1. Introduction

Taylor–Aris dispersion describes the enhanced spreading of solute in a fluid due to the coupled effects of advection and diffusion. G. I. Taylor (Reference Taylor1953) first developed an analytical solution for the long-term dispersive behaviour of solute based largely on the idea that the radial diffusion (i.e. transverse to flow) approximately balances axial dispersion caused by the non-uniform velocity field. The analysis was later formalised and significantly extended by Aris (Reference Aris1956). Aris introduced a solution method that is now called the method of moments (MoM). The MoM reformulates the dispersion problem in terms of axial integrals of the concentration field which correspond to, for example, the axial mean and variance of the solute zone. Generally, Taylor–Aris dispersion is highly relevant to a wide variety of applications, ranging from analytical chemistry to microfluidics and to large-scale environmental flows (Brenner & Edwards Reference Brenner and Edwards1993).

Taylor’s original analysis, focused on classic pressure-driven flow (PDF) in a cylindrical tube, provided a closed-form solution for solute dispersion for a regime that can be summarised as

![]() $L/a\gg P\hspace{0pt}e\gg 6.9$

. Here,

$L/a\gg P\hspace{0pt}e\gg 6.9$

. Here,

![]() $L$

is an axial distance of travel of the solute,

$L$

is an axial distance of travel of the solute,

![]() $a$

is the inner radius of the tube and

$a$

is the inner radius of the tube and

![]() $P\hspace{0pt}e$

is a Péclet number (

$P\hspace{0pt}e$

is a Péclet number (

![]() $a\langle u\rangle /D$

where

$a\langle u\rangle /D$

where

![]() $D$

is the molecular diffusivity) based on

$D$

is the molecular diffusivity) based on

![]() $a$

and the area-averaged bulk velocity

$a$

and the area-averaged bulk velocity

![]() $\langle u\rangle$

(the brackets indicate a cross-sectional area average). This condition implies that the advective time scale,

$\langle u\rangle$

(the brackets indicate a cross-sectional area average). This condition implies that the advective time scale,

![]() $L/\langle u\rangle$

, is large relative to the characteristic time of transverse diffusion,

$L/\langle u\rangle$

, is large relative to the characteristic time of transverse diffusion,

![]() $a^{2}/D$

, which we will here refer to as the ‘long-time limit’ or the ‘quasi-steady’ regime of the problem. Aris (Reference Aris1956) subsequently expanded upon G. I. Taylor’s work in several important ways. First, he included the effects of axial molecular diffusion for the quasi-steady problem. Aris also generalised the problem and introduced the MoM as a mathematical framework that enables the analysis of solute dispersion across all time regimes, starting from arbitrary initial conditions. Aris’ MoM is applicable to channels of arbitrary cross-sectional geometries and, relevant here, to arbitrary velocity fields. Taylor’s analysis and Aris’ model in the quasi-steady (long-time) regime predict that the area-averaged concentration of the solute will reach an axial Gaussian distribution that has a variance which grows linearly with time. This linear growth can be characterised by an effective dispersion coefficient.

$a^{2}/D$

, which we will here refer to as the ‘long-time limit’ or the ‘quasi-steady’ regime of the problem. Aris (Reference Aris1956) subsequently expanded upon G. I. Taylor’s work in several important ways. First, he included the effects of axial molecular diffusion for the quasi-steady problem. Aris also generalised the problem and introduced the MoM as a mathematical framework that enables the analysis of solute dispersion across all time regimes, starting from arbitrary initial conditions. Aris’ MoM is applicable to channels of arbitrary cross-sectional geometries and, relevant here, to arbitrary velocity fields. Taylor’s analysis and Aris’ model in the quasi-steady (long-time) regime predict that the area-averaged concentration of the solute will reach an axial Gaussian distribution that has a variance which grows linearly with time. This linear growth can be characterised by an effective dispersion coefficient.

While neither Taylor nor Aris rigorously analysed the early variance growth of the solute zone, Barton (Reference Barton1983) significantly extended Aris’ MoM to analyse solute behaviour across time regimes and for arbitrary velocity fields. In particular, Barton derived general expressions for the first three integral moments of the concentration field, valid in all time regimes. In the same paper, Barton applied his work to three specific flow profiles and geometries for select initial conditions: plane Couette flow, Poiseuille flow in a cylindrical tube and an analytical approximation of turbulent channel flow.

Gill & Sankarasubramanian (Reference Gill and Sankarasubramanian1970, Reference Gill and Sankarasubramanian1971) developed a distinct yet related approach to the MoM to describe solute concentration in a manner valid across all time regimes. They formulated the solute concentration field as an infinite series of axial derivatives of the area-averaged solute concentration, a method known as a Kramers–Moyal-type expansion. The dispersion coefficients, which correspond to the integral moments of the solute distribution, emerge naturally as the eigenvalues of this solution ansatz. Since Gill & Sankarasubramanian’s work, Chatwin (Reference Chatwin1970, Reference Chatwin1972), Degance & Johns (Reference Degance and Johns1978a ,Reference Degance and Johns b ), Mauri (Reference Mauri1991) and Wang & Chen (Reference Wang and Chen2016) extended this Kramers–Moyal-type solution method to various dispersion problems. For a detailed discussion of Kramers–Moyal-type expansions and other pre-asymptotic solution methods, see Taghizadeh, Valdés-Parada & Wood (Reference Taghizadeh, Valdés-Parada and Wood2020). Note that Aris and Barton’s MoM (which we leverage in our analysis in § 4) is a largely different approach to solving dispersion problems than Gill’s Kramers–Moyal-type expansions. The MoM produces one partial and one ordinary differential equation (per moment) that govern the nth integral moment of the concentration field. These equations can often be solved directly by techniques such as eigenfunction expansions or Laplace transforms. In contrast, Gill’s method derives dispersion coefficients as eigenvalues of a Kramers–Moyal expansion of the solute concentration field. However, both solution methods involve deriving expressions for either the nth moment of the concentration field (MoM) or the nth dispersion coefficient (Kramers–Moyal), whence constructing a formulation for the (n+1)st and (n+2)nd moment or coefficient. Both processes therefore generate equations that build on others to describe progressively higher-order moments.

Several other solution methods have been developed for these problems which further extend the mathematical and physical understanding of solute dispersion. Brenner (Reference Brenner1980) generalised Aris’ framework by analysing the so-called local and total moments of the probability density function of a tracer particle in a spatially periodic cell. Brenner demonstrated that the solution of various moments can be obtained by solving the elliptical partial differential equation of a cell field

![]() $\boldsymbol{B}$

defined on an individual period cell. The solution can be used to compute a tensor that characterises the long-term dispersion behaviour of solutes. Brenner’s approach, known as the Brenner–Aris theory or the macrotransport paradigm, provides a very broad framework for understanding transport phenomena in heterogeneous systems, such as porous media.

$\boldsymbol{B}$

defined on an individual period cell. The solution can be used to compute a tensor that characterises the long-term dispersion behaviour of solutes. Brenner’s approach, known as the Brenner–Aris theory or the macrotransport paradigm, provides a very broad framework for understanding transport phenomena in heterogeneous systems, such as porous media.

Mercer & Roberts (Reference Mercer and Roberts1990) pioneered the use of infinite-dimensional centre manifold theory in the analysis of Taylor dispersion by obtaining higher-order asymptotic approximations for the classic, Taylor-type diffusive model. In a significant development, Balakotaiah & Chang (Reference Balakotaiah and Chang1995) applied centre manifold theory to flows with additional complexities, such as bulk reactions, surface reactions, adsorption and desorption and transverse velocity gradients. Rosencrans (Reference Rosencrans1997) further extended the use of centre manifold theory to dispersion in channels with slow axial variations in width.

Later, Stone & Brenner (Reference Stone and Brenner1999) formalised and extended Taylor’s (Reference Taylor1953) original solution method. Stone & Brenner introduced a more organised set of assumptions for the problem, more intuitive notation (which we will here adopt) and extended the solution to velocity fields which slowly vary in the axial direction. Consistent with the original Taylor analysis, Stone & Brenner’s solution method is valid for the long-time limit of the problem.

Beyond advancements in solution methods, much effort has been devoted to analysing dispersion in varying channel geometries and for a variety of velocity fields. We here focus on dispersion in electrokinetic phenomena in a cylindrical tube. Specifically, electroosmotic flow (EOF) plays a pivotal role in analytical chemistry processes and electrokinetic microfluidic applications. Electroosmotic flow refers to the bulk flow of a liquid induced by an externally applied electric field imparting Coulombic forces on the diffuse charges of electric double layers (EDLs; Hunter Reference Hunter1988). These EDLs form spontaneously on the wetted walls of a liquid-filled channel. Electroosmotic flow is inherently applicable to small (micron- and nanometre-scale) channels and offers electrical control of flow and solutes in devices with no moving parts. The Poisson–Boltzmann equation describes the electric potential throughout a tube caused by the EDL. The most common approximate solution to the latter is the Debye–Hückel approximation, which assumes low zeta potential (

![]() $\zeta \lt 25.7\text{ mV}$

at room temperature; Probstein Reference Probstein1994, p. 193). Here, the zeta potential is defined as the electric potential at the shear plane (where the no-slip condition is applied). Using the Debye–Hückel approximation, Rice & Whitehead (Reference Rice and Whitehead1965) first described the EOF profile in a cylindrical tube by solving the steady Stokes equation for a Newtonian fluid. Given the linearity of the Stokes equation, the EOF profile is simply (arithmetically) superposable with PDF. Since Rice & Whitehead’s paper, many researchers have examined EOF velocity fields in a variety of contexts. This includes work in cylindrical channels with high zeta potentials (Levine et al. Reference Levine, Marriott, Neale and Epstein1975), channels with axially varying zeta potentials (Anderson & Idol Reference Anderson and Idol1985), porous media (Coelho et al. Reference Coelho, Shapiro, Thovert and Adler1996; Gupta, Coelho & Adler Reference Gupta, Coelho and Adler2006), annular geometries with both low (Tsao Reference Tsao2000) and finite (Kang, Yang & Huang Reference Kang, Yang and Huang2002) zeta potentials and rectangular channels (Wang et al. Reference Wang, Wong, Yang and Ooi2007; Mondal, Misra & De Reference Mondal, Misra and De2014). Additionally, note that applying a pressure gradient to a channel can cause a streaming potential to form (Scales et al. Reference Scales, Grieser, Healy, White and Chan1992). If substantial, this streaming potential can induce some amount of EOF. Hence, understanding the behaviour of EOF can be important even in the absence of an externally applied electric field, particularly in channels with thick EDLs relative to the channel radius (Kim & Kim Reference Kim and Kim2018; Riad, Khorshidi & Sadrzadeh Reference Riad, Khorshidi and Sadrzadeh2020).

$\zeta \lt 25.7\text{ mV}$

at room temperature; Probstein Reference Probstein1994, p. 193). Here, the zeta potential is defined as the electric potential at the shear plane (where the no-slip condition is applied). Using the Debye–Hückel approximation, Rice & Whitehead (Reference Rice and Whitehead1965) first described the EOF profile in a cylindrical tube by solving the steady Stokes equation for a Newtonian fluid. Given the linearity of the Stokes equation, the EOF profile is simply (arithmetically) superposable with PDF. Since Rice & Whitehead’s paper, many researchers have examined EOF velocity fields in a variety of contexts. This includes work in cylindrical channels with high zeta potentials (Levine et al. Reference Levine, Marriott, Neale and Epstein1975), channels with axially varying zeta potentials (Anderson & Idol Reference Anderson and Idol1985), porous media (Coelho et al. Reference Coelho, Shapiro, Thovert and Adler1996; Gupta, Coelho & Adler Reference Gupta, Coelho and Adler2006), annular geometries with both low (Tsao Reference Tsao2000) and finite (Kang, Yang & Huang Reference Kang, Yang and Huang2002) zeta potentials and rectangular channels (Wang et al. Reference Wang, Wong, Yang and Ooi2007; Mondal, Misra & De Reference Mondal, Misra and De2014). Additionally, note that applying a pressure gradient to a channel can cause a streaming potential to form (Scales et al. Reference Scales, Grieser, Healy, White and Chan1992). If substantial, this streaming potential can induce some amount of EOF. Hence, understanding the behaviour of EOF can be important even in the absence of an externally applied electric field, particularly in channels with thick EDLs relative to the channel radius (Kim & Kim Reference Kim and Kim2018; Riad, Khorshidi & Sadrzadeh Reference Riad, Khorshidi and Sadrzadeh2020).

The interplay between EOF and PDF introduces interesting flow dynamics that significantly affect solute dispersion. Datta & Kotamarthi (Reference Datta and Kotamarthi1990) first analysed Taylor–Aris dispersion for coupled EOF and PDF in cylindrical tubes, deriving an effective dispersion coefficient under long-time regimes. They also identified the optima of both the flow Péclet number and the relative magnitudes of PDF and EOF to minimise the theoretical plate height (Huang Reference Huang2021). However, Datta & Kotamarthi’s (Reference Datta and Kotamarthi1990) work had several limitations. For example, they did not present a derivation of their effective dispersion coefficient. They offered no benchmarking with other models (such as computational fluid dynamics models of dispersion or Brownian dynamics simulations). Datta & Kotamarthi (Reference Datta and Kotamarthi1990) also focused exclusively on the long-time (quasi-steady) regime. Griffiths & Nilson (Reference Griffiths and Nilson1999) later presented the coefficient of effective dispersion for pure EOF in both cylindrical tubes (a special case of Datta & Kotamarthi’s model) and a flow between large parallel plates. For both geometries, Griffiths & Nilson (Reference Griffiths and Nilson1999) considered the case of low zeta potential. Griffiths & Nilson (Reference Griffiths and Nilson1999) used an asymptotic method rather than the area-averaging method of Stone & Brenner (Reference Stone and Brenner1999), yet they considered a solution that is valid only in long-time regimes. Griffiths & Nilson (Reference Griffiths and Nilson2000) later generalised their models with numerical solutions to account for large zeta potentials. Zholkovskij, Masliyah & Czarnecki (Reference Zholkovskij, Masliyah and Czarnecki2003) subsequently analysed the long-term dispersive behaviour of solute under pure EOF in a channel with an arbitrary cross-section. Further analyses by Dutta & Leighton (Reference Dutta and Leighton2003) and Zholkovskij & Masliyah (Reference Zholkovskij and Masliyah2004) examined the effects of channel geometries on dispersion in coupled EOF and PDF, again focusing only on long-time regimes. Dutta (Reference Dutta2007) later investigated dispersion caused by EOF in a rectangular channel with low zeta potential. Thereafter, Paul & Ng (Reference Paul and Ng2012) analysed dispersion in pure EOF in a rectangular channel under low zeta potential across all time regimes.

