1. Introduction

The increasing reliance on fossil fuels has led to significant environmental pollution and climate change, prompting a shift toward clean energy sources. One promising approach involves harnessing flow-induced oscillations in flexible structures to convert flow energy into electricity using piezoelectric materials. These devices have diverse applications, including self-powered sensor networks, structural health monitoring for bridges and offshore platforms and supplementary energy sources for urban infrastructure. Additionally, they offer potential for capturing wind and water flow energy in remote or underwater environments where conventional power sources are impractical (Wang et al. Reference Wang, Ryu, Yang, Chen, He and Sung2020; Sezer & Koç Reference Sezer and Koç2021). Among these innovative designs, a flexible ring, which is capable of storing elastic energy in its initial state, shows substantial potential for energy harvesting. Thus, understanding the flow-induced oscillations of flexible rings is essential for advancing flexible energy-harvesting technologies.

Figure 1. Two energy harvesters based on flow-induced vibration: (a) a one-edge-clamped flag and (b) a two-edge-clamped flag.

Flexible energy harvesters are commonly made from piezoelectric materials. Although environmental factors can influence their properties, recent advancements have enhanced their durability and performance, highlighting their significant potential for energy harvesting. Traditional flexible energy harvesters that rely on flow-induced vibrations are generally categorised based on their edge conditions into two types: conventional flags and inverted flags (figure 1 a). The energy-harvesting performance of these systems is closely linked to factors such as critical bending rigidity, oscillation frequency and filament deflection during motion (Doaré & Michelin Reference Doaré and Michelin2011; Michelin & Doaré Reference Michelin and Doaré2013; Shoele & Mittal Reference Shoele and Mittal2016). A conventional flag, characterised by a clamped leading edge and a free trailing edge, exhibits different oscillation modes – stretched straight, limit-cycle flapping and chaotic flapping – depending on its Reynolds number (Re), mass ratio, filament length and bending rigidity (Zhang et al. Reference Zhang, Childress, Libchaber and Shelley2000; Zhu & Peskin Reference Zhu and Peskin2003; Shelley, Vandenberghe & Zhang Reference Shelley, Vandenberghe and Zhang2005; Alben & Shelley Reference Alben and Shelley2008; Michelin, Llewellyn Smith & Glover Reference Michelin, Llewellyn Smith and Glover2008; Banerjee, Connell & Yue Reference Banerjee, Connell and Yue2015; Cisonni et al. Reference Cisonni, Lucey, Elliott and Heil2017). The flapping motion of a conventional flag is considered flutter caused by structural instability, resulting in high-frequency, low-amplitude oscillations (Connell & Yue Reference Connell and Yue2007; Eloy et al. Reference Eloy, Lagrange, Souilliez and Schouveiler2008; Uddin, Huang & Sung Reference Uddin, Huang and Sung2015). However, the low critical bending rigidity of conventional flags limits their energy-harvesting performance (Michelin & Doaré Reference Michelin and Doaré2013). By contrast, the inverted flag, which has a clamped trailing edge and a free leading edge, was introduced by Kim et al. (Reference Kim, Cossé, Huertas Cerdeira and Gharib2013) to address this limitation by increasing the critical bending rigidity and enhancing the oscillation amplitude. Inverted flags display three distinct modes – straight, flapping and deflected – as the bending rigidity, flow velocity and filament length vary (Gurugubelli & Jaiman Reference Gurugubelli and Jaiman2015; Tang, Liu & Lu Reference Tang, Liu and Lu2015; Sader et al. Reference Sader, Cossé, Kim, Fan and Gharib2016; Orrego et al. Reference Orrego, Shoele, Ruas, Doran, Caggiano, Mittal and Kang2017; Yu, Liu & Chen Reference Yu, Liu and Chen2017; Tavallaeinejad et al. Reference Tavallaeinejad, Païdoussis, Salinas, Legrand, Kheiri and Botez2020a ,Reference Tavallaeinejad, Païdoussis, Legrand and Kheiri b ). The inverted flag achieves greater deflection and higher critical bending rigidity than the conventional flag, thus offering superior energy-harvesting performance (Ryu et al. Reference Ryu, Park, Kim and Sung2015; Shoele & Mittal Reference Shoele and Mittal2016). Despite these advantages, both conventional and inverted flags share a common limitation: one end is clamped while the other remains free. This configuration restricts the deflection of the flags, limiting their potential for energy harvesting.

To address limitations in flow energy harvesting, researchers used buckled filaments clamped at both ends (figure 1 b), storing substantial elastic energy in their initial shape (Chen, Liu & Sung Reference Chen, Liu and Sung2024). Kim et al. (Reference Kim, Zhou, Kim and Oh2020) examined the snap-through oscillation (STO) of such filaments for energy-harvesting applications. Mao, Liu & Sung (Reference Mao, Liu and Sung2023) applied the immersed boundary (IB) method to examine how filament length, bending rigidity and Reynolds number influence the snap-through dynamics, identifying three modes: STO, streamwise oscillation and equilibrium. The STO mode in buckled filaments shows substantial deformation but requires high external energy for initiation, leading to low critical bending rigidity (Kim et al. 2021). Moreover, the STO mode’s oscillation frequency is lower than that of conventional and inverted flags, limiting the energy-harvesting capacity of buckled filaments. To enhance critical bending rigidity and increase oscillation frequency, recent studies (Chen et al. Reference Chen, Mao, Liu and Sung2023, Reference Chen, Mao, Liu and Sung2024) investigated the effects of edge conditions and walls on STO performance. Although these modifications adjust the initiation conditions, they still yield insufficient critical bending rigidity and oscillation frequency, constraining the utility of buckled filaments for effective energy harvesting. To address these limitations, we propose using a transversely clamped filament, where the clamped edges are rotated 90° to align perpendicular to the flow direction (Chen, Liu & Sung Reference Chen, Liu and Sung2025). This configuration creates two types of transversely clamped buckled filaments – inverted and conventional – depending on the orientation. When the bending rigidity, filament length and Reynolds number are varied, several oscillation modes emerge: conventional transverse oscillation (TO), deflected oscillation, inverted TO and equilibrium. The TO mode, in particular, is driven by periodic vortex shedding from the filament’s bluff body, making it easier to initiate. The TO mode is also associated with a higher critical bending rigidity and synchronises with vortex shedding, resulting in a higher oscillation frequency than the STO mode, thereby improving energy-harvesting efficiency.

Although the larger deflection and higher frequency of the TO mode enhance the energy-harvesting potential compared with that of single-end-clamped filaments, the fixed distance between the clamped edges limits the motion of transversely clamped filaments. This constraint reduces the oscillation amplitude, thereby limiting overall energy generation in the TO mode. To overcome this challenge, we propose a flexible ring configuration in which the clamped edges of the buckled filament are positioned closer together. This design eliminates the fixed-edge constraint, enabling greater oscillation amplitude and improved energy-harvesting performance. In addition, the ring shape, as a classic bluff body, inherently generates vortices that induce TOs, similar to vortex-induced vibrations observed in elastically mounted cylinders (Bearman Reference Bearman1984; Williamson & Govardhan Reference Williamson and Govardhan2004; Prasanth & Mittal Reference Prasanth and Mittal2008; Navrose & Mittal Reference Navrose and Mittal2016; Fan et al. Reference Fan, Wang, Triantafyllou and Karniadakis2019).

Previous research has examined flow-induced oscillations in flexible rings with one side pinned (Jung et al. Reference Jung, Mareck, Shelley and Zhang2006; Shoele & Zhu Reference Shoele and Zhu2010; Kim et al. Reference Kim, Huang, Shin and Sung2012), whereas studies on clamped flexible rings remain limited. Understanding the fluid dynamics governing the oscillations of clamped flexible rings is crucial for advancing flexible energy-harvesting technology. Bending rigidity is a key factor influencing energy-harvesting efficiency. However, the experimental manipulation of bending rigidity is often constrained by material limitations. As a result, numerical approaches, such as the IB method, offer a practical and effective alternative for analysing these complex fluid–structure interactions (Huang, Shin & Sung Reference Huang, Shin and Sung2007; Huang & Sung Reference Huang and Sung2010; Huang, Chang & Sung Reference Huang, Chang and Sung2011; Ryu et al. Reference Ryu, Park, Kim and Sung2015).

The objective of the present study is to explore the flow-induced oscillations in clamped flexible rings using the penalty IB method. Two configurations – conventional and inverted rings – are analysed to assess the effects of bending rigidity (

![]() $\gamma$

) and ring eccentricity (

$\gamma$

) and ring eccentricity (

![]() $\epsilon$

) on mode transitions and energy-harvesting performance. The motion of the rings and their corresponding wake patterns are analysed across different modes, with the lock-in phenomenon identified through oscillation amplitude and frequency analysis. We compare the behaviour and underlying mechanisms of the flexible ring with other flexible energy harvesters. Additionally, we assess the contributions of each component to energy harvesting in both configurations and derive an estimate of the power coefficient using dimensional analysis. Lastly, we compare the energy-harvesting performance of clamped rings with those of streamwise and transversely buckled filaments.

$\epsilon$

) on mode transitions and energy-harvesting performance. The motion of the rings and their corresponding wake patterns are analysed across different modes, with the lock-in phenomenon identified through oscillation amplitude and frequency analysis. We compare the behaviour and underlying mechanisms of the flexible ring with other flexible energy harvesters. Additionally, we assess the contributions of each component to energy harvesting in both configurations and derive an estimate of the power coefficient using dimensional analysis. Lastly, we compare the energy-harvesting performance of clamped rings with those of streamwise and transversely buckled filaments.

2. Computational model

2.1. Problem formulation

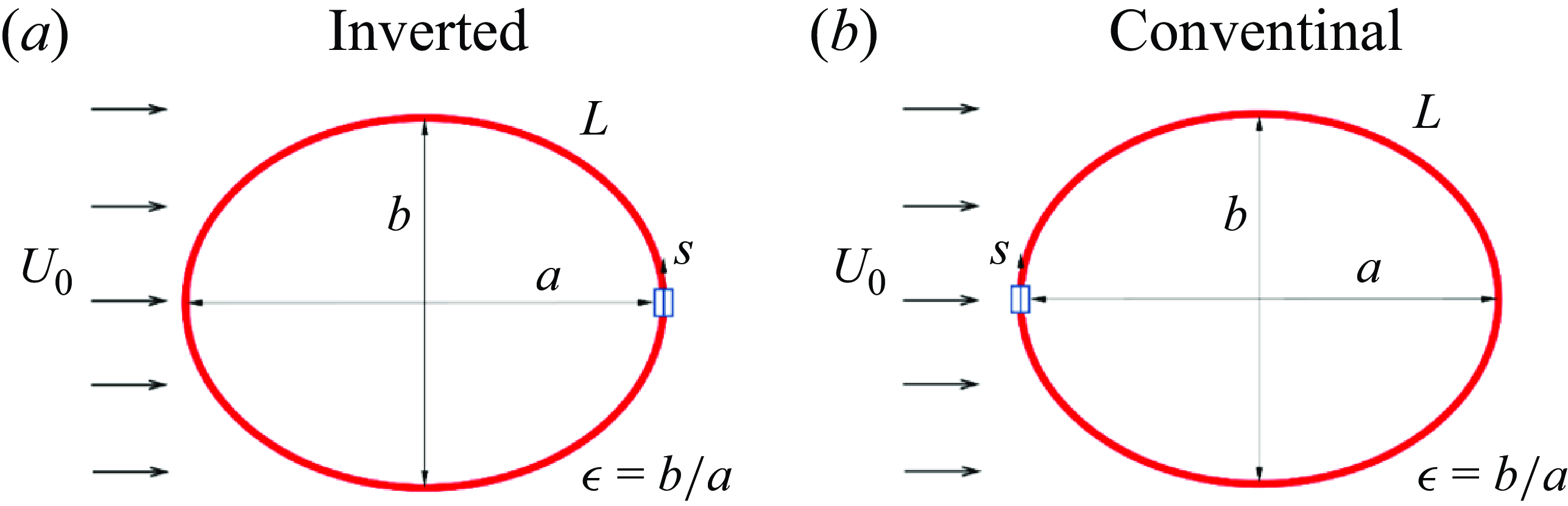

Clamped flexible rings can be classified into two configurations on the basis of their clamping orientation: conventional and inverted. Figure 2 illustrates these configurations, where

![]() $L$

denotes a ring’s length and

$L$

denotes a ring’s length and

![]() $a$

and

$a$

and

![]() $b$

represent its major and minor axes, respectively. The ring’s eccentricity is defined by

$b$

represent its major and minor axes, respectively. The ring’s eccentricity is defined by

![]() $\epsilon$

. Blue boxes at both ends indicate clamped boundary conditions. Fluid motion is analysed in a fixed Eulerian coordinate system, with the domain spanning

$\epsilon$

. Blue boxes at both ends indicate clamped boundary conditions. Fluid motion is analysed in a fixed Eulerian coordinate system, with the domain spanning

![]() $-10L_{0}\leq x\leq 22L_{0}$

in the streamwise direction and

$-10L_{0}\leq x\leq 22L_{0}$

in the streamwise direction and

![]() $-8L_{0}\leq y\leq 8L_{0}$

in the transverse direction. Here,

$-8L_{0}\leq y\leq 8L_{0}$

in the transverse direction. Here,

![]() $L_{0}$

represents the equivalent diameter of an elliptic ring, which corresponds to the diameter of a circular ring when

$L_{0}$

represents the equivalent diameter of an elliptic ring, which corresponds to the diameter of a circular ring when

![]() $\epsilon = 1$

. Dirichlet boundary conditions (

$\epsilon = 1$

. Dirichlet boundary conditions (

![]() $u=U_{0}$

,

$u=U_{0}$

,

![]() $v=0$

) are applied at the inlet, top and bottom boundaries, whereas a Neumann boundary condition (

$v=0$

) are applied at the inlet, top and bottom boundaries, whereas a Neumann boundary condition (

![]() $\partial \boldsymbol{u}/\partial x=0$

) is set at the outlet (Huang & Sung Reference Huang and Sung2007). The filament’s motion is described in a moving curvilinear coordinate system, where

$\partial \boldsymbol{u}/\partial x=0$

) is set at the outlet (Huang & Sung Reference Huang and Sung2007). The filament’s motion is described in a moving curvilinear coordinate system, where

![]() $s$

denotes the filament’s arc length.

$s$

denotes the filament’s arc length.

Figure 2. Schematics of (

![]() $a$

) inverted and (

$a$

) inverted and (

![]() $b$

) conventional clamped flexible rings in a uniform flow.

$b$

) conventional clamped flexible rings in a uniform flow.

The fluid motion is governed by the Navier–Stokes equations and the continuity equation, which are expressed in their non-dimensional forms as

where

![]() $\boldsymbol{u}=(u$

,

$\boldsymbol{u}=(u$

,

![]() $v)$

represents the fluid velocity vector,

$v)$

represents the fluid velocity vector,

![]() $p$

is the pressure and

$p$

is the pressure and

![]() $\boldsymbol{f}=(f_{x}$

,

$\boldsymbol{f}=(f_{x}$

,

![]() $f_{y})$

denotes the momentum forcing used to enforce the no-slip boundary condition along the IB. The Reynolds number is defined as

$f_{y})$

denotes the momentum forcing used to enforce the no-slip boundary condition along the IB. The Reynolds number is defined as

![]() $Re=\rho _{0}U_{0}D/\mu$

, where

$Re=\rho _{0}U_{0}D/\mu$

, where

![]() $\rho _{0}$

and

$\rho _{0}$

and

![]() $\mu$

are the fluid density and the dynamic viscosity, respectively. Equations (2.1) and (2.2) are non-dimensionalised using the following characteristic scales:

$\mu$

are the fluid density and the dynamic viscosity, respectively. Equations (2.1) and (2.2) are non-dimensionalised using the following characteristic scales:

![]() $L_{0}$

for length,

$L_{0}$

for length,

![]() $U_{0}$

for velocity,

$U_{0}$

for velocity,

![]() $L_{0}/U_{0}$

for time,

$L_{0}/U_{0}$

for time,

![]() $\rho _{0}{U_{0}}^{2}$

for pressure and

$\rho _{0}{U_{0}}^{2}$

for pressure and

![]() $\rho _{0}{U_{0}}^{2}/L_{0}$

for the momentum forcing

$\rho _{0}{U_{0}}^{2}/L_{0}$

for the momentum forcing

![]() $\boldsymbol{f}$

. For simplicity, the dimensionless variables are expressed in the same form as their dimensional counterparts.

$\boldsymbol{f}$

. For simplicity, the dimensionless variables are expressed in the same form as their dimensional counterparts.

