1. Introduction

Carbon capture and storage is an important mitigation method to offset ![]() ${\rm CO}_2$ emissions, including those from hard-to-abate industries such as steel and cement (Bickle Reference Bickle2009; Bui et al. Reference Bui2018; Krevor et al. Reference Krevor, de Coninck, Gasda, Ghaleigh, de Gooyert, Hajibeygi, Juanes, Neufeld, Roberts and Swennenhuis2023). Depleted oil and gas reservoirs within sedimentary basins represent a global potential storage resource of up to 1000 Gt

${\rm CO}_2$ emissions, including those from hard-to-abate industries such as steel and cement (Bickle Reference Bickle2009; Bui et al. Reference Bui2018; Krevor et al. Reference Krevor, de Coninck, Gasda, Ghaleigh, de Gooyert, Hajibeygi, Juanes, Neufeld, Roberts and Swennenhuis2023). Depleted oil and gas reservoirs within sedimentary basins represent a global potential storage resource of up to 1000 Gt ![]() ${\rm CO}_2$ (Benson et al. Reference Benson2012). Depleted reservoirs benefit from being proven secure storage sites for buoyant fluids, being well-characterised from previous oil and gas activities and having large pressure margins for safe storage (Barrufet, Bacquet & Falcone Reference Barrufet, Bacquet and Falcone2010; Loizzo et al. Reference Loizzo, Lecampion, Bérard, Harichandran and Jammes2010). Together, these factors reduce storage risks. For many mature petroleum regions, such as the North Sea, depleted reservoirs lie close to major sources of emissions (Ramírez et al. Reference Ramírez, Hagedoorn, Kramers, Wildenborg and Hendriks2010; Bentham et al. Reference Bentham, Mallows, Lowndes and Green2014). The possibility to reuse existing well infrastructure and to take advantage of smaller injection-pressure requirements also promise to reduce the costs of

${\rm CO}_2$ (Benson et al. Reference Benson2012). Depleted reservoirs benefit from being proven secure storage sites for buoyant fluids, being well-characterised from previous oil and gas activities and having large pressure margins for safe storage (Barrufet, Bacquet & Falcone Reference Barrufet, Bacquet and Falcone2010; Loizzo et al. Reference Loizzo, Lecampion, Bérard, Harichandran and Jammes2010). Together, these factors reduce storage risks. For many mature petroleum regions, such as the North Sea, depleted reservoirs lie close to major sources of emissions (Ramírez et al. Reference Ramírez, Hagedoorn, Kramers, Wildenborg and Hendriks2010; Bentham et al. Reference Bentham, Mallows, Lowndes and Green2014). The possibility to reuse existing well infrastructure and to take advantage of smaller injection-pressure requirements also promise to reduce the costs of ![]() ${\rm CO}_2$ storage. Despite these benefits, injection into highly depleted reservoirs is yet to be demonstrated at a large scale, with all commercial-scale carbon storage projects currently utilising deep saline aquifers.

${\rm CO}_2$ storage. Despite these benefits, injection into highly depleted reservoirs is yet to be demonstrated at a large scale, with all commercial-scale carbon storage projects currently utilising deep saline aquifers.

Depleted reservoirs with limited connectivity with surrounding aquifers are characterised by below-hydrostatic pressure as a result of past fossil fuel production. Typical oil and gas reservoirs within sedimentary basins occur at depth ranges of 700–4500 m (Gluyas & Hichens Reference Gluyas and Hichens2003; Hannis et al. Reference Hannis, Lu, Chadwick, Hovorka, Kirk, Romanak and Pearce2017), but can have abandonment pressures as low as 0.35–0.8 MPa (MacRoberts Reference MacRoberts1962). Unlike deep saline aquifers, which occur at similar depth ranges, depleted oil and gas reservoirs fall within the gas stability field of ![]() ${\rm CO}_2$, as shown in figure 1.

${\rm CO}_2$, as shown in figure 1.

Figure 1. Pressure–temperature, ![]() $p-T$, phase diagram for

$p-T$, phase diagram for ![]() ${\rm CO}_2$ showing typical reservoir and well-head conditions. Note that depleted reservoirs fall within the gas stability field of

${\rm CO}_2$ showing typical reservoir and well-head conditions. Note that depleted reservoirs fall within the gas stability field of ![]() ${\rm CO}_2$. The density contours are constructed using data from the NIST web-book (Linstrom & Mallard Reference Linstrom and Mallard2001, webbook.nist.gov).

${\rm CO}_2$. The density contours are constructed using data from the NIST web-book (Linstrom & Mallard Reference Linstrom and Mallard2001, webbook.nist.gov).

While pressure depletion increases the pressure margin for safe storage (Barrufet et al. Reference Barrufet, Bacquet and Falcone2010), injection of compressed high-pressure ![]() ${\rm CO}_2$ can cause severe cooling of the near-wellbore region, which leads to a number of technical challenges. This phenomenon is referred to as the Joule–Thomson effect, and describes the adiabatic cooling (or heating depending on the sign of the Joule–Thomson coefficient) due to expansion and depressurisation of a fluid as it flows through a pressure gradient. Although this effect is localised, there is concern that the cooling and associated thermal stresses during initial injection could cause thermal fracturing (Vilarrasa, Rinaldi & Rutqvist Reference Vilarrasa, Rinaldi and Rutqvist2017) and/or freezing of pore waters (Fan, Xu & Wu Reference Fan, Xu and Wu2020) and the formation of gas hydrates (Sun & Duan Reference Sun and Duan2005; Oldenburg Reference Oldenburg2007; Hoteit, Fahs & Soltanian Reference Hoteit, Fahs and Soltanian2019). Together these processes threaten to reduce injectivity in the near-wellbore region (Almenningen et al. Reference Almenningen, Gauteplass, Hauge, Barth, Fernø and Ersland2019) and may jeopardise near-wellbore stability and well integrity (Paluszny et al. Reference Paluszny, Graham, Daniels, Tsaparli, Xenias, Salimzadeh, Whitmarsh, Harrington and Zimmerman2020). Current methods to mitigate Joule–Thomson cooling involve heating of

${\rm CO}_2$ can cause severe cooling of the near-wellbore region, which leads to a number of technical challenges. This phenomenon is referred to as the Joule–Thomson effect, and describes the adiabatic cooling (or heating depending on the sign of the Joule–Thomson coefficient) due to expansion and depressurisation of a fluid as it flows through a pressure gradient. Although this effect is localised, there is concern that the cooling and associated thermal stresses during initial injection could cause thermal fracturing (Vilarrasa, Rinaldi & Rutqvist Reference Vilarrasa, Rinaldi and Rutqvist2017) and/or freezing of pore waters (Fan, Xu & Wu Reference Fan, Xu and Wu2020) and the formation of gas hydrates (Sun & Duan Reference Sun and Duan2005; Oldenburg Reference Oldenburg2007; Hoteit, Fahs & Soltanian Reference Hoteit, Fahs and Soltanian2019). Together these processes threaten to reduce injectivity in the near-wellbore region (Almenningen et al. Reference Almenningen, Gauteplass, Hauge, Barth, Fernø and Ersland2019) and may jeopardise near-wellbore stability and well integrity (Paluszny et al. Reference Paluszny, Graham, Daniels, Tsaparli, Xenias, Salimzadeh, Whitmarsh, Harrington and Zimmerman2020). Current methods to mitigate Joule–Thomson cooling involve heating of ![]() ${\rm CO}_2$ and subsequent injection in the gas phase using multiple injectors. This method will be applied for the Porthos project in the North Sea (Neele et al. Reference Neele2019, www.porthosco2.nl), but is both expensive and emissions intensive. Injection of cold, dense liquid

${\rm CO}_2$ and subsequent injection in the gas phase using multiple injectors. This method will be applied for the Porthos project in the North Sea (Neele et al. Reference Neele2019, www.porthosco2.nl), but is both expensive and emissions intensive. Injection of cold, dense liquid ![]() ${\rm CO}_2$ would considerably improve the operational viability of future projects. Understanding the risks of Joule–Thomson cooling, and developing new mitigation approaches, is therefore crucial for facilitating cold

${\rm CO}_2$ would considerably improve the operational viability of future projects. Understanding the risks of Joule–Thomson cooling, and developing new mitigation approaches, is therefore crucial for facilitating cold ![]() ${\rm CO}_2$ injection into depleted reservoirs and to enable safe, large-scale storage in depleted reservoirs.

${\rm CO}_2$ injection into depleted reservoirs and to enable safe, large-scale storage in depleted reservoirs.

There is particular concern about cooling during the start of injection, when the reservoir pressure is at its lowest point. On injection, the pressure will behave transiently, with a pressure wave propagating from the wellbore into the reservoir (Dake Reference Dake1983; Bear Reference Bear2012). The pressure differential between the wellbore and far-field reservoir will increase until the pressure wave reaches the outer boundary of the reservoir, at which point the pressure will build up at a relatively constant rate throughout the reservoir such that the pressure field can be characterised by a pseudo-steady-state solution (Dake Reference Dake1983; Bear Reference Bear2012). In deep saline aquifers, the compressibility of the pore fluids is low. This results in a pressure wave that migrates quickly into the reservoir, such that the steady-state regime is established rapidly – within a month for a reservoir of radius 2 km – relative to the time scale of injection (Zhou et al. Reference Zhou, Birkholzer, Tsang and Rutqvist2008; Mathias et al. Reference Mathias, González Martínez de Miguel, Thatcher and Zimmerman2011b). In depleted aquifers, the low-pressure reservoir gas is significantly more compressible. We therefore expect the pressure wave to propagate more slowly into the reservoir, leading to a prolonged transient phase – between 5 and 10 times longer than for an equivalent-sized reservoir – during which the differential pressure between the wellbore and far-field reservoir increases. As the maximum degree of cooling scales with this pressure differential, reservoir temperatures continue to decrease until the pressure wave reaches the outer boundary. To constrain the maximum degree of cooling, it is therefore important to understand the early transient behaviour of the system.

