1. Introduction

Propeller and foil designers are familiar with the erosion, noise, performance reduction and accelerated fatigue associated with the formation and collapse of vaporous bubbles on hydrodynamic lifting surfaces, known as cavitation. Cavitation is a bi-directional phase change between liquid and vapour at a nearly constant temperature, driven by local pressure variations. Vaporous bubbles form when the local pressure drops to or slightly below the saturated vapour pressure, which is typically between 1.5 and 3 kPa. The formation of vapour depends on factors that influence the fluid's tensile strength, such as suspended particulates and nucleation sites. Ventilation, on the other hand, is a distinct phenomenon involving the transport of incondensable gas without significant phase change (Breslin & Skalak Reference Breslin and Skalak1959; Rothblum Reference Rothblum1977; Harwood, Young & Ceccio Reference Harwood, Young and Ceccio2016).

Although cavitation and ventilation are different phenomena, the two types of multiphase flow can interact. For example, Rothblum (Reference Rothblum1977) and Young et al. (Reference Young, Harwood, Montero, Ward and Ceccio2017) described how cavitation can induce ventilation. This is especially true on surface-piercing hydrofoils, where any large cavitation bubble presents a low-pressure and separated region of flow susceptible to air ingestion (Swales et al. Reference Swales, Wright, McGregor and Rothblum1974; Rothblum Reference Rothblum1977). Low pressure in a cavitation bubble also induces downward acceleration of the free surface; random interactions between Taylor instabilities at the free surface, waves, and vaporous vortices at the cavity trailing edge can generate aerated pathways through which air may be sucked suddenly into the low-pressure region of flow – a process termed flash ventilation (Wetzel Reference Wetzel1957). Cavitation and ventilation are both forms of separated multiphase flow, which can be characterized by a generalized cavitation number

which is the ratio of the difference between the local absolute total hydrostatic pressure ![]() $P$ and the cavity pressure

$P$ and the cavity pressure ![]() $P_c$, and the fluid dynamic pressure. For vaporous cavitation,

$P_c$, and the fluid dynamic pressure. For vaporous cavitation, ![]() $P_c$ is the vapour pressure. For ventilation,

$P_c$ is the vapour pressure. For ventilation, ![]() $P_c$ is the pressure of the non-condensable gas entrained into the flow, which is approximately 100 kPa for natural (atmospheric) ventilation.

$P_c$ is the pressure of the non-condensable gas entrained into the flow, which is approximately 100 kPa for natural (atmospheric) ventilation.

Both cavitation and ventilation affect lift-generating surfaces like propellers, hydrofoils and control surfaces that operate at high speeds and near the free surface, altering the hydrodynamic and structural responses. This is especially true for compliant lifting surfaces. Avoidance of unanticipated ventilation is especially important to prevent sudden reductions in lift and thrust, which can lead to a loss of vessel control, structural failure and potential for capsizing. On the other hand, controlled injection of non-condensible gas can be used to force a fully wetted or partially cavitating flow to transition to fully ventilated flow, for the purpose of reducing drag, minimizing cavity-induced load fluctuations, and preventing erosion by enveloping most of the body in a large, compressible gaseous cavity. Such a process is called artificial supercavitation or forced ventilation (Young et al. Reference Young, Harwood, Montero, Ward and Ceccio2017).

A great deal of research exists on the topics of cavitation and ventilation, focused primarily on the steady-state flows around rigid bodies. Recently, there has been growing interest in transient events such as vessel manoeuvres (e.g. foil pitching or vessel yawing), waves, and dynamic transitions between fully wetted, cavitating and fully ventilated flows, as well as the fluid–structure interaction (FSI) response and stability. A hydrofoil, which is typically a slender structure exposed to high loading, can experience large static deformations and significant vibratory responses to unsteady excitation (Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2019). The composite hydrofoils deployed in the America's Cup, for example, experience hydrofoil deflections large enough to be observed with the naked eye, particularly during sudden unloading caused by the transition from fully wetted to fully ventilated flows. Tailored hydroelastic designs have been proposed that use a foil's flexibility to delay cavitation and ventilation (Young et al. Reference Young, Harwood, Montero, Ward and Ceccio2017; Liao, Martins & Young Reference Liao, Martins and Young2021). However, doing so requires comprehensive knowledge of the effects of multiphase flow on the coupled fluid–structure dynamics. In addition, dynamic loading events can produce foil vibrations, noise and accelerated fatigue. Such unsteady loads can arise from periodic flows like vaporous or gaseous cavity shedding, single-phase vortex shedding, wave-induced oscillations, transitions between flow regimes or body oscillations and manoeuvres (Young et al. Reference Young, Chang, Smith, Venning, Pearce and Brandner2021). Less-organized, or broad-banded, flow excitation can also energize resonances of hydrofoils, producing large structural responses. Even more severe vibration results from lock-in between periodic flow structures and a system natural frequency, leading to reduced damping and dynamic load amplification. The system natural frequencies and damping of the lightweight bodies are affected by flow conditions such as submergence, speed, waves, cavitation and ventilation (Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). If dynamic instabilities such as flutter (zero or negative modal damping) are to be avoided, then the changes in the system modal response with flow conditions must be understood. The changes in modal response due to flow conditions can also cause the re-ordering of structural modes due to changes in directionally dependent fluid inertia effects, which can lead to frequency coalescence to cause dynamic load amplifications and even hydroelastic instability (Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020; Young et al. Reference Young, Wright, Yoon and Harwood2020).

Many foils operate at or near the free surface, so the effect of waves should also be considered. The presence of waves not only produces unsteady loading at the wave encounter frequency (with the associated structural dynamics and FSI), but also affects the dynamics of cavitation and ventilation and transition between flow regimes (McGregor et al. Reference McGregor, Wright, Swales and Crapper1973).

The focus of this work is on the influence of monochromatic non-breaking waves on the hydroelastic response of a surface-piercing hydrofoil in cavitating and ventilating flows. To this end, the specific objectives are to investigate how waves impact the inception and evolution of cavitation and ventilation, quantify the effects of waves upon the mean and dynamic hydrodynamic loads, and quantify the effects of waves, vaporous cavities and ventilated cavities upon the mean and dynamic hydroelastic response of the hydrofoil.

2. Literature review

We first review the hydrodynamic and hydroelastic response of a surface-piercing hydrofoil in calm water in § 2.1. The effect of waves on surface-piercing hydrofoil response will be discussed in § 2.2, and an overview of previous work on the hydrofoil of focus will be discussed in § 2.3

2.1. Hydrodynamic and hydroelastic response of surface-piercing hydrofoils

The fully wetted, partially ventilated and fully ventilated flow regimes, along with ventilation formation and elimination mechanisms and flow hysteresis, are reviewed in Part 1 (Young et al. Reference Young, Valles, Di Napoli, Miguel, Minerva and Harwood2023) and in Young et al. (Reference Young, Motley, Barber, Chae and Garg2016, Reference Young, Harwood, Montero, Ward and Ceccio2017). Subsubsection 2.1.1 contains an overview of only those new or altered flow regimes affecting cavitating flow, followed by a summary of cavity-induced ventilation mechanism and hysteresis response in § 2.1.2 and a brief description of additional hydroelastic implications in § 2.1.3.

2.1.1. Characteristic cavitating flow regimes

Cavitation of lifting surfaces scales with not only the vaporous cavitation number, but also the attack angle ![]() $\alpha$. The generalized cavitation parameter

$\alpha$. The generalized cavitation parameter

demonstrates an approximately inverse relationship with sectional cavity lengths (Franc & Michel Reference Franc and Michel2004).

(a) Fully wetted, base cavitating and/or base ventilated flows: the flow is fully wetted on the suction and pressure sides of the body. In the case of bodies with non-zero trailing edge (TE) thickness, a vaporous or gaseous cavity may develop in the separated region behind the TE, dubbed base cavitation or base ventilation, respectively. For streamlined foils, base cavitation/ventilation generally does not affect hydrodynamic performance. However, thicker foils may experience altered drag as a result of the constant cavity pressure acting over the TE surface (Young et al. Reference Young, Motley, Barber, Chae and Garg2016).

(b) Partially cavitating flows: when the local absolute pressure drops to or slightly below the saturated vapour pressure of the working fluid, a small vaporous cavity develops, which expands, collapses or convects downstream, depending on pressure and velocity variations. Partial cavitation is defined by a cavity whose length is shorter than the body length. Cyclic shedding of cavities in the partially cavitating regime can be driven by Kelvin–Helmholtz wave instabilities, re-entrant jets, and/or shockwave mechanisms (Brandner et al. Reference Brandner, Walker, Niekamp and Anderson2010; Ganesh, Mäkiharju & Ceccio Reference Ganesh, Mäkiharju and Ceccio2016; Young et al. Reference Young, Harwood, Montero, Ward and Ceccio2017, Reference Young, Chang, Smith, Venning, Pearce and Brandner2021; Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a,Reference Smith, Venning, Pearce, Young and Brandnerb), which yield different cavity shedding frequencies.

(c) Supercavitating flows: supercavitation occurs when the length of the cavity exceeds the body length. When the cavity collapses well past the body TE, the cavity stabilizes and is accompanied by substantial reductions in the mean lift, moment, drag and amplitude of flow-induced vibrations and noise.