The motion of the flexible structure is governed by the nonlinear structural equation and the inextensibility condition, which are expressed in their non-dimensional forms as

where

![]() $\boldsymbol{X}=(X(s,t),Y(s,t))$

denotes the displacement vector of the filament,

$\boldsymbol{X}=(X(s,t),Y(s,t))$

denotes the displacement vector of the filament,

![]() $s$

is the arclength,

$s$

is the arclength,

![]() $T$

and

$T$

and

![]() $\gamma$

represent the tension coefficient and bending rigidity along the filament, respectively,

$\gamma$

represent the tension coefficient and bending rigidity along the filament, respectively,

![]() $K$

is the curvature of the filament,

$K$

is the curvature of the filament,

![]() $\boldsymbol{n}$

denotes the normal direction and

$\boldsymbol{n}$

denotes the normal direction and

![]() $\boldsymbol{F}_{{f}}$

represents the Lagrangian momentum forcing exerted by the surrounding fluid on the filament. These equations are non-dimensionalised using the following characteristic scales:

$\boldsymbol{F}_{{f}}$

represents the Lagrangian momentum forcing exerted by the surrounding fluid on the filament. These equations are non-dimensionalised using the following characteristic scales:

![]() $D$

for length,

$D$

for length,

![]() $L_{0}/U_{0}$

for time,

$L_{0}/U_{0}$

for time,

![]() $\rho _{1}U_{0}^{2}$

for the tension coefficient

$\rho _{1}U_{0}^{2}$

for the tension coefficient

![]() $T$

$T$

![]() $\rho _{1}U_{0}^{2}L_{0}^{2}$

for the bending rigidity

$\rho _{1}U_{0}^{2}L_{0}^{2}$

for the bending rigidity

![]() $\gamma$

and

$\gamma$

and

![]() $\rho _{1}U_{0}^{2}/L_{0}$

for the Lagrangian forcing

$\rho _{1}U_{0}^{2}/L_{0}$

for the Lagrangian forcing

![]() $\boldsymbol{F}_{{f}}$

, where

$\boldsymbol{F}_{{f}}$

, where

![]() $\rho _{1}$

denotes the density difference between the filament and the surrounding fluid. Given that the filament’s cross-sectional length is negligible,

$\rho _{1}$

denotes the density difference between the filament and the surrounding fluid. Given that the filament’s cross-sectional length is negligible,

![]() $\rho _{1}$

is considered the density of the filament. The elastic force of the filament is given by

$\rho _{1}$

is considered the density of the filament. The elastic force of the filament is given by

![]() $\boldsymbol{F}_{{s}}=({\partial }/{\partial s})(T ({\partial \boldsymbol{X}}/{\partial s}))-\gamma ({\partial }/{\partial s})(({\partial K}/{\partial s})\boldsymbol{n})$

. In the present study, the value of

$\boldsymbol{F}_{{s}}=({\partial }/{\partial s})(T ({\partial \boldsymbol{X}}/{\partial s}))-\gamma ({\partial }/{\partial s})(({\partial K}/{\partial s})\boldsymbol{n})$

. In the present study, the value of

![]() $\gamma$

is constant during filament motion, whereas

$\gamma$

is constant during filament motion, whereas

![]() $T$

is a function of both

$T$

is a function of both

![]() $s$

and

$s$

and

![]() $t$

, determined by the inextensibility condition. A Poisson equation is constructed to solve the value of

$t$

, determined by the inextensibility condition. A Poisson equation is constructed to solve the value of

![]() $T$

(Huang et al. Reference Huang, Shin and Sung2007). Clamped boundary conditions are applied at the two fixed edges of the filament, which are

$T$

(Huang et al. Reference Huang, Shin and Sung2007). Clamped boundary conditions are applied at the two fixed edges of the filament, which are

The penalty IB method is used to calculate the interaction between the filament and the fluid. In this method, the IB is divided into a `massive boundary’ and a `massless boundary,’ which are connected by a stiff spring to simulate the interaction. The Lagrangian force

![]() $\boldsymbol{F}_{{f}}$

exerted by the fluid on the filament is computed using the equation (Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1993)

$\boldsymbol{F}_{{f}}$

exerted by the fluid on the filament is computed using the equation (Goldstein, Handler & Sirovich Reference Goldstein, Handler and Sirovich1993)

where

![]() $\alpha = -3\times 10^{6}$

and

$\alpha = -3\times 10^{6}$

and

![]() $\beta = -$

100 are large negative constants chosen to enforce the no-slip boundary condition (Huang et al. Reference Huang, Shin and Sung2007; Shin, Huang & Sung Reference Shin, Huang and Sung2008). Here,

$\beta = -$

100 are large negative constants chosen to enforce the no-slip boundary condition (Huang et al. Reference Huang, Shin and Sung2007; Shin, Huang & Sung Reference Shin, Huang and Sung2008). Here,

![]() $\boldsymbol{U}_{{ib}}$

represents the velocity of the massless boundary, as obtained by interpolation at the IB, and

$\boldsymbol{U}_{{ib}}$

represents the velocity of the massless boundary, as obtained by interpolation at the IB, and

![]() $\boldsymbol{U}$

is the velocity of the massive boundary obtained by

$\boldsymbol{U}$

is the velocity of the massive boundary obtained by

![]() $\boldsymbol{U}=\mathrm{d}\boldsymbol{X}/\mathrm{d}t$

. The transformation between Eulerian (fluid) and Lagrangian (filament) variables is achieved using the Dirac delta function. The parameters

$\boldsymbol{U}=\mathrm{d}\boldsymbol{X}/\mathrm{d}t$

. The transformation between Eulerian (fluid) and Lagrangian (filament) variables is achieved using the Dirac delta function. The parameters

![]() $\boldsymbol{U}_{{ib}}$

and

$\boldsymbol{U}_{{ib}}$

and

![]() $\boldsymbol{f}$

are calculated using the equations

$\boldsymbol{f}$

are calculated using the equations

where the density ratio (

![]() $\rho$

) is derived from the non-dimensionalisation process (

$\rho$

) is derived from the non-dimensionalisation process (

![]() $\rho =\rho _{1}/\rho _{0}D=1$

). In this context,

$\rho =\rho _{1}/\rho _{0}D=1$

). In this context,

![]() $\rho _{1}$

refers to the line density, whereas

$\rho _{1}$

refers to the line density, whereas

![]() $\rho _{0}$

represents the area density.

$\rho _{0}$

represents the area density.

To address the issue of volume conservation in simulations involving incompressible fluids enclosed by a flexible ring, we used a penalty IB method incorporating fluid compressibility (Peng, Asaro & Zhu Reference Peng, Asaro and Zhu2010; Kim et al. Reference Kim, Huang, Shin and Sung2012). This method compensates for the volume leakage caused by the smoothed Dirac delta function in traditional IB methods. The compressibility of the fluid is defined as

where

![]() $V$

is the volume enclosed by the ring and

$V$

is the volume enclosed by the ring and

![]() $p$

represents the pressure. On the basis of this relationship, the pressure difference can be expressed as

$p$

represents the pressure. On the basis of this relationship, the pressure difference can be expressed as

where

![]() $V_{0}$

represents the initial volume. To enhance volume conservation, an integral term, inspired by proportional-integral control, is added to mitigate steady-state error, yielding an updated pressure difference expression (Kim et al. Reference Kim, Huang, Shin and Sung2012)

$V_{0}$

represents the initial volume. To enhance volume conservation, an integral term, inspired by proportional-integral control, is added to mitigate steady-state error, yielding an updated pressure difference expression (Kim et al. Reference Kim, Huang, Shin and Sung2012)

The penalty force ensuring volume conservation is then derived as

where

![]() $\boldsymbol{e}_{n}$

is the local outward normal vector of the ring. Consequently, the structural equation incorporating the volume conservation force is formulated as

$\boldsymbol{e}_{n}$

is the local outward normal vector of the ring. Consequently, the structural equation incorporating the volume conservation force is formulated as

To evaluate the electrical energy generated by the flexible ring, the piezoelectric–structure coupling effect is incorporated. The flexible ring surface is assumed to be fully covered with infinitesimal piezoelectric patches, each with a segmentation length substantially smaller than L, connected to external circuits. These patches convert strain energy into electrical energy as the filament deflects. The concurrent application of an electric voltage to the electrodes induces additional internal torque on both the piezoelectric patches and the filament (Doaré & Michelin Reference Doaré and Michelin2011). The local electrical state of each patch is described by the electric voltage between the positive electrodes, denoted as

![]() $V(s,t)$

, and the charge transfer

$V(s,t)$

, and the charge transfer

![]() $Q(s,t)$

along the filament axis, both of which are continuous functions of

$Q(s,t)$

along the filament axis, both of which are continuous functions of

![]() $s$

and

$s$

and

![]() $t$

(Michelin & Doaré Reference Michelin and Doaré2013). The piezoelectric coupling effect is governed by the following equations:

$t$

(Michelin & Doaré Reference Michelin and Doaré2013). The piezoelectric coupling effect is governed by the following equations:

where

![]() $M(s,t)$

represents the torque of the filament and

$M(s,t)$

represents the torque of the filament and

![]() $c$

and

$c$

and

![]() $\chi$

are the lineic capacitance and piezoelectric coupling coefficient, respectively, which are related to the material and geometric properties of the patch pair (Doaré & Michelin Reference Doaré and Michelin2011). The positive electrodes are connected to a purely resistive circuit with lineic conductivity, as described by the following equation:

$\chi$

are the lineic capacitance and piezoelectric coupling coefficient, respectively, which are related to the material and geometric properties of the patch pair (Doaré & Michelin Reference Doaré and Michelin2011). The positive electrodes are connected to a purely resistive circuit with lineic conductivity, as described by the following equation:

where

![]() $\varsigma$

represents the linear conductivity coefficient between the piezoelectric patches on the upper and lower surfaces of the filament. When the piezoelectric effect is taken into account, the equivalent bending rigidity can be expressed as

$\varsigma$

represents the linear conductivity coefficient between the piezoelectric patches on the upper and lower surfaces of the filament. When the piezoelectric effect is taken into account, the equivalent bending rigidity can be expressed as

By combining equations (2.14)−(2.17), we can express the nonlinear structure equation incorporating the piezoelectric effect, the inextensible condition and the electrical equation as follows:

where

![]() $\alpha _{{e}}=\chi /\sqrt{c\gamma _{L}}$

and

$\alpha _{{e}}=\chi /\sqrt{c\gamma _{L}}$

and

![]() $\beta _{{e}}=cU/\varsigma L$

represent the coupling coefficient and the tuning coefficient of the electrical system, respectively (Shoele & Mittal Reference Shoele and Mittal2016). Here,

$\beta _{{e}}=cU/\varsigma L$

represent the coupling coefficient and the tuning coefficient of the electrical system, respectively (Shoele & Mittal Reference Shoele and Mittal2016). Here,

![]() $\gamma _{{L}}$

denotes the dimensional bending rigidity of the filament. The voltage and charge density are non-dimensionalised by

$\gamma _{{L}}$

denotes the dimensional bending rigidity of the filament. The voltage and charge density are non-dimensionalised by

![]() $U\sqrt{\rho L/c}$

and

$U\sqrt{\rho L/c}$

and

![]() $U\sqrt{\rho Lc}$

, respectively. In the present study,

$U\sqrt{\rho Lc}$

, respectively. In the present study,

![]() $\alpha _{{e}}$

and

$\alpha _{{e}}$

and

![]() $\beta _{{e}}$

are held constant at values of 0.1, ensuring that they do not affect the overall filament motion.

$\beta _{{e}}$

are held constant at values of 0.1, ensuring that they do not affect the overall filament motion.

The energy-harvesting performance can be evaluated by examining both the elastic strain energy

![]() $E_{{s}}$

and the power coefficient c

p

. Here,

$E_{{s}}$

and the power coefficient c

p

. Here,

![]() $E_{{s}}$

represents the strain energy generated by the filament’s deformation during motion. It is defined as

$E_{{s}}$

represents the strain energy generated by the filament’s deformation during motion. It is defined as

In addition, the harvested energy, which corresponds to the instantaneous power dissipated in the piezoelectric patches (Michelin & Doaré Reference Michelin and Doaré2013; Shoele & Mittal Reference Shoele and Mittal2016), can be quantified using the power coefficient, defined as

The fractional step method on a staggered Cartesian grid is used to solve the Navier–Stokes equations (Kim, Baek & Sung Reference Kim, Baek and Sung2002). A direct numerical method developed by Huang et al. (Reference Huang, Shin and Sung2007) is used to calculate the filament motion. Details of the discretisation of the governing equations and numerical method can be found in the works of (Kim et al. Reference Kim, Sung and Hyun1992, Reference Kim, Baek and Sung2002). We validated the accuracy of the solver in capturing the dynamics of the flexible ring in our previous work (Kim et al. Reference Kim, Huang, Shin and Sung2012: Lee, Sung & Zaki Reference Lee, Sung and Zaki2017).

2.2. Validation

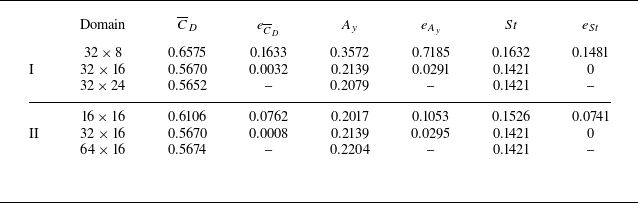

Table 1 presents the results of the domain test for the conventional clamped ring with

![]() $\epsilon = 0.6$

,

$\epsilon = 0.6$

,

![]() $\gamma =$

0.01 and

$\gamma =$

0.01 and

![]() $Re=$

100. These results include the averaged drag coefficient

$Re=$

100. These results include the averaged drag coefficient

![]() $\overline{C}_{{D}}$

, oscillation amplitude

$\overline{C}_{{D}}$

, oscillation amplitude

![]() $A_{y}$

and the Strouhal number

$A_{y}$

and the Strouhal number

![]() $St$

(

$St$

(

![]() $=f_{v}D/U_{0}$

), along with the corresponding relative error

$=f_{v}D/U_{0}$

), along with the corresponding relative error

![]() $\varepsilon$

. Here,

$\varepsilon$

. Here,

![]() $f_{v}$

represents the vortex shedding frequency from the ring. The simulation does not converge for the

$f_{v}$

represents the vortex shedding frequency from the ring. The simulation does not converge for the

![]() $16\times 16$

domain. The results for the

$16\times 16$

domain. The results for the

![]() $32\times 16$

domain are consistent with those for the

$32\times 16$

domain are consistent with those for the

![]() $32\times 24$

and

$32\times 24$

and

![]() $64\times 16$

domains. Therefore, a domain size of

$64\times 16$

domains. Therefore, a domain size of

![]() $32\times 16$

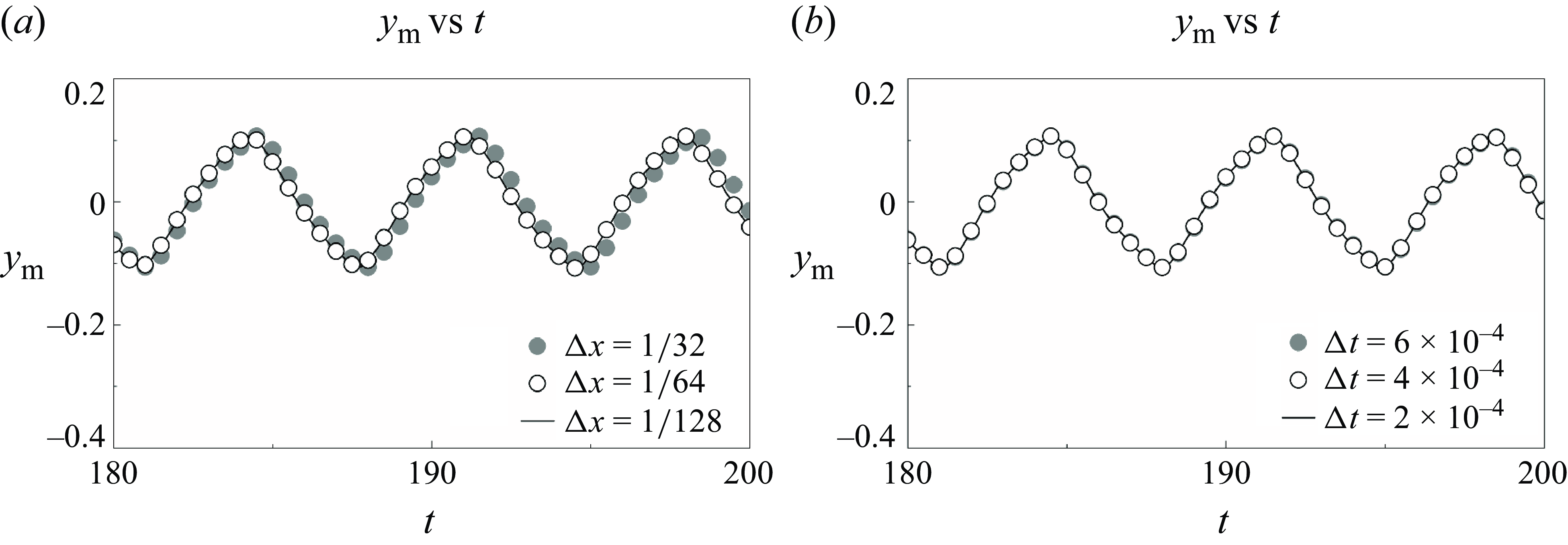

was selected because it allows for simulation over a greater number of time steps, thereby enhancing the accuracy of the results. To assess the effect of grid resolution and time step on the simulation outcomes, we conducted convergence studies for various grid resolutions and time steps. Figure 3 shows the time evolution of the transverse displacement at the midpoint of the ring. The results obtained for

$32\times 16$

was selected because it allows for simulation over a greater number of time steps, thereby enhancing the accuracy of the results. To assess the effect of grid resolution and time step on the simulation outcomes, we conducted convergence studies for various grid resolutions and time steps. Figure 3 shows the time evolution of the transverse displacement at the midpoint of the ring. The results obtained for

![]() $\Delta x=1/64$

and

$\Delta x=1/64$

and

![]() $\Delta t=4\times 10^{-4}$

align well with those for

$\Delta t=4\times 10^{-4}$

align well with those for

![]() $\Delta x=1/128$

and

$\Delta x=1/128$

and

![]() $\Delta t=2\times 10^{-4}$

. Consequently, a grid resolution of

$\Delta t=2\times 10^{-4}$

. Consequently, a grid resolution of

![]() $1/64$

and a time step of

$1/64$

and a time step of

![]() $4\times 10^{-4}$

were chosen to ensure high accuracy in the simulation. The maximum Courant number was approximately 0.04 in the simulation. The grid was uniform in the

$4\times 10^{-4}$

were chosen to ensure high accuracy in the simulation. The maximum Courant number was approximately 0.04 in the simulation. The grid was uniform in the

![]() $x$

-direction but stretched in the

$x$

-direction but stretched in the

![]() $y$

-direction. Specifically, within the range

$y$

-direction. Specifically, within the range

![]() $-Y/4\leq y\leq Y/4$

, the grid size was

$-Y/4\leq y\leq Y/4$

, the grid size was

![]() $\Delta y=\Delta x$

. Outside this range, the grid size was adjusted to

$\Delta y=\Delta x$

. Outside this range, the grid size was adjusted to

![]() $\Delta y=2\Delta x$

. The grid resolution for the ring was chosen to match that of the surrounding fluid domain for consistency.

