Contents

Research Article

Wearable armband with a floating mobile exploratory electrode at fingertip for on-demand touch-and-measure multilead electrocardiography

-

- Published online by Cambridge University Press:

- 05 May 2025, e21

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Autonomous slip control inspired by human physiology for improved shared control strategy

-

- Published online by Cambridge University Press:

- 09 June 2025, e22

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Evaluation of fatigue progression during overhead tasks and the effects of exoskeleton assistance

-

- Published online by Cambridge University Press:

- 11 June 2025, e23

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Design, development, and evaluation of a novel shoulder phantom testbed for analyzing interaction forces and reachability of wearable exoskeletons

-

- Published online by Cambridge University Press:

- 17 June 2025, e24

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Comparative analysis of spatiotemporal gait parameters in patients with distal femoral megaprosthesis and healthy subjects using an inertial measurement unit (IMU)

-

- Published online by Cambridge University Press:

- 13 June 2025, e25

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

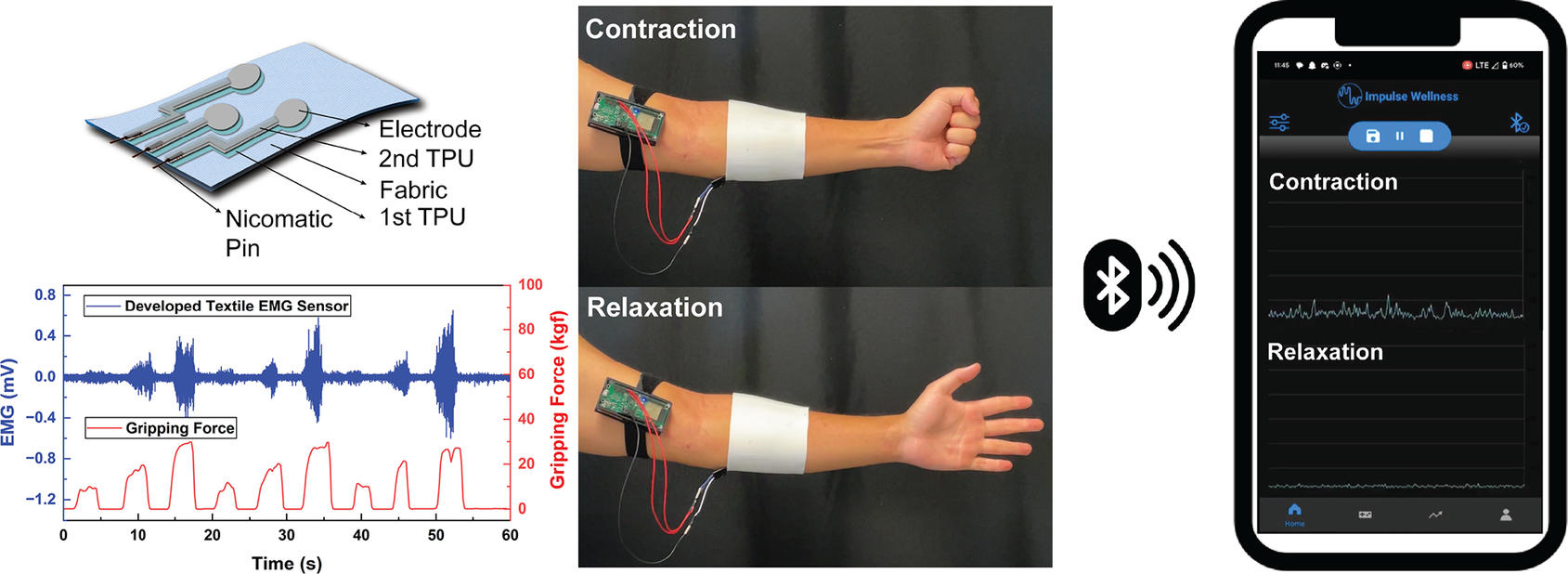

Feasibility assessment of textile electromyography sensors for a wearable telehealth biofeedback system

-

- Published online by Cambridge University Press:

- 16 June 2025, e26

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Quantifying sitting posture: A pilot feasibility study of computer vision and wearable sensors (Posture Lab) using a manikin model

-

- Published online by Cambridge University Press:

- 16 June 2025, e27

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Novel magnetometer-free inertial-measurement-unit-based orientation estimation approach for measuring upper limb kinematics

-

- Published online by Cambridge University Press:

- 30 June 2025, e28

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Review Article

Clinical and instrument-based assessment of balance, gait, and motor functions in pediatric cerebral palsy: A systematic review

-

- Published online by Cambridge University Press:

- 30 June 2025, e29

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Research Article

Design optimization platform for assistive wearable devices applied to a knee damper exoskeleton

-

- Published online by Cambridge University Press:

- 10 July 2025, e30

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Understanding the perspectives of older adults and physiotherapists on home-based lower-limb exoskeletons

-

- Published online by Cambridge University Press:

- 14 July 2025, e31

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

A soft 3-DOF interaction force measurement system for estimating the biomechanical effects of a soft wearable robot on the human joint

-

- Published online by Cambridge University Press:

- 15 July 2025, e32

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Closed-loop versus open-loop “remind-to-move” treatment using wearables for hemiparetic upper extremity in patients after stroke: A proof-of-concept study

-

- Published online by Cambridge University Press:

- 17 July 2025, e33

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Design of an ankle exoskeleton with twisted string actuation for running assistance

-

- Published online by Cambridge University Press:

- 22 July 2025, e34

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Frugally inventive carbon fabric-based wearable sensor for monitoring human body movements

-

- Published online by Cambridge University Press:

- 25 July 2025, e35

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Performance characterization of a novel semi-active exoskeleton for overhead work

-

- Published online by Cambridge University Press:

- 30 July 2025, e36

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Biomechanical and physiological effects of passive upper limb exoskeletons in simulated manufacturing tasks

-

- Published online by Cambridge University Press:

- 01 August 2025, e37

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Decoupled, wearable soft robotic rehabilitation device for the upper limb

-

- Published online by Cambridge University Press:

- 07 August 2025, e38

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

Simulation of stroke gait impairment correction using cable-driven lower limb rehabilitation exoskeleton (C-LREX)

-

- Published online by Cambridge University Press:

- 08 August 2025, e39

-

- Article

-

- You have access

- Open access

- HTML

- Export citation

A novel portable device and validation procedure for transcutaneous electrical nerve stimulation

-

- Published online by Cambridge University Press:

- 11 August 2025, e40

-

- Article

-

- You have access

- Open access

- HTML

- Export citation