Joule–Thomson cooling has been modelled in a number of numerical studies (Oldenburg Reference Oldenburg2007; André, Azaroual & Menjoz Reference André, Azaroual and Menjoz2010; Singh, Goerke & Kolditz Reference Singh, Goerke and Kolditz2011; Han et al. Reference Han, Kim, Park, McPherson, Lee and Park2012; Singh et al. Reference Singh, Baumann, Henninges, Görke and Kolditz2012; Mathias, McElwaine & Gluyas Reference Mathias, McElwaine and Gluyas2014; Ziabakhsh-Ganji & Kooi Reference Ziabakhsh-Ganji and Kooi2014; Creusen Reference Creusen2018). Oldenburg (Reference Oldenburg2007) showed that, for a large pressure differential of 5 MPa between injection well and reservoir, Joule–Thomson cooling could cause the temperature to drop by up to ![]() $20\,^{\circ }{\rm C}$, but he concluded that the cooling was unlikely to lead to freezing or formation of gas hydrates. However, with the exception of Creusen (Reference Creusen2018) and Mathias et al. (Reference Mathias, McElwaine and Gluyas2014), these studies have focused on low injection rates of

$20\,^{\circ }{\rm C}$, but he concluded that the cooling was unlikely to lead to freezing or formation of gas hydrates. However, with the exception of Creusen (Reference Creusen2018) and Mathias et al. (Reference Mathias, McElwaine and Gluyas2014), these studies have focused on low injection rates of ![]() $3\unicode{x2013}6\ {\rm kg}\ {\rm s}^{-1}$, and initial reservoir pressures >5 MPa. While these conditions are relevant to

$3\unicode{x2013}6\ {\rm kg}\ {\rm s}^{-1}$, and initial reservoir pressures >5 MPa. While these conditions are relevant to ![]() ${\rm CO}_2$ sequestration with enhanced gas recovery (Oldenburg, Stevens & Benson Reference Oldenburg, Stevens and Benson2004), they are not relevant to prospective sequestration in ultra-depleted reservoirs which have very low reservoir pressures of 0.5–4 MPa and, for economic feasibility, require high injection rates in the range

${\rm CO}_2$ sequestration with enhanced gas recovery (Oldenburg, Stevens & Benson Reference Oldenburg, Stevens and Benson2004), they are not relevant to prospective sequestration in ultra-depleted reservoirs which have very low reservoir pressures of 0.5–4 MPa and, for economic feasibility, require high injection rates in the range ![]() $1\unicode{x2013}4\ {\rm Mt}\ {\rm yr}^{-1}$ (equivalent to

$1\unicode{x2013}4\ {\rm Mt}\ {\rm yr}^{-1}$ (equivalent to ![]() $30\unicode{x2013}125\ {\rm kg}\ {\rm s}^{-1}$) (Neele et al. Reference Neele2019).

$30\unicode{x2013}125\ {\rm kg}\ {\rm s}^{-1}$) (Neele et al. Reference Neele2019).

Analytical or semi-analytical solutions to the flow, depressurisation and cooling of ![]() ${\rm CO}_2$ are useful tools for understanding the general scaling behaviour of the system and for screening out injection regimes that produce prohibitively large Joule–Thomson cooling. Mathias et al. (Reference Mathias, Gluyas, Oldenburg and Tsang2010) developed an analytical reference solution for Joule–Thomson cooling under the assumption of constant fluid properties and a steady-state pressure field. Their solutions give analytic expressions for the position of the thermal front and the degree of cooling, and qualitatively agree with numerical models. However, the assumption of steady-state pressure and fixed density are not consistent with the transient response of the system that is expected during injection start-up and shut-in, when the pressure field changes dynamically and the rate of pressure change varies with distance and time. Developing a simplified framework for understanding the initial transient response that occurs within the first month to year of injection will therefore prove useful.

${\rm CO}_2$ are useful tools for understanding the general scaling behaviour of the system and for screening out injection regimes that produce prohibitively large Joule–Thomson cooling. Mathias et al. (Reference Mathias, Gluyas, Oldenburg and Tsang2010) developed an analytical reference solution for Joule–Thomson cooling under the assumption of constant fluid properties and a steady-state pressure field. Their solutions give analytic expressions for the position of the thermal front and the degree of cooling, and qualitatively agree with numerical models. However, the assumption of steady-state pressure and fixed density are not consistent with the transient response of the system that is expected during injection start-up and shut-in, when the pressure field changes dynamically and the rate of pressure change varies with distance and time. Developing a simplified framework for understanding the initial transient response that occurs within the first month to year of injection will therefore prove useful.

In this paper we show that, under certain conditions, the transient Joule–Thomson effect in the near-wellbore region can be described by similarity solutions which give the pressure and temperature fields as a function of time and radial distance from the well. We begin in §§ 2 and 3 by outlining the conservation equations for mass and energy of non-isothermal single-phase flow during injection of ![]() ${\rm CO}_2$ into a methane (

${\rm CO}_2$ into a methane (![]() ${\rm CH}_4$)-filled reservoir. This leads to governing equations for the pressure and temperature field around the well in addition to equations for the positions of the

${\rm CH}_4$)-filled reservoir. This leads to governing equations for the pressure and temperature field around the well in addition to equations for the positions of the ![]() ${\rm CO}_2$ and thermal fronts. We solve these governing equations for the case of a radially spreading injection within a cylindrical reservoir in § 4. Following Mathias et al. (Reference Mathias, Gluyas, Oldenburg and Tsang2010), analytical reference solutions for steady-state flow are derived along with an analytical reference solution for a diffusive pressure field. We then show that the transient pressure and temperature fields away from the well can be described by similarity solutions, with the front positions described by self-similar scaling relations. In § 5 we present numerical solutions for the spreading

${\rm CO}_2$ and thermal fronts. We solve these governing equations for the case of a radially spreading injection within a cylindrical reservoir in § 4. Following Mathias et al. (Reference Mathias, Gluyas, Oldenburg and Tsang2010), analytical reference solutions for steady-state flow are derived along with an analytical reference solution for a diffusive pressure field. We then show that the transient pressure and temperature fields away from the well can be described by similarity solutions, with the front positions described by self-similar scaling relations. In § 5 we present numerical solutions for the spreading ![]() ${\rm CO}_2$ with comparison with the steady-state solutions in addition to an analysis of the parametric controls. Finally we discuss the results in § 6, and finish with some concluding remarks in § 7.

${\rm CO}_2$ with comparison with the steady-state solutions in addition to an analysis of the parametric controls. Finally we discuss the results in § 6, and finish with some concluding remarks in § 7.

2. Model description

We consider the injection of ![]() ${\rm CO}_2$ into a reservoir comprising a homogeneous, isotropic and incompressible rock matrix. The pore space is initially filled with

${\rm CO}_2$ into a reservoir comprising a homogeneous, isotropic and incompressible rock matrix. The pore space is initially filled with ![]() ${\rm CH}_4$ and an immobile residual water fraction. The

${\rm CH}_4$ and an immobile residual water fraction. The ![]() ${\rm CO}_2$ is then injected from the wellbore and flows into the reservoir, displacing the ambient

${\rm CO}_2$ is then injected from the wellbore and flows into the reservoir, displacing the ambient ![]() ${\rm CH}_4$. The

${\rm CH}_4$. The ![]() ${\rm CO}_2$ and

${\rm CO}_2$ and ![]() ${\rm CH}_4$ are miscible, however, for simplicity we neglect dispersive mixing within the gas phase (Hughes et al. Reference Hughes, Honari, Graham, Chauhan, Johns and May2012) and assume a sharp front between

${\rm CH}_4$ are miscible, however, for simplicity we neglect dispersive mixing within the gas phase (Hughes et al. Reference Hughes, Honari, Graham, Chauhan, Johns and May2012) and assume a sharp front between ![]() ${\rm CO}_2$-rich and

${\rm CO}_2$-rich and ![]() ${\rm CH}_4$-rich gas regions. Dissolution of

${\rm CH}_4$-rich gas regions. Dissolution of ![]() ${\rm CO}_2$ and

${\rm CO}_2$ and ![]() ${\rm CH}_4$ and water evaporation are also neglected. There is only single-phase gas flow with a constant relative permeability because the water is at irreducible saturation. This is a reasonable assumption because the gas–water contact in depleted gas reservoirs at abandonment is typically far from the well, such that the region around the well has high gas saturation. An example of this is the P18-2 reservoir, where

${\rm CH}_4$ and water evaporation are also neglected. There is only single-phase gas flow with a constant relative permeability because the water is at irreducible saturation. This is a reasonable assumption because the gas–water contact in depleted gas reservoirs at abandonment is typically far from the well, such that the region around the well has high gas saturation. An example of this is the P18-2 reservoir, where ![]() ${\rm CO}_2$ injection is planned as part of the Porthos project (Neele et al. Reference Neele2019). Neglecting variable saturation also greatly simplifies the model, permitting a focus on the interplay between pressure and temperature diffusion away from the wellbore.

${\rm CO}_2$ injection is planned as part of the Porthos project (Neele et al. Reference Neele2019). Neglecting variable saturation also greatly simplifies the model, permitting a focus on the interplay between pressure and temperature diffusion away from the wellbore.