More recent studies of solute dispersion have continued to focus largely on the long-term limit of the problem. For example, Dejam, Hassanzadeh & Chen (Reference Dejam, Hassanzadeh and Chen2015) examined dispersion in combined EOF and PDF in porous channels, while Hoshyargar et al. (Reference Hoshyargar, Talebi, Ashrafizadeh and Sadeghi2018) analysed the effects of viscoelastic fluids on dispersion, both in long-time regimes. Thus, most of the literature regarding Taylor–Aris dispersion of combined EOF and PDF is applicable only in physical regimes where

![]() $\textit{Pe}\lt \lt \sigma _{x}/a$

, where

$\textit{Pe}\lt \lt \sigma _{x}/a$

, where

![]() $\sigma _{x}$

is the characteristic width of the solute zone. This limitation is particularly important as microfluidic transport is oftentimes rapid enough that this quasi-steady regime does not apply (Stone & Kim Reference Stone and Kim2001). Lastly, we note that Taylor-type analysis also offers an approximation of the radial distribution of solute, and this radial distribution has never been addressed for neither EOF nor combined EOF and PDF.

$\sigma _{x}$

is the characteristic width of the solute zone. This limitation is particularly important as microfluidic transport is oftentimes rapid enough that this quasi-steady regime does not apply (Stone & Kim Reference Stone and Kim2001). Lastly, we note that Taylor-type analysis also offers an approximation of the radial distribution of solute, and this radial distribution has never been addressed for neither EOF nor combined EOF and PDF.

To our knowledge, all previous analyses of Taylor dispersion for coupled EOF and PDF focused on the long-term dispersion behaviour and were not able to provide a prediction of both the short- and long-term evolution of the solute zone. In the current study, we address this by presenting a more comprehensive analysis of Taylor–Aris dispersion for coupled EOF and PDF in cylindrical tubes. We first derive an expression for the EOF velocity profile that is valid for an EDL of arbitrary thickness relative to the channel radius. We then present a long-time analysis of the solute dispersion. To our knowledge, this is the first presentation of such a derivation and first analysis of the radial component of the resulting distribution. We next apply the MoM to analyse dispersion conditions across all time regimes. To this end, we derive the first two integral moments of the solute zone and examine specific initial conditions of solute. We benchmark both our Taylor-type and MoM formulations against Brownian dynamics simulations for a broad range of cases, including various time scales; flow Péclet numbers; relative magnitudes of EOF versus PDF; and tube radii relative to the Debye length. Finally, we present methods and analytical expressions useful in minimising dispersion for combined PDF and EOF in all time regimes. Specifically, we find optima associated with the relative magnitudes of EOF and PDF and the optimal Péclet number to minimise band broadening across all time regimes.

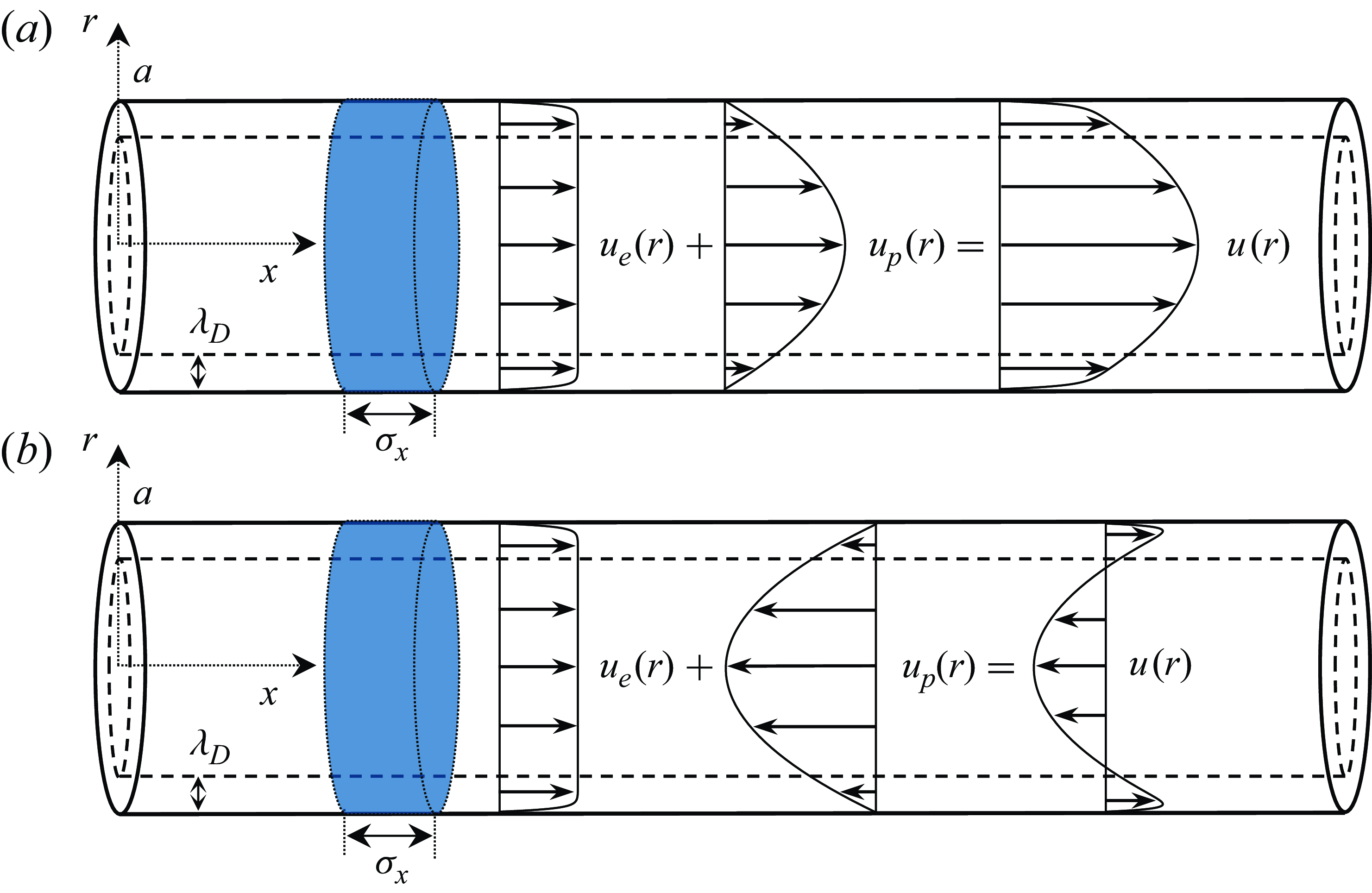

Figure 1. Schematics of a solute transported in a cylindrical tube of inner radius a under a combination of PDF and EOF. A solute zone of characteristic length of

![]() $\sigma _{x}$

is subjected to a flow consisting of combinations of steady PDF,

$\sigma _{x}$

is subjected to a flow consisting of combinations of steady PDF,

![]() $u_{p}(r)$

, and steady EOF,

$u_{p}(r)$

, and steady EOF,

![]() $u_{e}(r)$

, (with finite EDL thickness) along the axial direction,

$u_{e}(r)$

, (with finite EDL thickness) along the axial direction,

![]() $x$

.

$x$

.

![]() $(a)$

Pressure-driven flow and EOF in the same direction.

$(a)$

Pressure-driven flow and EOF in the same direction.

![]() $(b)$

Pressure-driven flow in opposition to EOF. The resulting net flow profile is denoted as

$(b)$

Pressure-driven flow in opposition to EOF. The resulting net flow profile is denoted as

![]() $u(r)$

, and Debye length is denoted as

$u(r)$

, and Debye length is denoted as

![]() $\lambda _{D}$

. Both the tube radius and Debye length are depicted enlarged relative to the axial length of the tube for clarity of presentation.

$\lambda _{D}$

. Both the tube radius and Debye length are depicted enlarged relative to the axial length of the tube for clarity of presentation.

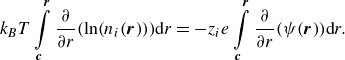

2. Formulation of the basic flow and solute transport problem

2.1. Flow field and basic problem description

We study the flow and dispersion of a neutral (uncharged) solute subject to simultaneous PDF and EOF in a cylindrical tube of inner radius

![]() $a\,.$

Figure 1 shows schematics of an initial condition of the solute and example flow profiles. The flow is generated from applied axial pressure differentials (resulting in a Poiseuille-type flow component, see, e.g. Langlois & Deville Reference Langlois and Deville2014) and/or by EOF caused by the presence of a finite sized EDL at the wetted wall and an electric field applied along the axis of the tube. The EDL may or may not overlap with itself at the centre of the tube (see Appendix A). We will denote the characteristic axial width of the solute zone as

$a\,.$

Figure 1 shows schematics of an initial condition of the solute and example flow profiles. The flow is generated from applied axial pressure differentials (resulting in a Poiseuille-type flow component, see, e.g. Langlois & Deville Reference Langlois and Deville2014) and/or by EOF caused by the presence of a finite sized EDL at the wetted wall and an electric field applied along the axis of the tube. The EDL may or may not overlap with itself at the centre of the tube (see Appendix A). We will denote the characteristic axial width of the solute zone as

![]() $\sigma _{x}$

and assume the solute is of uniform molecular diffusivity (

$\sigma _{x}$

and assume the solute is of uniform molecular diffusivity (

![]() $D$

) throughout the tube. The Debye length is denoted as

$D$

) throughout the tube. The Debye length is denoted as

![]() $\lambda _{D}$

. Let

$\lambda _{D}$

. Let

![]() $r^{*}=r/a$

denote the dimensionless radial coordinate and

$r^{*}=r/a$

denote the dimensionless radial coordinate and

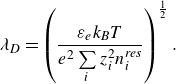

![]() $\phi =a/\lambda _{D}$

be the tube radius scaled by Debye length. For EOF, we consider a general electrolyte and a wall zeta potential sufficiently weak such that the Debye–Hückel approximation holds (Probstein Reference Probstein1994). We will further neglect the effects of streaming potential on the fluid velocity field. Note the latter effects should not create new shapes of the velocity field but may introduce a coupling between EOF and PDF which is not explicitly treated here. We provide a derivation of the electric potential field and EOF velocity profile, valid for an EDL of arbitrary thickness relative to the channel radius, in Appendix A. From (A11), the electric potential field within the tube is given by

$\phi =a/\lambda _{D}$

be the tube radius scaled by Debye length. For EOF, we consider a general electrolyte and a wall zeta potential sufficiently weak such that the Debye–Hückel approximation holds (Probstein Reference Probstein1994). We will further neglect the effects of streaming potential on the fluid velocity field. Note the latter effects should not create new shapes of the velocity field but may introduce a coupling between EOF and PDF which is not explicitly treated here. We provide a derivation of the electric potential field and EOF velocity profile, valid for an EDL of arbitrary thickness relative to the channel radius, in Appendix A. From (A11), the electric potential field within the tube is given by

![]() $\psi (r^{*})=\zeta I_{0}(\phi r^{*})/I_{0}(\phi )$

, where

$\psi (r^{*})=\zeta I_{0}(\phi r^{*})/I_{0}(\phi )$

, where

![]() $I_{0}(z)$

is a zeroth-order modified Bessel function of the first kind and

$I_{0}(z)$

is a zeroth-order modified Bessel function of the first kind and

![]() $\zeta$

is the zeta potential. Further, from (A14), the EOF velocity profile can be expressed as

$\zeta$

is the zeta potential. Further, from (A14), the EOF velocity profile can be expressed as

![]() $u_{e}(r^{*})=u_{\textit{HS}}(1-\psi (r^{*})/\zeta )$

where

$u_{e}(r^{*})=u_{\textit{HS}}(1-\psi (r^{*})/\zeta )$

where

![]() $u_{\textit{HS}}=-\varepsilon _{e}E\zeta /\mu$

is the Helmholtz–Smoluchowski velocity scale. Here,

$u_{\textit{HS}}=-\varepsilon _{e}E\zeta /\mu$

is the Helmholtz–Smoluchowski velocity scale. Here,

![]() $\varepsilon _{e}$

is the permittivity of the fluid (assumed to be uniform throughout the tube),

$\varepsilon _{e}$

is the permittivity of the fluid (assumed to be uniform throughout the tube),

![]() $E$

is the magnitude of the applied electric field and

$E$

is the magnitude of the applied electric field and

![]() $\mu$

is the dynamic viscosity of the fluid. For a compact notation, we define the following dimensionless cross-sectional average of the radial electric potential:

$\mu$

is the dynamic viscosity of the fluid. For a compact notation, we define the following dimensionless cross-sectional average of the radial electric potential:

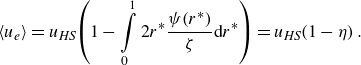

\begin{equation} \eta =\int \limits_{0}^{1}2r^{*}\frac{\psi\!\left(r^{*}\right)}{\zeta }\mathrm{d}r^{*}=\frac{2}{\phi }\frac{I_{1}\!\left(\phi \right)}{I_{0}\!\left(\phi \right)} .\end{equation}

\begin{equation} \eta =\int \limits_{0}^{1}2r^{*}\frac{\psi\!\left(r^{*}\right)}{\zeta }\mathrm{d}r^{*}=\frac{2}{\phi }\frac{I_{1}\!\left(\phi \right)}{I_{0}\!\left(\phi \right)} .\end{equation}

Taking the area average of the EOF profile

\begin{equation} \left\langle u_{e}\right\rangle =u_{\textit{HS}}\!\left(1-\int\limits _{0}^{1}2r^{*}\frac{\psi\!\left(r^{*}\right)}{\zeta }\mathrm{d}r^{*}\right)=u_{\textit{HS}}\!\left(1-\eta \right) .\end{equation}

\begin{equation} \left\langle u_{e}\right\rangle =u_{\textit{HS}}\!\left(1-\int\limits _{0}^{1}2r^{*}\frac{\psi\!\left(r^{*}\right)}{\zeta }\mathrm{d}r^{*}\right)=u_{\textit{HS}}\!\left(1-\eta \right) .\end{equation}

Further, for the case of a thick EDL relative to the tube radius (

![]() $\phi \ll 1$

), we can expand

$\phi \ll 1$

), we can expand

![]() $I_{0}$

using a Taylor series expansion. Neglecting terms of order

$I_{0}$

using a Taylor series expansion. Neglecting terms of order

![]() $O[\phi ^{4}]$

and higher, we can approximate

$O[\phi ^{4}]$

and higher, we can approximate

Thus, as the EDL becomes thicker relative to the radius of the channel, EOF tends to a parabolic profile, and

![]() $\phi$

informs the bulk velocity of the flow.