$\Delta y=2\Delta x$

. The grid resolution for the ring was chosen to match that of the surrounding fluid domain for consistency.

Table 1. Domain test, including the averaged drag coefficient

![]() $\overline{C}_{{D}}$

, oscillation amplitude of

$\overline{C}_{{D}}$

, oscillation amplitude of

![]() $A_{y}$

, the Strouhal number

$A_{y}$

, the Strouhal number

![]() $St$

and the relative errors

$St$

and the relative errors

![]() $e$

to

$e$

to

![]() $32\times 24$

(domain height test in part I) and

$32\times 24$

(domain height test in part I) and

![]() $64\times 16$

(domain length test in part II) in the conventional configuration (

$64\times 16$

(domain length test in part II) in the conventional configuration (

![]() $L/D=3$

,

$L/D=3$

,

![]() $\gamma =0.01$

,

$\gamma =0.01$

,

![]() $Re=100$

).

$Re=100$

).

Figure 3. Time evolution of the transverse displacement of the midpoint of the ring (

![]() $y_{{m}}$

) for different (a) grid sizes and (b) time steps.

$y_{{m}}$

) for different (a) grid sizes and (b) time steps.

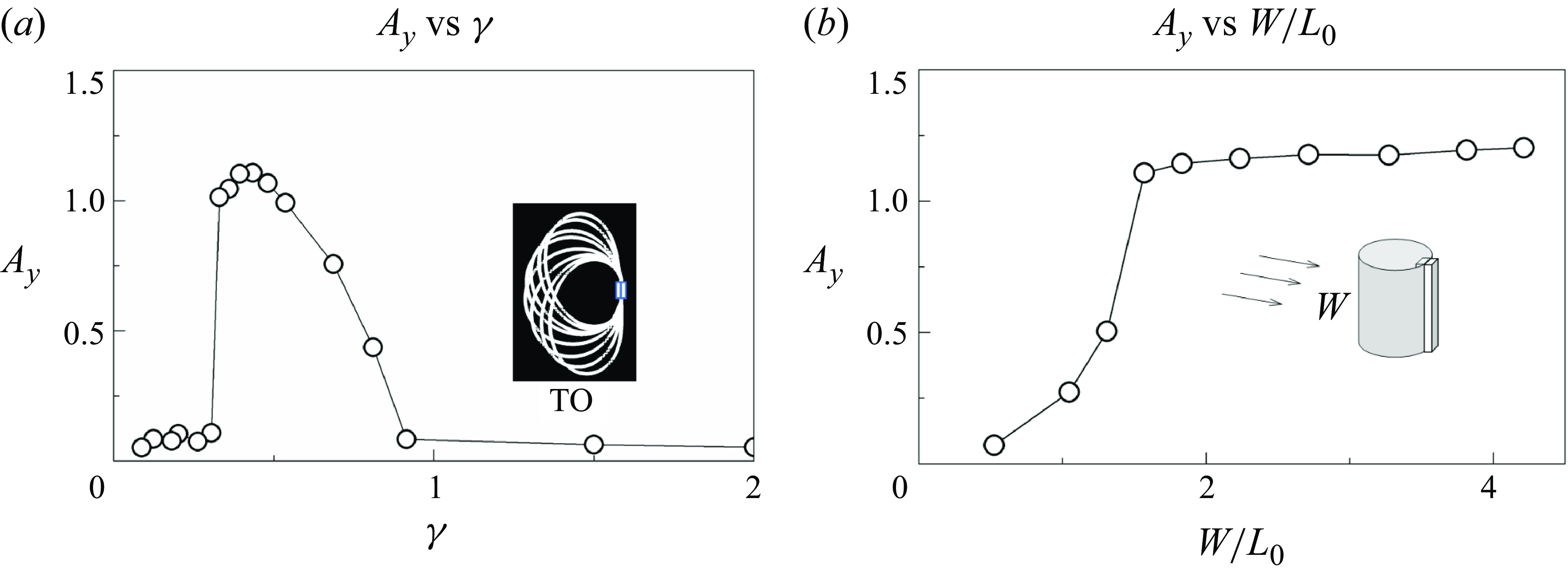

To validate our simulation framework, we conducted experiments in a small open suction wind tunnel with wind speeds ranging from 10 to 55 m s–1. An event camera was used to capture the instantaneous shapes of the flexible ring. The ring was fabricated from polyethylene terephthalate (PET) film with a thickness of 0.05 mm, a Young’s modulus of 4 GPa, a Poisson’s ratio of 0.4 and a density of 1.3 × 10³ kg m–3. Details of the experimental setup are provided in the work of Lyu, Cai & Liu (Reference Lyu, Cai and Liu2024). Obtaining high-quality Particle Image Velocimetry measurements was challenging due to the PET film’s tendency to reflect and scatter the laser sheet, as well as optical occlusions resulting from the ring’s continuously varying curvature. Instead, we focused on examining the influence of non-dimensional bending rigidity on the oscillation amplitude (

![]() $A_{y}$

), providing valuable insights into the ring’s dynamic behaviour under varying aerodynamic conditions (Chen et al. Reference Chen, Mao, Liu and Sung2024, Reference Chen, Liu and Sung2025). Although varying the wind speed to modify

$A_{y}$

), providing valuable insights into the ring’s dynamic behaviour under varying aerodynamic conditions (Chen et al. Reference Chen, Mao, Liu and Sung2024, Reference Chen, Liu and Sung2025). Although varying the wind speed to modify

![]() $\gamma$

makes it challenging to maintain a constant

$\gamma$

makes it challenging to maintain a constant

![]() $Re$

, our experiments captured three distinct oscillation modes that match the predictions from our numerical simulations (figure 4). Moreover, our investigation into the effect of the ring’s aspect ratio (

$Re$

, our experiments captured three distinct oscillation modes that match the predictions from our numerical simulations (figure 4). Moreover, our investigation into the effect of the ring’s aspect ratio (

![]() $W/L_{0}$

, where

$W/L_{0}$

, where

![]() $W$

is the ring’s spanwise width and

$W$

is the ring’s spanwise width and

![]() $L_{0}$

is the equivalent diameter) showed that as

$L_{0}$

is the equivalent diameter) showed that as

![]() $W/L_{0}$

increases,

$W/L_{0}$

increases,

![]() $A_{y}$

converges to a constant value, indicating that three-dimensional effects become negligible (Banerjee et al. Reference Banerjee, Connell and Yue2015; Gurugubelli & Jaiman Reference Gurugubelli and Jaiman2019). Overall, experimental studies are limited by the difficulty of altering the parameters of filament materials, which constrains the scope of research. In contrast, simulations offer greater flexibility, enabling the exploration of a broader range of parameters and the examination of additional phenomena.

$A_{y}$

converges to a constant value, indicating that three-dimensional effects become negligible (Banerjee et al. Reference Banerjee, Connell and Yue2015; Gurugubelli & Jaiman Reference Gurugubelli and Jaiman2019). Overall, experimental studies are limited by the difficulty of altering the parameters of filament materials, which constrains the scope of research. In contrast, simulations offer greater flexibility, enabling the exploration of a broader range of parameters and the examination of additional phenomena.

Figure 4. Oscillation amplitude for an inverted ring as a function of (a)

![]() $\gamma$

and (b)

$\gamma$

and (b)

![]() $W/L_{0}$

.

$W/L_{0}$

.

3. Results and discussion

3.1. Modes of ring motion

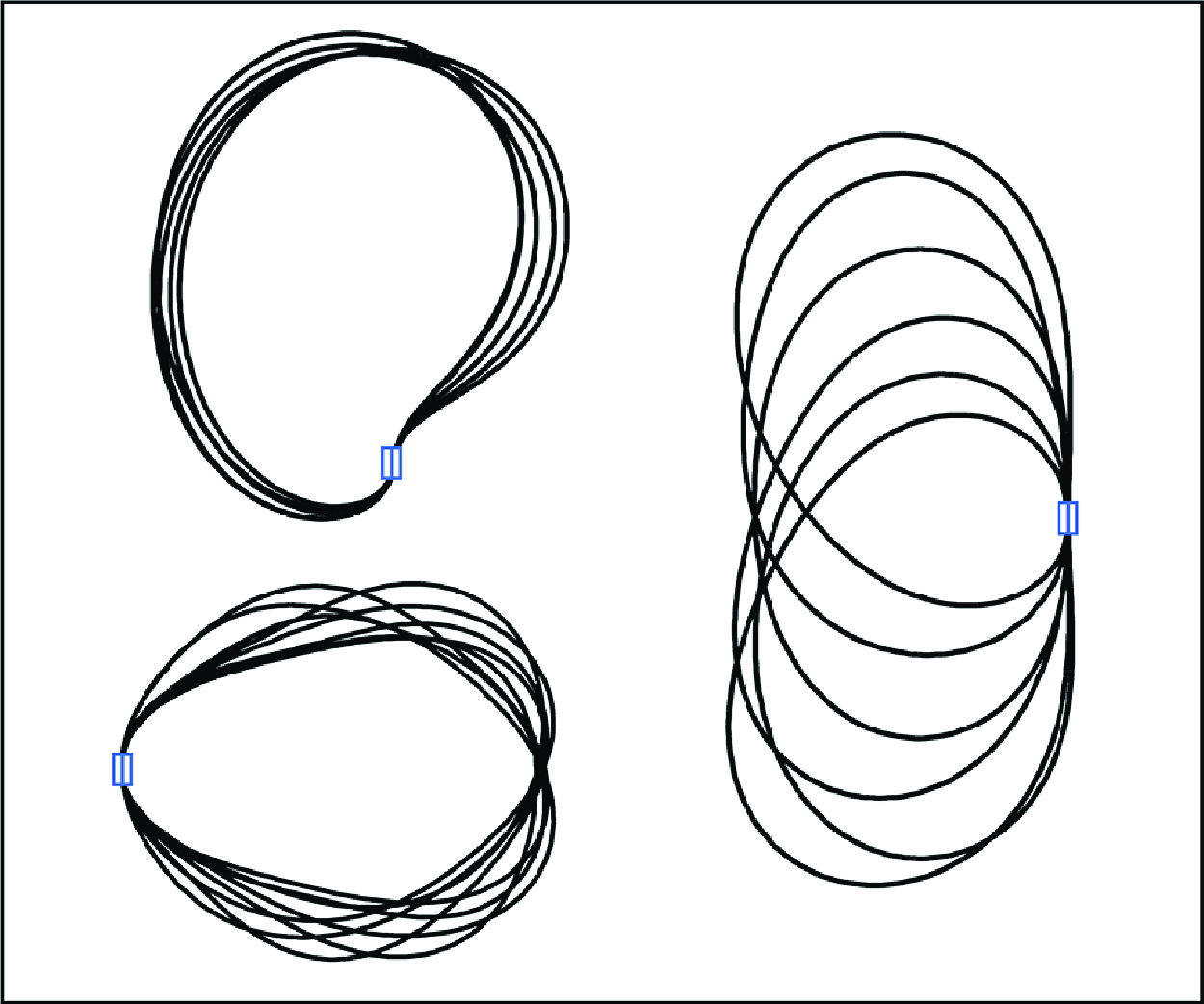

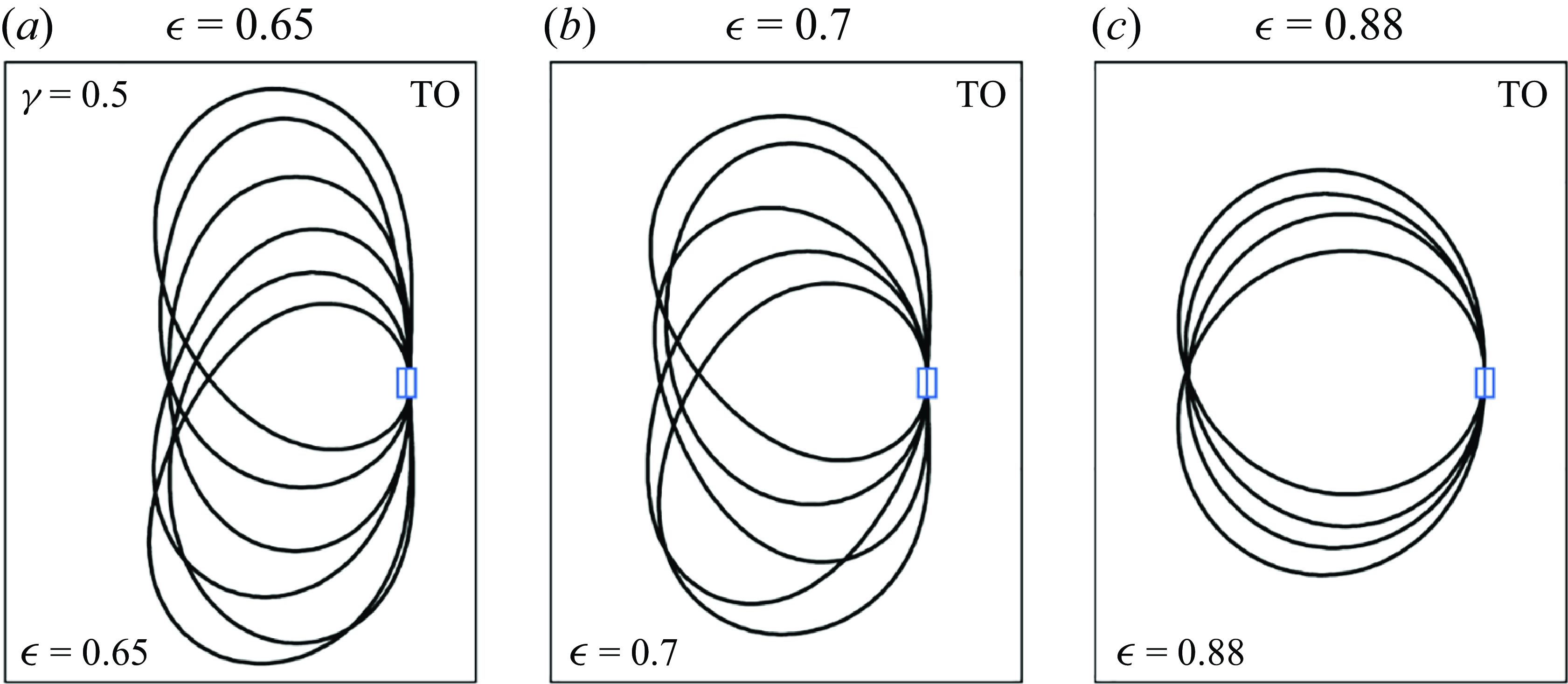

We examined the motion and wake patterns of both conventional and inverted flexible rings under different dynamic modes. As shown in figure 5, the flapping (F) mode, deflected oscillation (DO) mode, and TO mode were identified as

![]() $\gamma$

was varied, with

$\gamma$

was varied, with

![]() $\epsilon = 0.65$

kept constant. Experimental observations are included in each inset for qualitative comparison. The F mode, resembling the motion of a conventional flag, is characterised by low-amplitude, high-frequency oscillations and occurs in the conventional configuration. By contrast, the inverted configuration exhibits either DO or TO, depending on the conditions. In the DO mode, the ring deflects to one side and undergoes low-amplitude oscillations, similar to an inverted flag. As

$\epsilon = 0.65$

kept constant. Experimental observations are included in each inset for qualitative comparison. The F mode, resembling the motion of a conventional flag, is characterised by low-amplitude, high-frequency oscillations and occurs in the conventional configuration. By contrast, the inverted configuration exhibits either DO or TO, depending on the conditions. In the DO mode, the ring deflects to one side and undergoes low-amplitude oscillations, similar to an inverted flag. As

![]() $\gamma$

increases, the ring transitions to the TO mode, characterised by large-amplitude oscillations perpendicular to the flow direction. The experiments were conducted in a wind tunnel, where the three modes were identified as the wind speed was varied under comparable bending rigidity. Despite differences between the simulation and experimental conditions, the qualitatively similar results confirm the existence of these modes. Experimental studies are constrained by the difficulty of altering filament material parameters, limiting the scope of research. By contrast, simulations enable broader parameter exploration and the study of additional phenomena in both inverted and conventional flexible rings.