Buoyancy and capillary forces are neglected in order to focus more narrowly on depressurisation around the wellbore, such that the flow is assumed to be driven by injection pressure only (Benham, Neufeld & Woods Reference Benham, Neufeld and Woods2022). This assumption is reasonable in a ![]() ${\rm CH}_4$-filled reservoir as viscous forces can be shown to dominate over buoyancy forces in the near-wellbore region at low pressure (Nordbotten & Celia Reference Nordbotten and Celia2006). Vapour-phase

${\rm CH}_4$-filled reservoir as viscous forces can be shown to dominate over buoyancy forces in the near-wellbore region at low pressure (Nordbotten & Celia Reference Nordbotten and Celia2006). Vapour-phase ![]() ${\rm CO}_2$ is slightly denser than

${\rm CO}_2$ is slightly denser than ![]() ${\rm CH}_4$ (Linstrom & Mallard Reference Linstrom and Mallard2001) leading to slight density under-ride. Modelling by Mathias et al. (Reference Mathias, McElwaine and Gluyas2014), which accounted for the difference in fluid properties and gravitational forces, demonstrated that the front is semi-vertical on the scale of the reservoir. Furthermore, despite work showing a small dependence of relative permeability on fluid composition (Ren et al. Reference Ren, Chen, Yan and Guo2000), here, we assume that the relative permeabilities of

${\rm CH}_4$ (Linstrom & Mallard Reference Linstrom and Mallard2001) leading to slight density under-ride. Modelling by Mathias et al. (Reference Mathias, McElwaine and Gluyas2014), which accounted for the difference in fluid properties and gravitational forces, demonstrated that the front is semi-vertical on the scale of the reservoir. Furthermore, despite work showing a small dependence of relative permeability on fluid composition (Ren et al. Reference Ren, Chen, Yan and Guo2000), here, we assume that the relative permeabilities of ![]() ${\rm CO}_2$ and

${\rm CO}_2$ and ![]() ${\rm CH}_4$ are equal. The density of

${\rm CH}_4$ are equal. The density of ![]() ${\rm CO}_2$ and

${\rm CO}_2$ and ![]() ${\rm CH}_4$ are dependent on pressure and temperature. We assume all fluid properties of

${\rm CH}_4$ are dependent on pressure and temperature. We assume all fluid properties of ![]() ${\rm CO}_2$ and

${\rm CO}_2$ and ![]() ${\rm CH}_4$ are equivalent and equal to those of

${\rm CH}_4$ are equivalent and equal to those of ![]() ${\rm CO}_2$. Note that this is equivalent to

${\rm CO}_2$. Note that this is equivalent to ![]() ${\rm CO}_2$ injection into a

${\rm CO}_2$ injection into a ![]() ${\rm CO}_2$-filled reservoir.

${\rm CO}_2$-filled reservoir.

The compressibility and expansivity of residual water and rock have been shown to have negligible effect on the pressure and temperature fields (Singh et al. Reference Singh, Goerke and Kolditz2011, Reference Singh, Baumann, Henninges, Görke and Kolditz2012). We therefore neglect these effects and assume the volume fractions of water and rock remain constant. Note that rocks in real sedimentary reservoirs are, to some extent, compressible. The following analysis could readily be extended to incorporate matrix compressibility, but it is neglected here for simplicity of presentation. The rock and all fluid components are assumed to be in local thermodynamic equilibrium. Here, we focus on the thermal effects caused by Joule–Thomson cooling. We therefore do not consider the thermal effects of water vaporisation or ![]() ${\rm CO}_2$ dissolution – this assumption does not significantly change the behaviour of the system. Models from Creusen (Reference Creusen2018) show that while water vaporisation produces around

${\rm CO}_2$ dissolution – this assumption does not significantly change the behaviour of the system. Models from Creusen (Reference Creusen2018) show that while water vaporisation produces around ![]() $2\,^{\circ }{\rm C}$ of additional cooling,

$2\,^{\circ }{\rm C}$ of additional cooling, ![]() ${\rm CO}_2$ dissolution has negligible thermal effect in the near-wellbore region. Neglecting partial miscibility of

${\rm CO}_2$ dissolution has negligible thermal effect in the near-wellbore region. Neglecting partial miscibility of ![]() ${\rm CO}_2$ and water means that we also do not model the formation of a dry-out zone or salt precipitation around the wellbore. While these are expected to slightly modify the pressure field, these effects are beyond the scope of this work. We refer to other studies that have focused on these effects (Zeidouni, Pooladi-Darvish & Keith Reference Zeidouni, Pooladi-Darvish and Keith2009; Mathias et al. Reference Mathias, Gluyas, González Martínez de Miguel and Hosseini2011a; Hosseini, Mathias & Javadpour Reference Hosseini, Mathias and Javadpour2012).

${\rm CO}_2$ and water means that we also do not model the formation of a dry-out zone or salt precipitation around the wellbore. While these are expected to slightly modify the pressure field, these effects are beyond the scope of this work. We refer to other studies that have focused on these effects (Zeidouni, Pooladi-Darvish & Keith Reference Zeidouni, Pooladi-Darvish and Keith2009; Mathias et al. Reference Mathias, Gluyas, González Martínez de Miguel and Hosseini2011a; Hosseini, Mathias & Javadpour Reference Hosseini, Mathias and Javadpour2012).

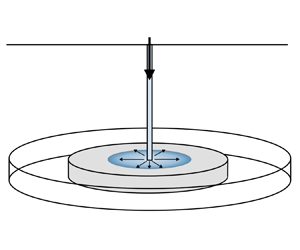

A schematic of the injection is shown in figure 2. While the near-well fluid flow is often approximately radial, injection into a channel may lead to linear flow. For simplicity, we will initially use rectilinear coordinates. The injection well is at ![]() $\boldsymbol {x}_W$, and the injected

$\boldsymbol {x}_W$, and the injected ![]() ${\rm CO}_2$ front occurs at

${\rm CO}_2$ front occurs at ![]() $\boldsymbol {x}_C(t)$. Injection of a cold fluid into a warm porous reservoir leads to the development of a thermal front at

$\boldsymbol {x}_C(t)$. Injection of a cold fluid into a warm porous reservoir leads to the development of a thermal front at ![]() $\boldsymbol {x}_T(t)$, across which the temperature of the fluid adjusts to that of the formation (Jupp & Woods Reference Jupp and Woods2003; Rayward-Smith & Woods Reference Rayward-Smith and Woods2011). Due to local thermal equilibrium between the fluid and the immobile solid matrix, the transient thermal front always travels slower than the injected

$\boldsymbol {x}_T(t)$, across which the temperature of the fluid adjusts to that of the formation (Jupp & Woods Reference Jupp and Woods2003; Rayward-Smith & Woods Reference Rayward-Smith and Woods2011). Due to local thermal equilibrium between the fluid and the immobile solid matrix, the transient thermal front always travels slower than the injected ![]() ${\rm CO}_2$ front. This thermal inertia is due to the significant heat capacity of the solid grains within the reservoir, which heat up the fluid as it advects through the pore space. Joule–Thomson cooling is superimposed on top of the advected temperature field, with heat conduction having the effect of smearing out the thermal front, as shown in figure 2. The minimum temperature

${\rm CO}_2$ front. This thermal inertia is due to the significant heat capacity of the solid grains within the reservoir, which heat up the fluid as it advects through the pore space. Joule–Thomson cooling is superimposed on top of the advected temperature field, with heat conduction having the effect of smearing out the thermal front, as shown in figure 2. The minimum temperature ![]() $T_{min} = T_w - \varDelta T_{JT}$, is therefore a function of both Joule–Thomson cooling and the bottom-hole temperature

$T_{min} = T_w - \varDelta T_{JT}$, is therefore a function of both Joule–Thomson cooling and the bottom-hole temperature ![]() $T_w$, where

$T_w$, where ![]() $\Delta T_{JT}$ is the maximum Joule–Thomson cooling, which occurs just before the thermal front.

$\Delta T_{JT}$ is the maximum Joule–Thomson cooling, which occurs just before the thermal front.

Figure 2. Schematic diagram showing injection of ![]() ${\rm CO}_2$ into a low-pressure, gas-filled reservoir. Here,

${\rm CO}_2$ into a low-pressure, gas-filled reservoir. Here, ![]() $\boldsymbol {x}_W$,

$\boldsymbol {x}_W$, ![]() $\boldsymbol {x}_T$ and

$\boldsymbol {x}_T$ and ![]() $\boldsymbol {x}_C$ denote the edge of the wellbore, the positions of the thermal front and

$\boldsymbol {x}_C$ denote the edge of the wellbore, the positions of the thermal front and ![]() ${\rm CO}_2$ front, respectively. Schematic temperature fields are shown in red subject to: (i) fluid advection only (dashed), (ii) fluid advection, heat conduction and Joule–Thomson cooling (solid). Here

${\rm CO}_2$ front, respectively. Schematic temperature fields are shown in red subject to: (i) fluid advection only (dashed), (ii) fluid advection, heat conduction and Joule–Thomson cooling (solid). Here ![]() $\Delta T_{JT}$ denotes the maximum Joule–Thomson cooling.

$\Delta T_{JT}$ denotes the maximum Joule–Thomson cooling.

3. Governing equations

Given the assumptions described above, conservation of mass, Darcy's law (conservation of momentum) and conservation of energy may be expressed as

where the pressure, ![]() $p$, and temperature,

$p$, and temperature, ![]() $T$, are functions of position,

$T$, are functions of position, ![]() $\boldsymbol {x}$, and time,

$\boldsymbol {x}$, and time, ![]() $t$. The

$t$. The ![]() ${\rm CO}_2$-

${\rm CO}_2$-![]() ${\rm CH}_4$ fluid phase (which we will refer to as the ‘fluid’), water and solid rock are denoted by subscripts

${\rm CH}_4$ fluid phase (which we will refer to as the ‘fluid’), water and solid rock are denoted by subscripts ![]() $f$,

$f$, ![]() $w$ and

$w$ and ![]() $s$ respectively. The volume fractions of each phase

$s$ respectively. The volume fractions of each phase ![]() $\phi _i$ fully occupy the space,

$\phi _i$ fully occupy the space, ![]() $\sum _i\phi _i=1$. The phase densities are

$\sum _i\phi _i=1$. The phase densities are ![]() $\rho _i$,

$\rho _i$, ![]() $\mu$ is the fluid viscosity,

$\mu$ is the fluid viscosity, ![]() $\boldsymbol {u}$ is the Darcy velocity,

$\boldsymbol {u}$ is the Darcy velocity, ![]() $k$ and

$k$ and ![]() $k_r$ are the reservoir permeability and relative permeability of the fluid respectively,

$k_r$ are the reservoir permeability and relative permeability of the fluid respectively, ![]() $U_i$ are the specific internal energies and

$U_i$ are the specific internal energies and ![]() $k_T$ is the effective thermal conductivity of the bulk medium. While this could include both thermal conductivity and thermal dispersivity, the effect of mechanical dispersion on heat transport is thought to be negligible within the Darcian range (Bear Reference Bear2013). The final term in (3.3) describes the work done by the fluid due to expansion and viscous dissipation.