2.1.2. Cavity-induced ventilation and hysteresis response

The presence of a vaporous cavity increases the likelihood of ventilation occurring because a vaporous cavity is a region of separated flow at very low pressure (typically 1.5–3 kPa). Both properties favour the development of ventilation if a path exists for air ingress. Even in partially cavitating flow, a thin layer of attached liquid flow exists at the free surface – termed a surface seal (Swales et al. Reference Swales, Wright, McGregor and Rothblum1974; Rothblum Reference Rothblum1980). This layer occurs where the constant pressure condition at the free surface causes the flow near the surface to remain attached to the suction surface of a surface-piercing foil. The relatively large kinetic energy of the liquid layer presents a barrier between the low-pressure region around the submerged body and the relatively high pressure at the free surface which, if breached, permits the ingress of air into the vaporous cavity beneath. Such breaches can occur through external perturbations, the growth of Taylor instabilities (Taylor Reference Taylor1950) at the free surface, or interactions with shed vaporous cavity bubbles rising towards the free surface. Previous works (Wadlin Reference Wadlin1958; Rothblum, Mayer & Wilburn Reference Rothblum, Mayer and Wilburn1969) have shown that the presence of a vaporous partial cavity can amplify Taylor instabilities, as an unstable partial cavity will generate significant vorticity in its wake.

It is well known that cavitation desinence occurs at higher values of the cavitation parameters (lower speed, higher operational depth, higher ambient pressure and/or lower angle of attack) than when cavitation first appears (inception), i.e. the behaviour is hysteretic (Katz Reference Katz1982). Transition from partial cavitation to fully ventilated flow further amplifies the hysteresis behaviour because ventilation persists to very small speeds and angles of attack before fully wetted flow is re-established (Harwood et al. Reference Harwood, Young and Ceccio2016). This nonlinearity associated with the foil operation, along with significant changes in the mean and dynamic load response, can pose a challenge in the control of cavitating and/or ventilated lifting bodies.

2.1.3. Hydroelastic response of surface-piercing hydrofoils

Surface-piercing foils are susceptible to changes in modal response and dynamic stability from flow conditions such as cavitation, ventilation, body motions or the presence of waves. Previous studies have shown that the natural frequencies of a lifting body are highly dependent on flow conditions that include submergence, the presence of ventilation or cavitation, and speed (Fu & Price Reference Fu and Price1987; Kramer, Liu & Young Reference Kramer, Liu and Young2013; Motley, Kramer & Young Reference Motley, Kramer and Young2013; Young et al. Reference Young, Motley, Barber, Chae and Garg2016, Reference Young, Harwood, Montero, Ward and Ceccio2017, Reference Young, Wright, Yoon and Harwood2020; Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). The hydroelastic response of a hydrofoil in fully wetted and ventilated flows is discussed in Part 1 of this paper series. To avoid redundancy, the following review is limited to the effects of cavitation on hydroelasticity and ventilation in calm water and waves.

Cavitation affects the hydroelastic response of a foil both directly and indirectly. The direct interaction occurs because vapour is nearly five orders of magnitude less dense than liquid water, hence the hydrodynamic added mass of the foil reduces with increasing extent of cavitation (Benaouicha & Astolfi Reference Benaouicha and Astolfi2012; Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). Cavitation also alters damping mechanisms and the hydrodynamic pseudo-stiffness (referred to in some works as the fluid disturbing force) (Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2019, Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). As a result, cavitation alters the modal response and can lead to hydroelastic instabilities such as static divergence, flutter and parametric resonance. Additionally, the presence of cavitation can promote ventilation, and unsteady cavity shedding can act as an oscillatory load, driving flow-induced vibration or lock-in (Akcabay & Young Reference Akcabay and Young2015; Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a).

2.2. The effect of waves on surface-piercing hydrofoils

As described in Part 1, the presence of waves can have profound effects on the character and stability of flow around a surface-piercing hydrofoil. This is especially true in cavitating conditions. To date, however, the literature that investigates the effects of simultaneous cavitation and ventilation addresses only calm-water conditions (Wadlin Reference Wadlin1958; Rothblum et al. Reference Rothblum, Mayer and Wilburn1969; Brizzolara & Young Reference Brizzolara and Young2012; Young & Brizzolara Reference Young and Brizzolara2013). McGregor et al. (Reference McGregor, Wright, Swales and Crapper1973) showed experimentally that wave-induced accelerations, in addition to the surface disturbances created by waves (wave breaking), both contributed to the ventilation of surface-piercing hydrofoils through the enhancement of Taylor instabilities at the free surface. Because Taylor instabilities are a principal mechanism in cavitation-induced ventilation mechanisms, the effect of waves upon cavitating flows is of significant interest. In addition to the oscillatory wave-induced forces and modulation of hydrofoil modal properties shown by Young et al. (Reference Young, Wright, Yoon and Harwood2020) and discussed in Part 1, orbital wave velocities and dynamic pressure variations must also affect the size and stability of vaporous cavities. The modulation in vaporous cavity size by waves will likewise modulate the effects of vaporous cavitation upon the hydrodynamic forces, the ventilation inception mechanisms, and the associated added mass, damping and hydrodynamic stiffness (Akcabay & Young Reference Akcabay and Young2014, Reference Akcabay and Young2015; Akcabay et al. Reference Akcabay, Chae, Young, Ducoin and Astolfi2014). The complex dynamic interactions between the unsteady multiphase flows, waves and structural response, however, have yet to be studied experimentally.

2.3. Previous experiments on the surface-piercing hydrofoil

Previous efforts that serve as the foundation for this study have been presented in Harwood et al. (Reference Harwood, Young and Ceccio2016, Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2019, Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020) and Young et al. (Reference Young, Garg, Brandner, Pearce, Butler, Clarke and Phillips2018, Reference Young, Wright, Yoon and Harwood2020). These prior tests were conducted in two different testing facilities: the Physical Model Basin at the Aaron Friedman Marine Hydrodynamics Laboratory at the University of Michigan (UM) in Michigan, USA, and the free surface variable pressure recirculating water channel (also called the free surface cavitation channel) at the Italian National Research Council – Institute of Marine Engineering (CNR INM) in Rome, Italy. All experiments concerned a vertical, yawed hydrofoil, piercing the free surface. The aims of previous studies were to examine: (1) ventilation formation and elimination mechanisms and boundaries in atmospheric and depressurized conditions in calm water; (2) variation of steady-state hydrodynamic load coefficients with angle of attack (![]() $\alpha$), submerged aspect ratio (

$\alpha$), submerged aspect ratio (![]() $AR_h=h/c$, with

$AR_h=h/c$, with ![]() $h$ the submerged depth and

$h$ the submerged depth and ![]() $c$ the foil chord), submerged-depth-based Froude number (

$c$ the foil chord), submerged-depth-based Froude number (![]() $F_{nh}=U/\sqrt {gh}$, with

$F_{nh}=U/\sqrt {gh}$, with ![]() $g$ the gravitational constant), and vaporous cavitation number, defined at the free surface (

$g$ the gravitational constant), and vaporous cavitation number, defined at the free surface (![]() $\sigma _v=(P_t-P_v)/(0.5\rho U^2)$, with

$\sigma _v=(P_t-P_v)/(0.5\rho U^2)$, with ![]() $P_t$ and

$P_t$ and ![]() $P_v$ the tunnel and vapour pressures, respectively); (3) the influence of foil flexibility on the hydrodynamic load coefficients and ventilation boundaries; (4) variation of the generalized fluid forces (added mass, damping and hydrodynamic stiffness / disturbing force) with operating conditions and the resultant changes in the system resonance frequencies and damping coefficients; and (5) the influence of waves on the steady-state and dynamic performance of the surface-piercing hydrofoil in an atmospheric towing tank.

$P_v$ the tunnel and vapour pressures, respectively); (3) the influence of foil flexibility on the hydrodynamic load coefficients and ventilation boundaries; (4) variation of the generalized fluid forces (added mass, damping and hydrodynamic stiffness / disturbing force) with operating conditions and the resultant changes in the system resonance frequencies and damping coefficients; and (5) the influence of waves on the steady-state and dynamic performance of the surface-piercing hydrofoil in an atmospheric towing tank.

In contrast, the focus of the new experiments in the Depressurized Wave Basin (DWB) at the Maritime Research Institute Netherlands (MARIN) are the effects of waves on the steady and dynamic response of the hydrofoil in the absence of cavitation (Part 1, through tests in atmospheric conditions) and with cavitation (Part 2, through tests in depressurized conditions). The hydrofoil has a rectangular planform and simple section geometry, with an ogival leading edge and a blunt trailing edge. The simple geometry enables a focus on physics and serves as a canonical representation of a typical control surface, rudder or hydrofoil. The studies presented in Part 1 in atmospheric pressure conditions showed that shallow monochromatic waves tended to delay ventilation in the absence of vaporous cavitation. The delay of FV flow is theorized to be caused by the disruption of a stable low-energy separation bubble on the suction side of the foil from wave-induced pressure and velocity variations.

3. Experimental set-up and analysis procedure

As with Part 1, this work describes experiments on a flexible surface-piercing hydrofoil conducted in the DWB at MARIN. Part 1 was limited to tests at atmospheric pressure. In this work, we expand upon those results by exploring the effects of waves on the cavitating and ventilating responses of the same hydrofoil under reduced ambient pressure. The following description is an abbreviated summary; a more comprehensive account of the experimental set-up may be found in Part 1.