$\phi$

informs the bulk velocity of the flow.

The PDF profile is given as

![]() $u_{p}(r^{*})=2\langle u_{p}\rangle (1-r^{*2})$

with

$u_{p}(r^{*})=2\langle u_{p}\rangle (1-r^{*2})$

with

![]() $\langle u_{p}\rangle$

denoting the area-averaged PDF profile. A tube subject to both pressure gradients and EOF has a net velocity profile given by

$\langle u_{p}\rangle$

denoting the area-averaged PDF profile. A tube subject to both pressure gradients and EOF has a net velocity profile given by

![]() $u(r^{*})=u_{e}(r^{*})+u_{p}(r^{*})$

. Combining with (2.2), we can express the full velocity profile as

$u(r^{*})=u_{e}(r^{*})+u_{p}(r^{*})$

. Combining with (2.2), we can express the full velocity profile as

The area average of (2.4) is simply

![]() $\langle u\rangle =\langle u_{e}\rangle +\langle u_{p}\rangle$

. Lastly, we take the deviation from this area average as

$\langle u\rangle =\langle u_{e}\rangle +\langle u_{p}\rangle$

. Lastly, we take the deviation from this area average as

Figure 1(a) shows a flow profile where PDF and EOF are in the same direction, corresponding to values of

![]() $\langle u_{p}\rangle \gt 0$

and

$\langle u_{p}\rangle \gt 0$

and

![]() $\langle u_{e}\rangle \gt 0$

. Figure 1(b) shows a flow profile where EOF is opposed by PDF, corresponding to values of

$\langle u_{e}\rangle \gt 0$

. Figure 1(b) shows a flow profile where EOF is opposed by PDF, corresponding to values of

![]() $\langle u_{p}\rangle \lt 0\lt \langle u_{e}\rangle$

.

$\langle u_{p}\rangle \lt 0\lt \langle u_{e}\rangle$

.

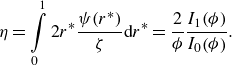

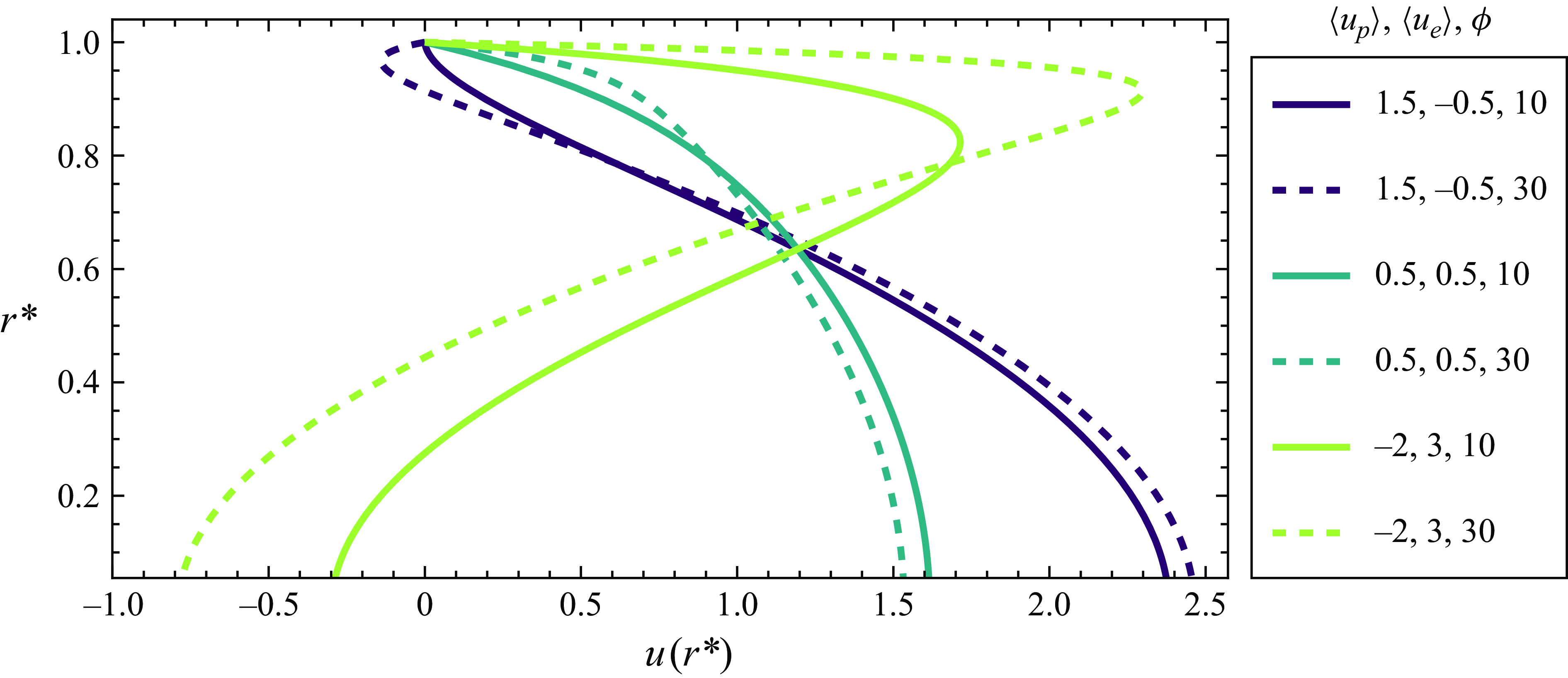

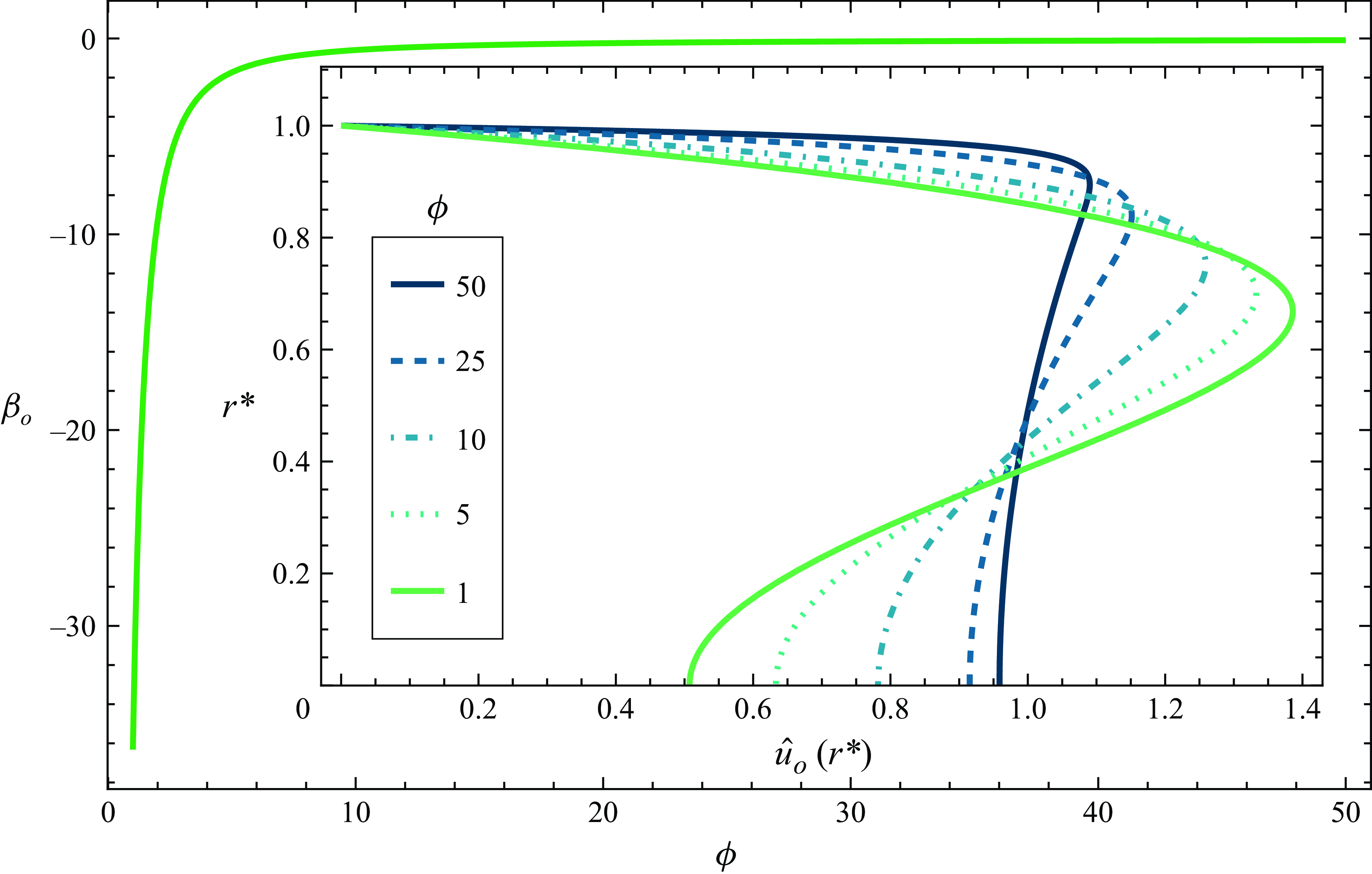

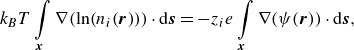

Figure 2 shows examples of the well-known axial flow profiles of combined PDF and EOF in coordinates of

![]() $u(r^{*})$

versus the dimensionless inner radius,

$u(r^{*})$

versus the dimensionless inner radius,

![]() $r^{*}$

. We show velocity profiles for three combinations of

$r^{*}$

. We show velocity profiles for three combinations of

![]() $\langle u_{p}\rangle$

and

$\langle u_{p}\rangle$

and

![]() $\langle u_{e}\rangle$

(three line colours) such that

$\langle u_{e}\rangle$

(three line colours) such that

![]() $\langle u_{e}\rangle +\langle u_{p}\rangle =1$

. For each combination of

$\langle u_{e}\rangle +\langle u_{p}\rangle =1$

. For each combination of

![]() $\langle u_{p}\rangle$

and

$\langle u_{p}\rangle$

and

![]() $\langle u_{e}\rangle$

, we present profiles for

$\langle u_{e}\rangle$

, we present profiles for

![]() $\phi$

values of 10 and 30 (different line types). We shall later show and discuss EOF profiles where

$\phi$

values of 10 and 30 (different line types). We shall later show and discuss EOF profiles where

![]() $\langle u_{p}\rangle \lt 0\lt \langle u_{e}\rangle$

which are useful for minimising the variance of the solute zone. That is, PDF in opposition to bulk EOF can be used to reduce dispersion for a fixed value of overall bulk velocity.

$\langle u_{p}\rangle \lt 0\lt \langle u_{e}\rangle$

which are useful for minimising the variance of the solute zone. That is, PDF in opposition to bulk EOF can be used to reduce dispersion for a fixed value of overall bulk velocity.

Figure 2. Example axial flow profiles for three combinations of PDF and EOF, and two values of the tube radius scaled by the Debye length,

![]() $\phi$

. The ordinate shows dimensionless radius,

$\phi$

. The ordinate shows dimensionless radius,

![]() $r^{*}$

, and the abscissa is the flow velocity,

$r^{*}$

, and the abscissa is the flow velocity,

![]() $u(r^{*})$

. The three line colours correspond to cases of EOF in opposition to bulk PDF, EOF and PDF in the same direction and PDF in opposition to bulk EOF. For each combination of EOF and PDF, profiles are shown for

$u(r^{*})$

. The three line colours correspond to cases of EOF in opposition to bulk PDF, EOF and PDF in the same direction and PDF in opposition to bulk EOF. For each combination of EOF and PDF, profiles are shown for

![]() $\phi$

values of 10 and 30 (different line types). All curves were produced with unit bulk velocity.

