicitly acknowledged that the technology would be competing with, e.g., diesel-driven generation rather than the national grid. (Notably, the 3 kWe system constructed in Rome in 1961 had similar motivations and goals.) At the upper end of the micro-CSP range is the 1 MWe Saguaro Power Plant in Arizona, USA. 36 This PTC-ORC system was envisioned, at least in part, to explore economic viability at a scale that could serve decentralized communities (expected to require far less power than generated by traditional plants), and while tax credits and renewables regulations in part drove construction of this grid-tied system, the break-even tariffs achieved would easily compete with diesel generation in an off-grid scenario.

Significantly, a number of small solar plants have already been constructed and commissioned for use in decentralized applications (though many as demonstration or R&D projects). The earliest of these is the 1913 75 kWe PTC-Rankine plant in Egypt Reference Ragheb117–119 which used solar power to displace the need for an alternate fuel source to power water pumps; the 1966 1 kWe flat plate collector (FPC)-ORC plant in Mali Reference Grossman120,Reference Bronicki121 had a similar use. In the past decade, interest has grown in solar-driven electricity generation for more general purposes, with systems from 1 to 10 kWe being demonstrated on the African continent (in Lesotho by the authors Reference Orosz, Mueller, Sylvain and Hemond176 and Burkina Faso Reference N’Tsoukpoe and Seshie165,Reference Edem166 ) using small ORC engines and a range of solar collector types. A larger (100 kWe) Power Tower-Brayton system was installed in 2009 to serve a community of approximately 230 people living in the desert in Israel; while this system is grid-tied, it does not require the connection. One step more isolated from the grid is the 256 kWe hybrid PTC-ORC/biomass plant that provides electricity to Shive, a rural village of approximately 1400 people, near Pune, India. 146–148 This system also has a grid-tie, and it is used exclusively to serve the community during periods when power is not available from the grid (grid availability a few times per week is scheduled by the utility). In areas where fresh water delivery is unreliable, solar desalination has similarly been considered to replace centralized government/utility services: the desalination plant (using linear Fresnel concentrators) at Narippaiyur, India provides 6000 L/h of potable water exclusively for an otherwise underserved rural community. 76–79 Finally, two projects in Thailand highlight the medium-scale potential for cogeneration and tri-generation. The PTC-Rankine system at Phitsanulok (installed 2012) 177,Reference Kruger, Kruger, Sukchai, Breitzke, Rahbani, Schenk, Hempel, Caf, Karthikeyan and Hennecke178 provides 22 kWe, 500 kWth, and cooling via a single-stage chiller, and was designed “to demonstrate an innovative technology for the decentralized provision of electrical energy, heat, and air conditioning from solar energy and biomass and to introduce it to potential cooperation partners in the region of Southeast Asia.” The PTC-Rankine system installed at Chonburi in 2006 (Refs. 179 and Reference Krueger, Rakwichian, Sukchai and Pongtornkulpanich180) further integrates biomass hybridization to enable night-time generation, providing approximately 10 kWe and 100 kWth. Like the projects in Lesotho, Burkina Faso, and Shive, the Chonburi project design further included the goal “to demonstrate the possibility of simple operation that can be carried out by local community staff.”

Taken together, these initiatives demonstrate an awareness of a service gap and provide initial examples of ways in which micro-CST/CSP has a potentially important role to play for decentralized communities. In many cases (e.g., hybridization with biomass to enable energy supply at night or in rainy seasons, or co-generation applications) providing a similar service using PV panels is either infeasible or would have be prohibitively expensive. It is thus critical when assessing projects for these applications to consider the true alternative options to determine economic competitiveness and to examine the existing (often lacking) solutions for an appropriate benchmark in ability and willingness of the customer to pay.

Applications, economics, and analysis

Suitable applications for micro-CSP systems include situations where either heat alone or combined heat and power are needed, where there is a potential supplementary thermal resource available (biomass combustion, industrial waste heat, or even internal combustion generator exhaust waste heat to recover), or where the interaction between solar availability and load dynamics favors low cost TES over extensive use of batteries in ‘islanded’ systems. The factors that influence the decision to deploy any particular type of energy solution include the total cost (capital, operation and maintenance) and performance, both of which are mediated by local conditions (markets, meteorology, etc.). Szabo et al. Reference Szabó, Bódis, Huld and Moner-Girona23 used a mapping methodology to overlay the differential costs of competing electrification schemes (distributed solar, diesel, and grid extension) in rural Africa using geographically determined diesel prices and solar insolation. A similar exercise is yet to be performed for micro-CSP, although Orosz et al. Reference Orosz, Quoilin and Hemond29 presented a comparison of PV, micro-CSP, and diesel hybrid systems for cogeneration deployment at health centers in Africa as a function of latitude.