$\gamma$

increases, the ring transitions to the TO mode, characterised by large-amplitude oscillations perpendicular to the flow direction. The experiments were conducted in a wind tunnel, where the three modes were identified as the wind speed was varied under comparable bending rigidity. Despite differences between the simulation and experimental conditions, the qualitatively similar results confirm the existence of these modes. Experimental studies are constrained by the difficulty of altering filament material parameters, limiting the scope of research. By contrast, simulations enable broader parameter exploration and the study of additional phenomena in both inverted and conventional flexible rings.

Figure 5. Superposition of the instantaneous shapes of the flexible ring for different oscillation modes: (a) F mode at

![]() $\gamma =$

0.01, (b) DO mode at

$\gamma =$

0.01, (b) DO mode at

![]() $\gamma =$

0.02 and (c) TO mode at

$\gamma =$

0.02 and (c) TO mode at

![]() $\gamma =$

0.5, with

$\gamma =$

0.5, with

![]() $\epsilon = 0.65$

. The white line in each inset represents the experimentally observed mode.

$\epsilon = 0.65$

. The white line in each inset represents the experimentally observed mode.

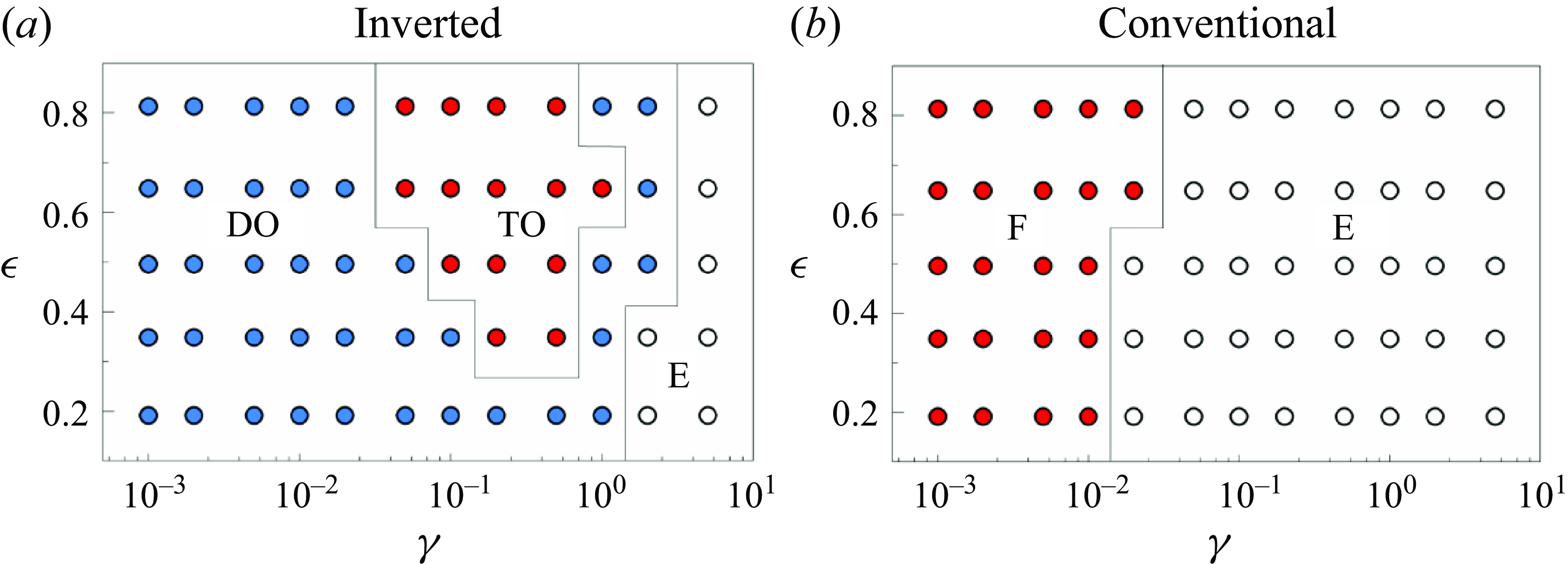

To illustrate the distribution of modes for both inverted and conventional flexible rings as

![]() $\gamma$

and

$\gamma$

and

![]() $\epsilon$

were varied, mode diagrams are presented in figure 6. All simulations in the present study are run for at least 80 oscillation cycles to ensure that the motion has fully converged. For the inverted flexible ring, three distinct modes emerge depending on

$\epsilon$

were varied, mode diagrams are presented in figure 6. All simulations in the present study are run for at least 80 oscillation cycles to ensure that the motion has fully converged. For the inverted flexible ring, three distinct modes emerge depending on

![]() $\gamma$

and

$\gamma$

and

![]() $\epsilon$

. At low bending rigidity and in the transition zone between the TO and equilibrium (E) modes, the DO mode dominates. This mode is characterised by motion confined to one side of the

$\epsilon$

. At low bending rigidity and in the transition zone between the TO and equilibrium (E) modes, the DO mode dominates. This mode is characterised by motion confined to one side of the

![]() $y$

-axis, resembling the DO mode of the inverted flag. Unlike the symmetric up-and-down flapping observed in the conventional ring, the DO mode occurs asymmetrically on one side, either above or below the

$y$

-axis, resembling the DO mode of the inverted flag. Unlike the symmetric up-and-down flapping observed in the conventional ring, the DO mode occurs asymmetrically on one side, either above or below the

![]() $x$

-axis, depending on the initial excitation. As

$x$

-axis, depending on the initial excitation. As

![]() $\gamma$

increases to a level where the flexible ring can resist the fluid forces, the ring transitions into the TO mode, where it exhibits symmetric oscillation along the

$\gamma$

increases to a level where the flexible ring can resist the fluid forces, the ring transitions into the TO mode, where it exhibits symmetric oscillation along the

![]() $y$

-axis. Notably, the TO mode is more likely to occur at higher

$y$

-axis. Notably, the TO mode is more likely to occur at higher

![]() $\epsilon$

values and is absent at lower

$\epsilon$

values and is absent at lower

![]() $\epsilon$

values (i.e.

$\epsilon$

values (i.e.

![]() $\epsilon = 0.2$

), possibly because of the flatter shape of the ring under low

$\epsilon = 0.2$

), possibly because of the flatter shape of the ring under low

![]() $\epsilon$

, which causes it to deflect to one side rather than oscillate in the TO motion. When

$\epsilon$

, which causes it to deflect to one side rather than oscillate in the TO motion. When

![]() $\gamma$

becomes sufficiently high, the ring’s motion diminishes, eventually leading to the E mode. By contrast, the conventional ring only exhibits two modes: the F mode at low

$\gamma$

becomes sufficiently high, the ring’s motion diminishes, eventually leading to the E mode. By contrast, the conventional ring only exhibits two modes: the F mode at low

![]() $\gamma$

and the E mode as

$\gamma$

and the E mode as

![]() $\gamma$

increases beyond the critical bending rigidity.

$\gamma$

increases beyond the critical bending rigidity.

Figure 6. Mode diagram for (a) inverted and (b) conventional initial states depending on

![]() $\gamma$

and

$\gamma$

and

![]() $\epsilon$

; regions DO, TO, F and E correspond to the DO mode, the TO mode, the F mode and the E mode, respectively.

$\epsilon$

; regions DO, TO, F and E correspond to the DO mode, the TO mode, the F mode and the E mode, respectively.

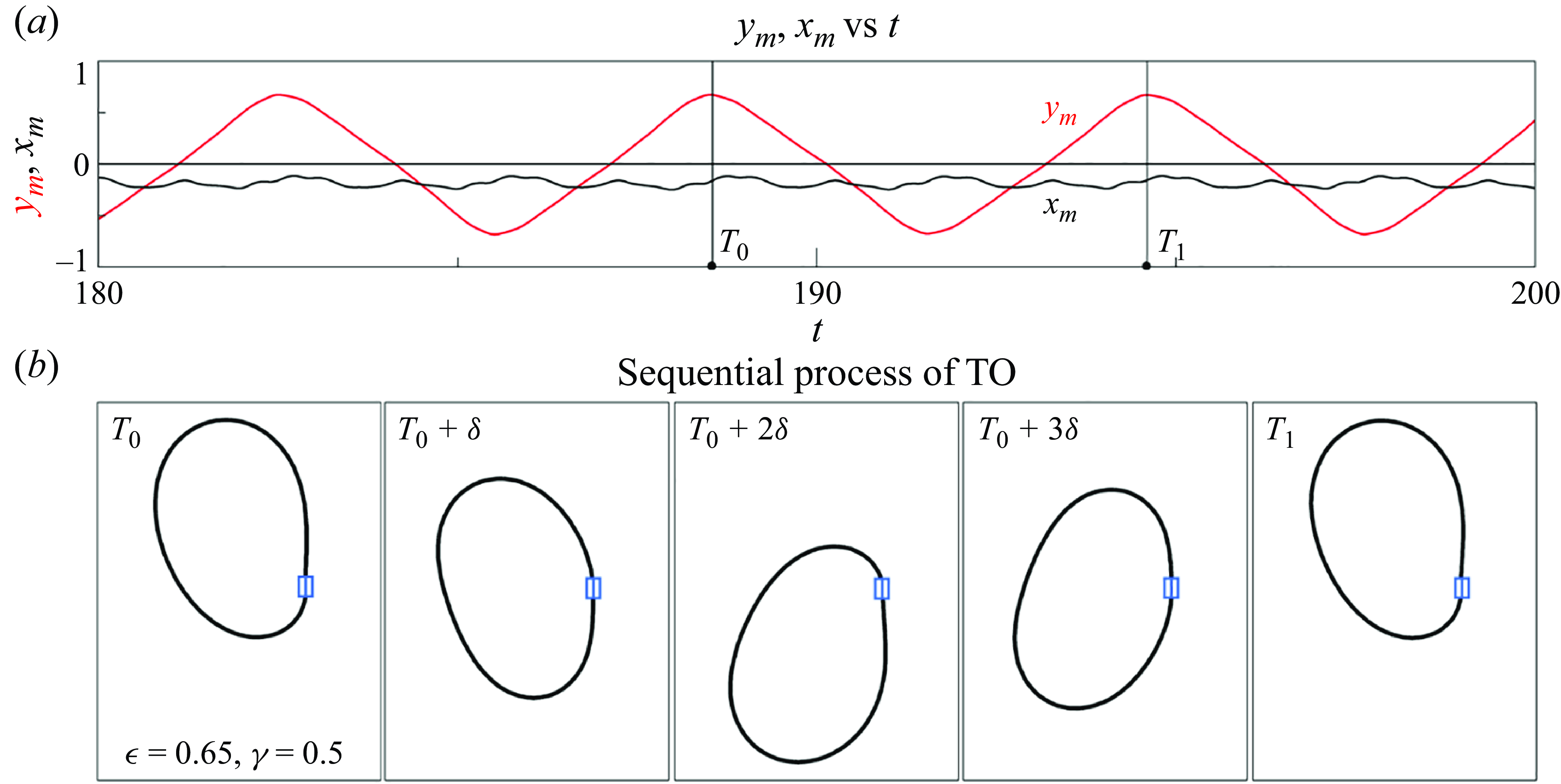

The TO mode of the inverted flexible ring, characterised by a large oscillation amplitude and high critical bending rigidity, is particularly well suited for energy harvesting. To better illustrate the TO mode, the time history of the midpoint (

![]() $x_{{m}}$

,

$x_{{m}}$

,

![]() $y_{{m}}$

), along with the sequential motion of the flexible ring, is presented in figure 7. From the time history of the midpoint, it is evident that the motion in the

$y_{{m}}$

), along with the sequential motion of the flexible ring, is presented in figure 7. From the time history of the midpoint, it is evident that the motion in the

![]() $y$

-direction dominates in the TO mode, whereas the

$y$

-direction dominates in the TO mode, whereas the

![]() $x$

-direction motion is almost negligible. Figure 7(b) depicts a complete TO mode cycle from

$x$

-direction motion is almost negligible. Figure 7(b) depicts a complete TO mode cycle from

![]() $T_{0}$

to

$T_{0}$

to

![]() $T_{1}$

. At

$T_{1}$

. At

![]() $T_{0}$

,

$T_{0}$

,

![]() $y_{{m}}$

is at its maximum value, signalling the beginning of a downward motion. By

$y_{{m}}$

is at its maximum value, signalling the beginning of a downward motion. By

![]() $T_{0}+\delta$

, the

$T_{0}+\delta$

, the

![]() $y_{{m}}$

crosses the

$y_{{m}}$

crosses the

![]() $x$

-axis, revealing an asymmetric shape. As the time progresses to

$x$

-axis, revealing an asymmetric shape. As the time progresses to

![]() $T_{0}+2\delta$

,

$T_{0}+2\delta$

,

![]() $y_{{m}}$

reaches its minimum value, positioning the flexible ring at its lowest point. The ring then initiates an upward motion mirroring the earlier downward movement. Finally, at

$y_{{m}}$

reaches its minimum value, positioning the flexible ring at its lowest point. The ring then initiates an upward motion mirroring the earlier downward movement. Finally, at

![]() $T_{1}$

, the flexible ring returns to its upper position, marking the completion of one TO cycle.

$T_{1}$

, the flexible ring returns to its upper position, marking the completion of one TO cycle.

Figure 7. (a) Time histories of the midpoint (

![]() $x_{{m}}$

,

$x_{{m}}$

,

![]() $y_{{m}}$

) in the TO mode. (b) The sequential process of the TO mode (

$y_{{m}}$

) in the TO mode. (b) The sequential process of the TO mode (

![]() $\epsilon = 0.65$

,

$\epsilon = 0.65$

,

![]() $\gamma =$

0.5).

$\gamma =$

0.5).