$\phi$

values of 10 and 30 (different line types). All curves were produced with unit bulk velocity.

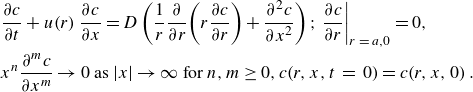

2.2. Convective diffusion of solute

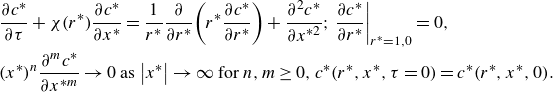

We will consider the advective diffusion of a neutral solute subject to the aforementioned velocity profiles. The governing equation, boundary conditions and initial condition for the concentration

![]() $c(r,x,t)$

of a solute are

$c(r,x,t)$

of a solute are

\begin{align} &\frac{\partial c}{\partial t}+u\!\left(r\right)\frac{\partial c}{\partial x}=D\left(\frac{1}{r}\frac{\partial }{\partial r}\!\left(r\frac{\partial c}{\partial r}\right)+\frac{\partial ^{2}c}{\partial x^{2}}\right); \left.\frac{\partial c}{\partial r}\right| _{r\,=\,a,0}=0,\nonumber\\ &x^{n}\frac{\partial ^{m}c}{\partial x^{m}}\rightarrow 0\text{ as }\!\left| x\right| \rightarrow \infty \text{ for }n, m\geq 0,c\!\left(r,x,t\,=\,0\right) = c\!\left(r,x,0\right). \end{align}

\begin{align} &\frac{\partial c}{\partial t}+u\!\left(r\right)\frac{\partial c}{\partial x}=D\left(\frac{1}{r}\frac{\partial }{\partial r}\!\left(r\frac{\partial c}{\partial r}\right)+\frac{\partial ^{2}c}{\partial x^{2}}\right); \left.\frac{\partial c}{\partial r}\right| _{r\,=\,a,0}=0,\nonumber\\ &x^{n}\frac{\partial ^{m}c}{\partial x^{m}}\rightarrow 0\text{ as }\!\left| x\right| \rightarrow \infty \text{ for }n, m\geq 0,c\!\left(r,x,t\,=\,0\right) = c\!\left(r,x,0\right). \end{align}

Here, the boundary condition at

![]() $r=0$

is a result of the assumed azimuthal symmetry and

$r=0$

is a result of the assumed azimuthal symmetry and

![]() $c(r,x,0)$

denotes the initial solute distribution. We shall consider two analytical solution methods for this equation in §§ 3 and 4.

$c(r,x,0)$

denotes the initial solute distribution. We shall consider two analytical solution methods for this equation in §§ 3 and 4.

2.3. Brownian dynamics simulations

We will employ Brownian dynamics simulations (Schlick Reference Schlick2002) to benchmark our analytical solutions of the concentration field, effective dispersion coefficient, radial solute distribution and optimal relative magnitudes of EOF and PDF to minimise dispersion. Each of our Brownian dynamics simulations consisted of 5000 point particles. We considered particles distributed initially uniformly across the cross-section of the tube. At each time step in these simulations, each particle is subject to an advection as per (2.4) and a diffusion (random) displacement. The system was allowed to evolve according to the first-order forward Euler method. For each test case, multiple simulations with random seed initial conditions were run, and the reported results represent their average. In this work, we use an identical Brownian dynamics simulation model to that of Chang & Santiago (Reference Chang and Santiago2023) (except for the fact that we here use finer time steps and consider only a channel of uniform radius). This provides a benchmark for the accuracy of our simulations. Additionally, further details around the Brownian dynamics simulations may be found in Chang & Santiago (Reference Chang and Santiago2023). Lastly, all simulation code and results required to recreate the figures of this manuscript may be found on GitHub (csamuel133/Taylor_dispersion_EOF_PDF_Alltime).

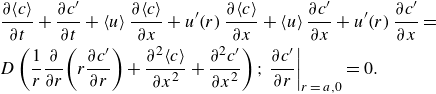

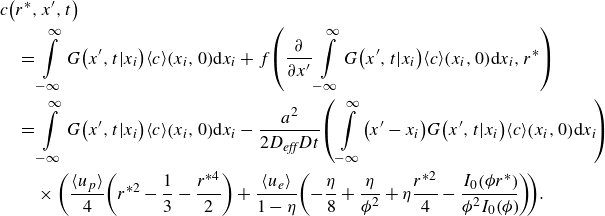

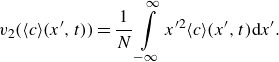

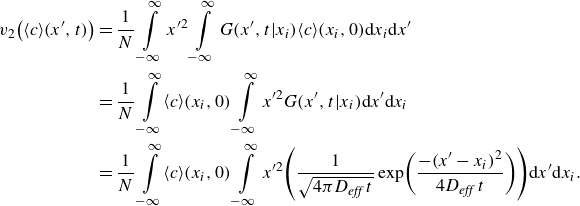

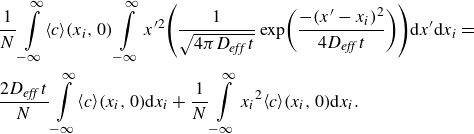

3. Taylor dispersion solution of the quasi-steady regime

We here present a derivation of the effective Taylor dispersion (Taylor Reference Taylor1953) for combined PDF and EOF. We will use an area-averaging and deviation formulation (and notation) similar to that of Stone & Brenner (Reference Stone and Brenner1999). Accordingly, we seek to derive the two-dimensional solute concentration field in regimes where the observation time scale is large with respect to the characteristic time of transverse diffusion, for flows described in § 2.1. We expand the concentration and flow fields into cross-sectional averages, defined as

![]() $\langle (.)\rangle = (1/\pi a^{2})\int _{0}^{a}2\pi r(.)\mathrm{d}r$

, and deviations therefrom,

$\langle (.)\rangle = (1/\pi a^{2})\int _{0}^{a}2\pi r(.)\mathrm{d}r$

, and deviations therefrom,

![]() $(.)^{\prime}$

, such that

$(.)^{\prime}$

, such that

![]() $(.)^{\prime} = (.)-\langle (.)\rangle$

. First, we expand (2.6) as

$(.)^{\prime} = (.)-\langle (.)\rangle$

. First, we expand (2.6) as

\begin{align} &\frac{\partial \!\left\langle c\right\rangle }{\partial t}+\frac{\partial c^{\prime}}{\partial t}+\left\langle u\right\rangle \frac{\partial \!\left\langle c\right\rangle }{\partial x}+u^{\prime}\!\left(r\right)\frac{\partial \!\left\langle c\right\rangle }{\partial x}+\left\langle u\right\rangle \frac{\partial c^{\prime}}{\partial x}+u^{\prime}\!\left(r\right)\frac{\partial c^{\prime}}{\partial x}=\nonumber\\ &D\left(\frac{1}{r}\frac{\partial }{\partial r}\!\left(r\frac{\partial c^{\prime}}{\partial r}\right)+\frac{\partial ^{2}\!\left\langle c\right\rangle }{\partial x^{2}}+\frac{\partial ^{2}c^{\prime}}{\partial x^{2}}\right);\left.\frac{\partial c^{\prime}}{\partial r}\right| _{r\, =\, a,0}=0. \end{align}

\begin{align} &\frac{\partial \!\left\langle c\right\rangle }{\partial t}+\frac{\partial c^{\prime}}{\partial t}+\left\langle u\right\rangle \frac{\partial \!\left\langle c\right\rangle }{\partial x}+u^{\prime}\!\left(r\right)\frac{\partial \!\left\langle c\right\rangle }{\partial x}+\left\langle u\right\rangle \frac{\partial c^{\prime}}{\partial x}+u^{\prime}\!\left(r\right)\frac{\partial c^{\prime}}{\partial x}=\nonumber\\ &D\left(\frac{1}{r}\frac{\partial }{\partial r}\!\left(r\frac{\partial c^{\prime}}{\partial r}\right)+\frac{\partial ^{2}\!\left\langle c\right\rangle }{\partial x^{2}}+\frac{\partial ^{2}c^{\prime}}{\partial x^{2}}\right);\left.\frac{\partial c^{\prime}}{\partial r}\right| _{r\, =\, a,0}=0. \end{align}

Taking the area average of this equation

Subtracting (3.2) from (3.1), we derive an expression for the deviation variable

![]() $c^{\prime}$

$c^{\prime}$

The latter equation is again subject to the condition that

![]() $\partial c^{\prime}/\partial r| _{r=a,0}=0$

. Let

$\partial c^{\prime}/\partial r| _{r=a,0}=0$

. Let

![]() $c_{o}$

denote the characteristic scale (magnitude) of the area-averaged concentration of solute and

$c_{o}$

denote the characteristic scale (magnitude) of the area-averaged concentration of solute and

![]() $c_{o}{}^{\prime}$

denote the (much smaller) characteristic scale for the deviation from this average. We non-dimensionalise (3.3) using

$c_{o}{}^{\prime}$

denote the (much smaller) characteristic scale for the deviation from this average. We non-dimensionalise (3.3) using

Note that we choose the width of the solute cloud as the characteristic axial scale. This choice is different than that of Taylor (Reference Taylor1953) and Stone & Brenner (Reference Stone and Brenner1999), who chose a macroscopic, dimensional length

![]() $L$

along the channel to a detector. This is an important distinction as combined (and opposed) PDF and EOF profiles with zero area-averaged net (bulk) velocity result in a dynamic condition wherein the solute zone disperses but its centroid does not move. In the latter case, a distance to a detector L has no meaning. As in Taylor’s (Reference Taylor1953) original analysis, we assume that the magnitude of the area-averaged concentration field is much larger than the magnitude of the deviation therefrom. Next, we assume that the characteristic axial width of the solute cloud is much greater than the inner radius of the tube (

$L$

along the channel to a detector. This is an important distinction as combined (and opposed) PDF and EOF profiles with zero area-averaged net (bulk) velocity result in a dynamic condition wherein the solute zone disperses but its centroid does not move. In the latter case, a distance to a detector L has no meaning. As in Taylor’s (Reference Taylor1953) original analysis, we assume that the magnitude of the area-averaged concentration field is much larger than the magnitude of the deviation therefrom. Next, we assume that the characteristic axial width of the solute cloud is much greater than the inner radius of the tube (

![]() $\sigma _{x}\gg a$

). Further assuming the characteristic advection time of the cloud over

$\sigma _{x}\gg a$

). Further assuming the characteristic advection time of the cloud over

![]() $\sigma _{x}$

is large compared with radial diffusion time, we consider three smallness parameters as follows:

$\sigma _{x}$

is large compared with radial diffusion time, we consider three smallness parameters as follows:

Here,

![]() $\textit{Pe}=a\langle u\rangle /D$

is the flow Péclet number. Our non-dimensionalisation of (3.3) then becomes

$\textit{Pe}=a\langle u\rangle /D$

is the flow Péclet number. Our non-dimensionalisation of (3.3) then becomes

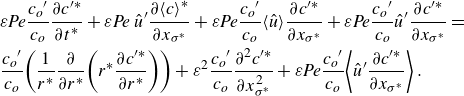

\begin{align} &\varepsilon \textit{Pe}\frac{c_{o}{}^{\prime}}{c_{o}}\frac{\partial c^{\prime*}}{\partial t^{*}}+\varepsilon \textit{Pe} \,{\hat u^{\prime}}\frac{\partial \!\left\langle c\right\rangle^{*}}{\partial x_{\sigma ^{\ast}}}+\varepsilon \textit{Pe}\frac{c_{o}{}^{\prime}}{c_{o}}{\langle \hat u\rangle }\frac{\partial c^{\prime*}}{\partial x_{\sigma^{\ast}}}+\varepsilon \textit{Pe}\frac{c_{o}{}^{\prime}}{c_{o}}{\hat u^{\prime}}\frac{\partial c^{\prime*}}{\partial x_{\sigma^{\ast}}}=\nonumber\\ &\frac{c_{o}{}^{\prime}}{c_{o}}\!\left(\frac{1}{r^{*}}\frac{\partial }{\partial r^{*}}\!\left(r^{*}\frac{\partial c^{\prime*}}{\partial r^{*}}\right)\right)+\varepsilon ^{2}\frac{c_{o}{}^{\prime}}{c_{o}}\frac{\partial ^{2}c^{\prime*}}{\partial x_{\sigma^{\ast}}^{2}}+\varepsilon \textit{Pe}\frac{c_{o}{}^{\prime}}{c_{o}}\!\left\langle {\hat u^{\prime}}\frac{\partial c^{\prime*}}{\partial x_{\sigma ^{\ast}}}\right\rangle . \end{align}

\begin{align} &\varepsilon \textit{Pe}\frac{c_{o}{}^{\prime}}{c_{o}}\frac{\partial c^{\prime*}}{\partial t^{*}}+\varepsilon \textit{Pe} \,{\hat u^{\prime}}\frac{\partial \!\left\langle c\right\rangle^{*}}{\partial x_{\sigma ^{\ast}}}+\varepsilon \textit{Pe}\frac{c_{o}{}^{\prime}}{c_{o}}{\langle \hat u\rangle }\frac{\partial c^{\prime*}}{\partial x_{\sigma^{\ast}}}+\varepsilon \textit{Pe}\frac{c_{o}{}^{\prime}}{c_{o}}{\hat u^{\prime}}\frac{\partial c^{\prime*}}{\partial x_{\sigma^{\ast}}}=\nonumber\\ &\frac{c_{o}{}^{\prime}}{c_{o}}\!\left(\frac{1}{r^{*}}\frac{\partial }{\partial r^{*}}\!\left(r^{*}\frac{\partial c^{\prime*}}{\partial r^{*}}\right)\right)+\varepsilon ^{2}\frac{c_{o}{}^{\prime}}{c_{o}}\frac{\partial ^{2}c^{\prime*}}{\partial x_{\sigma^{\ast}}^{2}}+\varepsilon \textit{Pe}\frac{c_{o}{}^{\prime}}{c_{o}}\!\left\langle {\hat u^{\prime}}\frac{\partial c^{\prime*}}{\partial x_{\sigma ^{\ast}}}\right\rangle . \end{align}