$k_T$ is the effective thermal conductivity of the bulk medium. While this could include both thermal conductivity and thermal dispersivity, the effect of mechanical dispersion on heat transport is thought to be negligible within the Darcian range (Bear Reference Bear2013). The final term in (3.3) describes the work done by the fluid due to expansion and viscous dissipation.

To close the conservation equations we use the definition of internal energy for the fluid, water and rock, which relates changes in internal energy to changes in temperature, pressure and density:

where ![]() $c_{pi}$ are the isobaric heat capacities of the different phases,

$c_{pi}$ are the isobaric heat capacities of the different phases, ![]() $\mu _{JT}=\partial {T}/\partial P|_H=({\alpha _f T-1})/{\rho _f c_{pf}}$ is the Joule–Thomson coefficient of the fluid, which describes the change in temperature when a real gas flows from high pressure to low pressure at constant enthalpy and

$\mu _{JT}=\partial {T}/\partial P|_H=({\alpha _f T-1})/{\rho _f c_{pf}}$ is the Joule–Thomson coefficient of the fluid, which describes the change in temperature when a real gas flows from high pressure to low pressure at constant enthalpy and ![]() $\alpha _f$ is defined below. The sign of

$\alpha _f$ is defined below. The sign of ![]() $\mu _{JT}$ for

$\mu _{JT}$ for ![]() ${\rm CO}_2$ and

${\rm CO}_2$ and ![]() ${\rm CH}_4$ within the

${\rm CH}_4$ within the ![]() $p-T$ range of interest are always positive, meaning that expansion produces cooling. It is important to note that Joule–Thomson cooling is an inherently irreversible process and arises from work done due to both fluid expansion and pressure changes as the fluid flows from regions of high to low pressure.

$p-T$ range of interest are always positive, meaning that expansion produces cooling. It is important to note that Joule–Thomson cooling is an inherently irreversible process and arises from work done due to both fluid expansion and pressure changes as the fluid flows from regions of high to low pressure.

To write the governing equations in terms of ![]() $p$ and

$p$ and ![]() $T$, we also need an equation of state for the fluid phase, which specifies

$T$, we also need an equation of state for the fluid phase, which specifies ![]() $\rho _f = \rho _f(p,T)$. In its most general form this can be expressed as

$\rho _f = \rho _f(p,T)$. In its most general form this can be expressed as

\begin{equation} \rho_f(p,T) = \rho_r \exp\left[\int_{p_r}^p\beta_f \,{\rm d}p - \int_{T_r}^T\alpha_f \,{\rm d}T\right], \end{equation}

\begin{equation} \rho_f(p,T) = \rho_r \exp\left[\int_{p_r}^p\beta_f \,{\rm d}p - \int_{T_r}^T\alpha_f \,{\rm d}T\right], \end{equation}

where ![]() $\rho _r$ is the density at the reference pressure,

$\rho _r$ is the density at the reference pressure, ![]() $p_r$, and temperature,

$p_r$, and temperature, ![]() $T_r$. The isothermal compressibility and isobaric thermal expansivity are defined as

$T_r$. The isothermal compressibility and isobaric thermal expansivity are defined as

respectively, where in general ![]() $\beta _f$ and

$\beta _f$ and ![]() $\alpha _f$ may be arbitrary functions of

$\alpha _f$ may be arbitrary functions of ![]() $p$ and

$p$ and ![]() $T$. Substituting these definitions and Darcy's law into (3.1) and (3.3) and expanding the derivatives allows us to rewrite the conservation equations as a set of coupled nonlinear hyperbolic–parabolic partial differential equations for

$T$. Substituting these definitions and Darcy's law into (3.1) and (3.3) and expanding the derivatives allows us to rewrite the conservation equations as a set of coupled nonlinear hyperbolic–parabolic partial differential equations for ![]() $p$ and

$p$ and ![]() $T$:

$T$:

where ![]() $\overline {\rho c_p}=\phi _f\rho _f c_{pf} + \phi _w\rho _wc_{pw}+\phi _s\rho _s c_{ps}$ is the average bulk volumetric heat capacity. Here, we have assumed for simplicity that

$\overline {\rho c_p}=\phi _f\rho _f c_{pf} + \phi _w\rho _wc_{pw}+\phi _s\rho _s c_{ps}$ is the average bulk volumetric heat capacity. Here, we have assumed for simplicity that ![]() $kk_r$,

$kk_r$, ![]() $\mu$ and

$\mu$ and ![]() $k_T$ do not vary significantly within the reservoir. The different sources of heat on the right-hand side of (3.10) are heat advection from fluid flow, Joule–Thomson cooling due to flow through a pressure gradient and heat conduction. The second term on the left-hand side of (3.10) describes the work done due to expansion/compression in response to transient pressure changes. In contrast to the Joule–Thomson effect, this is a function of the properties of the bulk medium rather than those of the fluid alone.

$k_T$ do not vary significantly within the reservoir. The different sources of heat on the right-hand side of (3.10) are heat advection from fluid flow, Joule–Thomson cooling due to flow through a pressure gradient and heat conduction. The second term on the left-hand side of (3.10) describes the work done due to expansion/compression in response to transient pressure changes. In contrast to the Joule–Thomson effect, this is a function of the properties of the bulk medium rather than those of the fluid alone.

For ![]() ${\rm CO}_2$ in the gaseous state, compressibility

${\rm CO}_2$ in the gaseous state, compressibility ![]() $\beta _f$ varies by a factor of

$\beta _f$ varies by a factor of ![]() $\sim$5 between 1 and 5 MPa at

$\sim$5 between 1 and 5 MPa at ![]() $40\,^{\circ }{\rm C}$ while thermal expansivity

$40\,^{\circ }{\rm C}$ while thermal expansivity ![]() $\alpha _f$ varies by a factor of

$\alpha _f$ varies by a factor of ![]() $\sim$2 (Linstrom & Mallard Reference Linstrom and Mallard2001). The

$\sim$2 (Linstrom & Mallard Reference Linstrom and Mallard2001). The ![]() $p-T$ dependence of compressibility and expansivity, and to a lesser extent viscosity, therefore introduce an additional nonlinearity into the equations. Even for an isothermal system, this precludes direct analytic solution of the pressure field. A number of authors (e.g. Tartakovsky Reference Tartakovsky2000; Mukhopadhyay, Yang & Yeh Reference Mukhopadhyay, Yang and Yeh2012; Mathias et al. Reference Mathias, McElwaine and Gluyas2014) have used the pseudo-pressure concept of Al-Hussainy, Ramey & Crawford (Reference Al-Hussainy, Ramey and Crawford1966) which relies on tabulated values of integrated fluid properties. For simplicity of the following analysis, in the following section we assume that

$p-T$ dependence of compressibility and expansivity, and to a lesser extent viscosity, therefore introduce an additional nonlinearity into the equations. Even for an isothermal system, this precludes direct analytic solution of the pressure field. A number of authors (e.g. Tartakovsky Reference Tartakovsky2000; Mukhopadhyay, Yang & Yeh Reference Mukhopadhyay, Yang and Yeh2012; Mathias et al. Reference Mathias, McElwaine and Gluyas2014) have used the pseudo-pressure concept of Al-Hussainy, Ramey & Crawford (Reference Al-Hussainy, Ramey and Crawford1966) which relies on tabulated values of integrated fluid properties. For simplicity of the following analysis, in the following section we assume that ![]() $\beta _f$ and

$\beta _f$ and ![]() $\alpha _f$ are constant over the relevant

$\alpha _f$ are constant over the relevant ![]() $p-T$ range, such that density is described by

$p-T$ range, such that density is described by

A similar analysis as presented here could be carried out in which ![]() $\beta _f$ and

$\beta _f$ and ![]() $\alpha _f$ are allowed to be

$\alpha _f$ are allowed to be ![]() $p-T$-dependent. While this would yield more rigorous prediction of the

$p-T$-dependent. While this would yield more rigorous prediction of the ![]() $p-T$ trajectories, it does not substantially alter the presented results.

$p-T$ trajectories, it does not substantially alter the presented results.

3.1. Pressure and temperature diffusivity

Equations (3.9) and (3.10) for ![]() $p$ and

$p$ and ![]() $T$ appear as advection–diffusion equations with coupled source terms. The pressure equation, (3.9), is predominantly diffusive, with a pressure diffusivity given by

$T$ appear as advection–diffusion equations with coupled source terms. The pressure equation, (3.9), is predominantly diffusive, with a pressure diffusivity given by

such that the higher the permeability and the lower the porosity, viscosity and compressibility, the faster pressure diffuses into the reservoir. The length scale of pressure decay is time-dependent, and is given by

\begin{equation} L_p = \left(\frac{kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}. \end{equation}

\begin{equation} L_p = \left(\frac{kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}. \end{equation}Thermal diffusivity is given by

leading to a thermal diffusion length scale

\begin{equation} L_T = \left(\frac{k_T t}{\overline{\rho c_p}}\right)^{{1}/{2}}. \end{equation}

\begin{equation} L_T = \left(\frac{k_T t}{\overline{\rho c_p}}\right)^{{1}/{2}}. \end{equation}

Thermal diffusion is small in contrast to the pressure diffusion, ![]() $D_T\ll D_p$, and hence temperature is advection dominated, meaning that the system admits sharp temperature fronts. As heat advection is controlled by the pressure gradient, we expect the advection length scale of the temperature field to be set by the pressure diffusion length scale

$D_T\ll D_p$, and hence temperature is advection dominated, meaning that the system admits sharp temperature fronts. As heat advection is controlled by the pressure gradient, we expect the advection length scale of the temperature field to be set by the pressure diffusion length scale ![]() $L_p$. For representative parameter values, we find that

$L_p$. For representative parameter values, we find that

Thermal diffusivity therefore has the effect of regularising the local structure of the thermal front, but does not control the long range structure of the temperature field.