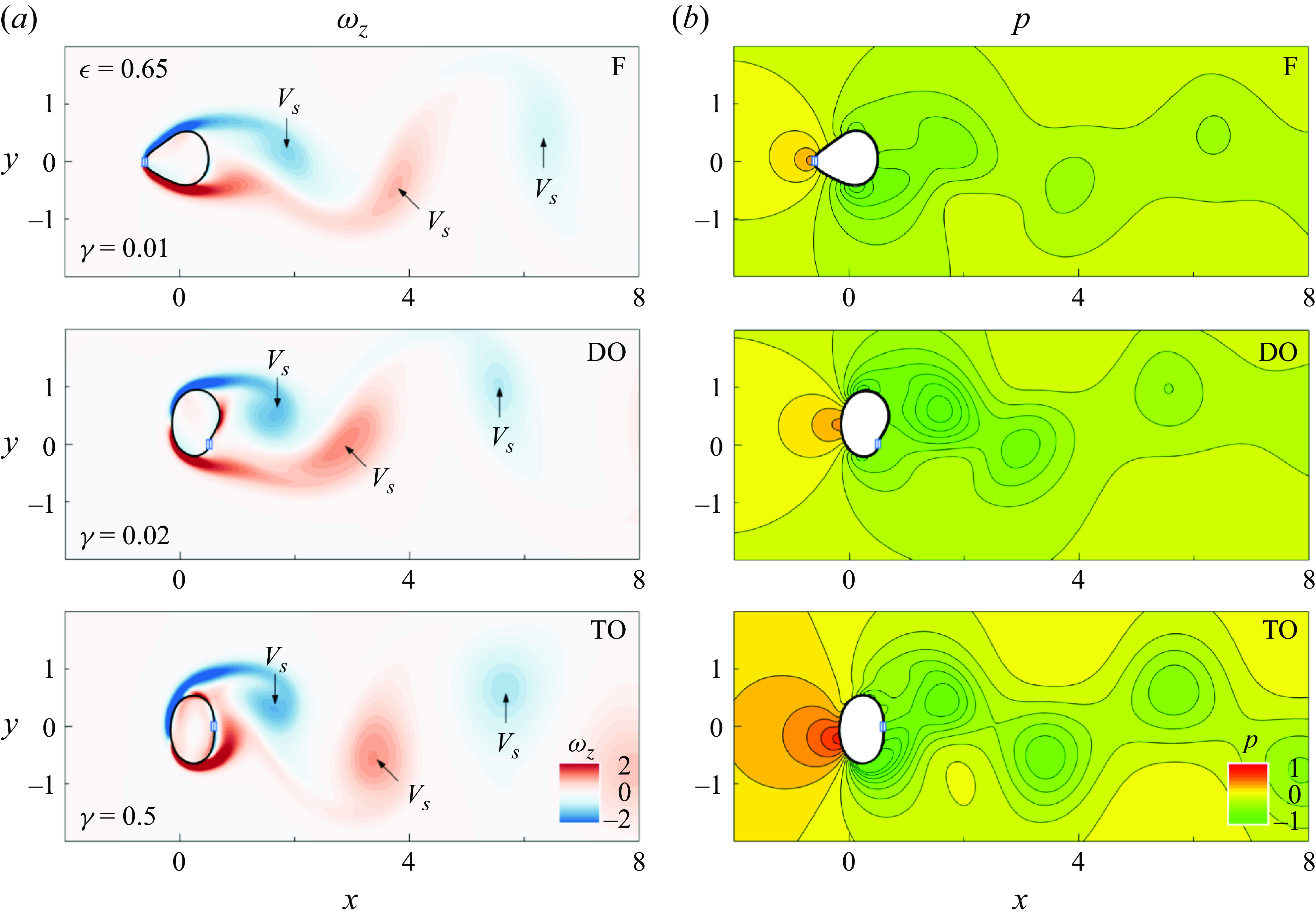

We examined the vortex shedding and pressure distribution of the flexible ring across different modes. Figure 8 shows the instantaneous contours of

![]() $\omega _{z}$

and

$\omega _{z}$

and

![]() $p$

for the F, DO and TO modes. Although all three modes exhibit a 2S wake pattern, the shapes of the shed vortices and the corresponding pressure fields differ. In the F mode, the interaction between the two closed shear layers and the adjacent vortices causes the vortices to stretch and diverge. This interaction suppresses the low-pressure regions in the wake as the vortices dissipate. In the DO mode, the distance between the two shear layers increases, reducing the interaction between the shedding vortices. This reduced interaction results in more concentrated vortices and increased vorticity. In addition, the low-pressure region in the DO mode is more prominent than in the F mode. In the TO mode, vorticity intensifies, leading to even lower wake pressure, likely due to greater fluctuations in fluid forces, which enhance the oscillation amplitude. A detailed analysis of vortex shedding for each mode is presented in subsequent sections.

$p$

for the F, DO and TO modes. Although all three modes exhibit a 2S wake pattern, the shapes of the shed vortices and the corresponding pressure fields differ. In the F mode, the interaction between the two closed shear layers and the adjacent vortices causes the vortices to stretch and diverge. This interaction suppresses the low-pressure regions in the wake as the vortices dissipate. In the DO mode, the distance between the two shear layers increases, reducing the interaction between the shedding vortices. This reduced interaction results in more concentrated vortices and increased vorticity. In addition, the low-pressure region in the DO mode is more prominent than in the F mode. In the TO mode, vorticity intensifies, leading to even lower wake pressure, likely due to greater fluctuations in fluid forces, which enhance the oscillation amplitude. A detailed analysis of vortex shedding for each mode is presented in subsequent sections.

Figure 8. Instantaneous contours of (a)

![]() $\omega _{z}$

and (b)

$\omega _{z}$

and (b)

![]() $p$

for the F mode (

$p$

for the F mode (

![]() $\gamma =0.01$

), DO mode (

$\gamma =0.01$

), DO mode (

![]() $\gamma =0.02$

) and TO mode (

$\gamma =0.02$

) and TO mode (

![]() $\gamma =0.5$

) under

$\gamma =0.5$

) under

![]() $\epsilon = 0.65$

.

$\epsilon = 0.65$

.

Figure 9. (a) Time histories of

![]() $x_{{m}}$

,

$x_{{m}}$

,

![]() $y_{{m}}$

,

$y_{{m}}$

,

![]() $F$

and

$F$

and

![]() $E$

. Instantaneous contours of (b)

$E$

. Instantaneous contours of (b)

![]() $\omega _{z}$

and (c)

$\omega _{z}$

and (c)

![]() $p$

at A, B, C and D for

$p$

at A, B, C and D for

![]() $\epsilon = 0.65$

and

$\epsilon = 0.65$

and

![]() $\gamma =$

0.5 under the TO mode.

$\gamma =$

0.5 under the TO mode.

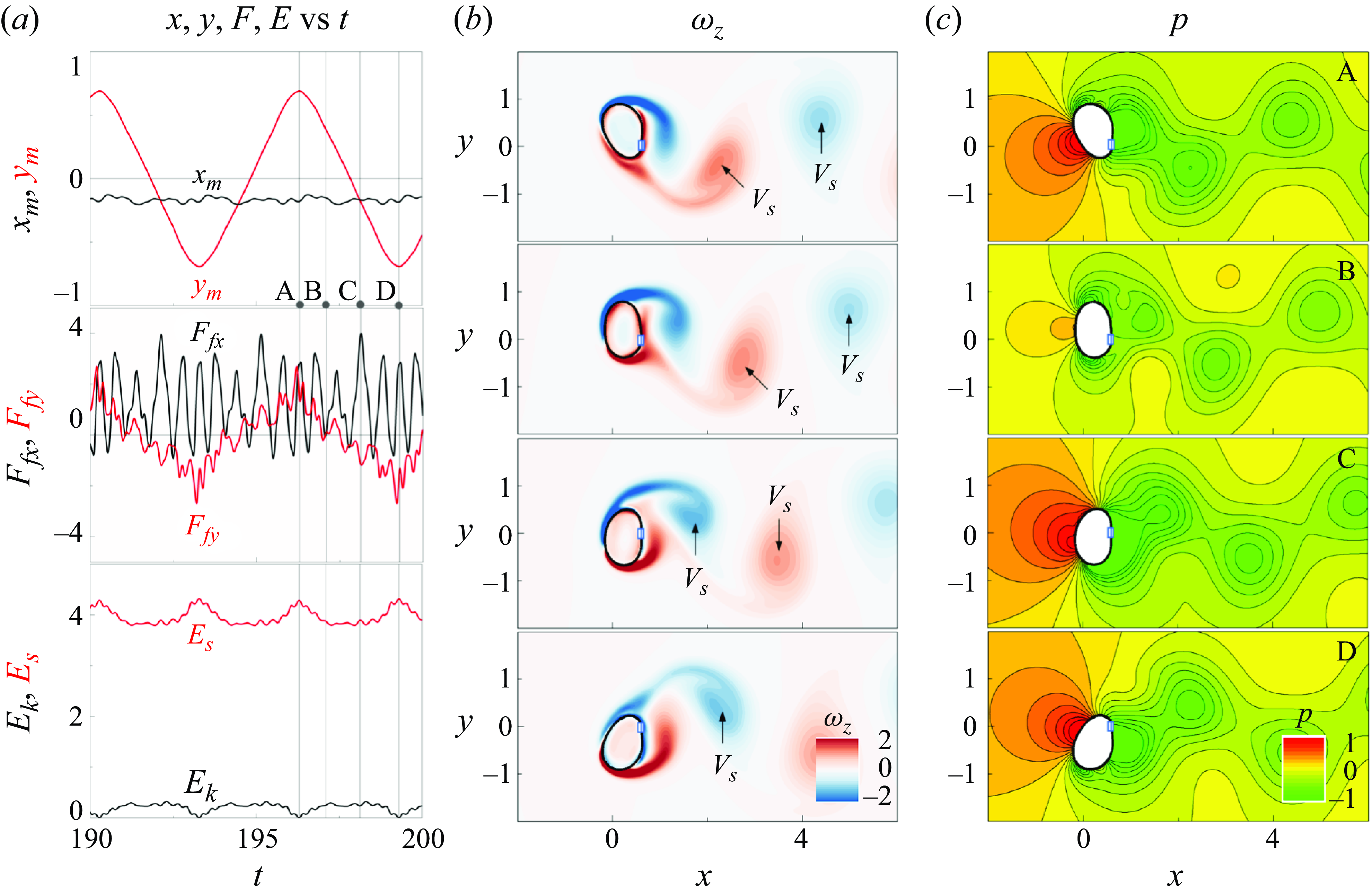

To elucidate the relationship between vortex shedding and ring motion, we analysed the vorticity and pressure contours around the flexible ring in the TO mode, alongside time histories of the midpoint position, fluid force, elastic force and energy (figure 9). Four specific time steps within one half of an oscillation period, denoted as A, B, C and D, are highlighted; the corresponding contours of

![]() $\omega _{z}$

and

$\omega _{z}$

and

![]() $p$

at these specific times are displayed in figure 9(b). Notably, the fluid force exhibits a higher-frequency component than the oscillation itself, likely because of the streamwise vibration of the ring. At time A, the flexible ring is in its uppermost position, with the

$p$

at these specific times are displayed in figure 9(b). Notably, the fluid force exhibits a higher-frequency component than the oscillation itself, likely because of the streamwise vibration of the ring. At time A, the flexible ring is in its uppermost position, with the

![]() $y_{{m}}$

at its maximum value. A high-pressure region forms on the lower-left side of the ring, whereas a low-pressure region, induced by vortex shedding, develops near the rear part. This pressure distribution results in a maximum value of

$y_{{m}}$

at its maximum value. A high-pressure region forms on the lower-left side of the ring, whereas a low-pressure region, induced by vortex shedding, develops near the rear part. This pressure distribution results in a maximum value of

![]() $F_{{f}y}$

. The elastic energy (

$F_{{f}y}$

. The elastic energy (

![]() $E_{{s}}$

) also peaks because of the large deflection at this position. Simultaneously, a negative vortex is forming on the top of the ring and a positive vortex is being shed from it. After time A, the ring begins its downward motion, driven by the elastic restoring force. At time B, the high-pressure region diminishes and

$E_{{s}}$

) also peaks because of the large deflection at this position. Simultaneously, a negative vortex is forming on the top of the ring and a positive vortex is being shed from it. After time A, the ring begins its downward motion, driven by the elastic restoring force. At time B, the high-pressure region diminishes and

![]() $F_{{f}y}$

approaches zero. Here,

$F_{{f}y}$

approaches zero. Here,

![]() $E_{{s}}$

is largely converted into kinetic energy (

$E_{{s}}$

is largely converted into kinetic energy (

![]() $E_{{k}}$

), leading to a minimum in

$E_{{k}}$

), leading to a minimum in

![]() $E_{{s}}$

and a peak of

$E_{{s}}$

and a peak of

![]() $E_{{k}}$

. At time C, the

$E_{{k}}$

. At time C, the

![]() $y_{{m}}$

passes the

$y_{{m}}$

passes the

![]() $x$

-axis, a negative vortex is shed, and a new high-pressure region forms on the upper-left side of the ring, generating a negative

$x$

-axis, a negative vortex is shed, and a new high-pressure region forms on the upper-left side of the ring, generating a negative

![]() $F_{{f}y}$

that pushes the ring further downward. During the period from B to C, the elastic energy remains low, indicating minimal deformation. By time D, the ring reaches its lowest position, with elastic energy again at its maximum, mirroring the conditions at time A. After time D, the ring begins its upward motion, completing the oscillation cycle. The periodic formation and shedding of vortices play a critical role in driving the TO motion, with the associated fluid forces and pressure gradients directly influencing the ring’s dynamic behaviour.

$F_{{f}y}$

that pushes the ring further downward. During the period from B to C, the elastic energy remains low, indicating minimal deformation. By time D, the ring reaches its lowest position, with elastic energy again at its maximum, mirroring the conditions at time A. After time D, the ring begins its upward motion, completing the oscillation cycle. The periodic formation and shedding of vortices play a critical role in driving the TO motion, with the associated fluid forces and pressure gradients directly influencing the ring’s dynamic behaviour.