While commercial capital costs of micro-CSP systems are generally unavailable due to a lack of standardization and long-term benchmarking in the market, estimates based on plausible component costs range upwards from 4.7 USD/W for a micro-CSP system without TES to 8.4 USD/W for a system with 6 h of storage and a solar multiple of 1.3 and 2, respectively—however, specific cost of power can be misleading in terms of the realized specific cost of energy, which for the above cases (assuming cumulative energy generated over 15 years operation) would be 0.11 USD/kW h without storage and 0.07 USD/kW h with TES (the difference being due to the higher capacity factor and amortization of the power block over total energy output). The following supporting assumptions were used to arrive at these estimates: 220 USD/m2 for solar collectors Reference Price, Lüpfert, Kearney, Zarza, Cohen, Gee and Mahoney181 (and vendor quotations), 800 W/m2 DNI for peak solar resource, 70% HCE thermal efficiency, Reference Burkholder and Kutscher182 and 21% power block efficiency (Chambadal–Novikov efficiency assuming a 10 °C temperature pinch and source and sink temperatures of 250 and 35 °C, respectively Reference Chen, Yan, Lin and Andresen183 ) with a specific cost of 1.5 USD/W for the power block, 22.5 USD/kWth for the TES 1.5× the US DOE Sunshot goal of 15 USD/kW hth (Ref. 184) and within the range of costs identified by IRENA 185 and 20% indirect costs. Reference Turchi186 In comparison, PV specific costs for similar systems would be 1.7 USD/W and 3.8 USD/W for a system with 6 hours storage (useful in the case of PV sunlight-to-electricity systems due to the substantial fraction of most developing country loads that occur in the early evening when the sun is no longer shining) with a 1.3 and 2 solar multiple, respectively, and levelized energy costs over 15 years of 0.04 and 0.07 USD/kW h (assuming the battery bank is replaced once). These estimates use the following cost basis from commercially active vendor quotations: a cost including freight and customs to Africa from Chinese PV manufacturers of 0.9 USD/W (320 W mono panels Shanghai, CN to Durban, ZA), 110 USD/kW h for sealed lead acid batteries (L-16 type), 0.2 USD/W for a charge controller, and 0.15 USD/W for an inverter (plus 20% indirect costs).

This comparison is simplified and does not capture any divergence between direct and global irradiance in a location, or the fact that as a tracking system the CSP will tend to have a greater energy output than PV for an equivalent peak watt rating (unless the PV is also mounted on a tracker, which is not considered here). Moving from capital to levelized costs requires taking into account any differential in operations and maintenance between micro-CSP and PV, e.g., the lead acid batteries will need replacement within 5–10 years whereas the TES does not, impacting the project finance scenarios. A full system level performance and cash flow analysis is required for every application to validate the financial figure of merit [levelized cost of electricity (LCOE), net present value (NPV), internal rate of return, total cost of ownership, etc.]. (This requirement for costly and repeated application engineering and the fact that there is no “one size fits all” solution for diverse energy access needs is a contributing factor to the persistence of energy access deficits.)

Analysis of the capital and LCOE from a PTC-driven solar ORC (configured for electricity generation alone, i.e., no cogeneration considered) in various regions of Africa was presented by Mitterhofer, Reference Mitterhofer and Orosz187 and the use of micro-CSP in hybrid microgrid applications was investigated by Orosz et al. Reference Orosz and Mueller188 for a typical ∼100 household village using Lesotho as a case study with a load profile created from a probabilistic distribution function derived from load measurements in a comparable community in South Africa. In the former case study, which was validated to data from a PTC-ORC plant at Eckerd College in St. Petersburg Florida, LCOE in USD/kW h was predicted to be 0.58 in Johannesburg, ZA, 0.72 in Harare, ZW, 0.67 in Addis Ababa, ET, and 1.05 in Nairobi, KE (accounting for variation in ambient temperature and insolation with fixed demand). In the latter study, hybridizing micro-CSP with PVs, batteries, and back up liquid petroleum gas (LPG) generation yielded an optimized tariff of 0.35 USD/kW h for the plant. Even under optimistic scenarios, the levelized cost of energy from micro-CSP systems is likely to be 2–3 times higher than the typical on-grid tariff. In 2010, the average effective electricity tariff in Africa was US $0.14 per kilowatt-hour (kW h) (against an average of US $0.18 per kW h in production costs; the discrepancy reflects government subsidy of on grid consumption). 189 Managing expectations of off-grid consumers and government regulators as to an appropriate cost-recovery scheme or off-grid tariff subsidy will be critical to enabling market entry for micro-CSP platforms in distributed applications. In India, a federal financial subsidy of about 90% of the capital cost for renewable and hybrid technology based electrification for remote villages is theoretically available to state governments under the Remote Village Electrification program of RGGVY scheme. Reference Aggarwal, Fahey, Freymiller, Li, Huang, Moilanen, Onda, Ratledge, Speirs and Wong190