3.2. Front positions

The injected ![]() ${\rm CO}_2$ and resident

${\rm CO}_2$ and resident ![]() ${\rm CH}_4$ have so far been modelled as a combined fluid phase with the same properties. Neglecting dispersion and mixing, the concentration of injected

${\rm CH}_4$ have so far been modelled as a combined fluid phase with the same properties. Neglecting dispersion and mixing, the concentration of injected ![]() ${\rm CO}_2$ in this fluid phase

${\rm CO}_2$ in this fluid phase ![]() $c$ may be described by

$c$ may be described by

where the concentration of ![]() ${\rm CH}_4$ is given by

${\rm CH}_4$ is given by ![]() $1-c$. The injected

$1-c$. The injected ![]() ${\rm CO}_2$ extends to the front at

${\rm CO}_2$ extends to the front at ![]() $\boldsymbol {x}_C(t)$ and therefore propagates at the local fluid velocity which is given by Darcy's law:

$\boldsymbol {x}_C(t)$ and therefore propagates at the local fluid velocity which is given by Darcy's law:

This expression could equivalently be derived by equating the mass flux through the well to the change in injected ![]() ${\rm CO}_2$ mass within the reservoir

${\rm CO}_2$ mass within the reservoir

\begin{equation} \frac{\text{d} }{\text{d} t}\int^{\boldsymbol{x}_C,t}_{\boldsymbol{x}_W,t}\rho_f\,{\rm d}r ={-} \left.\frac{kk_r}{\phi_f\mu}\rho_f\boldsymbol{\nabla} p\right|_{\boldsymbol{x}_W}, \end{equation}

\begin{equation} \frac{\text{d} }{\text{d} t}\int^{\boldsymbol{x}_C,t}_{\boldsymbol{x}_W,t}\rho_f\,{\rm d}r ={-} \left.\frac{kk_r}{\phi_f\mu}\rho_f\boldsymbol{\nabla} p\right|_{\boldsymbol{x}_W}, \end{equation}

where ![]() $\boldsymbol {x}_W$ is the position of the well. Applying the chain rule and substituting conservation of mass, this leads to expression (3.18).

$\boldsymbol {x}_W$ is the position of the well. Applying the chain rule and substituting conservation of mass, this leads to expression (3.18).

Neglecting thermal diffusion results in a jump discontinuity in the temperature field at the thermal front created during cold ![]() ${\rm CO}_2$ injection. The position of the thermal front

${\rm CO}_2$ injection. The position of the thermal front ![]() $\boldsymbol {x}_T(t)$ can be derived by restricting the temperature equation, (3.10), to the purely advective component

$\boldsymbol {x}_T(t)$ can be derived by restricting the temperature equation, (3.10), to the purely advective component

where ![]() $\varGamma = {\phi _f\rho _fc_{pf}}/{\overline {\rho c_p}}$ is the fractional volumetric heat capacity of the fluid. The speed at which the thermal front

$\varGamma = {\phi _f\rho _fc_{pf}}/{\overline {\rho c_p}}$ is the fractional volumetric heat capacity of the fluid. The speed at which the thermal front ![]() $\boldsymbol {x}_T(t)$ propagates is therefore given by the fluid velocity scaled by

$\boldsymbol {x}_T(t)$ propagates is therefore given by the fluid velocity scaled by ![]() $\varGamma$, such that

$\varGamma$, such that

4. Application to radial flow in a confined reservoir

We apply this model to the injection geometry illustrated in figure 3, which considers a radially spreading injection within a confined reservoir of thickness ![]() $H$. As we are considering the initial transient response before the pressure wave reaches the outer boundaries of the reservoir, the reservoir is modelled as infinite. The injection well, of radius

$H$. As we are considering the initial transient response before the pressure wave reaches the outer boundaries of the reservoir, the reservoir is modelled as infinite. The injection well, of radius ![]() $r_W$, penetrates the full thickness of the formation. The radial positions of the

$r_W$, penetrates the full thickness of the formation. The radial positions of the ![]() ${\rm CO}_2$ and thermal fronts are

${\rm CO}_2$ and thermal fronts are ![]() $r_C(t)$ and

$r_C(t)$ and ![]() $r_T(t)$ respectively. The governing equations in terms of the radial distance

$r_T(t)$ respectively. The governing equations in terms of the radial distance ![]() $r$ are then given by

$r$ are then given by

Figure 3. Schematic diagram of a radial ![]() ${\rm CO}_2$ injection into a cylindrical

${\rm CO}_2$ injection into a cylindrical ![]() ${\rm CH}_4$-filled reservoir with thickness

${\rm CH}_4$-filled reservoir with thickness ![]() $H$. The

$H$. The ![]() ${\rm CO}_2$ and thermal front are denoted

${\rm CO}_2$ and thermal front are denoted ![]() $r_C$ and

$r_C$ and ![]() $r_T$, respectively.

$r_T$, respectively.

A constant mass flux inner boundary condition can be defined at the wellbore ![]() $r_W$, along with a fixed bottom-hole temperature

$r_W$, along with a fixed bottom-hole temperature ![]() $T_w$. Here we define the problem on an infinite domain, such that the outer boundary maintains the initial reservoir pressure and temperature (

$T_w$. Here we define the problem on an infinite domain, such that the outer boundary maintains the initial reservoir pressure and temperature (![]() $p_0, T_0$) as

$p_0, T_0$) as ![]() $r\rightarrow \infty$. The boundary and initial conditions are then

$r\rightarrow \infty$. The boundary and initial conditions are then

where ![]() $Q$ is the mass injection rate through the well (

$Q$ is the mass injection rate through the well (![]() ${\rm kg}\ {\rm s}^{-1}$). Note that this represents an idealised injection scenario. During actual injections, the bottom-hole

${\rm kg}\ {\rm s}^{-1}$). Note that this represents an idealised injection scenario. During actual injections, the bottom-hole ![]() ${\rm CO}_2$ conditions depend on

${\rm CO}_2$ conditions depend on ![]() ${\rm CO}_2$ properties at the well head and on the dynamics of flow within the well. These are likely to vary over time leading to time-dependent boundary conditions.

${\rm CO}_2$ properties at the well head and on the dynamics of flow within the well. These are likely to vary over time leading to time-dependent boundary conditions.

4.1. Analytical reference solutions

4.1.1. Pressure diffusion

Given low fluid compressibility and small pressure gradients, ![]() $\rho _f$ can be assumed constant and (3.9) can be linearised by neglecting the first and second terms on the right-hand side. Assuming temperature changes are negligible, this leads to the classical pressure diffusion equation (Dake Reference Dake1983; Bear Reference Bear2012)

$\rho _f$ can be assumed constant and (3.9) can be linearised by neglecting the first and second terms on the right-hand side. Assuming temperature changes are negligible, this leads to the classical pressure diffusion equation (Dake Reference Dake1983; Bear Reference Bear2012)

Note that in scenarios in which pressure gradients are very high, such as near the wellbore in radially spreading injections, or for fluids with high ![]() $\beta _f$, this linearisation is not appropriate. Comparison of the approximate pressure solution to (4.5) with the fully coupled equations will allow us to explore the effect of the nonlinear terms. Because the temperature and pressure fields vary over a length scale

$\beta _f$, this linearisation is not appropriate. Comparison of the approximate pressure solution to (4.5) with the fully coupled equations will allow us to explore the effect of the nonlinear terms. Because the temperature and pressure fields vary over a length scale ![]() $L_p\propto t^{{1}/{2}}$, it is instructive to seek a similarity solution (Barenblatt & Isaakovich Reference Barenblatt and Isaakovich1996) using the similarity variable

$L_p\propto t^{{1}/{2}}$, it is instructive to seek a similarity solution (Barenblatt & Isaakovich Reference Barenblatt and Isaakovich1996) using the similarity variable

\begin{equation} \eta(r,t) = r\left(4D_pt\right)^{-{1}/{2}} = r\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{-{1}/{2}}. \end{equation}

\begin{equation} \eta(r,t) = r\left(4D_pt\right)^{-{1}/{2}} = r\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{-{1}/{2}}. \end{equation}

Use of ![]() $\eta$ transforms (4.5) into an ordinary differential equation for the structure of the pressure field:

$\eta$ transforms (4.5) into an ordinary differential equation for the structure of the pressure field:

where the primes denote derivatives with respect to ![]() $\eta$. Integrating and applying the constant mass flux inner boundary condition gives

$\eta$. Integrating and applying the constant mass flux inner boundary condition gives

where ![]() $\eta _W$ is the value of

$\eta _W$ is the value of ![]() $\eta$ at the wellbore. As the well has a finite and fixed radius,

$\eta$ at the wellbore. As the well has a finite and fixed radius, ![]() $r_W$,

$r_W$,

\begin{equation} \eta_W(t) = r_W\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{-{1}/{2}}, \end{equation}

\begin{equation} \eta_W(t) = r_W\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{-{1}/{2}}, \end{equation}

and hence ![]() $\eta _W\rightarrow 0$ as

$\eta _W\rightarrow 0$ as ![]() $t\rightarrow \infty$. Because we have assumed that