Keeping only terms with one smallness parameter, and keeping only the radial term in dimensionless form, we find

This approximate balance between the non-uniform advective dispersion and the radial diffusion is a classic result for Taylor dispersion (Taylor Reference Taylor1953). Next, we multiply (3.7) by

![]() $r^{*}$

and integrate,

$r^{*}$

and integrate,

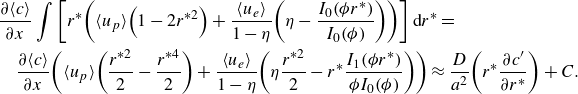

\begin{align} &\frac{\partial \!\left\langle c\right\rangle }{\partial x}\int \left[r^{*}\!\left(\langle u_{p}\rangle \!\left(1-2r^{*2}\right)+\frac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta -\frac{I_{0}\!\left(\phi r^{*}\right)}{I_{0}\!\left(\phi \right)}\right)\right)\right]\mathrm{d}r^{*}= \nonumber \\&\quad\frac{\partial \!\left\langle c\right\rangle }{\partial x}\!\left(\langle u_{p} \rangle \!\left(\frac{r^{*2}}{2}-\frac{r^{*4}}{2}\right) +\frac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta \frac{r^{*2}}{2}-r^{*}\frac{I_{1}\!\left(\phi r^{*}\right)}{\phi I_{0}\!\left(\phi \right)}\right)\right)\approx \frac{D}{a^{2}}\!\left(r^{*}\frac{\partial c^{\prime}}{\partial r^{*}}\right)+C. \end{align}

\begin{align} &\frac{\partial \!\left\langle c\right\rangle }{\partial x}\int \left[r^{*}\!\left(\langle u_{p}\rangle \!\left(1-2r^{*2}\right)+\frac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta -\frac{I_{0}\!\left(\phi r^{*}\right)}{I_{0}\!\left(\phi \right)}\right)\right)\right]\mathrm{d}r^{*}= \nonumber \\&\quad\frac{\partial \!\left\langle c\right\rangle }{\partial x}\!\left(\langle u_{p} \rangle \!\left(\frac{r^{*2}}{2}-\frac{r^{*4}}{2}\right) +\frac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta \frac{r^{*2}}{2}-r^{*}\frac{I_{1}\!\left(\phi r^{*}\right)}{\phi I_{0}\!\left(\phi \right)}\right)\right)\approx \frac{D}{a^{2}}\!\left(r^{*}\frac{\partial c^{\prime}}{\partial r^{*}}\right)+C. \end{align}

We use the boundary condition at

![]() $r^{*}=1$

to see that the constant of integration

$r^{*}=1$

to see that the constant of integration

![]() $C$

must vanish. We divide by

$C$

must vanish. We divide by

![]() $r^{*}$

, multiply both sides by

$r^{*}$

, multiply both sides by

![]() $a^{2}/D$

, and integrate from 0 to

$a^{2}/D$

, and integrate from 0 to

![]() $r^{*}$

, arriving at

$r^{*}$

, arriving at

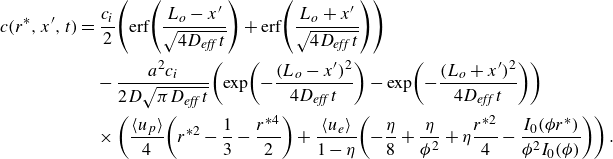

\begin{align} c^{\prime}\!\left(r,x,t\right)&=c^{\prime}\!\left(0,x,t\right)+\frac{a^{2}}{D}\frac{\partial \!\left\langle c\right\rangle }{\partial x}\!\left(\frac{ \langle u_{p}\rangle }{4}\!\left(r^{*2}-\frac{r^{*4}}{2}\right)\right.\nonumber \\&\quad+\left.\frac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta \frac{r^{*2}}{4}-\frac{I_{0}\!\left(\phi r^{*}\right)-1}{\phi ^{2}I_{0}\!\left(\phi \right)}\right)\right). \end{align}

\begin{align} c^{\prime}\!\left(r,x,t\right)&=c^{\prime}\!\left(0,x,t\right)+\frac{a^{2}}{D}\frac{\partial \!\left\langle c\right\rangle }{\partial x}\!\left(\frac{ \langle u_{p}\rangle }{4}\!\left(r^{*2}-\frac{r^{*4}}{2}\right)\right.\nonumber \\&\quad+\left.\frac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta \frac{r^{*2}}{4}-\frac{I_{0}\!\left(\phi r^{*}\right)-1}{\phi ^{2}I_{0}\!\left(\phi \right)}\right)\right). \end{align}

Applying cross-sectional averaging, we are left with

Subtracting (3.10) from (3.9), we derive

\begin{align} c^{\prime}\!\left(r,x,t\right)&=\frac{a^{2}}{D}\frac{\partial \!\left\langle c\right\rangle }{\partial x}\!\left(\frac{ \langle u_{p} \rangle }{4}\!\left(r^{*2}-\frac{1}{3}-\frac{r^{*4}}{2}\right)\right.\nonumber \\&\quad+\left.\frac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(-\frac{\eta }{8}+\frac{\eta }{\phi ^{2}}+\eta \frac{r^{*2}}{4}-\frac{I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)}\right)\right) . \end{align}

\begin{align} c^{\prime}\!\left(r,x,t\right)&=\frac{a^{2}}{D}\frac{\partial \!\left\langle c\right\rangle }{\partial x}\!\left(\frac{ \langle u_{p} \rangle }{4}\!\left(r^{*2}-\frac{1}{3}-\frac{r^{*4}}{2}\right)\right.\nonumber \\&\quad+\left.\frac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(-\frac{\eta }{8}+\frac{\eta }{\phi ^{2}}+\eta \frac{r^{*2}}{4}-\frac{I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)}\right)\right) . \end{align}

Equation (3.11), combined with our solution for

![]() $\partial \langle c\rangle /\partial x$

, will provide an analytical expression for the unsteady, two-dimensional (radial and axial) distribution of the solute. To our knowledge, this is the first reported expression for the radial concentration of solute for combined EOF and PDF. We will use (3.11) to show solute concentration profiles versus axial position for several values of

$\partial \langle c\rangle /\partial x$

, will provide an analytical expression for the unsteady, two-dimensional (radial and axial) distribution of the solute. To our knowledge, this is the first reported expression for the radial concentration of solute for combined EOF and PDF. We will use (3.11) to show solute concentration profiles versus axial position for several values of

![]() $r^{*}$

in figure 3. We will then visualise the two-dimensional solute concentration field in figures 4 and 5, and visualise the radial solute distribution alone in figure 6. Returning to (3.9), we take the derivative with respect to

$r^{*}$

in figure 3. We will then visualise the two-dimensional solute concentration field in figures 4 and 5, and visualise the radial solute distribution alone in figure 6. Returning to (3.9), we take the derivative with respect to

![]() $x$

, multiply by

$x$

, multiply by

![]() $u^{\prime}(r)$

, and apply cross-sectional averaging

$u^{\prime}(r)$

, and apply cross-sectional averaging

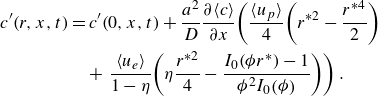

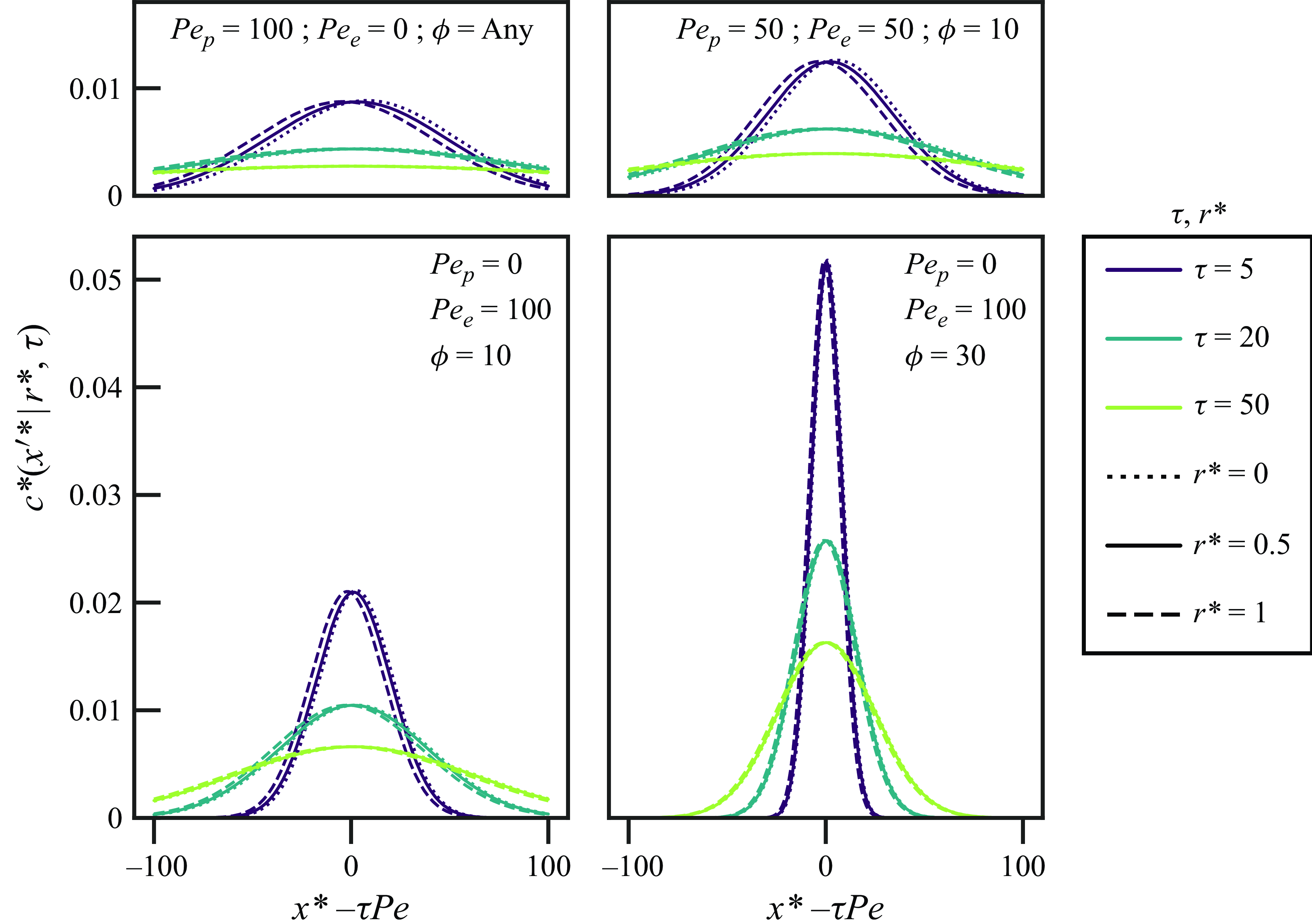

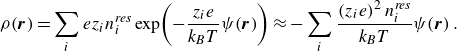

Figure 3. The four figure panels show axial solute concentration profiles corresponding to four combinations of the Péclet number based on EOF,

![]() $\textit{Pe}_{e}$

, the Péclet number based on PDF,

$\textit{Pe}_{e}$

, the Péclet number based on PDF,

![]() $\textit{Pe}_{p}$

, and the tube radius scaled by Debye length,

$\textit{Pe}_{p}$

, and the tube radius scaled by Debye length,

![]() $\phi$

. The ordinate shows dimensionless solute concentration,

$\phi$

. The ordinate shows dimensionless solute concentration,

![]() $c^{*}(x^{\prime*}|r^{*},\tau )=\pi a^{3}c(x^{\prime*}|r^{*},\tau )/N$

, and the abscissa is dimensionless axial position in a frame moving at the solute bulk velocity,

$c^{*}(x^{\prime*}|r^{*},\tau )=\pi a^{3}c(x^{\prime*}|r^{*},\tau )/N$

, and the abscissa is dimensionless axial position in a frame moving at the solute bulk velocity,

![]() $x^{\prime*}=x^{*}-\tau P\hspace{0pt}e$

. In each panel, solute concentration curves are shown at three values of dimensionless time (different line colours) for three distinct dimensionless radial positions (different line types), resulting in nine total concentration profiles per panel. The dimensionless solute concentration is obtained by evaluating (3.40) for an initial ‘top hat’ of solute with a width negligible to the final axial width of the solute and then normalising the solute concentration as

$x^{\prime*}=x^{*}-\tau P\hspace{0pt}e$

. In each panel, solute concentration curves are shown at three values of dimensionless time (different line colours) for three distinct dimensionless radial positions (different line types), resulting in nine total concentration profiles per panel. The dimensionless solute concentration is obtained by evaluating (3.40) for an initial ‘top hat’ of solute with a width negligible to the final axial width of the solute and then normalising the solute concentration as

![]() $c^{*}(x^{\prime*}|r^{*},\tau )=\pi a^{3}c(x^{\prime*}|r^{*},\tau )/N$

.

$c^{*}(x^{\prime*}|r^{*},\tau )=\pi a^{3}c(x^{\prime*}|r^{*},\tau )/N$

.