None of the micro-CSP plants identified in the inventory were specifically targeted for individual household use, although single institutional systems (health clinics, schools) are represented. The most likely deployment scenarios for micro-CSP include industrial process heat, institutional and community-scale cogeneration applications requiring several to hundreds of kilowatts. In microgrid applications, the hub and spoke topology of electricity distribution networks tends to dictate a break-even household density (number of consumers per km of wire), where centralized systems would be more appropriate than e.g., individual solar PV home systems (SHS). For the foreseeable future, PV home systems will be less expensive to deploy than comparable output micro-CSP systems. On the other hand, micro-CSP at larger scales in the applications identified above can leverage lower cost of energy storage via TES and the ability to integrate flexibly with both demand and supply thermal processes/resources (e.g., heating loads, or the availability of biomass). Nearly 73% of sub-Saharan African countries have national average population densities lower than 100 persons/km2 (as well as low per capita energy consumption), 191,192 whereas in India the population density in 2013 was 421 persons/km2 (Ref. 191). While this would seem to indicate that India is a more likely candidate for microgrids, in practice, several determining factors will mediate the applicability of such systems over alternatives such as grid connection or SHS. The proximity of underserved communities to the grid is relatively closer in India than in Africa, where approximately 75% of people lack energy access. The layout of communities in dispersed agricultural homesteads versus tightly packed village residential centers is also site and region specific. For this reason, satellite or aerial image based mapping and demographic survey integrated planning processes are needed to (i) geo-locate individual household connections, (ii) determine the likely loads using representative baseline data, and (iii) choose the optimal technology solution (grid extension, microgrids, or SHS) able to serve diverse communities given local conditions (DNI versus global irradiance, cost per km to extend the grid, etc.). For those communities down-selected as microgrid candidates, optimized micro-CSP systems can play an important role in enabling combined heat and power for any institutional or local business process heat needs, while mitigating some of the cost of expensive and limited cycle lifetime battery systems to dispatch energy during nighttime.

Conclusions

The historical and potential roles for small-to-medium scale solar thermal technologies were reviewed in the context of increasing energy access in off-grid communities. Solar thermal or CSP systems may be appropriate for integration with community-scale systems under certain conditions, such as a demand for process heat, combined heat and power, or load following requirements under variable solar insolation. Experience with deployment of micro-CSP systems was investigated and an inventory of 124 installations across 25 countries was identified with a nearly even mixture of commercial and research pilot projects. The commercial sector for micro-CSP remains immature, characterized by a high level of market player turnover, and lack of standardized systems with long-term operation needed for benchmarking performance and cost.

While in many cases solar PV may be the most cost-effective option for electricity provision, especially during daylight hours, meeting thermal energy needs and coupling with battery storage to maintain output at night and during cloudy weather it remains uneconomical using traditional solar panels. In comparison, micro-CSP systems, while not economically competitive with utility-scale coal and natural gas generation, may be viable in microgrid applications in comparison to equivalent alternatives such as diesel generators or PV coupled with a large battery bank, particularly when the micro-CSP can integrate TES. The economic optimization of particular projects will be driven by features of the specific demand curve of the target application, local supply chain, labor markets, and other locally driven variables such as meteorology. System level analysis and application engineering for each unique situation is therefore necessary to validate the financial figure of merit (LCOE, NPV, internal rate of return, total cost of ownership, etc.) for any distributed generation project. This requirement and the fact that there is no “one size fits all” solution for diverse energy access needs is a contributing factor to the persistence of energy access deficits.

Despite this challenge, optimized community-scale micro-CSP systems with TES can play an important role in enabling combined heat and power for institutional or local business process heat needs, while mitigating some of the cost and maintenance burden associated with battery systems. Further research, development, and commercialization of micro-CSP technology with specific application to decentralized power applications is justified in light of the commercial and R&D progress to date and its unique potential for flexible electricity and heat delivery and low cost storage.

Appendix A: Inventory of historical and existing CSP/CST systems

Table A-1. Identified micro-CST systems (thermal products) globally, sorted by deployment year.

Table A-2. Identified micro-CST systems (cooling applications) globally, sorted by deployment year a .

Table A-3. Identified micro-CSP systems (electricity production) globally, sorted by deployment year.

Table A-4. Identified micro-CSP/micro-CST systems (combined applications) globally, sorted by deployment year. a