The hydrofoil has a nominal chord of length ![]() $c=27.9$ cm, TE thickness

$c=27.9$ cm, TE thickness ![]() $\tau =2.79$ cm, and span

$\tau =2.79$ cm, and span ![]() $S=0.914$ m. The hydrofoil is oriented vertically, with the free tip piercing the surface of the water. The immersed span

$S=0.914$ m. The hydrofoil is oriented vertically, with the free tip piercing the surface of the water. The immersed span ![]() $h$ is varied by raising/lowering the carriage from which the foil is suspended, while a geared servo was used to yaw the hydrofoil, altering its angle of attack (

$h$ is varied by raising/lowering the carriage from which the foil is suspended, while a geared servo was used to yaw the hydrofoil, altering its angle of attack (![]() $\alpha$). The DWB is 240 m long by 18 m wide. The 240 m length allows for a sufficient time at constant velocity for dynamic measurements. The 18 m width ensures that there are little to no side wall effects. The water depth was set to be 8 m and is designed to study deep-water waves. The maximum steady-state speed of the towing carriage is

$\alpha$). The DWB is 240 m long by 18 m wide. The 240 m length allows for a sufficient time at constant velocity for dynamic measurements. The 18 m width ensures that there are little to no side wall effects. The water depth was set to be 8 m and is designed to study deep-water waves. The maximum steady-state speed of the towing carriage is ![]() $6.0\,{\rm m}\,{\rm s}^{-1}$ with uncertainty 0.061 %. The wave maker can generate waves with maximum height 0.4 m and period 3 s. The unique advantage of the DWB is that it allows testing at reduced pressure with free surface waves, unlike cavitation channels. By reducing the basin tunnel pressure (

$6.0\,{\rm m}\,{\rm s}^{-1}$ with uncertainty 0.061 %. The wave maker can generate waves with maximum height 0.4 m and period 3 s. The unique advantage of the DWB is that it allows testing at reduced pressure with free surface waves, unlike cavitation channels. By reducing the basin tunnel pressure (![]() $P_t$) below a standard atmosphere,

$P_t$) below a standard atmosphere, ![]() $P_t< P_{atm}$, the DWB allows control of the vaporous cavitation number, so that the hydrodynamics of cavitation may be scaled independently of the Froude number (Young et al. Reference Young, Motley, Barber, Chae and Garg2016, Reference Young, Harwood, Montero, Ward and Ceccio2017) over a range of carriage speeds, foil submergence, wave heights and wave periods. The internal pressure of the DWB that encloses the test article can be reduced to 29 mbar (verified using a Rosemount 3051 pressure transmitter with measurement range 4–800 mbar and uncertainty 0.02 %). All experiments were conducted remotely from the control room.

$P_t< P_{atm}$, the DWB allows control of the vaporous cavitation number, so that the hydrodynamics of cavitation may be scaled independently of the Froude number (Young et al. Reference Young, Motley, Barber, Chae and Garg2016, Reference Young, Harwood, Montero, Ward and Ceccio2017) over a range of carriage speeds, foil submergence, wave heights and wave periods. The internal pressure of the DWB that encloses the test article can be reduced to 29 mbar (verified using a Rosemount 3051 pressure transmitter with measurement range 4–800 mbar and uncertainty 0.02 %). All experiments were conducted remotely from the control room.

Both the atmospheric tests presented in Part 1 and the depressurized tests presented in Part 2 were conducted in the same test campaign at the end of January 2020. The atmospheric tests were conducted on Day 1 and are denoted with run identifiers of the format 1-![]() $xxxx$, where the last four digits signify the specific run number. The depressurized tests were conducted on Day 2 and are denoted by run identifiers of 2-

$xxxx$, where the last four digits signify the specific run number. The depressurized tests were conducted on Day 2 and are denoted by run identifiers of 2-![]() $xxxx$. The water temperature in the tank was an approximately constant 12

$xxxx$. The water temperature in the tank was an approximately constant 12 ![]() $^{\circ }$C, measured using a TR25 Modular RTD thermometer. The density, viscosity and vapour pressure of water were computed from the instantaneous measured temperature using water and steam properties according to IAPWS IF-97. The test set-up and procedure are identical to that of Part 1 except for the control of the tunnel pressure.

$^{\circ }$C, measured using a TR25 Modular RTD thermometer. The density, viscosity and vapour pressure of water were computed from the instantaneous measured temperature using water and steam properties according to IAPWS IF-97. The test set-up and procedure are identical to that of Part 1 except for the control of the tunnel pressure.

Two high-speed underwater cameras were used to observe the underwater response of the hydrofoil. A Photron Multi was used to observe the cavitation and ventilation patterns on the suction side of the hydrofoil. An IDT Os7 camera was placed aft of the hydrofoil to observe the trailing edge deflections. Both cameras acquired monochrome images at 500 frames per second (fps). In addition, Bradley BE HD10 cameras were used to acquire videos of the above-water surface patterns at rate 25 fps. The DAQ system was an HBM Quantum, with MX840B and MX411 modules and operated with Marin Measurement System software, and the sampling frequency was set to ![]() $F_s=4800$ Hz. Similar to Part 1, snapshots are shown only for the suction-side high-speed camera. The hydrofoil's fixed root was mounted on a six-degrees-of-freedom load cell (ATI Omega-190). The load cell possesses a calibrated range of 3.6 kN in lift and drag and 680 N m in all moments, with estimated uncertainty

$F_s=4800$ Hz. Similar to Part 1, snapshots are shown only for the suction-side high-speed camera. The hydrofoil's fixed root was mounted on a six-degrees-of-freedom load cell (ATI Omega-190). The load cell possesses a calibrated range of 3.6 kN in lift and drag and 680 N m in all moments, with estimated uncertainty ![]() ${\pm }2.6\,\%$ of the mean values. A kinematic shape-sensing spar, of the design described by Di Napoli & Harwood (Reference Di Napoli and Harwood2020), was inserted into a milled slot along the hydrofoil's mid-plane, providing measurements of the flexural and torsional deformations of the hydrofoil along its span. Readers should refer to Part 1 for details and images of the test set-up and analysis methods.

${\pm }2.6\,\%$ of the mean values. A kinematic shape-sensing spar, of the design described by Di Napoli & Harwood (Reference Di Napoli and Harwood2020), was inserted into a milled slot along the hydrofoil's mid-plane, providing measurements of the flexural and torsional deformations of the hydrofoil along its span. Readers should refer to Part 1 for details and images of the test set-up and analysis methods.

The flow conditions are characterized by the immersed aspect ratio (![]() $AR_h=h/c$), angle of attack (

$AR_h=h/c$), angle of attack (![]() $\alpha$), depth-based Froude number (

$\alpha$), depth-based Froude number (![]() $F_{nh}=U/\sqrt {gh}$, incident wave period (

$F_{nh}=U/\sqrt {gh}$, incident wave period (![]() $T_w=1/f_w$), incident wave amplitude (

$T_w=1/f_w$), incident wave amplitude (![]() $A_w$) and tunnel pressure (

$A_w$) and tunnel pressure (![]() $P_t$). The tunnel pressure was varied to yield specific free surface vaporous cavitation numbers, defined as

$P_t$). The tunnel pressure was varied to yield specific free surface vaporous cavitation numbers, defined as ![]() $\sigma _v=(P_t-P_v)/(0.5\rho U^2)$, where

$\sigma _v=(P_t-P_v)/(0.5\rho U^2)$, where ![]() $P_v$ is the saturated vapour pressure,

$P_v$ is the saturated vapour pressure, ![]() $\rho$ is the water density,

$\rho$ is the water density, ![]() $g$ is gravitational acceleration, and

$g$ is gravitational acceleration, and ![]() $U$ is the steady-state speed of the carriage.

$U$ is the steady-state speed of the carriage.

A summary of the test conditions, including the non-dimensional wavelength to immersion depth ratio (![]() $\lambda _w/h$), and incident wave amplitude to wavelength ratio (

$\lambda _w/h$), and incident wave amplitude to wavelength ratio (![]() $A_w/\lambda _w$), as well as wavelength to chord ratio (

$A_w/\lambda _w$), as well as wavelength to chord ratio (![]() $\lambda _w/c$), is given in table 1. Note that only one yaw angle,

$\lambda _w/c$), is given in table 1. Note that only one yaw angle, ![]() $\alpha =5^{\circ }$, was used, as the yaw angle has to be set manually in the current set-up, and could not be changed without opening up the DWB once in depressurized condition.

$\alpha =5^{\circ }$, was used, as the yaw angle has to be set manually in the current set-up, and could not be changed without opening up the DWB once in depressurized condition.

Table 1. Test matrix of the 2020 experiments conducted in the DWB at MARIN at depressurized conditions on Day 2: ![]() $P_t=2.92\unicode{x2013}26.57$ kPa or

$P_t=2.92\unicode{x2013}26.57$ kPa or ![]() $\sigma _v=0.1\unicode{x2013}1.5$.

$\sigma _v=0.1\unicode{x2013}1.5$.