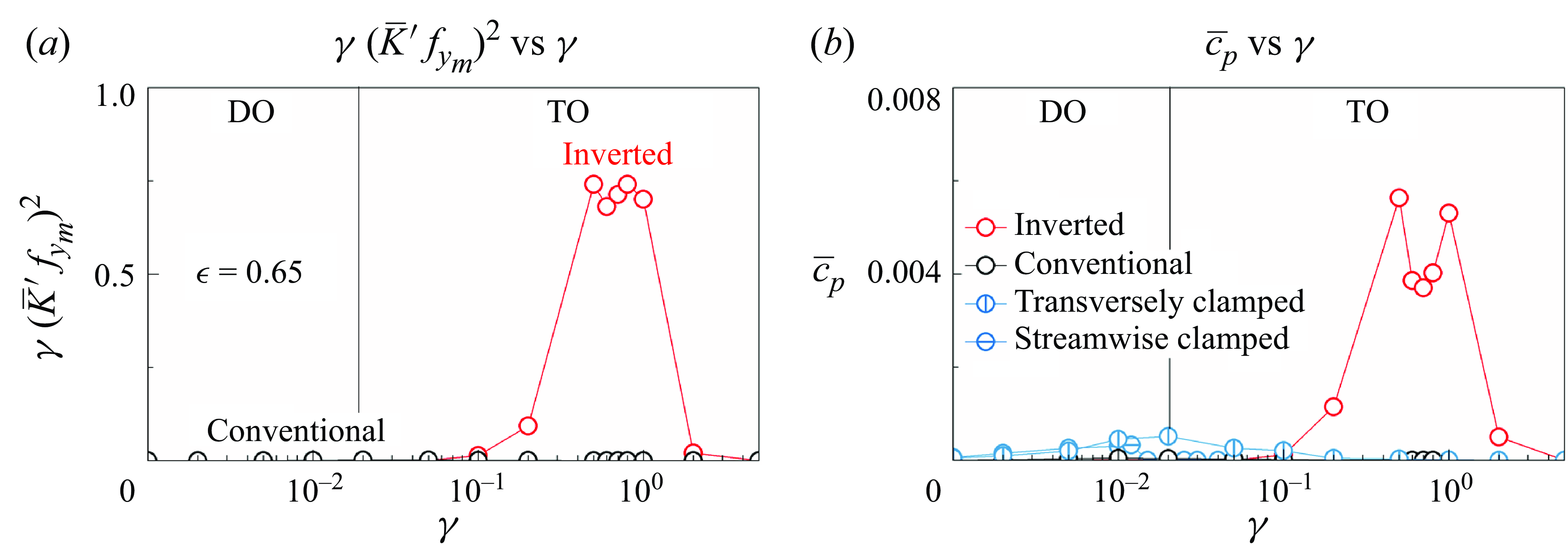

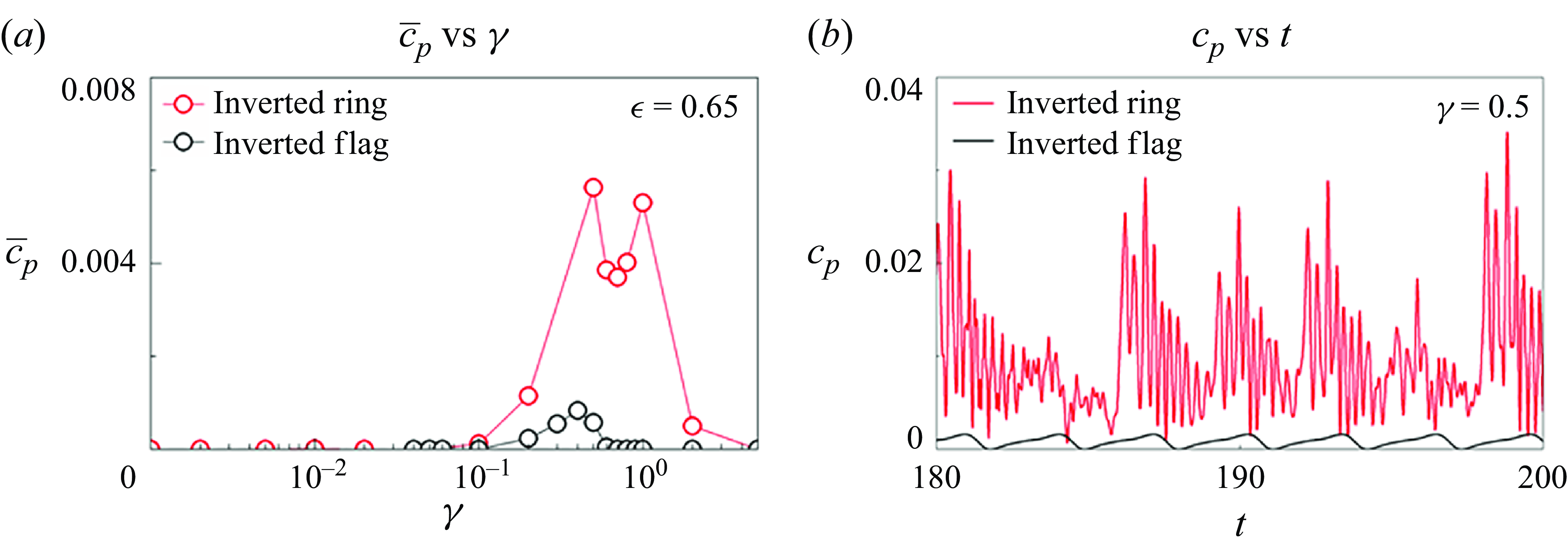

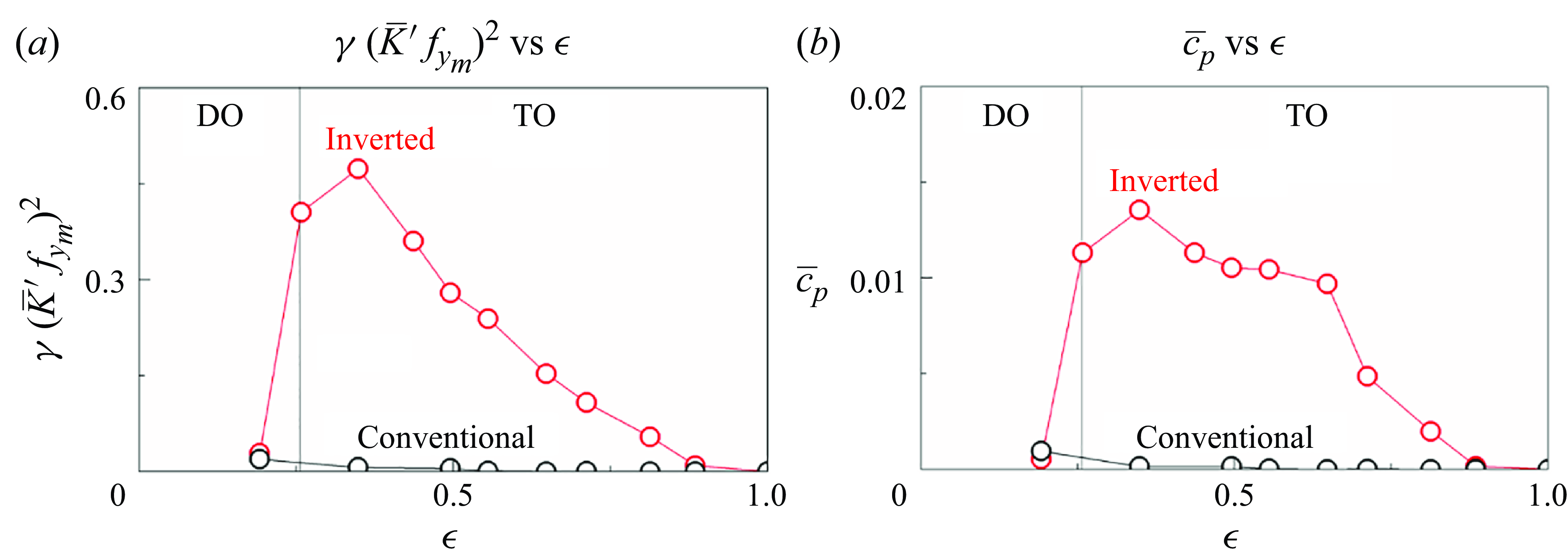

3.2. Dimensional analysis of the energy equation

Having analysed the motion and wake patterns of the flexible ring across different modes, we here focus on the energy-harvesting performance. A dimensional analysis of the energy equation is applied to assess the contribution of each component to the overall energy-harvesting efficiency. By applying a Fourier transform to both sides of (2.20), we derive the energy equation in the frequency domain

where

![]() $\omega =2\pi f_{{y_{{m}}}}$

is the dominant angular frequency of the filament and

$\omega =2\pi f_{{y_{{m}}}}$

is the dominant angular frequency of the filament and

![]() $\hat{V}$

is the amplitude of the

$\hat{V}$

is the amplitude of the

![]() $V$

component with frequency

$V$

component with frequency

![]() $\omega$

. By combining Parseval’s theorem with (3.1), we can estimate the mean power coefficient

$\omega$

. By combining Parseval’s theorem with (3.1), we can estimate the mean power coefficient

![]() $\overline{c}_{{p}}$

as

$\overline{c}_{{p}}$

as

Given the small value of

![]() $\beta _{{e}}$

used in the present study, the expression simplifies to

$\beta _{{e}}$

used in the present study, the expression simplifies to

From this analysis, we can directly assess the influence of bending rigidity, oscillation frequency and filament deformation on energy harvesting. Deformation and oscillation frequency are critical because

![]() $\overline{c}_{{p}}$

is proportional to the square of the ring’s curvature. This relationship suggests that motion involving both high frequency and large deflection substantially enhances energy harvesting. Although

$\overline{c}_{{p}}$

is proportional to the square of the ring’s curvature. This relationship suggests that motion involving both high frequency and large deflection substantially enhances energy harvesting. Although

![]() $\overline{c}_{{p}}$

is only linearly proportional to

$\overline{c}_{{p}}$

is only linearly proportional to

![]() $\gamma$

, the operational range of

$\gamma$

, the operational range of

![]() $\gamma$

spans several orders of magnitude, which closely affects

$\gamma$

spans several orders of magnitude, which closely affects

![]() $\overline{c}_{{p}}.$

The following sections examine the influence of bending rigidity and eccentricity on the flexible ring’s motion and energy-harvesting performance. Using prior analysis, we assess the contributions of bending rigidity, deflection and oscillation frequency to the efficiency of energy extraction from fluid–structure interactions.

$\overline{c}_{{p}}.$

The following sections examine the influence of bending rigidity and eccentricity on the flexible ring’s motion and energy-harvesting performance. Using prior analysis, we assess the contributions of bending rigidity, deflection and oscillation frequency to the efficiency of energy extraction from fluid–structure interactions.

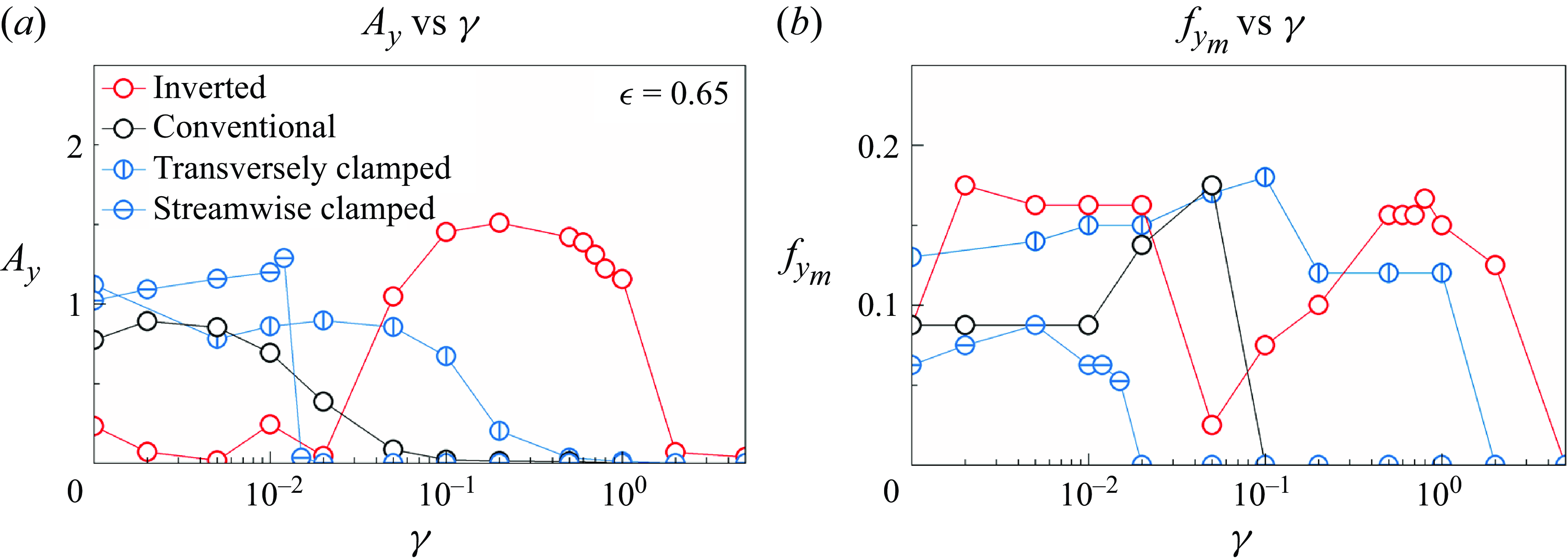

3.3. Effect of bending rigidity

We investigate the effect of bending rigidity on the dynamic and energy-harvesting performance of the clamped flexible ring, with eccentricity (

![]() $\epsilon$

) fixed at 0.65 for clarity. For comparison, results for transversely and streamwise buckled filaments are also included (Mao et al. Reference Mao, Liu and Sung2024; Chen et al. Reference Chen, Mao, Liu and Sung2024). Figure 10 illustrates the oscillation amplitude

$\epsilon$

) fixed at 0.65 for clarity. For comparison, results for transversely and streamwise buckled filaments are also included (Mao et al. Reference Mao, Liu and Sung2024; Chen et al. Reference Chen, Mao, Liu and Sung2024). Figure 10 illustrates the oscillation amplitude

![]() $(A_{y})$

and frequency

$(A_{y})$

and frequency

![]() $(f_{{y_{{m}}}})$

for both conventional and inverted flexible rings as

$(f_{{y_{{m}}}})$

for both conventional and inverted flexible rings as

![]() $\gamma$

is varied. At low bending rigidity, the flexible ring is too soft to withstand the fluid forces, resulting in a deflected motion confined to one side and sustained in the DO mode, with a Strouhal number of ∼0.163. In this mode,

$\gamma$

is varied. At low bending rigidity, the flexible ring is too soft to withstand the fluid forces, resulting in a deflected motion confined to one side and sustained in the DO mode, with a Strouhal number of ∼0.163. In this mode,

![]() $A_{y}$

is small, whereas

$A_{y}$

is small, whereas

![]() $f_{{y_{{m}}}}$

is relatively high. As

$f_{{y_{{m}}}}$

is relatively high. As

![]() $\gamma$

increases to 0.05, the inverted ring transitions from the DO mode to the TO mode, leading to a sudden increase in

$\gamma$

increases to 0.05, the inverted ring transitions from the DO mode to the TO mode, leading to a sudden increase in

![]() $A_{y}$

, indicating the onset of large-amplitude motion. The Strouhal number in the TO mode is approximately 0.15, slightly lower than that in the DO mode. Notably, the oscillation frequency decreases after the transition. As

$A_{y}$

, indicating the onset of large-amplitude motion. The Strouhal number in the TO mode is approximately 0.15, slightly lower than that in the DO mode. Notably, the oscillation frequency decreases after the transition. As

![]() $\gamma$

continues to increase, both

$\gamma$

continues to increase, both

![]() $A_{y}$

and

$A_{y}$

and

![]() $f_{{y_{{m}}}}$

increase, reaching their maximum values at 0.2 and 0.5, respectively. The lock-in and resonance phenomena are observed near

$f_{{y_{{m}}}}$

increase, reaching their maximum values at 0.2 and 0.5, respectively. The lock-in and resonance phenomena are observed near

![]() $\gamma =$

0.5, where the oscillation frequency aligns with the vortex shedding frequency, suggesting that the TO mode exhibits vortex-induced vibration (VIV). This phenomenon resembles the lock-in behaviour observed in elastically mounted cylinders (Williamson & Govardhan Reference Williamson and Govardhan2004; Prasanth & Mittal Reference Prasanth and Mittal2008; Navrose & Mittal Reference Navrose and Mittal2016) because of their similar geometries. Beyond the lock-in regime, both amplitude and frequency decrease, resulting in a transition to the E mode. By contrast, for the conventional clamped ring, vigorous motion occurs under low bending rigidity, with the vortex shedding frequency being twice the oscillation frequency for

$\gamma =$

0.5, where the oscillation frequency aligns with the vortex shedding frequency, suggesting that the TO mode exhibits vortex-induced vibration (VIV). This phenomenon resembles the lock-in behaviour observed in elastically mounted cylinders (Williamson & Govardhan Reference Williamson and Govardhan2004; Prasanth & Mittal Reference Prasanth and Mittal2008; Navrose & Mittal Reference Navrose and Mittal2016) because of their similar geometries. Beyond the lock-in regime, both amplitude and frequency decrease, resulting in a transition to the E mode. By contrast, for the conventional clamped ring, vigorous motion occurs under low bending rigidity, with the vortex shedding frequency being twice the oscillation frequency for

![]() $\gamma \lt$

0.01. Once

$\gamma \lt$

0.01. Once

![]() $\gamma$

exceeds 0.01, the oscillation of the conventional ring synchronises with the vortex shedding. As

$\gamma$

exceeds 0.01, the oscillation of the conventional ring synchronises with the vortex shedding. As

![]() $\gamma$

increases further,

$\gamma$

increases further,

![]() $A_{y}$

decreases, ultimately approaching zero at

$A_{y}$

decreases, ultimately approaching zero at

![]() $\gamma =$

0.1, indicating a transition to the E mode. The conventional ring does not demonstrate a lock-in phenomenon across various

$\gamma =$

0.1, indicating a transition to the E mode. The conventional ring does not demonstrate a lock-in phenomenon across various

![]() $\gamma$

, suggesting that its F mode is not VIV. This comparison reveals that the inverted ring exhibits a larger oscillation amplitude, higher frequency and greater bending rigidity in the lock-in regime compared with both transversely and streamwise buckled filaments, leading to superior energy-harvesting potential. Consequently, the following discussion focuses on the inverted-clamped filament.

$\gamma$

, suggesting that its F mode is not VIV. This comparison reveals that the inverted ring exhibits a larger oscillation amplitude, higher frequency and greater bending rigidity in the lock-in regime compared with both transversely and streamwise buckled filaments, leading to superior energy-harvesting potential. Consequently, the following discussion focuses on the inverted-clamped filament.

Figure 10. (a) Oscillation amplitude (

![]() $A_{y}$

) and (b) oscillation frequency (

$A_{y}$

) and (b) oscillation frequency (

![]() $f_{{y_{{m}}}}$

) as a function of

$f_{{y_{{m}}}}$

) as a function of

![]() $\gamma$

(

$\gamma$

(

![]() $\epsilon = 0.65$

).

$\epsilon = 0.65$

).