$t\rightarrow \infty$. Because we have assumed that ![]() $\beta _f$ is small and

$\beta _f$ is small and ![]() $\rho _f$ is relatively constant within the reservoir, we can integrate (4.8) again and apply the far-field outer boundary condition (4.3a,b) to give the similarity solution

$\rho _f$ is relatively constant within the reservoir, we can integrate (4.8) again and apply the far-field outer boundary condition (4.3a,b) to give the similarity solution

where ![]() $\rho _f$ is the average fluid density and

$\rho _f$ is the average fluid density and ![]() $E_i(y)$ is the exponential integral. We assume a self-similar

$E_i(y)$ is the exponential integral. We assume a self-similar ![]() ${\rm CO}_2$ front position, given by

${\rm CO}_2$ front position, given by

\begin{equation} r_C(t) = \eta_C\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}, \end{equation}

\begin{equation} r_C(t) = \eta_C\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}, \end{equation}

where ![]() $\eta _C$ is a numerical constant to be determined. The position of the front can be found by substituting this expression for

$\eta _C$ is a numerical constant to be determined. The position of the front can be found by substituting this expression for ![]() $r_C(t)$ and (4.8) into the expression for the front position (3.18), which gives

$r_C(t)$ and (4.8) into the expression for the front position (3.18), which gives

\begin{equation} \eta_C = \left(\frac{\mu\beta_fQ}{4{\rm \pi} Hkk_r\rho_f}\exp({\eta_W^2-\eta_C^2})\right)^{{1}/{2}}. \end{equation}

\begin{equation} \eta_C = \left(\frac{\mu\beta_fQ}{4{\rm \pi} Hkk_r\rho_f}\exp({\eta_W^2-\eta_C^2})\right)^{{1}/{2}}. \end{equation}4.1.2. Steady-state Joule–Thomson cooling

Mathias et al. (Reference Mathias, Gluyas, Oldenburg and Tsang2010) presented an analytical solution for Joule–Thomson cooling, which can be derived if the pressure field is assumed to be in steady state and uncoupled to the temperature field. A truly steady-state pressure field requires mass flux through the outer boundaries to equal that at the injection well. This is a non-physical condition for a cylindrical reservoir with an impermeable caprock, in which the radial symmetry is preserved. However, a pseudo-steady-state condition can be established in a closed reservoir when the pressure wave reaches the outer impermeable boundaries of the reservoir. In this regime ![]() $\partial p/\partial t$ is approximately constant and small over the whole reservoir such that

$\partial p/\partial t$ is approximately constant and small over the whole reservoir such that ![]() $\partial p/\partial r$ at a given radius does not vary substantially with time (Dake Reference Dake1983; Bear Reference Bear2012). The pressure field near the well in the pseudo-steady-state regime can therefore be approximated by

$\partial p/\partial r$ at a given radius does not vary substantially with time (Dake Reference Dake1983; Bear Reference Bear2012). The pressure field near the well in the pseudo-steady-state regime can therefore be approximated by

which on imposition of the constant mass flux inner boundary condition gives

where ![]() $\rho _f$ is the average fluid density. Note that, for small

$\rho _f$ is the average fluid density. Note that, for small ![]() $r$, this steady-state pressure gradient is the same as the linearised pressure diffusion solution above. If at a given time the wellbore pressure is known to be

$r$, this steady-state pressure gradient is the same as the linearised pressure diffusion solution above. If at a given time the wellbore pressure is known to be ![]() $p_W(t)$ and the reservoir properties can be assumed to be constant, integrating again gives the pressure field as described by Thiem's equation:

$p_W(t)$ and the reservoir properties can be assumed to be constant, integrating again gives the pressure field as described by Thiem's equation:

which is recovered from (4.10) as ![]() $r\rightarrow 0$. The radial position of the

$r\rightarrow 0$. The radial position of the ![]() ${\rm CO}_2$ front,

${\rm CO}_2$ front, ![]() $r_C$, is found by substituting (4.14) into (3.18) and integrating with respect to time, giving

$r_C$, is found by substituting (4.14) into (3.18) and integrating with respect to time, giving

\begin{equation} r_C = \left(\frac{Qt}{{\rm \pi} H\phi\rho_f}+r_W^2\right)^{{1}/{2}}\simeq \left(\frac{Qt}{{\rm \pi} H\phi\rho_f}\right)^{{1}/{2}}. \end{equation}

\begin{equation} r_C = \left(\frac{Qt}{{\rm \pi} H\phi\rho_f}+r_W^2\right)^{{1}/{2}}\simeq \left(\frac{Qt}{{\rm \pi} H\phi\rho_f}\right)^{{1}/{2}}. \end{equation} The temperature field is calculated by coupling this pressure field to a transient temperature equation. Assuming ![]() $\partial p/\partial t$ is small and neglecting heat conduction, substituting (4.14) into (4.2) gives

$\partial p/\partial t$ is small and neglecting heat conduction, substituting (4.14) into (4.2) gives

Mathias et al. (Reference Mathias, Gluyas, Oldenburg and Tsang2010) solved the temperature equation by applying a Laplace transform. An alternative derivation using intermediate asymptotics is shown in Appendix A, which gives the following solution:

\begin{equation} T(r,t) = \begin{cases} T_w - \dfrac{\mu_{JT}\mu Q}{2{\rm \pi} H\rho_fkk_r}\text{ln}\left(\dfrac{r}{r_W}\right), & r< r_T,\\ T_0 + \dfrac{\mu_{JT}\mu Q}{4{\rm \pi} H\rho_fkk_r}\text{ln}\left(1-\dfrac{c_{pf}Qt}{\overline{\rho c_p}{\rm \pi} Hr^2}\right), & r>r_T,\\ \end{cases} \end{equation}

\begin{equation} T(r,t) = \begin{cases} T_w - \dfrac{\mu_{JT}\mu Q}{2{\rm \pi} H\rho_fkk_r}\text{ln}\left(\dfrac{r}{r_W}\right), & r< r_T,\\ T_0 + \dfrac{\mu_{JT}\mu Q}{4{\rm \pi} H\rho_fkk_r}\text{ln}\left(1-\dfrac{c_{pf}Qt}{\overline{\rho c_p}{\rm \pi} Hr^2}\right), & r>r_T,\\ \end{cases} \end{equation}

where ![]() $r_T$ is the radial position of the thermal front, which is given by

$r_T$ is the radial position of the thermal front, which is given by

\begin{equation} r_T = \left[\frac{c_{pf}Qt}{\overline{\rho c_p}{\rm \pi} H} + r_W^2\exp \left(\frac{4{\rm \pi} H kk_r\rho_f(T_w-T_0)}{\mu_{JT}\mu Q}\right)\right]^{{1}/{2}}. \end{equation}

\begin{equation} r_T = \left[\frac{c_{pf}Qt}{\overline{\rho c_p}{\rm \pi} H} + r_W^2\exp \left(\frac{4{\rm \pi} H kk_r\rho_f(T_w-T_0)}{\mu_{JT}\mu Q}\right)\right]^{{1}/{2}}. \end{equation}

When ![]() $T_w=T_0$, as reported by Mathias et al. (Reference Mathias, Gluyas, Oldenburg and Tsang2010), the front condition is

$T_w=T_0$, as reported by Mathias et al. (Reference Mathias, Gluyas, Oldenburg and Tsang2010), the front condition is

\begin{equation} r_T \approx \left[\frac{c_{pf}Qt}{\overline{\rho c_p}{\rm \pi} H} + r_W^2\right]^{{1}/{2}}, \end{equation}

\begin{equation} r_T \approx \left[\frac{c_{pf}Qt}{\overline{\rho c_p}{\rm \pi} H} + r_W^2\right]^{{1}/{2}}, \end{equation}

which could equivalently have been derived by substituting the pressure gradient (4.14) into the condition for the thermal front (3.21). Because ![]() $T_w< T_0$ in most injection scenarios, at long times the front condition is better approximated by

$T_w< T_0$ in most injection scenarios, at long times the front condition is better approximated by

\begin{equation} r_T \approx \left(\frac{c_{pf}Qt}{\overline{\rho c_p}{\rm \pi} H}\right)^{{1}/{2}}=\varGamma^{{1}/{2}}r_C, \end{equation}

\begin{equation} r_T \approx \left(\frac{c_{pf}Qt}{\overline{\rho c_p}{\rm \pi} H}\right)^{{1}/{2}}=\varGamma^{{1}/{2}}r_C, \end{equation}

where ![]() $\varGamma = {\phi _f\rho _fc_{pf}}/{\overline {\rho c_p}}$ is the fractional volumetric heat capacity. Unlike for the transient pressure field solution above, in which the

$\varGamma = {\phi _f\rho _fc_{pf}}/{\overline {\rho c_p}}$ is the fractional volumetric heat capacity. Unlike for the transient pressure field solution above, in which the ![]() $t^{{1}/{2}}$ dependence arises from the diffusive length scale of the problem, the

$t^{{1}/{2}}$ dependence arises from the diffusive length scale of the problem, the ![]() $t^{{1}/{2}}$ dependence of the front positions in the steady-state case arises geometrically due to radial spreading. The maximum degree of Joule–Thomson cooling

$t^{{1}/{2}}$ dependence of the front positions in the steady-state case arises geometrically due to radial spreading. The maximum degree of Joule–Thomson cooling ![]() $\Delta T_{JT}$ occurs at the thermal front and is given by

$\Delta T_{JT}$ occurs at the thermal front and is given by

In the steady-state case, Joule–Thomson cooling is therefore simply given by ![]() $\mu _{JT}$ multiplied by the pressure drop between the well and thermal front. As the thermal front propagates into the reservoir at a distance

$\mu _{JT}$ multiplied by the pressure drop between the well and thermal front. As the thermal front propagates into the reservoir at a distance ![]() ${\sim }t^{{1}/{2}}$ through a static logarithmic pressure field, the degree of cooling increases logarithmically with time.