3.1. Test and analysis procedure

The test procedure for cavitating conditions is similar to that in Part 1. The difference lies in the tunnel pressure control. The depressurized runs began with cases with the lowest tunnel pressure ![]() $P_t= 2.92$ kPa. At each tunnel pressure setting, the lowest-speed runs were conducted first in calm water, then in waves, and finally followed by runs at higher speeds. The influence of linear acceleration and deceleration rates in the range 0.10–0.45 m s

$P_t= 2.92$ kPa. At each tunnel pressure setting, the lowest-speed runs were conducted first in calm water, then in waves, and finally followed by runs at higher speeds. The influence of linear acceleration and deceleration rates in the range 0.10–0.45 m s![]() $^{-2}$ were examined, and the results were found to be independent of acceleration rate for accelerations faster than or equal to 0.3 m s

$^{-2}$ were examined, and the results were found to be independent of acceleration rate for accelerations faster than or equal to 0.3 m s![]() $^{-2}$. To limit the length of this paper, the results shown correspond to cases with acceleration and deceleration rates equal to or higher than 0.3 m s

$^{-2}$. To limit the length of this paper, the results shown correspond to cases with acceleration and deceleration rates equal to or higher than 0.3 m s![]() $^{-2}$. Since the length of the DWB is fixed, the steady-speed (SS) time is limited to approximately 55 s for

$^{-2}$. Since the length of the DWB is fixed, the steady-speed (SS) time is limited to approximately 55 s for ![]() $AR_h=1$ and

$AR_h=1$ and ![]() $F_{nh}=1.5$ (

$F_{nh}=1.5$ (![]() $U=2.48\, {\rm m}\,{\rm s}^{-1}$), 33 s for

$U=2.48\, {\rm m}\,{\rm s}^{-1}$), 33 s for ![]() $AR_h=2$ and

$AR_h=2$ and ![]() $F_{nh}=1.5$ (

$F_{nh}=1.5$ (![]() $U=3.51\, {\rm m}\,{\rm s}^{-1}$), and 15 s for

$U=3.51\, {\rm m}\,{\rm s}^{-1}$), and 15 s for ![]() $AR_h=1$ and

$AR_h=1$ and ![]() $F_{nh}=3.0$ (

$F_{nh}=3.0$ (![]() $U=4.96\, {\rm m}\,{\rm s}^{-1}$). Each run was carried out by first zeroing out all signals and then starting the measurements when the carriage was at zero speed; measurements were stopped after the carriage came to a halt. This procedure allowed corrections for intra-run drift in signals. Additional details about run set-up and procedure, including wave sensor and calibration, can be found in Part 1.

$U=4.96\, {\rm m}\,{\rm s}^{-1}$). Each run was carried out by first zeroing out all signals and then starting the measurements when the carriage was at zero speed; measurements were stopped after the carriage came to a halt. This procedure allowed corrections for intra-run drift in signals. Additional details about run set-up and procedure, including wave sensor and calibration, can be found in Part 1.

In the analysis of the results, the raw time histories of the hydrodynamic loads and deformations from the start to the stop of the carriage are decomposed into a slowly moving mean component and a fluctuating component. The ‘movmean’ algorithm in Matlab was used with a 1 s sliding window for cases without waves, and with a sliding window equal in duration to four encounter periods (![]() $4 T_e$) for cases with waves, to find the moving mean, which is then subtracted from the raw signal to get the dynamic fluctuations. Here,

$4 T_e$) for cases with waves, to find the moving mean, which is then subtracted from the raw signal to get the dynamic fluctuations. Here, ![]() $T_e=1/f_e$ is the wave encounter period defined based on the steady-state speed

$T_e=1/f_e$ is the wave encounter period defined based on the steady-state speed ![]() $U$,

$U$, ![]() $f_e={\tfrac {1}{2} {\rm \pi}}\{\omega _w+{{\omega _w^2U}/{g}}\}$ is the wave encounter frequency, and

$f_e={\tfrac {1}{2} {\rm \pi}}\{\omega _w+{{\omega _w^2U}/{g}}\}$ is the wave encounter frequency, and ![]() $\omega _w=2{\rm \pi} /T_w$ is the incident wave period.

$\omega _w=2{\rm \pi} /T_w$ is the incident wave period.

As noted in Part 1, the ‘pwelch’ algorithm in Matlab was used to determine Welch's power spectral density (PSD) estimate, where the number of fast Fourier transform (FFT) points was selected to yield minimum frequency resolution 0.5 Hz, and the minimum window length was set to 2 s. The length of the FFT was set to be two-thirds of the window length. The PSD plots shown in subsequent sections correspond to the full test duration, from start to stop of the carriage, for each run, as a negligible difference was observed when compared to the PSD for the SS region only. To illustrate transient events (such as transition from fully wetted to partially cavitating to fully ventilated flows), the time–frequency spectra are obtained using the wavelet synchrosqueezed transform (WSST) via Matlab, which is based on the work of Thakur et al. (Reference Thakur, Brevdo, Fučkar and Wu2013). To understand the source of the various frequency peaks, the location of the carriage surge mode frequency (![]() $\,f_{car}=18$ Hz), hydrofoil modal frequencies (given in Part 1), vortex shedding frequency (

$\,f_{car}=18$ Hz), hydrofoil modal frequencies (given in Part 1), vortex shedding frequency (![]() $\,f_{vs}=0.265 U/ \tau$ based on Strouhal's law, with

$\,f_{vs}=0.265 U/ \tau$ based on Strouhal's law, with ![]() $\tau =0.1c$ as the foil TE thickness) and wave encounter frequency (

$\tau =0.1c$ as the foil TE thickness) and wave encounter frequency (![]() $\,f_e$) are indicated in the PSD and WSST plots.

$\,f_e$) are indicated in the PSD and WSST plots.

3.2. Fluid–structure co-analysis

The method used to assess the FSI of the flexible hydrofoil is the same as that reported in Part 1 of this paper, to which the reader is referred for a more detailed description. Deformations from the kinematic shape-sensing spars (in bending and torsion) were extracted interactively during the steady-state portions of each trial, and processed using the covariance-based stochastic subspace identification (SSI) algorithm (Akaike Reference Akaike1974; Aoki Reference Aoki1987; Peeters & De Roeck Reference Peeters and De Roeck1999). The SSI algorithm approximates the set of all cross-power spectral densities by a linear model with a user-defined order. The output of the SSI algorithm is a set of complex poles and estimated mode shapes. In parallel, high-speed video recordings were processed using the spectral proper orthogonal decomposition (SPOD) toolbox published by Schmidt et al. (Reference Schmidt, Towne, Rigas, Colonius and Bres2018) and applied successfully to visualize cavity shedding patterns on a flexible hydrofoil by Smith et al. (Reference Smith, Venning, Pearce, Young and Brandner2020a,Reference Smith, Venning, Pearce, Young and Brandnerb). SPOD produces a set of orthogonal complex modes at each discrete frequency, ensuring that every mode is spatio-temporally orthogonal. In this work, only the single most energetic SPOD mode was retained at each frequency and visualized by its real part at phase angle zero.

From the complex poles fitted by the SSI algorithm were estimated damped and undamped frequencies, as well as estimated damping ratios. Videographic SPOD modes were extracted at the frequencies most closely matching the identified damped frequencies from SSI. In this fluid–structure co-analysis framework, videographic data were used to visualize cyclic features of the observed flow field that occurred synchronously with structural vibration.

Because SSI is an output-only parameter estimation method, it should be noted that peaks in the hydrodynamic excitation spectra will produce peaks in the output spectra that will be fitted as modes. For the same reason, mode shapes associated with each SSI pole are more correctly termed operational deflection shapes (ODS) and may contain a mixture of deflection patterns from other nearby modes or forced vibration responses.

4. Steady-state hydrodynamic response

The focus of this section is on the steady-state hydrodynamic response of the surface-piercing hydrofoil. From here on, the acronyms FW, PC and FV are used to denote fully wetted, partially cavitating and fully ventilated flows, respectively. The variation of the FW and FV mean load coefficients (lift ![]() $C_L$, moment

$C_L$, moment ![]() $C_M$ and drag

$C_M$ and drag ![]() $C_D$ coefficients, as defined in (4.1)) with the angle of attack (

$C_D$ coefficients, as defined in (4.1)) with the angle of attack (![]() $\alpha$), Froude number (

$\alpha$), Froude number (![]() $F_{nh}$) and submerged aspect ratio (

$F_{nh}$) and submerged aspect ratio (![]() $AR_h$) are shown in Part 1, which focused on tests conducted in atmospheric conditions (

$AR_h$) are shown in Part 1, which focused on tests conducted in atmospheric conditions (![]() $P_t=P_{atm}$):

$P_t=P_{atm}$):

\begin{equation} \left. \begin{aligned} C_L & =\frac{L}{\rho U^2 A/2}, \\ C_D & =\frac{D}{\rho U^2 A/2}, \\ C_M & =\frac{M}{\rho U^2 A c^2/2}. \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} C_L & =\frac{L}{\rho U^2 A/2}, \\ C_D & =\frac{D}{\rho U^2 A/2}, \\ C_M & =\frac{M}{\rho U^2 A c^2/2}. \end{aligned} \right\} \end{equation}

Here, ![]() $L$,

$L$, ![]() $D$ and

$D$ and ![]() $M$ are respectively the lift, drag and moment, and

$M$ are respectively the lift, drag and moment, and ![]() $A=ch$ is the submerged planform area. All the hydrodynamic load coefficients are defined about the mid-chord at the root (fixed end) of the hydrofoil. All are non-dimensionalized using the average of the measured speed in the SS region,

$A=ch$ is the submerged planform area. All the hydrodynamic load coefficients are defined about the mid-chord at the root (fixed end) of the hydrofoil. All are non-dimensionalized using the average of the measured speed in the SS region, ![]() $U$.