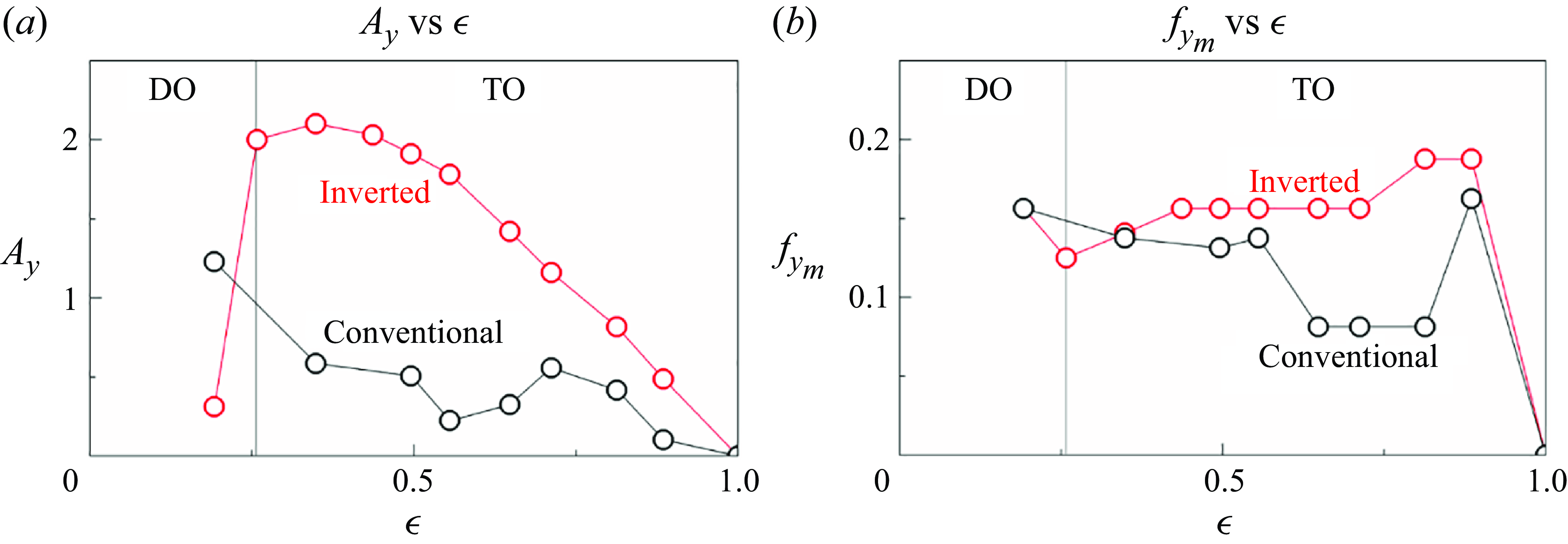

To further explore the transition between the DO and TO modes of the inverted ring, we examine the instantaneous contours of vorticity (

![]() $\omega _{z}$

) and the corresponding power spectral density (PSD) of both

$\omega _{z}$

) and the corresponding power spectral density (PSD) of both

![]() $f_{{y_{{m}}}}$

and

$f_{{y_{{m}}}}$

and

![]() $f_{v}$

in the transition region (figure 11). At

$f_{v}$

in the transition region (figure 11). At

![]() $\gamma = 0.02$

, the inverted ring is in the DO mode, exhibiting a 2S wake pattern. In this mode, the DO motion is synchronised with the vortex shedding, as indicated by a peak at the same frequency in the PSD analysis. As

$\gamma = 0.02$

, the inverted ring is in the DO mode, exhibiting a 2S wake pattern. In this mode, the DO motion is synchronised with the vortex shedding, as indicated by a peak at the same frequency in the PSD analysis. As

![]() $\gamma$

increases to 0.1, the inverted ring transitions to the TO mode. Although the wake pattern is similar to that observed at

$\gamma$

increases to 0.1, the inverted ring transitions to the TO mode. Although the wake pattern is similar to that observed at

![]() $\gamma =$

0.02, a notable difference is observed:

$\gamma =$

0.02, a notable difference is observed:

![]() $f_{{y_{{m}}}}$

is lower than

$f_{{y_{{m}}}}$

is lower than

![]() $f_{v}$

, indicating that the TO and vortex shedding are no longer synchronised. This desynchronisation contributes to the sudden decrease in

$f_{v}$

, indicating that the TO and vortex shedding are no longer synchronised. This desynchronisation contributes to the sudden decrease in

![]() $f_{{y_{{m}}}}$

observed in figure 10. At

$f_{{y_{{m}}}}$

observed in figure 10. At

![]() $\gamma =$

0.5, the inverted ring enters a lock-in regime, where

$\gamma =$

0.5, the inverted ring enters a lock-in regime, where

![]() $f_{{y_{{m}}}}$

and

$f_{{y_{{m}}}}$

and

![]() $f_{v}$

match. The wake pattern in this regime shows a distinct gap between the positive and negative vortices in the

$f_{v}$

match. The wake pattern in this regime shows a distinct gap between the positive and negative vortices in the

![]() $y$

-direction, whereas the vortices gather closely in the

$y$

-direction, whereas the vortices gather closely in the

![]() $x$

-direction, marking a clear change in the wake dynamics.

$x$

-direction, marking a clear change in the wake dynamics.

Figure 11. (a) Instantaneous contours of

![]() $\omega _{z}$

and (b) the PSD of

$\omega _{z}$

and (b) the PSD of

![]() $f_{{y_{{m}}}}$

and

$f_{{y_{{m}}}}$

and

![]() $f_{v}$

for an inverted-clamped ring under different

$f_{v}$

for an inverted-clamped ring under different

![]() $\gamma$

(

$\gamma$

(

![]() $\epsilon = 0.65$

).

$\epsilon = 0.65$

).

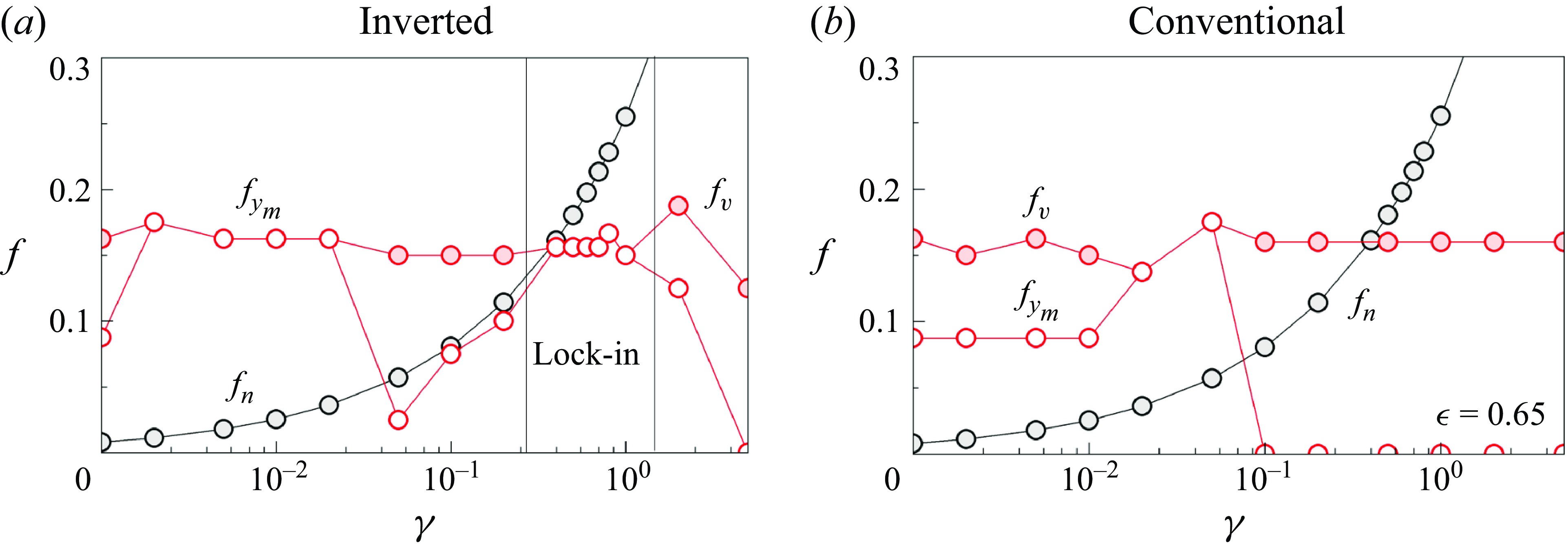

To further explore the interaction between the ring’s motion and vortex shedding, as well as to clarify the synchronisation phenomenon, we systematically analyse the oscillation frequency (

![]() $f_{{y_{{m}}}}$

), vortex shedding frequency (

$f_{{y_{{m}}}}$

), vortex shedding frequency (

![]() $f_{v}$

) and the natural frequency (

$f_{v}$

) and the natural frequency (

![]() $f_{n}$

) of the flexible ring as

$f_{n}$

) of the flexible ring as

![]() $\gamma$

varies, as illustrated in figure 12. The natural frequency is determined using the Euler–Bernoulli beam theory with clamped boundary conditions, yielding the formula

$\gamma$

varies, as illustrated in figure 12. The natural frequency is determined using the Euler–Bernoulli beam theory with clamped boundary conditions, yielding the formula

![]() $f_{n}=2.267\sqrt{\gamma /\rho _{s}}/2\pi$

. This analysis provides deeper insight into the coupling mechanisms governing the ring’s oscillations and its energy-harvesting potential. Figure 12 reveals that the different oscillation modes – F, DO and TO – are distinctly characterised by the relationships between the oscillation frequency, vortex shedding frequency and natural frequency. In the DO mode, the oscillation frequency matches the vortex shedding frequency while remaining different from the ring’s natural frequency. This observation suggests that the DO mode results from a simple forced vibration driven by unsteady fluid forces. In contrast, for the TO mode, the oscillation frequency initially increases with the natural frequency as

$f_{n}=2.267\sqrt{\gamma /\rho _{s}}/2\pi$

. This analysis provides deeper insight into the coupling mechanisms governing the ring’s oscillations and its energy-harvesting potential. Figure 12 reveals that the different oscillation modes – F, DO and TO – are distinctly characterised by the relationships between the oscillation frequency, vortex shedding frequency and natural frequency. In the DO mode, the oscillation frequency matches the vortex shedding frequency while remaining different from the ring’s natural frequency. This observation suggests that the DO mode results from a simple forced vibration driven by unsteady fluid forces. In contrast, for the TO mode, the oscillation frequency initially increases with the natural frequency as

![]() $\gamma$

increases. Once the system enters the lock-in regime, the oscillation frequency synchronises with the vortex shedding frequency and maintains this synchronisation until the system exits the lock-in regime. This behaviour is reminiscent of VIV observed in elastically mounted cylinders, confirming that the TO mode is a form of VIV. Conversely, the F mode of the conventional ring does not exhibit any synchronisation, indicating that it is not associated with VIV. This distinction further highlights the different underlying mechanisms governing each oscillation mode.

$\gamma$

increases. Once the system enters the lock-in regime, the oscillation frequency synchronises with the vortex shedding frequency and maintains this synchronisation until the system exits the lock-in regime. This behaviour is reminiscent of VIV observed in elastically mounted cylinders, confirming that the TO mode is a form of VIV. Conversely, the F mode of the conventional ring does not exhibit any synchronisation, indicating that it is not associated with VIV. This distinction further highlights the different underlying mechanisms governing each oscillation mode.

Figure 12. Oscillation frequency (

![]() $f_{{y_{{m}}}}$

), vortex shedding frequency (

$f_{{y_{{m}}}}$

), vortex shedding frequency (

![]() $f_{v}$

) and natural frequency (

$f_{v}$

) and natural frequency (

![]() $f_{n}$

) for (a) inverted rings and (b) conventional rings as a function of

$f_{n}$

) for (a) inverted rings and (b) conventional rings as a function of

![]() $\gamma$

(

$\gamma$

(

![]() $\epsilon = 0.65$

).

$\epsilon = 0.65$

).

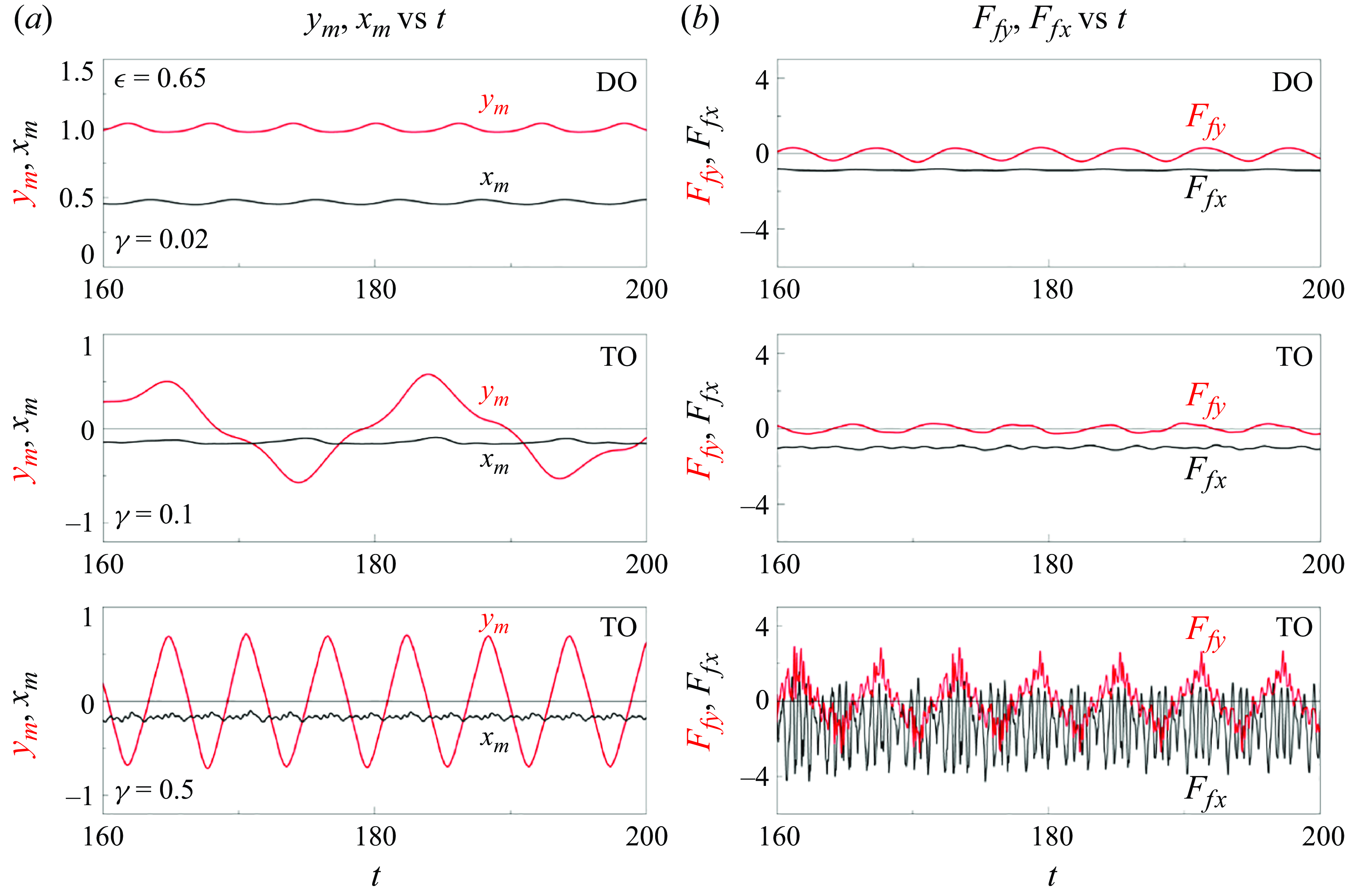

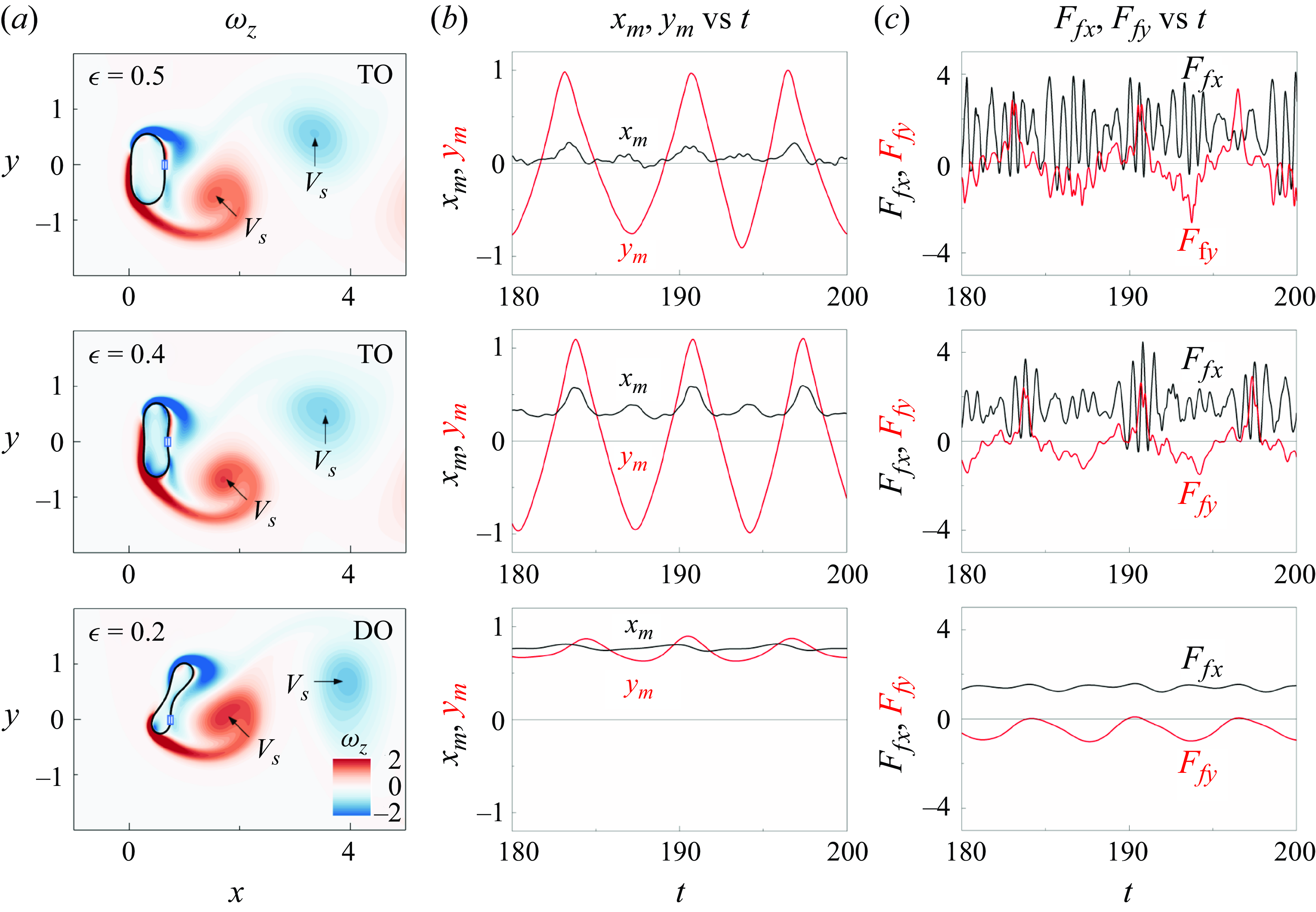

We here shift our focus to the relationship between the ring’s motion and fluid force during the transition between the DO and TO modes. Figure 13 presents the time histories of the midpoint position (