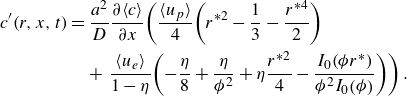

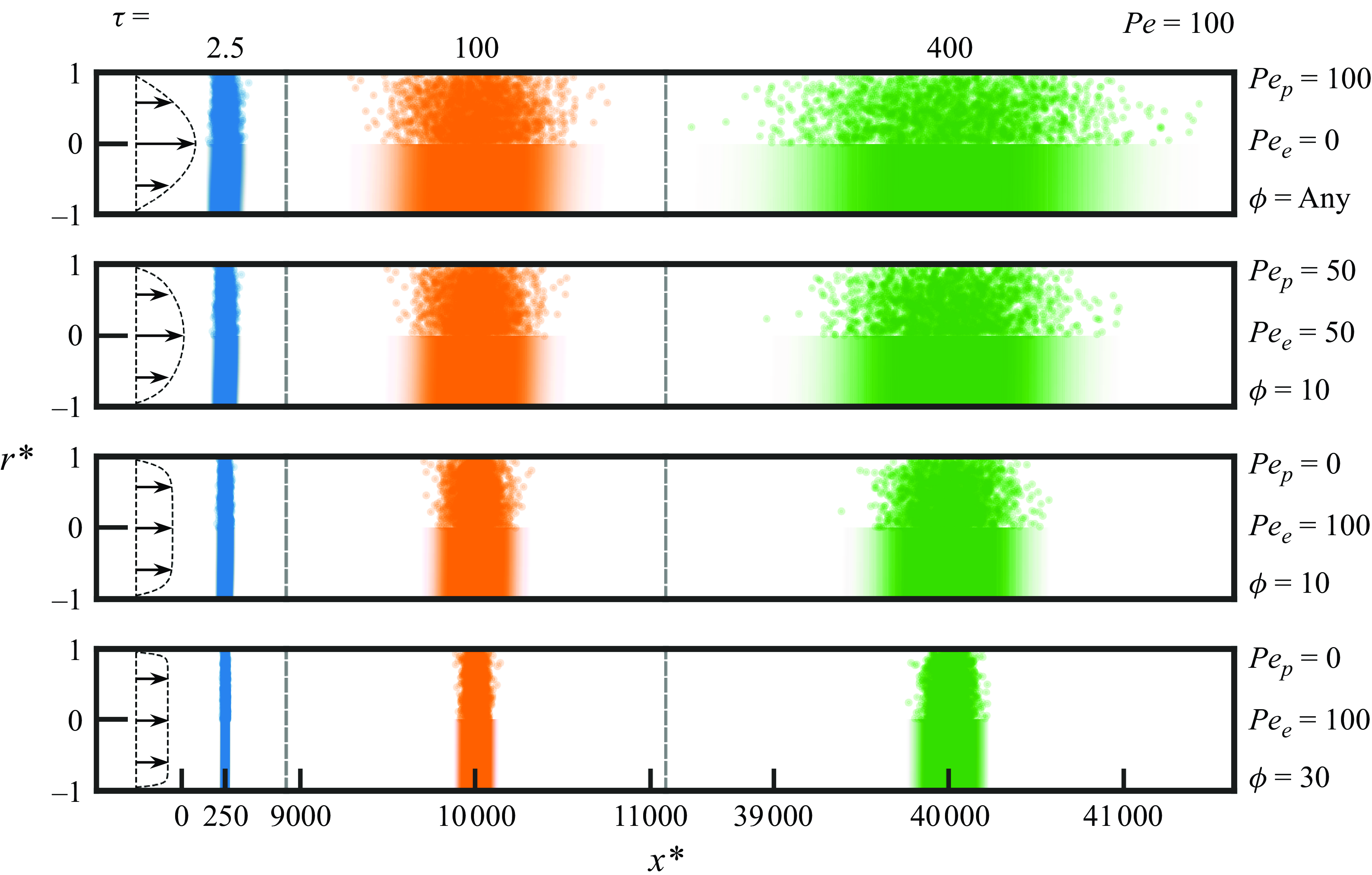

Figure 4. Benchmark comparisons between Brownian dynamics simulations and the analytical solution of the quasi-steady solute concentration field at three values of dimensionless time,

![]() $\tau =\textit{tD}/a^{2}$

. The figure shows dimensionless radius,

$\tau =\textit{tD}/a^{2}$

. The figure shows dimensionless radius,

![]() $r^{*}$

, on the ordinate and dimensionless axial position,

$r^{*}$

, on the ordinate and dimensionless axial position,

![]() $x^{*}$

, on the abscissa. The top half of each panel shows individual particles from the Brownian dynamics simulations and the bottom half of each panel shows the concentration field predicted by the analytical solution in (3.40). Panels show four combinations of the Péclet number based on PDF,

$x^{*}$

, on the abscissa. The top half of each panel shows individual particles from the Brownian dynamics simulations and the bottom half of each panel shows the concentration field predicted by the analytical solution in (3.40). Panels show four combinations of the Péclet number based on PDF,

![]() $P\hspace{0pt}e_{p}$

, the Péclet number based on EOF,

$P\hspace{0pt}e_{p}$

, the Péclet number based on EOF,

![]() $P\hspace{0pt}e_{e}$

, and the tube radius scaled by Debye length,

$P\hspace{0pt}e_{e}$

, and the tube radius scaled by Debye length,

![]() $\phi$

. The far left of the panels shows the flow profile used to generate the data for each row. Figure was produced with a Péclet number of

$\phi$

. The far left of the panels shows the flow profile used to generate the data for each row. Figure was produced with a Péclet number of

![]() $\textit{Pe}=100$

(§ B of the SM has similar figures for

$\textit{Pe}=100$

(§ B of the SM has similar figures for

![]() $\textit{Pe}=$

20 and 1000).

$\textit{Pe}=$

20 and 1000).

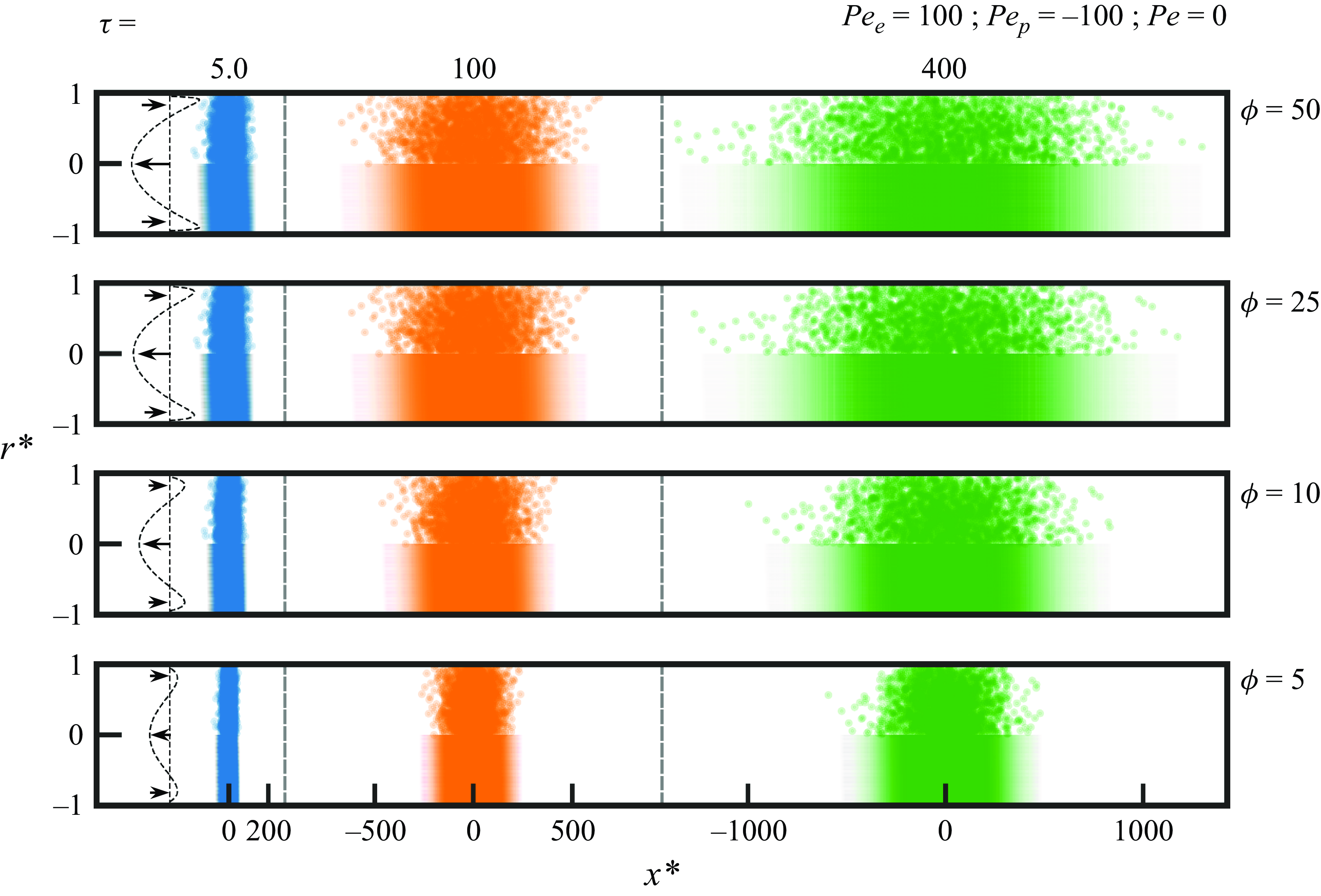

Figure 5. Benchmark comparisons between Brownian dynamics simulations and the analytical solution of the quasi-steady solute concentration field at three values of dimensionless time,

![]() $\tau =\textit{tD}/a^{2}$

. Solute zones were subject to flows wherein EOF is perfectly opposed by PDF to achieve a net flow with zero area-averaged bulk velocity. Panels show solute zones for four values of the tube radius scaled by Debye length,

$\tau =\textit{tD}/a^{2}$

. Solute zones were subject to flows wherein EOF is perfectly opposed by PDF to achieve a net flow with zero area-averaged bulk velocity. Panels show solute zones for four values of the tube radius scaled by Debye length,

![]() $\phi$

. The figure shows dimensionless radius,

$\phi$

. The figure shows dimensionless radius,

![]() $r^{*}$

, on the ordinate and dimensionless axial position,

$r^{*}$

, on the ordinate and dimensionless axial position,

![]() $x^{*}$

, on the abscissa. The top half of each panel shows individual particles from the Brownian dynamics simulations and the bottom half of each panel shows the concentration field predicted by the analytical solution in (3.40). The far left of the panels shows the flow profile used to generate the data for each row. Figure was produced with Péclet numbers based on EOF bulk velocity and PDF bulk velocity of

$x^{*}$

, on the abscissa. The top half of each panel shows individual particles from the Brownian dynamics simulations and the bottom half of each panel shows the concentration field predicted by the analytical solution in (3.40). The far left of the panels shows the flow profile used to generate the data for each row. Figure was produced with Péclet numbers based on EOF bulk velocity and PDF bulk velocity of

![]() $\textit{Pe}_{e}=100$

and

$\textit{Pe}_{e}=100$

and

![]() $\textit{Pe}_{p}=-100$

, respectively.

$\textit{Pe}_{p}=-100$

, respectively.

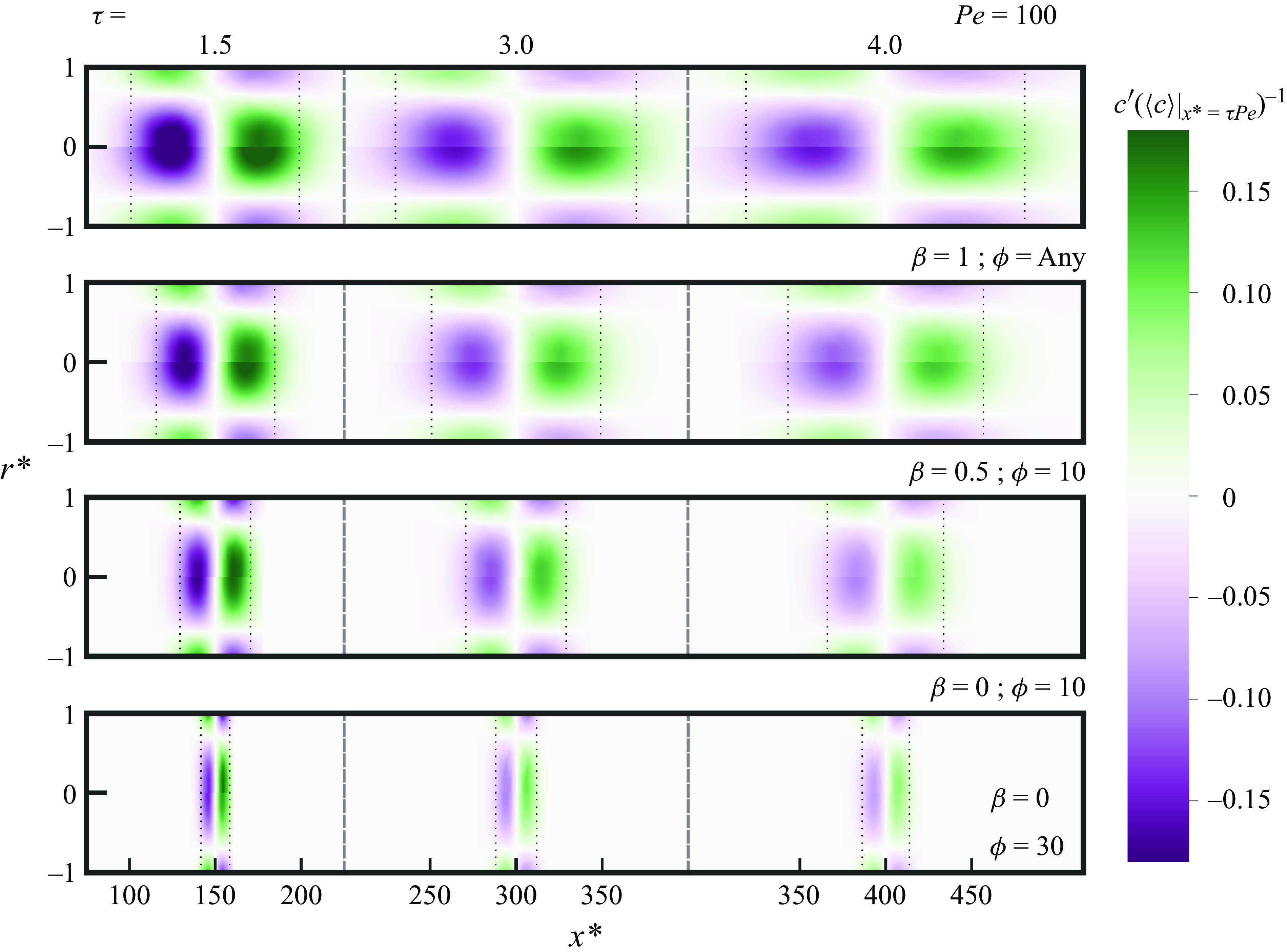

Figure 6. Comparisons between the analytical solution and Brownian dynamics simulations of the normalised quasi-steady radial distribution of solute at three values of dimensionless time,