$U$.

The results from Part 1 showed that the load coefficients in FW and FV flow follow different curves when plotted against ![]() $\alpha$. The FV

$\alpha$. The FV ![]() $C_L$ and

$C_L$ and ![]() $C_M$ are only slightly lower than the FW values for cases with low

$C_M$ are only slightly lower than the FW values for cases with low ![]() $F_{nh}$, but significantly lower for cases with high

$F_{nh}$, but significantly lower for cases with high ![]() $F_{nh}$. In the FW regime,

$F_{nh}$. In the FW regime, ![]() $C_L$ and

$C_L$ and ![]() $C_M$ are independent of

$C_M$ are independent of ![]() $F_{nh}$, but FV values of

$F_{nh}$, but FV values of ![]() $C_L$ and

$C_L$ and ![]() $C_M$ decrease with increasing

$C_M$ decrease with increasing ![]() $F_{nh}$ due to a reduction in effective camber caused by the FV cavity (Breslin & Skalak Reference Breslin and Skalak1959). Hence the sudden load drop that accompanies the transition from FW to FV flow is much more significant for cases with high

$F_{nh}$ due to a reduction in effective camber caused by the FV cavity (Breslin & Skalak Reference Breslin and Skalak1959). Hence the sudden load drop that accompanies the transition from FW to FV flow is much more significant for cases with high ![]() $F_{nh}$. The coefficient

$F_{nh}$. The coefficient ![]() $C_M$ is much more sensitive to transition between flow regimes than

$C_M$ is much more sensitive to transition between flow regimes than ![]() $C_L$ because

$C_L$ because ![]() $C_M$ depends on the centre of pressure, which moves from near the quarter-chord to towards the mid-chord when flow separation or ventilation develops. The FV

$C_M$ depends on the centre of pressure, which moves from near the quarter-chord to towards the mid-chord when flow separation or ventilation develops. The FV ![]() $C_D$ can be lower or higher than the FW values because of competition between frictional, lift-induced, pressure, wave and spray drag components. All load coefficients increase with increasing

$C_D$ can be lower or higher than the FW values because of competition between frictional, lift-induced, pressure, wave and spray drag components. All load coefficients increase with increasing ![]() $AR_h$ because of a reduction in three-dimensional effects. Transition to FV flow occurred at lower

$AR_h$ because of a reduction in three-dimensional effects. Transition to FV flow occurred at lower ![]() $\alpha$ for cases with higher

$\alpha$ for cases with higher ![]() $AR_h$ and higher

$AR_h$ and higher ![]() $F_{nh}$ because of higher lift and a more significant depression in the free surface, which reduces the distance between the high-pressure gas at the free surface and the low-pressure separated flow on the foil's suction surface. The presence of long-period and small-amplitude regular waves led to oscillations about the mean load coefficients but did not affect the mean load coefficients themselves for cases sufficiently far away from the ventilation boundary. Very near the ventilation boundary, shallow waves tended to delay the transition from FW to FV flow. The flow regime was susceptible to random perturbations near the ventilation boundary, where runs in identical flow conditions can bifurcate into either FW or FV flow regimes with tiny changes in initial conditions.

$F_{nh}$ because of higher lift and a more significant depression in the free surface, which reduces the distance between the high-pressure gas at the free surface and the low-pressure separated flow on the foil's suction surface. The presence of long-period and small-amplitude regular waves led to oscillations about the mean load coefficients but did not affect the mean load coefficients themselves for cases sufficiently far away from the ventilation boundary. Very near the ventilation boundary, shallow waves tended to delay the transition from FW to FV flow. The flow regime was susceptible to random perturbations near the ventilation boundary, where runs in identical flow conditions can bifurcate into either FW or FV flow regimes with tiny changes in initial conditions.

The above summary of the hydrodynamic performance of the hydrofoil provides the basis to analyse the performance of the hydrofoil in depressurized conditions (![]() $P_t< P_{atm}$). Experimental data collected across all three facilities (UM, CNR and MARIN) are shown in figure 1. The results are plotted against the cavitation parameter defined at mid-submerged-span

$P_t< P_{atm}$). Experimental data collected across all three facilities (UM, CNR and MARIN) are shown in figure 1. The results are plotted against the cavitation parameter defined at mid-submerged-span ![]() $\sigma _c$:

$\sigma _c$:

where ![]() $P=P_t+0.5\rho gh$ is the absolute total hydrostatic pressure at the mid-submerged-span,

$P=P_t+0.5\rho gh$ is the absolute total hydrostatic pressure at the mid-submerged-span, ![]() $h/2$. Here,

$h/2$. Here, ![]() $P_t$ is the tunnel pressure and

$P_t$ is the tunnel pressure and ![]() $P_c$ is the cavity pressure, which is equal to the vapour pressure in PC conditions (

$P_c$ is the cavity pressure, which is equal to the vapour pressure in PC conditions (![]() $P_c=P_v$), and is equal to the atmospheric pressure in ventilated conditions (

$P_c=P_v$), and is equal to the atmospheric pressure in ventilated conditions (![]() $P_c=P_{atm}$). Also,

$P_c=P_{atm}$). Also, ![]() $\sigma _v= {(P_t-P_v)/(0.5\rho U^2)}$ is the vapour-pressure-based cavitation number, which is equal to zero in ventilated conditions.

$\sigma _v= {(P_t-P_v)/(0.5\rho U^2)}$ is the vapour-pressure-based cavitation number, which is equal to zero in ventilated conditions.

Figure 1. Influence of attack angle ![]() $\alpha$, depth-based Froude number

$\alpha$, depth-based Froude number ![]() $F_{nh}$ and generalized cavitation number

$F_{nh}$ and generalized cavitation number ![]() $\sigma _c = \sigma _v + 1/F_{nh}^2$ on (a) the measured mean lift coefficient

$\sigma _c = \sigma _v + 1/F_{nh}^2$ on (a) the measured mean lift coefficient ![]() $C_L$, and (b) the moment coefficient

$C_L$, and (b) the moment coefficient ![]() $C_M$, for

$C_M$, for ![]() $AR_h = 1$. Data from UM and CNR are aggregated and plotted as squares and crosses. MARIN data (calm water and waves) are plotted as circles and plus symbols. Semi-empirical predictions from Damley-Strnad et al. (Reference Damley-Strnad, Harwood and Young2019) are shown as dashed lines for

$AR_h = 1$. Data from UM and CNR are aggregated and plotted as squares and crosses. MARIN data (calm water and waves) are plotted as circles and plus symbols. Semi-empirical predictions from Damley-Strnad et al. (Reference Damley-Strnad, Harwood and Young2019) are shown as dashed lines for ![]() $F_{nh}=1.5$ and dotted lines for

$F_{nh}=1.5$ and dotted lines for ![]() $F_{nh}=3.0$. Angles of attack are differentiated by colour. For each angle of attack, the flow regimes move from predominantly FW at large values of

$F_{nh}=3.0$. Angles of attack are differentiated by colour. For each angle of attack, the flow regimes move from predominantly FW at large values of ![]() $\sigma _c$ to predominantly FV at small values of

$\sigma _c$ to predominantly FV at small values of ![]() $\sigma _c$, with PC flows occupying the middle of the

$\sigma _c$, with PC flows occupying the middle of the ![]() $x$-axis. FV flows at large values of

$x$-axis. FV flows at large values of ![]() $\sigma _c$ correspond to cases where ventilation was forced via air injection near the foil leading edge (Harwood et al. Reference Harwood, Young and Ceccio2016). Decreasing values of

$\sigma _c$ correspond to cases where ventilation was forced via air injection near the foil leading edge (Harwood et al. Reference Harwood, Young and Ceccio2016). Decreasing values of ![]() $\sigma _c$ tend to produce slight local increases in load coefficients, indicative of transition to PC flow. Sharp drops follow these in load coefficients that signal transition to FV flow. Increasing angles of attack produce much larger hydrodynamic loads, but they also cause transition at higher values of

$\sigma _c$ tend to produce slight local increases in load coefficients, indicative of transition to PC flow. Sharp drops follow these in load coefficients that signal transition to FV flow. Increasing angles of attack produce much larger hydrodynamic loads, but they also cause transition at higher values of ![]() $\sigma _c$. Changes in

$\sigma _c$. Changes in ![]() $F_{nh}$ alone are predicted by the semi-empirical model to have a weaker effect upon both load coefficients and flow regime, typically appearing only at the left-hand extent of the PC data points, where variations in

$F_{nh}$ alone are predicted by the semi-empirical model to have a weaker effect upon both load coefficients and flow regime, typically appearing only at the left-hand extent of the PC data points, where variations in ![]() $\sigma _v$ are most impactful.

$\sigma _v$ are most impactful.