${\sim }t^{{1}/{2}}$ through a static logarithmic pressure field, the degree of cooling increases logarithmically with time.

4.2. Transient Joule–Thomson cooling

Given these reference solutions, we now examine the fully coupled model for transient Joule–Thomson cooling. This allows us to quantify the effect of the nonlinear terms and temperature coupling on the pressure field, and the effect of pressure transience on Joule–Thomson cooling.

The consideration of pressure transience requires the solution of the full governing equations, (4.1) and (4.2). A scaling analysis of these equations suggests self-similar solutions in terms of non-dimensional variables for pressure, temperature, radial extent and well radius:

\begin{align}

&\mathcal{P}= \beta_f

\left(p-p_0\right), \quad \mathcal{T}=

\alpha_f\left(T-T_0\right), \nonumber\\

&\eta = r\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{-{1}/{2}},

\quad \eta_W = r_W\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{-{1}/{2}},

\end{align}

\begin{align}

&\mathcal{P}= \beta_f

\left(p-p_0\right), \quad \mathcal{T}=

\alpha_f\left(T-T_0\right), \nonumber\\

&\eta = r\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{-{1}/{2}},

\quad \eta_W = r_W\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{-{1}/{2}},

\end{align}

where ![]() $\eta$ is the similarity variable, and

$\eta$ is the similarity variable, and ![]() $\eta _W$ is a time-dependent variable introduced through the fixed wellbore radius. The initial reservoir pressure and temperature are

$\eta _W$ is a time-dependent variable introduced through the fixed wellbore radius. The initial reservoir pressure and temperature are ![]() $p_0$ and

$p_0$ and ![]() $T_0$, respectively, and

$T_0$, respectively, and ![]() $\beta _f$ and

$\beta _f$ and ![]() $\alpha _f$ are assumed constant. Substituting the above relations into (4.1) and (4.2) we obtain

$\alpha _f$ are assumed constant. Substituting the above relations into (4.1) and (4.2) we obtain

\begin{gather} \frac{\eta_W}{\eta}\left(\frac{\partial{\mathcal{T}}}{\partial{\eta_W}} -\mathcal{A}\frac{\partial{\mathcal{P}}}{\partial{\eta_W}}\right) + \frac{\partial{\mathcal{T}}}{\partial{\eta}} - \mathcal{A}\frac{\partial{\mathcal{P}}}{\partial{\eta}}\nonumber\\ \quad ={-}\frac{1}{2\eta}\left[\varGamma\frac{\partial{\mathcal{P}}}{\partial{\eta}}\left(\frac{\partial{\mathcal{T}}}{\partial{\eta}}- \mathcal{J}\frac{\partial{\mathcal{P}}}{\partial{\eta}}\right) + \frac{1}{Pe}\frac{1}{\eta}\frac{\partial{}}{\partial{\eta}}\left(\eta\frac{\partial{\mathcal{T}}}{\partial{\eta}}\right)\right]. \end{gather}

\begin{gather} \frac{\eta_W}{\eta}\left(\frac{\partial{\mathcal{T}}}{\partial{\eta_W}} -\mathcal{A}\frac{\partial{\mathcal{P}}}{\partial{\eta_W}}\right) + \frac{\partial{\mathcal{T}}}{\partial{\eta}} - \mathcal{A}\frac{\partial{\mathcal{P}}}{\partial{\eta}}\nonumber\\ \quad ={-}\frac{1}{2\eta}\left[\varGamma\frac{\partial{\mathcal{P}}}{\partial{\eta}}\left(\frac{\partial{\mathcal{T}}}{\partial{\eta}}- \mathcal{J}\frac{\partial{\mathcal{P}}}{\partial{\eta}}\right) + \frac{1}{Pe}\frac{1}{\eta}\frac{\partial{}}{\partial{\eta}}\left(\eta\frac{\partial{\mathcal{T}}}{\partial{\eta}}\right)\right]. \end{gather}

Equivalent equations for a fluid with variable ![]() $\beta _f$ and

$\beta _f$ and ![]() $\alpha _f$ are given in Appendix B. The solutions to these equations are self-similar in the far field, but have a slow time dependence in the near-wellbore region due to the requirement to match onto the fixed wellbore radius. The general solutions are therefore

$\alpha _f$ are given in Appendix B. The solutions to these equations are self-similar in the far field, but have a slow time dependence in the near-wellbore region due to the requirement to match onto the fixed wellbore radius. The general solutions are therefore ![]() $\mathcal {P}(\eta,\eta _W)$ and

$\mathcal {P}(\eta,\eta _W)$ and ![]() $\mathcal {T}(\eta,\eta _W)$. The governing equations are subject to the scaled boundary conditions

$\mathcal {T}(\eta,\eta _W)$. The governing equations are subject to the scaled boundary conditions

The non-dimensional parameters

\begin{align} \left.\begin{gathered} \varGamma = \frac{\phi\rho_fc_{pf}}{\overline{\rho c_{p}}}, \quad \mathcal{J} = \frac{\alpha_f\mu_{JT}}{\beta_f} = \frac{\left(\left.\dfrac{\partial{T}}{\partial{p}}\right|_H\right)_f}{\left(\left.\dfrac{\partial{T}}{\partial{p}}\right|_{\rho}\right)_f}, \quad \mathcal{A} = \frac{\phi\alpha_f^2 T}{\beta_f\overline{\rho c_p}} = \frac{\left(\left.\dfrac{\partial{T}}{\partial{p}}\right|_S\right)_{f+w+s}}{\left(\left.\dfrac{\partial{T}}{\partial{p}}\right|_{\rho}\right)_f}, \\ Pe = \frac{\overline{\rho c_p}kk_r}{k_T\phi\mu\beta_f} \end{gathered}\right\} \end{align}

\begin{align} \left.\begin{gathered} \varGamma = \frac{\phi\rho_fc_{pf}}{\overline{\rho c_{p}}}, \quad \mathcal{J} = \frac{\alpha_f\mu_{JT}}{\beta_f} = \frac{\left(\left.\dfrac{\partial{T}}{\partial{p}}\right|_H\right)_f}{\left(\left.\dfrac{\partial{T}}{\partial{p}}\right|_{\rho}\right)_f}, \quad \mathcal{A} = \frac{\phi\alpha_f^2 T}{\beta_f\overline{\rho c_p}} = \frac{\left(\left.\dfrac{\partial{T}}{\partial{p}}\right|_S\right)_{f+w+s}}{\left(\left.\dfrac{\partial{T}}{\partial{p}}\right|_{\rho}\right)_f}, \\ Pe = \frac{\overline{\rho c_p}kk_r}{k_T\phi\mu\beta_f} \end{gathered}\right\} \end{align}

depend on fluid and reservoir properties. As defined above, ![]() $\varGamma$ is the volumetric heat capacity ratio of the fluid to the bulk porous medium,

$\varGamma$ is the volumetric heat capacity ratio of the fluid to the bulk porous medium, ![]() $\mathcal {J}$ is the scaled Joule–Thomson coefficient of the fluid which controls the magnitude of Joule–Thomson cooling due to flow of the fluid down a pressure gradient,

$\mathcal {J}$ is the scaled Joule–Thomson coefficient of the fluid which controls the magnitude of Joule–Thomson cooling due to flow of the fluid down a pressure gradient, ![]() $\mathcal {A}$ is the scaled isentropic temperature gradient of the bulk medium which controls the temperature response to transient pressure changes and

$\mathcal {A}$ is the scaled isentropic temperature gradient of the bulk medium which controls the temperature response to transient pressure changes and ![]() $Pe$ is the thermal Péclet number. The non-dimensional parameters

$Pe$ is the thermal Péclet number. The non-dimensional parameters

depend on the boundary conditions at the wellbore.

Note that, as above for the linearised pressure solution, when the domain is rescaled in terms of ![]() $\eta$, the finite well radius causes the position of the inner boundary to be time-dependent,

$\eta$, the finite well radius causes the position of the inner boundary to be time-dependent, ![]() $\eta _W=\eta _W(t)$, with

$\eta _W=\eta _W(t)$, with ![]() $\eta _W\rightarrow 0$ as

$\eta _W\rightarrow 0$ as ![]() $t\rightarrow \infty$. The finite well radius therefore introduces an additional time dependence close to the well. Due to the fixed wellbore temperature, we can make the observation that

$t\rightarrow \infty$. The finite well radius therefore introduces an additional time dependence close to the well. Due to the fixed wellbore temperature, we can make the observation that

As observed for the reference solution, the fixed mass injection rate causes the pressure at the wellbore to buildup at a rate inversely proportional to ![]() $\eta _W$, such that the long time solution provides the envelope of the earlier time solutions. In other words, in the absence of temperature coupling, the pressure field is fully self-similar. This means that

$\eta _W$, such that the long time solution provides the envelope of the earlier time solutions. In other words, in the absence of temperature coupling, the pressure field is fully self-similar. This means that

Substituting the above approximations into (4.24) and (4.25) gives

where the primes now denote derivatives with respect to ![]() $\eta$.

$\eta$.