![]() $\tau$

. The radial distribution is normalised as

$\tau$

. The radial distribution is normalised as

![]() $c^{\prime}(r^{*},x^{*},\tau )/\langle c\rangle (x^{*}=\tau \textit{Pe},\tau )$

where

$c^{\prime}(r^{*},x^{*},\tau )/\langle c\rangle (x^{*}=\tau \textit{Pe},\tau )$

where

![]() $\langle c\rangle (x^{*}=\tau \textit{Pe},\tau )$

is the area-averaged concentration at the mean axial position of solute. Dimensionless radius,

$\langle c\rangle (x^{*}=\tau \textit{Pe},\tau )$

is the area-averaged concentration at the mean axial position of solute. Dimensionless radius,

![]() $r^{*}$

, is shown on the ordinate and dimensionless axial position,

$r^{*}$

, is shown on the ordinate and dimensionless axial position,

![]() $x^{*}$

, is shown on the abscissa. The top half of each panel shows the radial solute distribution calculated from the Brownian dynamics simulations and the bottom half of each panel shows the analytical solution (given by the second term on the right-hand side of (3.40)). Panels show four combinations of the fraction of bulk velocity caused by pressure,

$x^{*}$

, is shown on the abscissa. The top half of each panel shows the radial solute distribution calculated from the Brownian dynamics simulations and the bottom half of each panel shows the analytical solution (given by the second term on the right-hand side of (3.40)). Panels show four combinations of the fraction of bulk velocity caused by pressure,

![]() $\beta$

, and the tube radius scaled by Debye length,

$\beta$

, and the tube radius scaled by Debye length,

![]() $\phi$

. The dotted black lines denote two axial standard deviations of the Brownian particles’ position about their mean position. Figure was produced with a Péclet number of

$\phi$

. The dotted black lines denote two axial standard deviations of the Brownian particles’ position about their mean position. Figure was produced with a Péclet number of

![]() $\textit{Pe}=100$

.

$\textit{Pe}=100$

.

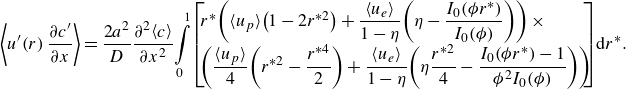

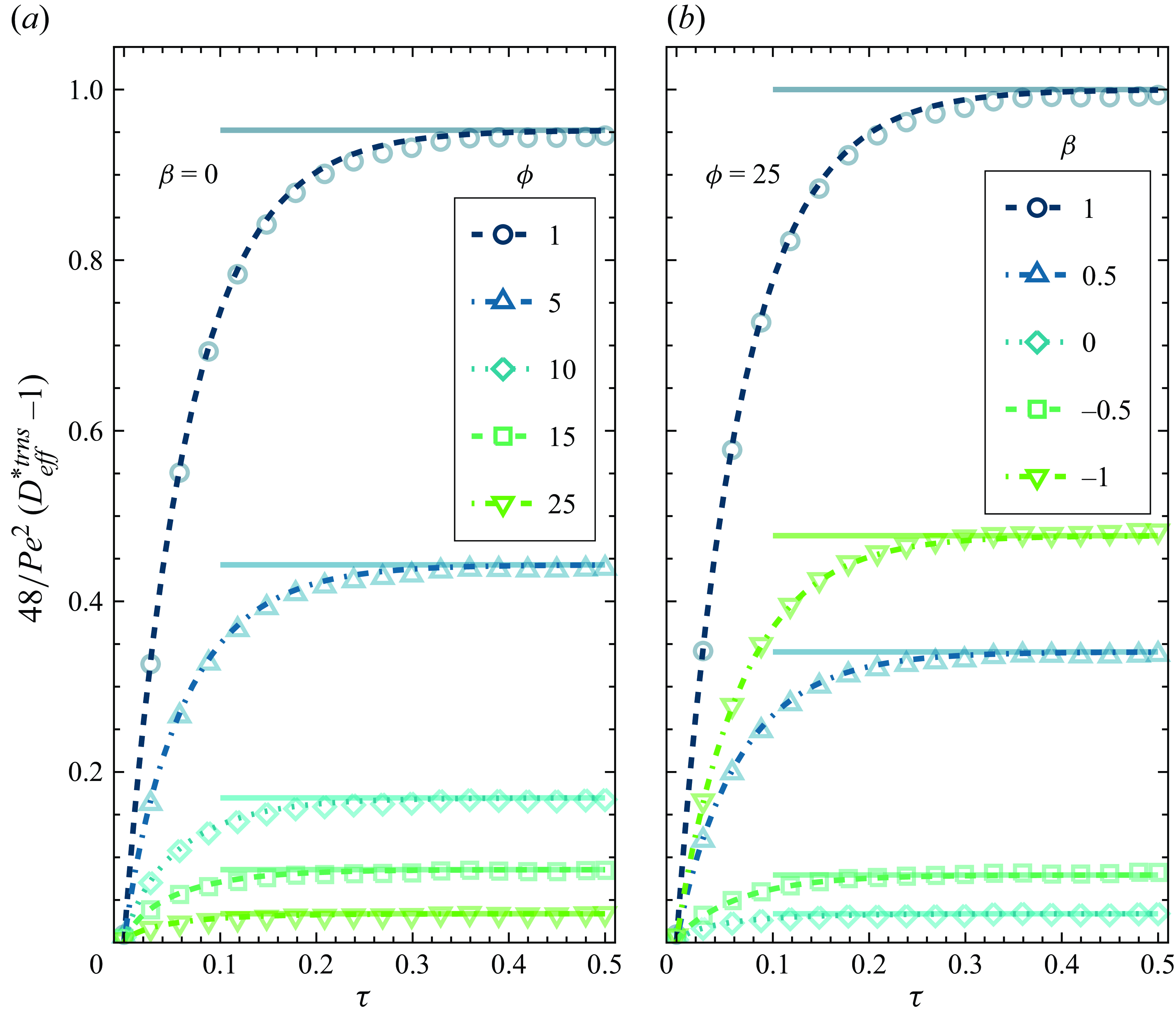

\begin{equation} \left\langle u^{\prime}\!\left(r\right)\frac{\partial c^{\prime}}{\partial x}\right\rangle =\frac{2a^{2}}{D}\frac{\partial ^{2}\!\left\langle c\right\rangle }{\partial x^{2}}\!\int \limits_{0}^{1}\!\left[\!\!\begin{array}{l} r^{*}\!\left( \langle u_{p} \rangle \!\left(1-2r^{*2}\right)+\dfrac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta -\dfrac{I_{0}\!\left(\phi r^{*}\right)}{I_{0}\!\left(\phi \right)}\right)\right) \times \\[6pt]\left(\dfrac{ \langle u_{p} \rangle }{4}\!\left(r^{*2}-\dfrac{r^{*4}}{2}\right)+\dfrac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta \dfrac{r^{*2}}{4}-\dfrac{I_{0}\!\left(\phi r^{*}\right)-1}{\phi ^{2}I_{0}\!\left(\phi \right)}\right)\right) \end{array}\!\!\!\right]\!\mathrm{d}r^{*}. \end{equation}

\begin{equation} \left\langle u^{\prime}\!\left(r\right)\frac{\partial c^{\prime}}{\partial x}\right\rangle =\frac{2a^{2}}{D}\frac{\partial ^{2}\!\left\langle c\right\rangle }{\partial x^{2}}\!\int \limits_{0}^{1}\!\left[\!\!\begin{array}{l} r^{*}\!\left( \langle u_{p} \rangle \!\left(1-2r^{*2}\right)+\dfrac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta -\dfrac{I_{0}\!\left(\phi r^{*}\right)}{I_{0}\!\left(\phi \right)}\right)\right) \times \\[6pt]\left(\dfrac{ \langle u_{p} \rangle }{4}\!\left(r^{*2}-\dfrac{r^{*4}}{2}\right)+\dfrac{\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\eta \dfrac{r^{*2}}{4}-\dfrac{I_{0}\!\left(\phi r^{*}\right)-1}{\phi ^{2}I_{0}\!\left(\phi \right)}\right)\right) \end{array}\!\!\!\right]\!\mathrm{d}r^{*}. \end{equation}

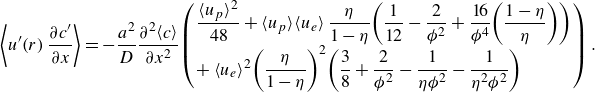

Expanding the right-hand side of (3.12) and simplifying yields 17 terms. We collect these into three groups as follows:

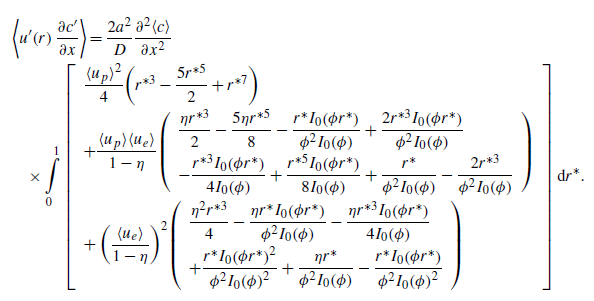

\begin{align} &\left\langle u^{\prime}\!\left(r\right)\dfrac{\partial c^{\prime}}{\partial x}\right\rangle =\dfrac{2a^{2}}{D}\dfrac{\partial ^{2}\!\left\langle c\right\rangle }{\partial x^{2}}\nonumber\\&\quad \times \int \limits_{0}^{1} \left[\begin{array}{l} \dfrac{ \langle u_{p} \rangle ^{2}}{4}\!\left(r^{*3}-\dfrac{5r^{*5}}{2}+r^{*7}\right)\\[9pt] +\dfrac{ \langle u_{p} \rangle \!\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\begin{array}{l} \dfrac{\eta r^{*3}}{2}-\dfrac{5\eta r^{*5}}{8}-\dfrac{r^{*}I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)}+\dfrac{2r^{*3}I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)}\\[9pt] -\dfrac{r^{*3}I_{0}\!\left(\phi r^{*}\right)}{4I_{0}\!\left(\phi \right)}+\dfrac{r^{*5}I_{0}\!\left(\phi r^{*}\right)}{8I_{0}\!\left(\phi \right)}+\dfrac{r^{*}}{\phi ^{2}I_{0}\!\left(\phi \right)}-\dfrac{2r^{*3}}{\phi ^{2}I_{0}\!\left(\phi \right)} \end{array}\right)\\[26pt] +\left(\dfrac{\left\langle u_{e}\right\rangle }{1-\eta }\right)^{2}\!\left(\begin{array}{l} \dfrac{\eta ^{2}r^{*3}}{4}-\dfrac{\eta r^{*}I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)}-\dfrac{\eta r^{*3}I_{0}\!\left(\phi r^{*}\right)}{4I_{0}\!\left(\phi \right)}\\[9pt] +\dfrac{r^{*}I_{0}\!\left(\phi r^{*}\right)^{2}}{\phi ^{2}I_{0}\!\left(\phi \right)^{2}}+\dfrac{\eta r^{*}}{\phi ^{2}I_{0}\!\left(\phi \right)}-\dfrac{r^{*}I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)^{2}} \end{array}\right) \end{array}\right]\mathrm{d}r^{*} .\nonumber\\[5pt] \end{align}

\begin{align} &\left\langle u^{\prime}\!\left(r\right)\dfrac{\partial c^{\prime}}{\partial x}\right\rangle =\dfrac{2a^{2}}{D}\dfrac{\partial ^{2}\!\left\langle c\right\rangle }{\partial x^{2}}\nonumber\\&\quad \times \int \limits_{0}^{1} \left[\begin{array}{l} \dfrac{ \langle u_{p} \rangle ^{2}}{4}\!\left(r^{*3}-\dfrac{5r^{*5}}{2}+r^{*7}\right)\\[9pt] +\dfrac{ \langle u_{p} \rangle \!\left\langle u_{e}\right\rangle }{1-\eta }\!\left(\begin{array}{l} \dfrac{\eta r^{*3}}{2}-\dfrac{5\eta r^{*5}}{8}-\dfrac{r^{*}I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)}+\dfrac{2r^{*3}I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)}\\[9pt] -\dfrac{r^{*3}I_{0}\!\left(\phi r^{*}\right)}{4I_{0}\!\left(\phi \right)}+\dfrac{r^{*5}I_{0}\!\left(\phi r^{*}\right)}{8I_{0}\!\left(\phi \right)}+\dfrac{r^{*}}{\phi ^{2}I_{0}\!\left(\phi \right)}-\dfrac{2r^{*3}}{\phi ^{2}I_{0}\!\left(\phi \right)} \end{array}\right)\\[26pt] +\left(\dfrac{\left\langle u_{e}\right\rangle }{1-\eta }\right)^{2}\!\left(\begin{array}{l} \dfrac{\eta ^{2}r^{*3}}{4}-\dfrac{\eta r^{*}I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)}-\dfrac{\eta r^{*3}I_{0}\!\left(\phi r^{*}\right)}{4I_{0}\!\left(\phi \right)}\\[9pt] +\dfrac{r^{*}I_{0}\!\left(\phi r^{*}\right)^{2}}{\phi ^{2}I_{0}\!\left(\phi \right)^{2}}+\dfrac{\eta r^{*}}{\phi ^{2}I_{0}\!\left(\phi \right)}-\dfrac{r^{*}I_{0}\!\left(\phi r^{*}\right)}{\phi ^{2}I_{0}\!\left(\phi \right)^{2}} \end{array}\right) \end{array}\right]\mathrm{d}r^{*} .\nonumber\\[5pt] \end{align}