The influences of ![]() $\alpha$,

$\alpha$, ![]() $F_{nh}$ and

$F_{nh}$ and ![]() $\sigma _c$ on the mean lift and moment coefficients at

$\sigma _c$ on the mean lift and moment coefficients at ![]() $AR_h = 1$ are presented in figure 1. All the symbols indicate experimental data. For all the cases where the flow regime remains the same in the SS region, the mean load coefficients are obtained by taking the average of the measured values in the SS region for each run. There were several cases where the flow transitioned from either FW or PC flow to FV flow during the SS region; for those cases, only the FV portion of the time history was used. The lines in figure 1 indicate predictions based on modified semi-empirical relations presented in Damley-Strnad, Harwood & Young (Reference Damley-Strnad, Harwood and Young2019). This paper focuses on the experimental analysis, and the model predictions are provided only to clarify trends where constraints on facility time and cost limited the number of trials.

$AR_h = 1$ are presented in figure 1. All the symbols indicate experimental data. For all the cases where the flow regime remains the same in the SS region, the mean load coefficients are obtained by taking the average of the measured values in the SS region for each run. There were several cases where the flow transitioned from either FW or PC flow to FV flow during the SS region; for those cases, only the FV portion of the time history was used. The lines in figure 1 indicate predictions based on modified semi-empirical relations presented in Damley-Strnad, Harwood & Young (Reference Damley-Strnad, Harwood and Young2019). This paper focuses on the experimental analysis, and the model predictions are provided only to clarify trends where constraints on facility time and cost limited the number of trials.

In figure 1, the open and filled squares indicate measured FW and FV values, and crosses indicate PC values, collected from UM and CNR. The plus signs indicate PC values, collected from MARIN from both calm water and wave runs. The black, blue and red symbols (and lines) correspond to measured (and predicted) values for ![]() $\alpha =5^{\circ }$,

$\alpha =5^{\circ }$, ![]() $7^{\circ }$ and

$7^{\circ }$ and ![]() $12^{\circ }$, respectively. The dashed lines correspond to predictions for

$12^{\circ }$, respectively. The dashed lines correspond to predictions for ![]() $F_{nh}=1.5$, and dotted lines for

$F_{nh}=1.5$, and dotted lines for ![]() $F_{nh}=3.0$. The FV results in the high

$F_{nh}=3.0$. The FV results in the high ![]() $\sigma _c$ range correspond to cases with forced ventilation via air injection near the foil leading edge – a technique described in detail by Harwood et al. (Reference Harwood, Young and Ceccio2016). As shown in figure 1, as

$\sigma _c$ range correspond to cases with forced ventilation via air injection near the foil leading edge – a technique described in detail by Harwood et al. (Reference Harwood, Young and Ceccio2016). As shown in figure 1, as ![]() $\alpha$ or

$\alpha$ or ![]() $F_{nh}$ increases, cavitation and ventilation inception occur earlier, i.e. at a higher

$F_{nh}$ increases, cavitation and ventilation inception occur earlier, i.e. at a higher ![]() $\sigma _c$. As

$\sigma _c$. As ![]() $\sigma _c$ decreases, the flow first transitions from FW to PC flow. The PC flow grows in size with further reduction in

$\sigma _c$ decreases, the flow first transitions from FW to PC flow. The PC flow grows in size with further reduction in ![]() $\sigma _c$, which leads to a local increase in load coefficients caused by an increase in the virtual camber effect created by the PC leading edge. Further reduction in

$\sigma _c$, which leads to a local increase in load coefficients caused by an increase in the virtual camber effect created by the PC leading edge. Further reduction in ![]() $\sigma _c$ leads to a large loading reduction because the flow transitions from PC to FV. As

$\sigma _c$ leads to a large loading reduction because the flow transitions from PC to FV. As ![]() $F_{nh}$ increases, the transition from PC to FV occurs earlier, i.e. at a higher

$F_{nh}$ increases, the transition from PC to FV occurs earlier, i.e. at a higher ![]() $\sigma _c$. The drop in the load coefficient is steeper because the FV values are lower for higher

$\sigma _c$. The drop in the load coefficient is steeper because the FV values are lower for higher ![]() $F_{nh}$ due to a drop in effective camber caused by a curvature in the FV cavity (Breslin & Skalak Reference Breslin and Skalak1959; Harwood et al. Reference Harwood, Young and Ceccio2016). Note that once the flow is ventilated (naturally or by air injection),

$F_{nh}$ due to a drop in effective camber caused by a curvature in the FV cavity (Breslin & Skalak Reference Breslin and Skalak1959; Harwood et al. Reference Harwood, Young and Ceccio2016). Note that once the flow is ventilated (naturally or by air injection), ![]() $\sigma _v = 0$ as

$\sigma _v = 0$ as ![]() $P_c = P_{atm}$,

$P_c = P_{atm}$, ![]() $\sigma _c = 1/F_{nh}^2$ and the load coefficients fall to match the predicted FV line for the given

$\sigma _c = 1/F_{nh}^2$ and the load coefficients fall to match the predicted FV line for the given ![]() $F_{nh}$. The FV load coefficients are lower with higher

$F_{nh}$. The FV load coefficients are lower with higher ![]() $F_{nh}$ because

$F_{nh}$ because ![]() $\sigma _c = 1/F_{nh}^2$. Reasonable agreement is observed between predictions and measurements, although there remains a fair amount of variability in the measured data.

$\sigma _c = 1/F_{nh}^2$. Reasonable agreement is observed between predictions and measurements, although there remains a fair amount of variability in the measured data.

5. Dynamic hydrodynamic and structural responses

The focus of this section is on the effect of waves on the dynamic hydroelastic response of the hydrofoil in cavitating and ventilating flows. All the results are obtained from tests in depressurized conditions.

To study systematically the interplay of the various parameters, dynamic results are presented in the following subsections. The influence of ![]() $\sigma _v$ and waves at

$\sigma _v$ and waves at ![]() $AR_h = 1$,

$AR_h = 1$, ![]() $F_{nh} = 3.0$ is shown in § 5.1, and

$F_{nh} = 3.0$ is shown in § 5.1, and ![]() $AR_h = 2$,

$AR_h = 2$, ![]() $F_{nh} = 1.5$ in § 5.2. For

$F_{nh} = 1.5$ in § 5.2. For ![]() $AR_h=2$,

$AR_h=2$, ![]() $F_{nh}$ was limited to 1.5 to avoid overloading the foil. A comparison of the results in these two subsections showcases the effect of

$F_{nh}$ was limited to 1.5 to avoid overloading the foil. A comparison of the results in these two subsections showcases the effect of ![]() $AR_h$. Section 5.3 illustrates the influence of wave steepness ratio at

$AR_h$. Section 5.3 illustrates the influence of wave steepness ratio at ![]() $AR_h=1$,

$AR_h=1$, ![]() $F_{nh}=3.5$ by varying the wave amplitude with a fixed wave period of

$F_{nh}=3.5$ by varying the wave amplitude with a fixed wave period of ![]() $T_w=1.5$ s. All the results shown here are for

$T_w=1.5$ s. All the results shown here are for ![]() $\alpha = 5^{\circ }$.

$\alpha = 5^{\circ }$.

5.1. Influence of  $\sigma _v$ and waves with small immersed aspect ratio

$\sigma _v$ and waves with small immersed aspect ratio

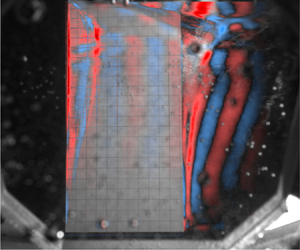

The underwater views of the cavitation pattern on the suction side of the foil are shown in figure 2 for ![]() $\sigma _v = 0.13$ and

$\sigma _v = 0.13$ and ![]() $0.29$, in calm water (CW) and waves, with

$0.29$, in calm water (CW) and waves, with ![]() $T_w = 1.5$ s,

$T_w = 1.5$ s, ![]() $A_w = 0.05$ m,

$A_w = 0.05$ m, ![]() $\alpha = 5^{\circ }$,

$\alpha = 5^{\circ }$, ![]() $AR_h = 1$ and

$AR_h = 1$ and ![]() $F_{nh} = 3.0$.

$F_{nh} = 3.0$.

Figure 2. Underwater views of the cavitation pattern on the suction side of the foil for (a,c) ![]() $\sigma _v = 0.13$, and (b,d)

$\sigma _v = 0.13$, and (b,d) ![]() $\sigma _v = 0.29$, in (a,b) calm water (CW) and (c,d) waves with

$\sigma _v = 0.29$, in (a,b) calm water (CW) and (c,d) waves with ![]() $T_w = 1.5$ s,

$T_w = 1.5$ s, ![]() $A_w = 0.05$ m; here,

$A_w = 0.05$ m; here, ![]() $\alpha = 5^{\circ }$,

$\alpha = 5^{\circ }$, ![]() $AR_h = 1$ and

$AR_h = 1$ and ![]() $F_{nh} = 3.0$. For

$F_{nh} = 3.0$. For ![]() $\sigma _v = 0.13$, the flow is PC in CW and FV in waves. For

$\sigma _v = 0.13$, the flow is PC in CW and FV in waves. For ![]() $\sigma _v = 0.29$, both CW and wave runs are PC. Two snapshots, one at the wave crest and one at the wave trough, are shown for the wave cases in (c,d). The presence of waves causes the larger cavity to transition to FV flow, while the smaller cavity remains in the PC flow regime. In CW, the PC flow is larger for

$\sigma _v = 0.29$, both CW and wave runs are PC. Two snapshots, one at the wave crest and one at the wave trough, are shown for the wave cases in (c,d). The presence of waves causes the larger cavity to transition to FV flow, while the smaller cavity remains in the PC flow regime. In CW, the PC flow is larger for ![]() $\sigma _v = 0.13$ in run 2-1001 than for

$\sigma _v = 0.13$ in run 2-1001 than for ![]() $\sigma _v = 0.29$ in run 2-4601. At

$\sigma _v = 0.29$ in run 2-4601. At ![]() $\sigma _v=0.13$, the turbulent, vortical flow at the cavity TE is nearer to the free surface, reducing the separation between the high-pressure gas at the free surface and the top boundary of the low-pressure PC flow. Consequently, waves tend to accelerate the transition to FV flow in the presence of a large vaporous PC flow, shown in (c), while a small PC flow can be stable in waves, such as shown in (d). Run identifiers are (a) 2-1001, (b) 2-4601, (c) 2-1201, and (d) 2-4801.