![]() $x_{{m}}$

,

$x_{{m}}$

,

![]() $y_{{m}}$

) and the fluid force acting on the inverted ring under various

$y_{{m}}$

) and the fluid force acting on the inverted ring under various

![]() $\gamma$

values. At

$\gamma$

values. At

![]() $\gamma =$

0.02, the inverted ring remains in the DO mode, characterised by small-amplitude, periodic motion and fluid force. As

$\gamma =$

0.02, the inverted ring remains in the DO mode, characterised by small-amplitude, periodic motion and fluid force. As

![]() $\gamma$

increases to 0.1, the ring stores more elastic energy due to its higher bending rigidity. This enhanced energy storage allows the ring’s elastic restoring forces to more effectively counteract the fluid forces induced by vortex shedding, triggering the transition to the TO mode. This transition highlights the critical role of bending rigidity in governing the dynamic response of the flexible ring and its mode selection under varying flow conditions. In addition, the TO motion becomes aperiodic at

$\gamma$

increases to 0.1, the ring stores more elastic energy due to its higher bending rigidity. This enhanced energy storage allows the ring’s elastic restoring forces to more effectively counteract the fluid forces induced by vortex shedding, triggering the transition to the TO mode. This transition highlights the critical role of bending rigidity in governing the dynamic response of the flexible ring and its mode selection under varying flow conditions. In addition, the TO motion becomes aperiodic at

![]() $\gamma =$

0.1. When

$\gamma =$

0.1. When

![]() $\gamma$

reaches 0.5, the inverted ring enters the lock-in regime, exhibiting large-amplitude, regular motion with a high oscillation frequency; this behaviour distinctly differs from that observed at

$\gamma$

reaches 0.5, the inverted ring enters the lock-in regime, exhibiting large-amplitude, regular motion with a high oscillation frequency; this behaviour distinctly differs from that observed at

![]() $\gamma =$

0.1. A high-frequency vibration in

$\gamma =$

0.1. A high-frequency vibration in

![]() $x_{{m}}$

is evident, manifesting as a shaking motion in the ring during TO. In addition, the fluid force increases substantially compared with the values at

$x_{{m}}$

is evident, manifesting as a shaking motion in the ring during TO. In addition, the fluid force increases substantially compared with the values at

![]() $\gamma =$

0.02 and 0.1, accompanied by a high-frequency component likely attributable to the vibrations in the

$\gamma =$

0.02 and 0.1, accompanied by a high-frequency component likely attributable to the vibrations in the

![]() $x$

-direction. The distinctive behaviour observed at

$x$

-direction. The distinctive behaviour observed at

![]() $\gamma =$

0.5 might be associated with the resonance of the inverted ring.

$\gamma =$

0.5 might be associated with the resonance of the inverted ring.

Figure 13. (a) Time histories of

![]() $x_{{m}}$

,

$x_{{m}}$

,

![]() $y_{{m}}$

,

$y_{{m}}$

,

![]() $F_{{f}x}$

and

$F_{{f}x}$

and

![]() $F_{{f}y}$

of the inverted-clamped ring under different

$F_{{f}y}$

of the inverted-clamped ring under different

![]() $\gamma$

(

$\gamma$

(

![]() $\epsilon = 0.65$

).

$\epsilon = 0.65$

).

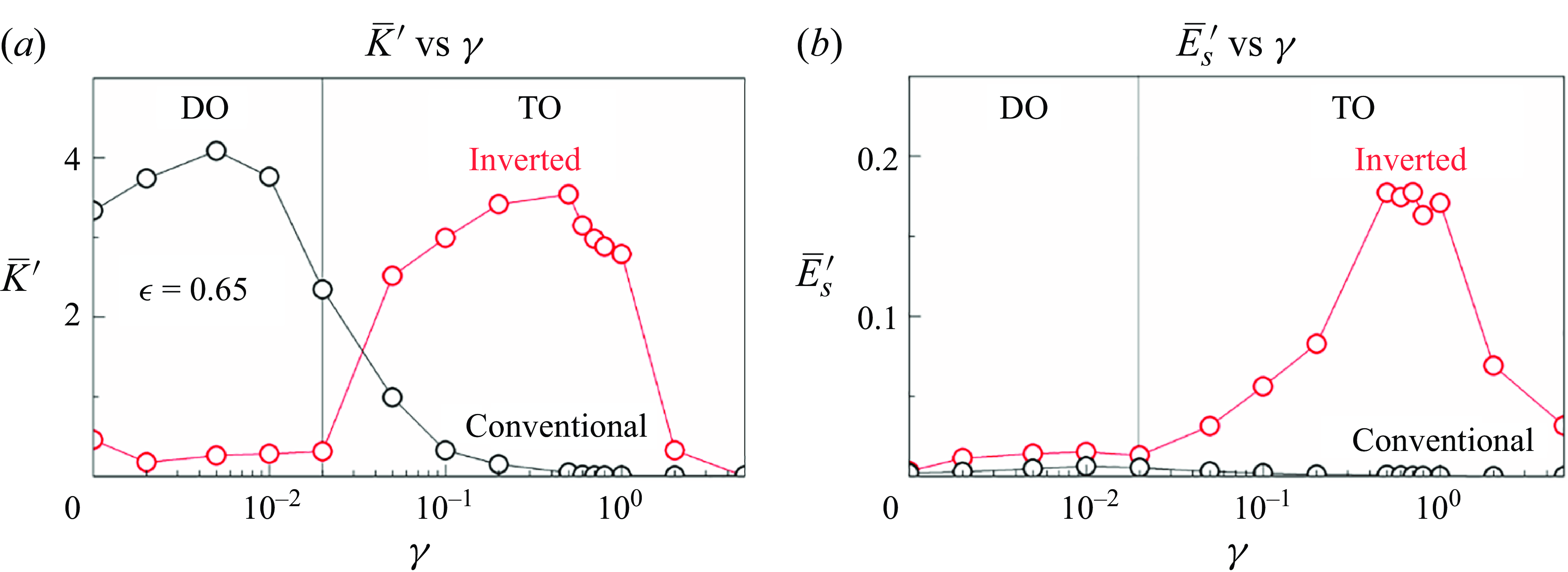

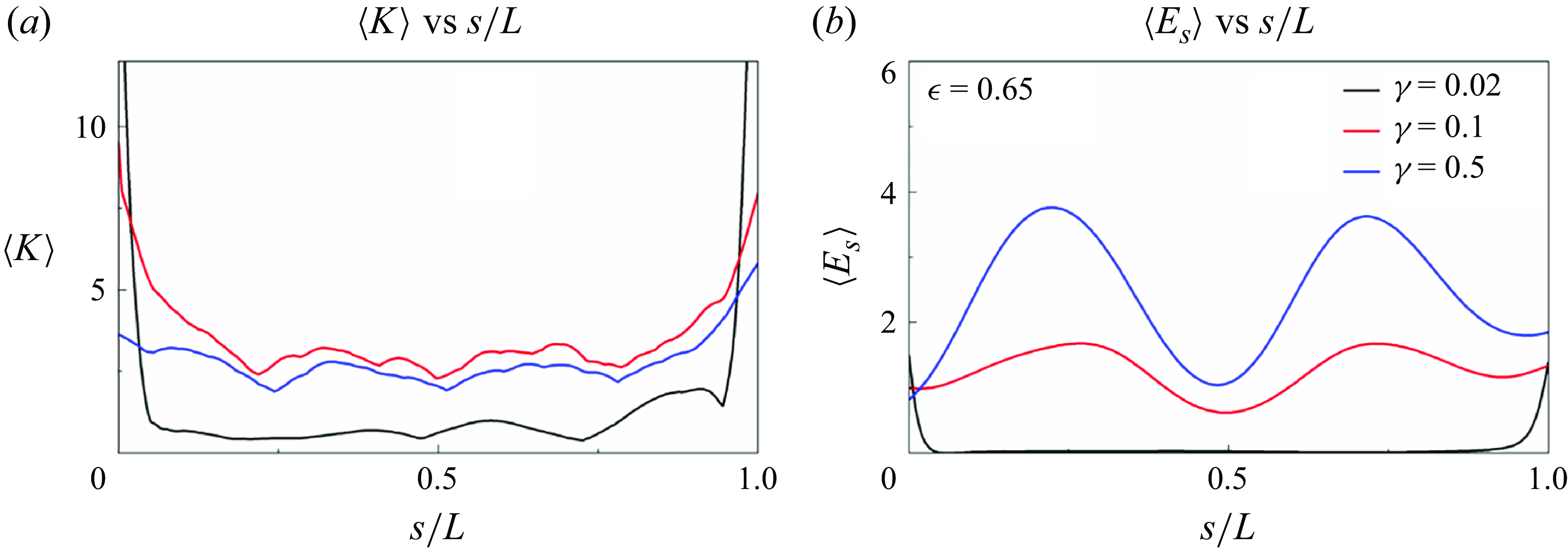

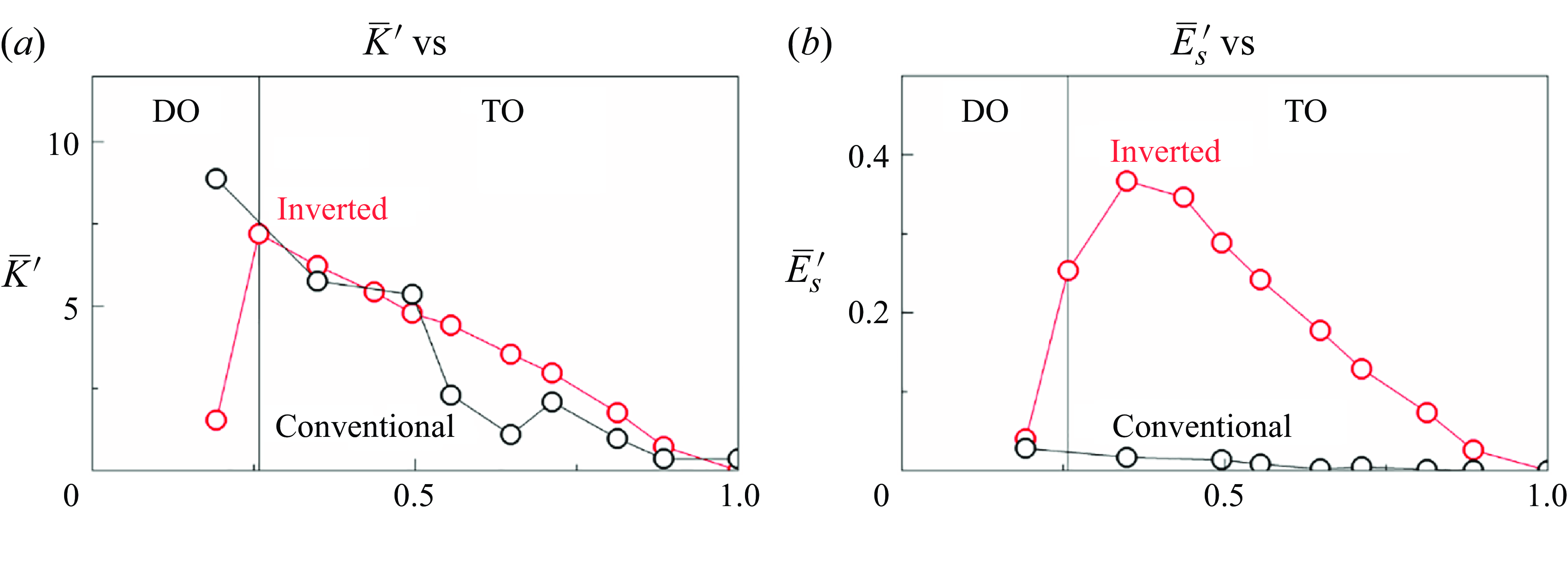

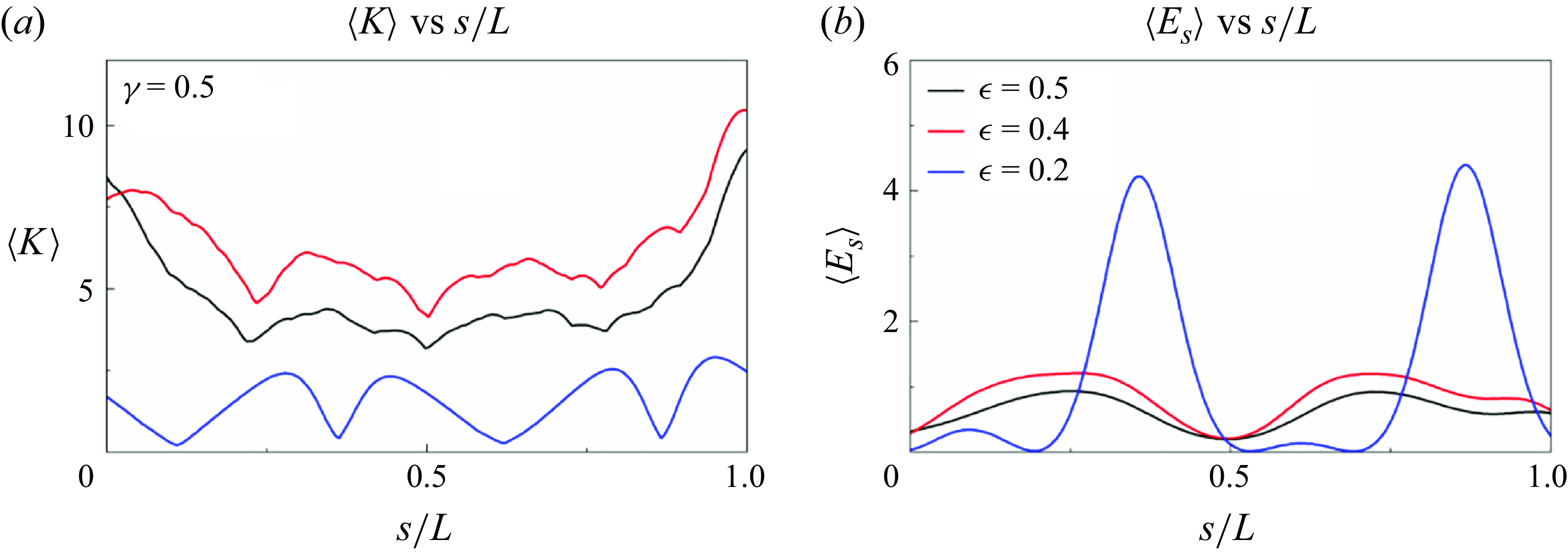

Here, we analyse the degree of deformation and the variation in elastic energy, both of which are directly linked to energy-harvesting performance. Figure 14 illustrates the average variation of curvature (

![]() $\overline{K}^{\prime}$

) and elastic energy (

$\overline{K}^{\prime}$

) and elastic energy (

![]() $\overline{E}_{s}^{\prime}$

) for both inverted and conventional ring functions of

$\overline{E}_{s}^{\prime}$

) for both inverted and conventional ring functions of

![]() $\gamma$

. Here,

$\gamma$

. Here,

![]() $\overline{K}^{\prime}$

is defined as

$\overline{K}^{\prime}$

is defined as

![]() $\overline{K}^{\prime}=\overline{K}-\overline{K}_{min }$

, where

$\overline{K}^{\prime}=\overline{K}-\overline{K}_{min }$

, where

![]() $\overline{K}=\int _{0}^{L}K(s,t)\mathrm{d}s$

represents the deflection during the ring’s motion. The time-averaged elastic energy

$\overline{K}=\int _{0}^{L}K(s,t)\mathrm{d}s$

represents the deflection during the ring’s motion. The time-averaged elastic energy

![]() $\overline{E}_{s}^{\prime}$

is defined as

$\overline{E}_{s}^{\prime}$

is defined as

![]() $\overline{E}_{s}^{\prime}=\overline{E}_{{s}}-\overline{E}_{{s}\,min }$

, indicating the elastic variation in the ring’s motion. Both

$\overline{E}_{s}^{\prime}=\overline{E}_{{s}}-\overline{E}_{{s}\,min }$

, indicating the elastic variation in the ring’s motion. Both

![]() $\overline{K}^{\prime}$

and

$\overline{K}^{\prime}$

and

![]() $\overline{E}_{{s}}^{\prime}$

of the inverted ring remain low in the DO mode because the oscillation amplitudes are small (figure 10). When the motion transitions to the TO mode, both