To isolate the effect of temperature coupling on the pressure field, we can additionally consider the solution to the pressure field under isothermal conditions. Employing the same approximations as above, this is described by

subject to the boundary conditions

4.2.1. Front positions

In the limit ![]() $\eta \gg \eta _W$ the effect of the finite well radius diminishes such that the solution is completely self-similar with respect to the variable

$\eta \gg \eta _W$ the effect of the finite well radius diminishes such that the solution is completely self-similar with respect to the variable ![]() $\eta$. Hence, the conditions (3.18) and (3.21) for the front positions

$\eta$. Hence, the conditions (3.18) and (3.21) for the front positions ![]() $\boldsymbol {x}_C(t)$ and

$\boldsymbol {x}_C(t)$ and ![]() $\boldsymbol {x}_T(t)$ can be rewritten in terms of

$\boldsymbol {x}_T(t)$ can be rewritten in terms of ![]() $\eta$ to give

$\eta$ to give

where ![]() $\eta _C$ and

$\eta _C$ and ![]() $\eta _T$ are the values of

$\eta _T$ are the values of ![]() $\eta$ at the

$\eta$ at the ![]() $\textrm {CO}_2$ and thermal fronts, respectively. Rearranging the temperature equation, (4.32), we also identify a stationary point in the temperature solution which represents a temperature maximum at

$\textrm {CO}_2$ and thermal fronts, respectively. Rearranging the temperature equation, (4.32), we also identify a stationary point in the temperature solution which represents a temperature maximum at

Because the conditions (4.34a,b)–(4.36) are only dependent on ![]() $\mathcal {P}$, given a self-similar pressure field, the fronts will be defined for fixed values of

$\mathcal {P}$, given a self-similar pressure field, the fronts will be defined for fixed values of ![]() $\eta _C$,

$\eta _C$, ![]() $\eta _T$ and

$\eta _T$ and ![]() $\eta _M$. This has the significant benefit that solutions to (4.34a,b) and (4.36) give the positions of the fronts for all time according to

$\eta _M$. This has the significant benefit that solutions to (4.34a,b) and (4.36) give the positions of the fronts for all time according to

\begin{equation} r_C = \eta_C\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}, \quad r_T = \eta_T\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}, \quad r_M = \eta_M\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}. \end{equation}

\begin{equation} r_C = \eta_C\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}, \quad r_T = \eta_T\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}, \quad r_M = \eta_M\left(\frac{4kk_rt}{\phi\mu\beta_f}\right)^{{1}/{2}}. \end{equation}

Furthermore, given a self-similar pressure field, the pressures at the fronts, ![]() $\mathcal {P}_C$,

$\mathcal {P}_C$, ![]() $\mathcal {P}_T$ and

$\mathcal {P}_T$ and ![]() $\mathcal {P}_M$, are constant in time.

$\mathcal {P}_M$, are constant in time.

4.2.2. Numerical approach

We solve (4.31) and (4.32) numerically in python using the scipy.integrate.solve_bvp library, which implements a fourth-order implicit Runge–Kutta method. Due to the time dependence of the inner region, the equations are solved for each time interval of interest, with the inner boundary conditions imposed at ![]() $\eta _W(t)$. The far-field boundary is imposed at a finite

$\eta _W(t)$. The far-field boundary is imposed at a finite ![]() $\eta$ that is sufficiently large that pressure and temperature gradients are negligible. Varying the position of the outer boundary can be shown to not influence the final solutions.

$\eta$ that is sufficiently large that pressure and temperature gradients are negligible. Varying the position of the outer boundary can be shown to not influence the final solutions.

5. Results

To illustrate the transient Joule–Thomson cooling effect, solutions are calculated for injection into a 2 MPa reservoir with an ambient temperature of ![]() $75\,^{\circ }\textrm {C}$. We consider a constant rate

$75\,^{\circ }\textrm {C}$. We consider a constant rate ![]() $\textrm {CO}_2$ injection at

$\textrm {CO}_2$ injection at ![]() $30\ \textrm {kg}\ \textrm {s}^{-1}$ (corresponding to

$30\ \textrm {kg}\ \textrm {s}^{-1}$ (corresponding to ![]() $\sim$1 Mt

$\sim$1 Mt![]() $\textrm {CO}_2$ yr

$\textrm {CO}_2$ yr![]() $^{-1}$) which is relevant to the high injection rates used at

$^{-1}$) which is relevant to the high injection rates used at ![]() $\textrm {CO}_2$ sequestration sites such as the Sleipner project (Furre et al. Reference Furre, Eiken, Alnes, Vevatne and Kiær2017). Solutions are calculated for injection temperatures of

$\textrm {CO}_2$ sequestration sites such as the Sleipner project (Furre et al. Reference Furre, Eiken, Alnes, Vevatne and Kiær2017). Solutions are calculated for injection temperatures of ![]() $25\,^{\circ }\textrm {C}$ and

$25\,^{\circ }\textrm {C}$ and ![]() $75\,^{\circ }\textrm {C}$ to represent a cold and heated injection, respectively.

$75\,^{\circ }\textrm {C}$ to represent a cold and heated injection, respectively.

The reference reservoir and fluid properties are given in table 1. The fluid thermophysical properties ![]() $\rho _r$,

$\rho _r$, ![]() $\beta _f$,

$\beta _f$, ![]() $\alpha _f$,

$\alpha _f$, ![]() $c_{pf}$ and

$c_{pf}$ and ![]() $\mu$ are assumed to be constant and are calculated using the CoolProp library (Bell et al. Reference Bell, Wronski, Quoilin and Lemort2014) which implements the Span-Wagner equation of state for pure

$\mu$ are assumed to be constant and are calculated using the CoolProp library (Bell et al. Reference Bell, Wronski, Quoilin and Lemort2014) which implements the Span-Wagner equation of state for pure ![]() $\textrm {CO}_2$. We use a reference pressure

$\textrm {CO}_2$. We use a reference pressure ![]() $p_r$ of 3 MPa and temperature

$p_r$ of 3 MPa and temperature ![]() $T_r$ equal to that of the wellbore

$T_r$ equal to that of the wellbore ![]() $T_w$. Density

$T_w$. Density ![]() $\rho _f$ is a function of

$\rho _f$ is a function of ![]() $p$ and

$p$ and ![]() $T$ as given in (3.11). This leads to values of the non-dimensional parameters

$T$ as given in (3.11). This leads to values of the non-dimensional parameters ![]() $\varGamma$,

$\varGamma$, ![]() $\mathcal {A}$,

$\mathcal {A}$, ![]() $Pe$ and

$Pe$ and ![]() $\chi$ which vary as a function of

$\chi$ which vary as a function of ![]() $p$ and

$p$ and ![]() $T$. Reference values for all the non-dimensional parameters at

$T$. Reference values for all the non-dimensional parameters at ![]() $p_r$ and

$p_r$ and ![]() $T_r$ are given in table 1.

$T_r$ are given in table 1.

Table 1. Reference reservoir properties, fluid properties and non-dimensional variables.

The solutions for the cold injection are plotted as a function of ![]() $\eta$ in figure 4 at time intervals up to 1 year, which is the time at which the pressure field would start to interact with the outer boundary of a reservoir with a radius of 2 km. We find that the pressure diffuses smoothly into the reservoir, while the temperature has a sharp advective front which lags behind the injected

$\eta$ in figure 4 at time intervals up to 1 year, which is the time at which the pressure field would start to interact with the outer boundary of a reservoir with a radius of 2 km. We find that the pressure diffuses smoothly into the reservoir, while the temperature has a sharp advective front which lags behind the injected ![]() $\textrm {CO}_2$ front due to the thermal inertia of the porous system. Because the fluid density is a function of

$\textrm {CO}_2$ front due to the thermal inertia of the porous system. Because the fluid density is a function of ![]() $p$ and

$p$ and ![]() $T$ we see that it decreases into the reservoir due to decreasing

$T$ we see that it decreases into the reservoir due to decreasing ![]() $p$, and exhibits a sharp drop across the thermal front due to the increase in

$p$, and exhibits a sharp drop across the thermal front due to the increase in ![]() $T$ at the thermal front. The positions of the

$T$ at the thermal front. The positions of the ![]() $\textrm {CO}_2$ front, the thermal maximum and the thermal front occur at constant values of

$\textrm {CO}_2$ front, the thermal maximum and the thermal front occur at constant values of ![]() $\eta$ for all time. The temperature is self-similar in the far field, but is time-dependent behind the thermal front due to the finite well radius. The maximum amount of cooling increases with time as the pressure drop between the well and thermal front increase. The expanded region shows the small amount of heating ahead of the thermal front due to transient compression of the fluid ahead of the thermal front, with a temperature maximum that lags slightly behind the

$\eta$ for all time. The temperature is self-similar in the far field, but is time-dependent behind the thermal front due to the finite well radius. The maximum amount of cooling increases with time as the pressure drop between the well and thermal front increase. The expanded region shows the small amount of heating ahead of the thermal front due to transient compression of the fluid ahead of the thermal front, with a temperature maximum that lags slightly behind the ![]() $\textrm {CO}_2$ front. In this case the transient heating is of the order of

$\textrm {CO}_2$ front. In this case the transient heating is of the order of ![]() $0.25\,^{\circ }\textrm {C}$.

$0.25\,^{\circ }\textrm {C}$.

Figure 4. Example transient solutions, calculated using the reference fluid and reservoir properties (see table 1), for pressure, temperature, density and ![]() $\textrm {CO}_2$ fraction in the mobile fluid phase, plotted against the similarity variable

$\textrm {CO}_2$ fraction in the mobile fluid phase, plotted against the similarity variable ![]() $\eta$. Solutions are calculated for a cold injection with

$\eta$. Solutions are calculated for a cold injection with ![]() $T_w=25\,^{\circ }\textrm {C}$. The dotted and dashed lines in the top plot show the uncoupled and linearised pressure field solutions at 1 year. The positions of

$T_w=25\,^{\circ }\textrm {C}$. The dotted and dashed lines in the top plot show the uncoupled and linearised pressure field solutions at 1 year. The positions of ![]() $\eta _W(t)$ at the various times are marked by ‘x’. The positions of

$\eta _W(t)$ at the various times are marked by ‘x’. The positions of ![]() $\eta _T$,

$\eta _T$, ![]() $\eta _M$, and

$\eta _M$, and ![]() $\eta _C$ are marked by the vertical blue, orange and grey lines, respectively.

$\eta _C$ are marked by the vertical blue, orange and grey lines, respectively.