$\sigma _v=0.13$, the turbulent, vortical flow at the cavity TE is nearer to the free surface, reducing the separation between the high-pressure gas at the free surface and the top boundary of the low-pressure PC flow. Consequently, waves tend to accelerate the transition to FV flow in the presence of a large vaporous PC flow, shown in (c), while a small PC flow can be stable in waves, such as shown in (d). Run identifiers are (a) 2-1001, (b) 2-4601, (c) 2-1201, and (d) 2-4801.

A relatively large vaporous partial cavity is present for ![]() $\sigma _v=0.13$. The cavity, which reaches length approximately

$\sigma _v=0.13$. The cavity, which reaches length approximately ![]() $L_c=0.85c$ near the mid-span, remains stable in CW, but transitions to FV flow in waves, as shown by comparing figures 2(a,c). For the CW case, the vaporous cavity has an asymmetric convex planform with cavity lengths that approach zero at the free surface and free tip because of the zero loading conditions at both sections. The cavity is relatively thin because of the sharp leading edge, which produces a well-defined detachment point. Liquid re-entrant jets form along the cavity closure line, with velocity vectors reflected about the local cavity closure line angle (see De Lange & De Bruin Reference De Lange and De Bruin1998; Laberteaux & Ceccio Reference Laberteaux and Ceccio2001; Harwood et al. Reference Harwood, Young and Ceccio2016; Young et al. Reference Young, Harwood, Montero, Ward and Ceccio2017). The tight curvature of the cavity closure line at the point of maximum length causes the re-entrant jets just above and just below to collide, which prevents the re-entrant jets from reaching the leading edge to cause complete cavity shedding. As a result, the upstream portion of the sheet cavity has a glassy surface, and only partial shedding near the cavity TE is observed. The resulting load fluctuations and deformations at the dominant cavity shedding frequency are weak. During deceleration, flow transitions back from PC to FW flow in CW, and from FV to FW in waves.

$L_c=0.85c$ near the mid-span, remains stable in CW, but transitions to FV flow in waves, as shown by comparing figures 2(a,c). For the CW case, the vaporous cavity has an asymmetric convex planform with cavity lengths that approach zero at the free surface and free tip because of the zero loading conditions at both sections. The cavity is relatively thin because of the sharp leading edge, which produces a well-defined detachment point. Liquid re-entrant jets form along the cavity closure line, with velocity vectors reflected about the local cavity closure line angle (see De Lange & De Bruin Reference De Lange and De Bruin1998; Laberteaux & Ceccio Reference Laberteaux and Ceccio2001; Harwood et al. Reference Harwood, Young and Ceccio2016; Young et al. Reference Young, Harwood, Montero, Ward and Ceccio2017). The tight curvature of the cavity closure line at the point of maximum length causes the re-entrant jets just above and just below to collide, which prevents the re-entrant jets from reaching the leading edge to cause complete cavity shedding. As a result, the upstream portion of the sheet cavity has a glassy surface, and only partial shedding near the cavity TE is observed. The resulting load fluctuations and deformations at the dominant cavity shedding frequency are weak. During deceleration, flow transitions back from PC to FW flow in CW, and from FV to FW in waves.

For cases in waves, shown in figure 2(c), a chance encounter of the upper boundary of the partial cavity with a wave trough produced a rapid transition to FV flow. As noted in McGregor et al. (Reference McGregor, Wright, Swales and Crapper1973), the downward acceleration of the free surface on wave backs enhances the growth of Taylor instabilities at the free surface, compromising the integrity of the surface seal. Hence waves tend to accelerate the transition from PC to FV flow. Once FV, the suction side is open to the free surface, and the foil leading edge becomes the stagnation point; a sizeable free jet spray is formed on the suction side. The ventilated cavity has an approximately triangular shape, the length of which decreases with depth as a result of increasing hydrostatic pressure. As shown in the photos, the gaseous cavity in FV flow covers nearly the entire suction side of the foil surface, and is stable. A clear ventilated tip vortex can be observed in figure 2(c), which ingests air from the ventilated suction side and base cavities.

For ![]() $\sigma _v=0.29$, only a tiny partial cavity developed near the leading edge, regardless of the presence of waves, shown in figures 2(b,d). The maximum attached cavity length is approximately

$\sigma _v=0.29$, only a tiny partial cavity developed near the leading edge, regardless of the presence of waves, shown in figures 2(b,d). The maximum attached cavity length is approximately ![]() $0.25c$ for the CW case, and fluctuates between

$0.25c$ for the CW case, and fluctuates between ![]() $0.20c$ and

$0.20c$ and ![]() $0.30c$ in waves. As a result of the shortened cavity, the closure line possesses a larger radius of curvature, which leads indirectly to re-entrant flow with a more significant upstream velocity component. Consequently, periodic cavity shedding can be observed near the mid-point of the submerged span, where the liquid re-entrant jet impinges on the cavity leading edge to produce periodic shedding. However, the intensities of the load and deformation fluctuation created by unsteady cavity shedding remain small because of the cavity's limited size. The shortened cavity does not bring the cavity closure region close enough to the free surface for the free surface seal to be ruptured in the presence of waves, so the flow remains PC. Instead, waves induce oscillations in both the hydrodynamic load and cavity size because of changes in the wetted area, effective velocity field and pressure distributions. The sizes of both the vaporous and gaseous cavities tend to increase during the up-cycle of the wave (as the water level rises) and reduce during the down-cycle. At the wave crest, the horizontal component of the wave's orbital velocity increases the effective inflow velocity; at the trough, the effective inflow velocity is reduced. The vertical component of the orbital velocity points upwards during the up-cycle and downwards during the down-cycle, modifying the direction of the re-entrant jet. Note that for

$0.30c$ in waves. As a result of the shortened cavity, the closure line possesses a larger radius of curvature, which leads indirectly to re-entrant flow with a more significant upstream velocity component. Consequently, periodic cavity shedding can be observed near the mid-point of the submerged span, where the liquid re-entrant jet impinges on the cavity leading edge to produce periodic shedding. However, the intensities of the load and deformation fluctuation created by unsteady cavity shedding remain small because of the cavity's limited size. The shortened cavity does not bring the cavity closure region close enough to the free surface for the free surface seal to be ruptured in the presence of waves, so the flow remains PC. Instead, waves induce oscillations in both the hydrodynamic load and cavity size because of changes in the wetted area, effective velocity field and pressure distributions. The sizes of both the vaporous and gaseous cavities tend to increase during the up-cycle of the wave (as the water level rises) and reduce during the down-cycle. At the wave crest, the horizontal component of the wave's orbital velocity increases the effective inflow velocity; at the trough, the effective inflow velocity is reduced. The vertical component of the orbital velocity points upwards during the up-cycle and downwards during the down-cycle, modifying the direction of the re-entrant jet. Note that for ![]() $T_w= 1.5$ s, the ratio of the wavelength to the chord is

$T_w= 1.5$ s, the ratio of the wavelength to the chord is ![]() $\lambda _w/c' = 12.3$, where

$\lambda _w/c' = 12.3$, where ![]() $c'=0.285$ m is the actual chord length, which is slightly larger than the nominal chord length

$c'=0.285$ m is the actual chord length, which is slightly larger than the nominal chord length ![]() $c = 0.279$ m because of the addition of the aluminium strip at the foil trailing edge. Wave effects are felt through the depth of the foil as

$c = 0.279$ m because of the addition of the aluminium strip at the foil trailing edge. Wave effects are felt through the depth of the foil as ![]() $\lambda _w/h = 12.6$ (

$\lambda _w/h = 12.6$ (![]() $h=0.279$ m for

$h=0.279$ m for ![]() $AR_h$ = 1), although the amplitude of the wave orbital velocities decreases exponentially with

$AR_h$ = 1), although the amplitude of the wave orbital velocities decreases exponentially with ![]() ${\rm \pi} z/\lambda _w$, where

${\rm \pi} z/\lambda _w$, where ![]() $z$ is the distance from the free surface.

$z$ is the distance from the free surface.

The time histories of the load coefficients (![]() $C_L, C_M, C_D$), and tip bending deformations normalized by the chord (

$C_L, C_M, C_D$), and tip bending deformations normalized by the chord (![]() $\delta /c$) and tip twist (

$\delta /c$) and tip twist (![]() $\theta$), are shown in figure 3 for the same set of runs. Figure 4 depicts the hysteresis loops formed by the moving time-averaged lift and moment coefficients (

$\theta$), are shown in figure 3 for the same set of runs. Figure 4 depicts the hysteresis loops formed by the moving time-averaged lift and moment coefficients (![]() $C_L$ and

$C_L$ and ![]() $C_M$) plotted against the instantaneous Froude number (

$C_M$) plotted against the instantaneous Froude number (![]() $F_{ni}=U_i/\sqrt {gh}$ where

$F_{ni}=U_i/\sqrt {gh}$ where ![]() $U_i$ is the instantaneous carriage towing speed).

