Introduction

Long blades were fundamental to Neolithic-Copper Age societies in Europe and the Mediterranean, especially between the third and fourth millennium BC (Gibaja & Mazzucco Reference Gibaja and Mazzucco2023). Their production reflects craft specialisation and the existence of extensive distribution networks. Moreover, the recurring association of long blades with funerary practices in Iberia indicates their social value.

From the Neolithic period onwards, the extraction of flint intensified in Europe, with the emergence of quarries and mines (Consuegra & Díaz-Del-Río Reference Consuegra, Díaz-Del-Río, Werra and Woźny2018). There is, however, currently a mismatch between the number of mining sites (Figure 1) and the extensive distribution of long blades. Given the abundance of flint outcrops in the Brihuega area of central Iberia, a survey of the Tajuña and Ungría river valleys in the Tagus basin was conducted with the aim of identifying prehistoric flint production and extraction sites. Two new long blade quarry/workshop sites, Romancos 1 (RM1) and Romancos 2 (RM2), fill a gap in the central Iberian record and provide a technological link to other sites known in Eurasia.

Figure 1. a) Map showing the distribution of long blade lithic production sites in Iberia (based on Morgado et al. Reference Morgado, Pelegrin, Martínez Fernández, Alfonso Marrero and Dias-Meirinho2008, Reference Morgado, Lozano and Pelegrin2011): 1) Brihuega quarries and workshops; 2) Montón; 3) La Tova; 4) Gallumbares; 5) Cerro del Reloj; 6) Puerto del Zegrí; 7) Loma de los Pedernales; 8) Malaver; 9) Valle del Turón; 10) Ardite; 11) Alcolea; 12) Andevalo; 13) Calañas; 14) Rio Mayor; 15) Caxarías. b) Detailed map of the survey area in the Tajuña River Valley (figure by authors; a) made with SimpleMappr (Shorthouse Reference Shorthouse2010); b) modified from OpendataJCCM, licensed under CCBY4.0).

Methods

An initial geological survey identified the flint outcrops and the subsequent surface collection of archaeological materials provided the basis for an intra-site spatial analysis. The lithic study then used technological and typological characteristics to reconstruct the chaîne opératoire.

The comprehensive geological analysis resulted in an updated stratigraphic column with detailed descriptions of the levels including flint-bearing beds. Petrological study involving macroscopic and thin-section observations allowed individual characterisation of the outcrops.

Results

The Brihuega region is characterised by moorland with an average altitude of 1000m above sea level, crossed by temperate valleys. A total of nine sites with the presence of long cores was located along a 5.83km stretch of the Tajuña slope. At two of these, RM1 (9.1ha) and RM2 (15.4ha) (Figure 2), we identified both flint quarrying and nearby workshops. The near-identical character of the two sites suggests a contemporaneity.

Figure 2. a) Geology map with stratigraphic column of the RM1 and RM2 sites showing archaeological materials dispersion; b) view north-west to south-east to the RM1 and RM2 sites; c) quarry front and debris (figure by authors).

Natural flint in the region tends to outcrop in rounded to irregular-shaped masses, up to 2m wide and 1m deep (Bustillo & Bustillo Reference Bustillo and Bustillo1987). These are usually found in carbonate (limestone, marl) or mud layers. The formation of flint resulted from the dissolution and precipitation of silica, driven by water-table oscillations in lake and alluvial deposits during the Miocene epoch (Bustillo & Bustillo Reference Bustillo and Bustillo1987). Locally, as flint forms, it replaces lenticular moulds of gypsum crystals through an intermediate calcification process (Figure 3b). The local flint is commonly white (Figure 3a) or, less frequently, grey or pinkish-red (Figure 3b) with a wackestone texture. It comprises small geodes, partially filled with macroquartz and iron oxides (Figure 3a), in a fine matrix where fibrous microquartz (chalcedony) is also abundant, exhibiting spherulitic and botryoidal morphologies (Figure 3c & d).

Figure 3. Petrographic characteristics of Brihuega flint on macroscopic images (a & b) and thin sections (c & d) (figure by author).

Sites RM1 and RM2 yielded 71 flint cores from various phases of the reduction process (Figure 4), 30 blades, with a high proportion of ridge blades (n = 12) (Figure 5), and a large quantity of core configuration flakes. The survey also identified one remarkably long flint blade core of 353mm, found at the RM1 site (Figure 4, no. 4). Flint quarrying activities were indicated by small circular pits, approximately 3m in diameter, and by quarry faces and trenches (Figure 2c).

Figure 4. Flint blade cores at different stages of production from the RM1 and RM2 sites: 1–3 core preforms; 4–8 cores in production (figure by author).

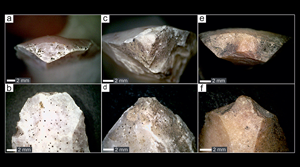

Figure 5. Flint blades from the RM1 and RM2 sites and technological details of the butt types: a & b) facetted; c & d) punctiform; e & f) sharp dihedron (figure by author).

Blade extraction was presumably carried out using a lever pressure system or a crutch for smaller cores, as shown by experimental studies (Pelegrin Reference Pelegrin and Desrosiers2012). The width of the blades and nature of the core removal are consistent with this technology (Figure 6b). The presence of sharp dihedron-shaped butts is noteworthy (Figure 5a & e), since this feature was thought to be indicative of southern Iberian workshops (Morgado & Pelegrin Reference Morgado, Pelegrin and Desrosiers2012: 230). This technology can be placed between the middle of the third millennium BC and the end of the fourth millennium BC, based on the appearance of blades in well-dated contexts (Morgado & Pelegrin Reference Morgado, Pelegrin and Desrosiers2012).

Figure 6. a) Relationship between the length and width of flint blade cores in different production stages; b) correspondence between core removals and blade width (figure by author).

Conclusion

Central Iberia has traditionally been regarded as a recipient of technical advances during late prehistory. The discovery of these production sites for long blades in Brihuega, comparable to other Iberian workshops, is key to understanding the dynamics of the distribution of both goods and technological knowledge among Late Neolithic-Copper Age populations. These new sites highlight the need for research projects to target systematically those areas where high concentrations of flint naturally occur. The next phases of the current project will include excavation, chronometric dating and flint characterisation to trace the circulation networks of the blades.

Acknowledgements

The survey was conducted under the project Aprovisionamiento y gestión del sílex durante la Prehistoria en los valles de los ríos Tajuña y Ungría (23.2140 P1) with a permit from the Junta de Comunidades de Castilla-La Mancha.

Funding statement

This work has not received funding.