$U_i$ is the instantaneous carriage towing speed).

Figure 3. Time histories of (a i,b i,c i,d i) hydrodynamic load coefficients and (a ii,b ii,c ii,d ii) tip bending and twisting deformations for (a,c) ![]() $\sigma _v = 0.13$ and (b,d)

$\sigma _v = 0.13$ and (b,d) ![]() $\sigma _v = 0.29$, in (a,b) CW and (c,d) in waves with

$\sigma _v = 0.29$, in (a,b) CW and (c,d) in waves with ![]() $T_w$ = 1.5 s,

$T_w$ = 1.5 s, ![]() $A_w$ = 0.05 m. All results at

$A_w$ = 0.05 m. All results at ![]() $\alpha = 5^{\circ }$,

$\alpha = 5^{\circ }$, ![]() $AR_h = 1$,

$AR_h = 1$, ![]() $F_{nh} = 3.0$. The horizontal black dashed lines indicate SS averages. For

$F_{nh} = 3.0$. The horizontal black dashed lines indicate SS averages. For ![]() $\sigma _v = 0.13$, the flow is (a) PC in CW, and (c) FV in waves. For

$\sigma _v = 0.13$, the flow is (a) PC in CW, and (c) FV in waves. For ![]() $\sigma _v = 0.29$, both (b) CW and (d) wave runs are PC. The plots in (c) show a sudden drop in loading and tip deflections caused by transition from PC to FV flow, which is triggered by interactions between the vaporous cavity and waves. The mean FV loads and deformations in the SS region of (c) are much lower than those in (a) because ventilated flow reduces the peak suction pressures relative to vaporous cavitation. Run identifiers are (a) 2-1001, (b) 2-4601, (c) 2-1201, and (d) 2-4801. Here, iFV indicates the status of flow (

$\sigma _v = 0.29$, both (b) CW and (d) wave runs are PC. The plots in (c) show a sudden drop in loading and tip deflections caused by transition from PC to FV flow, which is triggered by interactions between the vaporous cavity and waves. The mean FV loads and deformations in the SS region of (c) are much lower than those in (a) because ventilated flow reduces the peak suction pressures relative to vaporous cavitation. Run identifiers are (a) 2-1001, (b) 2-4601, (c) 2-1201, and (d) 2-4801. Here, iFV indicates the status of flow (![]() $0 = {\rm FW},\ 1 = {\rm FV},\ 2 = {\rm PV},\ 3 = {\rm PC}$). iwave similarly indicates the status of waves (

$0 = {\rm FW},\ 1 = {\rm FV},\ 2 = {\rm PV},\ 3 = {\rm PC}$). iwave similarly indicates the status of waves (![]() $0 = {\rm CW},\ 1 = \textrm{waves}$).

$0 = {\rm CW},\ 1 = \textrm{waves}$).

Figure 4. Hysteresis loops formed by the moving time-averaged response of the lift and moment coefficients (![]() $C_L$ and

$C_L$ and ![]() $C_M$) plotted against the instantaneous Froude number (

$C_M$) plotted against the instantaneous Froude number (![]() $F_{ni}$). Data are shown for varying

$F_{ni}$). Data are shown for varying ![]() $\sigma _v$ with constant

$\sigma _v$ with constant ![]() $\alpha = 5^{\circ }$,

$\alpha = 5^{\circ }$, ![]() $F_{nh}=3.0$ and

$F_{nh}=3.0$ and ![]() $AR_h=1.0$. (a,c) Calm water and (b,d) wave (

$AR_h=1.0$. (a,c) Calm water and (b,d) wave (![]() $T_w=1.5$ s and

$T_w=1.5$ s and ![]() $A_w=0.05$ m) runs, indicated by the tags

$A_w=0.05$ m) runs, indicated by the tags ![]() $iwave=0$ and

$iwave=0$ and ![]() $iwave=1$. The dominant flow regimes are indicated by line colour, as denoted in the legends. Load coefficients are similar across all of the runs during the acceleration phase until a sufficiently large partial cavity develops (

$iwave=1$. The dominant flow regimes are indicated by line colour, as denoted in the legends. Load coefficients are similar across all of the runs during the acceleration phase until a sufficiently large partial cavity develops (![]() $\sigma _v = 0.13$), which leads to a slight increase in

$\sigma _v = 0.13$), which leads to a slight increase in ![]() $C_L$ due to virtual camber effect and a slight decrease in

$C_L$ due to virtual camber effect and a slight decrease in ![]() $C_M$ due to the shift in centre of pressure towards the mid-chord. Large reductions in

$C_M$ due to the shift in centre of pressure towards the mid-chord. Large reductions in ![]() $C_L$ and

$C_L$ and ![]() $C_M$ for all the wave cases with

$C_M$ for all the wave cases with ![]() $\sigma _v=0.13$ in (b,d) result from wave-induced transition from PC to FV flow. Once FV, the atmospheric ventilated cavity persists during deceleration until

$\sigma _v=0.13$ in (b,d) result from wave-induced transition from PC to FV flow. Once FV, the atmospheric ventilated cavity persists during deceleration until ![]() $F_{ni} \approx 1.5$, forming a large hysteresis loop.

$F_{ni} \approx 1.5$, forming a large hysteresis loop.

For ![]() $\sigma _v=0.13$, the leading edge vaporous cavity (PC flow) produces an increase in

$\sigma _v=0.13$, the leading edge vaporous cavity (PC flow) produces an increase in ![]() $C_L$ due to a virtual camber effect, along with a slight reduction in

$C_L$ due to a virtual camber effect, along with a slight reduction in ![]() $C_M$ due to shifting of the centre of pressure towards the mid-chord, when compared to the smaller cavity at

$C_M$ due to shifting of the centre of pressure towards the mid-chord, when compared to the smaller cavity at ![]() $\sigma _v=0.29$. In waves, the transition of the larger cavity from PC to FV flow is accompanied by a dramatic reduction in the hydrodynamic forces and structural response in figure 3(c), as well as the plots on the right-hand side of figure 4. Transition from PC to FV flow caused a 70 % drop in

$\sigma _v=0.29$. In waves, the transition of the larger cavity from PC to FV flow is accompanied by a dramatic reduction in the hydrodynamic forces and structural response in figure 3(c), as well as the plots on the right-hand side of figure 4. Transition from PC to FV flow caused a 70 % drop in ![]() $C_M$ but only a 40 % drop in

$C_M$ but only a 40 % drop in ![]() $C_L$. Once FV, the gas cavity persists during deceleration until

$C_L$. Once FV, the gas cavity persists during deceleration until ![]() $F_{ni}\approx 1.5$, producing the large hysteresis loops observed on the right-hand side of figure 4. In addition, note the direct correlation between

$F_{ni}\approx 1.5$, producing the large hysteresis loops observed on the right-hand side of figure 4. In addition, note the direct correlation between ![]() $C_L$ and

$C_L$ and ![]() $\delta$ and between

$\delta$ and between ![]() $C_M$ and

$C_M$ and ![]() $\theta$ for all the cases, including the sudden transition from PC to FV flow in figure 4(c) and the wave-induced oscillations in figure 4(c,d). The apparent linearity of the structural response suggests that, although the deformations are small, they can be used to effectively infer the hydrodynamic loads, which has been discussed in Ward, Harwood & Young (Reference Ward, Harwood and Young2018).

$\theta$ for all the cases, including the sudden transition from PC to FV flow in figure 4(c) and the wave-induced oscillations in figure 4(c,d). The apparent linearity of the structural response suggests that, although the deformations are small, they can be used to effectively infer the hydrodynamic loads, which has been discussed in Ward, Harwood & Young (Reference Ward, Harwood and Young2018).

Comparison of the hysteresis loops in figure 4 for different values of ![]() $\sigma _v$ shows that the forces are very similar in the acceleration phase for all runs, with only a slight increase in

$\sigma _v$ shows that the forces are very similar in the acceleration phase for all runs, with only a slight increase in ![]() $C_L$ and a slight decrease in

$C_L$ and a slight decrease in ![]() $C_M$ when a sufficiently large partial cavity develops (attributed to the camber-like deflections in suction-side streamlines). Differences between the CW cases in figures 4(a,c) and the wave cases in figures 4(b,d) are most evident in the significant drops in

$C_M$ when a sufficiently large partial cavity develops (attributed to the camber-like deflections in suction-side streamlines). Differences between the CW cases in figures 4(a,c) and the wave cases in figures 4(b,d) are most evident in the significant drops in ![]() $C_L$ and

$C_L$ and ![]() $C_M$ when flow transitions from PC to FV, and the large hysteresis loop caused by the delay in flow re-attachment. The differences in the hysteresis loops shown for the CW cases in figures 4(a,c) and the wave cases in figures 4(b,d) indicate clearly that waves tend to accelerate transition to FV flow when a sufficiently large partial cavity is present. This is supported by figure 2. On the other hand, when a smaller partial cavity is present (