Evaluating the integral in (3.13), we obtain

\begin{equation} \left\langle u^{\prime}\!\left(r\right)\dfrac{\partial c^{\prime}}{\partial x}\right\rangle =-\dfrac{a^{2}}{D}\dfrac{\partial ^{2}\!\left\langle c\right\rangle }{\partial x^{2}}\!\left(\begin{array}{l} \dfrac{ \langle u_{p} \rangle ^{2}}{48}+ \langle u_{p} \rangle \!\left\langle u_{e}\right\rangle \dfrac{\eta }{1-\eta }\!\left(\dfrac{1}{12}-\dfrac{2}{\phi ^{2}}+\dfrac{16}{\phi ^{4}}\!\left(\dfrac{1-\eta }{\eta }\right)\right)\\ +\left\langle u_{e}\right\rangle ^{2}\!\left(\dfrac{\eta }{1-\eta }\right)^{2}\!\left(\dfrac{3}{8}+\dfrac{2}{\phi ^{2}}-\dfrac{1}{\eta \phi ^{2}}-\dfrac{1}{\eta ^{2}\phi ^{2}}\right) \end{array}\right) .\end{equation}

\begin{equation} \left\langle u^{\prime}\!\left(r\right)\dfrac{\partial c^{\prime}}{\partial x}\right\rangle =-\dfrac{a^{2}}{D}\dfrac{\partial ^{2}\!\left\langle c\right\rangle }{\partial x^{2}}\!\left(\begin{array}{l} \dfrac{ \langle u_{p} \rangle ^{2}}{48}+ \langle u_{p} \rangle \!\left\langle u_{e}\right\rangle \dfrac{\eta }{1-\eta }\!\left(\dfrac{1}{12}-\dfrac{2}{\phi ^{2}}+\dfrac{16}{\phi ^{4}}\!\left(\dfrac{1-\eta }{\eta }\right)\right)\\ +\left\langle u_{e}\right\rangle ^{2}\!\left(\dfrac{\eta }{1-\eta }\right)^{2}\!\left(\dfrac{3}{8}+\dfrac{2}{\phi ^{2}}-\dfrac{1}{\eta \phi ^{2}}-\dfrac{1}{\eta ^{2}\phi ^{2}}\right) \end{array}\right) .\end{equation}

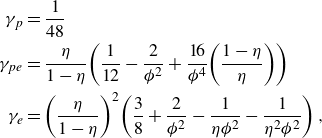

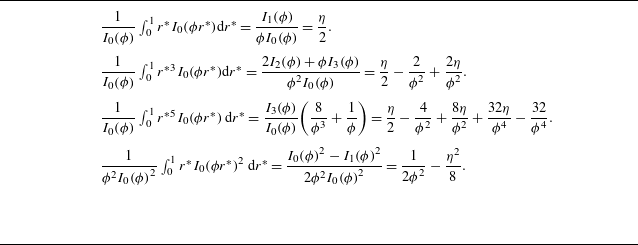

Table 1 lists the relevant integrals involving modified Bessel functions of the first kind which were used in this evaluation. Next, for a compact notation, we define

\begin{align} \gamma _{p}&=\frac{1}{48}\nonumber\\ \gamma _{pe}&=\frac{\eta }{1-\eta }\!\left(\frac{1}{12}-\frac{2}{\phi ^{2}}+\frac{16}{\phi ^{4}}\!\left(\frac{1-\eta }{\eta }\right)\right)\nonumber\\ \gamma _{e}&=\left(\frac{\eta }{1-\eta }\right)^{2}\!\left(\frac{3}{8}+\frac{2}{\phi ^{2}}-\frac{1}{\eta \phi ^{2}}-\frac{1}{\eta ^{2}\phi ^{2}}\right), \end{align}

\begin{align} \gamma _{p}&=\frac{1}{48}\nonumber\\ \gamma _{pe}&=\frac{\eta }{1-\eta }\!\left(\frac{1}{12}-\frac{2}{\phi ^{2}}+\frac{16}{\phi ^{4}}\!\left(\frac{1-\eta }{\eta }\right)\right)\nonumber\\ \gamma _{e}&=\left(\frac{\eta }{1-\eta }\right)^{2}\!\left(\frac{3}{8}+\frac{2}{\phi ^{2}}-\frac{1}{\eta \phi ^{2}}-\frac{1}{\eta ^{2}\phi ^{2}}\right), \end{align}

which allows us to express (3.14) as

Substituting (3.16) into (3.2), we derive the following one-dimensional, unsteady partial differential equation describing the area-averaged concentration field:

Table 1. Integrals applicable to the evaluation of (3.13).

The first, third and second parenthetic terms on the right-hand side respectively capture the effects of dispersion caused by PDF alone, by EOF alone and by the coupled, non-superposable effects of simultaneous PDF and EOF. From the latter equation, the effective dispersion coefficient valid for the Taylor-type limit of the problem is

Note that, in analogy to Taylor’s (Reference Taylor1953) original analysis, (3.17) has the form of a one-dimensional unsteady diffusion equation with the molecular diffusivity replaced by an effective dispersion coefficient given by (3.18). As such, the solution is an initial value problem that requires an initial axial distribution of the area-averaged solute. However, the solution of (3.17) does not accurately predict the evolution of solute until sufficient time has passed relative to the characteristic time of transverse diffusion,

![]() $a^{2}/D$

. In other words, this solution is valid as long as the solute variance gained in early times (during the pre-asymptotic dispersion regime) is small compared with either the initial variance or the variance gained due to the (long-term) Taylor dispersion. We will soon explore predictions by this solution given specific initial conditions. In § 4, we will derive dispersion solutions (given various initial conditions) which are valid for both short and long times. Next, we note that (3.18) is equivalent to the solution reported by Datta & Kotamarthi (Reference Datta and Kotamarthi1990) for the dimensional dispersion coefficient (see their equation (37)). Datta & Kotamarthi reported deriving their solution by applying a Taylor-type analysis but, as mentioned earlier, did not present a derivation in any detail. Further, we note that (3.18), for pure PDF (

$a^{2}/D$

. In other words, this solution is valid as long as the solute variance gained in early times (during the pre-asymptotic dispersion regime) is small compared with either the initial variance or the variance gained due to the (long-term) Taylor dispersion. We will soon explore predictions by this solution given specific initial conditions. In § 4, we will derive dispersion solutions (given various initial conditions) which are valid for both short and long times. Next, we note that (3.18) is equivalent to the solution reported by Datta & Kotamarthi (Reference Datta and Kotamarthi1990) for the dimensional dispersion coefficient (see their equation (37)). Datta & Kotamarthi reported deriving their solution by applying a Taylor-type analysis but, as mentioned earlier, did not present a derivation in any detail. Further, we note that (3.18), for pure PDF (

![]() $\langle u_{p}\rangle =\langle u\rangle$

), reduces to Aris’ (Reference Aris1956) classic solution of

$\langle u_{p}\rangle =\langle u\rangle$

), reduces to Aris’ (Reference Aris1956) classic solution of

![]() $D_{\textit{eff}}=D+D^{-1}a^{2}\langle u_{p}\rangle ^{2}\gamma _{p}$

. Additionally, for pure EOF (

$D_{\textit{eff}}=D+D^{-1}a^{2}\langle u_{p}\rangle ^{2}\gamma _{p}$

. Additionally, for pure EOF (

![]() $\langle u_{e}\rangle =\langle u\rangle$

), (3.18) becomes

$\langle u_{e}\rangle =\langle u\rangle$

), (3.18) becomes

![]() $D_{\textit{eff}}=D+D^{-1}a^{2}\langle u_{e}\rangle ^{2}\gamma _{e}$

, which agrees analytically with Griffiths & Nilson’s (Reference Griffiths and Nilson1999) solution of the coefficient of effective dispersion (their equation (38); see § A of the supplementary material (SM) for proof).

$D_{\textit{eff}}=D+D^{-1}a^{2}\langle u_{e}\rangle ^{2}\gamma _{e}$

, which agrees analytically with Griffiths & Nilson’s (Reference Griffiths and Nilson1999) solution of the coefficient of effective dispersion (their equation (38); see § A of the supplementary material (SM) for proof).

Next, we scale the expression for the dispersion coefficient. To this end, we note that

![]() $\langle u_{p}\rangle$

and

$\langle u_{p}\rangle$

and

![]() $\langle u_{e}\rangle$

are signed quantities. They are also variables which are fully independent of each other (e.g. they can be independently controlled in an experiment). Hence, we define here two corresponding (signed) Péclet numbers of the form

$\langle u_{e}\rangle$

are signed quantities. They are also variables which are fully independent of each other (e.g. they can be independently controlled in an experiment). Hence, we define here two corresponding (signed) Péclet numbers of the form

![]() $P\hspace{0pt}e_{p}=a\langle u_{p}\rangle /D$

and

$P\hspace{0pt}e_{p}=a\langle u_{p}\rangle /D$

and

![]() $P\hspace{0pt}e_{e}=a\langle u_{e}\rangle /D$

. For both, we use the characteristic length scale of the cylinder radius. The non-dimensional dispersion coefficient is then

$P\hspace{0pt}e_{e}=a\langle u_{e}\rangle /D$

. For both, we use the characteristic length scale of the cylinder radius. The non-dimensional dispersion coefficient is then

The last three terms on the right-hand side again capture the effects of pure PDF, coupled PDF and EOF and pure EOF. Because the values of

![]() $\gamma$

are functions of

$\gamma$

are functions of

![]() $\phi$

(cf. (3.15)),

$\phi$

(cf. (3.15)),

![]() $D_{\textit{eff}}^{*}$

is a function of only three dimensionless parameters:

$D_{\textit{eff}}^{*}$

is a function of only three dimensionless parameters:

![]() $\textit{Pe}_{p}, \textit{Pe}_{e}$

and

$\textit{Pe}_{p}, \textit{Pe}_{e}$

and

![]() $\phi$

.

$\phi$

.

Before continuing our presentation, we briefly compare our (3.19) with the non-dimensional dispersion coefficient presented by Datta & Kotamarthi (Reference Datta and Kotamarthi1990). The latter authors chose to combine the signed quantities

![]() $\langle u_{p}\rangle$

and

$\langle u_{p}\rangle$

and

![]() $\langle u_{e}\rangle$

as a sum within a single global Péclet number of the form

$\langle u_{e}\rangle$

as a sum within a single global Péclet number of the form

![]() $\textit{Pe}=(\langle u_{p}\rangle +\langle u_{e}\rangle )a/D$

. Further, they chose to use the ratio

$\textit{Pe}=(\langle u_{p}\rangle +\langle u_{e}\rangle )a/D$

. Further, they chose to use the ratio

![]() $\beta =\langle u_{p}\rangle /\langle u\rangle$

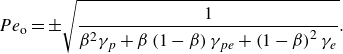

to distinguish between the effects of EOF and PDF. Their approach yields the following result:

$\beta =\langle u_{p}\rangle /\langle u\rangle$

to distinguish between the effects of EOF and PDF. Their approach yields the following result:

In this formulation,

![]() $D_{\textit{eff}}^{*}$

is again a function of three parameters, but these are now

$D_{\textit{eff}}^{*}$

is again a function of three parameters, but these are now

![]() $\phi, \beta$

and

$\phi, \beta$

and

![]() $P\hspace{0pt}e$

. We note this combination of two velocity scales into a single Péclet number is most useful to characterise dispersion when EOF and PDF act in the same direction. We recommend the formulation of (3.19) for cases wherein EOF and PDF are in opposition. When EOF and PDF are opposed and nearly equal in magnitude,

$P\hspace{0pt}e$

. We note this combination of two velocity scales into a single Péclet number is most useful to characterise dispersion when EOF and PDF act in the same direction. We recommend the formulation of (3.19) for cases wherein EOF and PDF are in opposition. When EOF and PDF are opposed and nearly equal in magnitude,

![]() $P\hspace{0pt}e$

approaches zero while

$P\hspace{0pt}e$

approaches zero while

![]() $\beta$

approaches infinity at the same rate and evaluation of (3.20) is more cumbersome than (3.19).

$\beta$

approaches infinity at the same rate and evaluation of (3.20) is more cumbersome than (3.19).

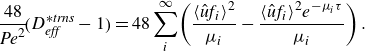

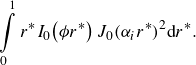

We can rewrite (3.20) as follows:

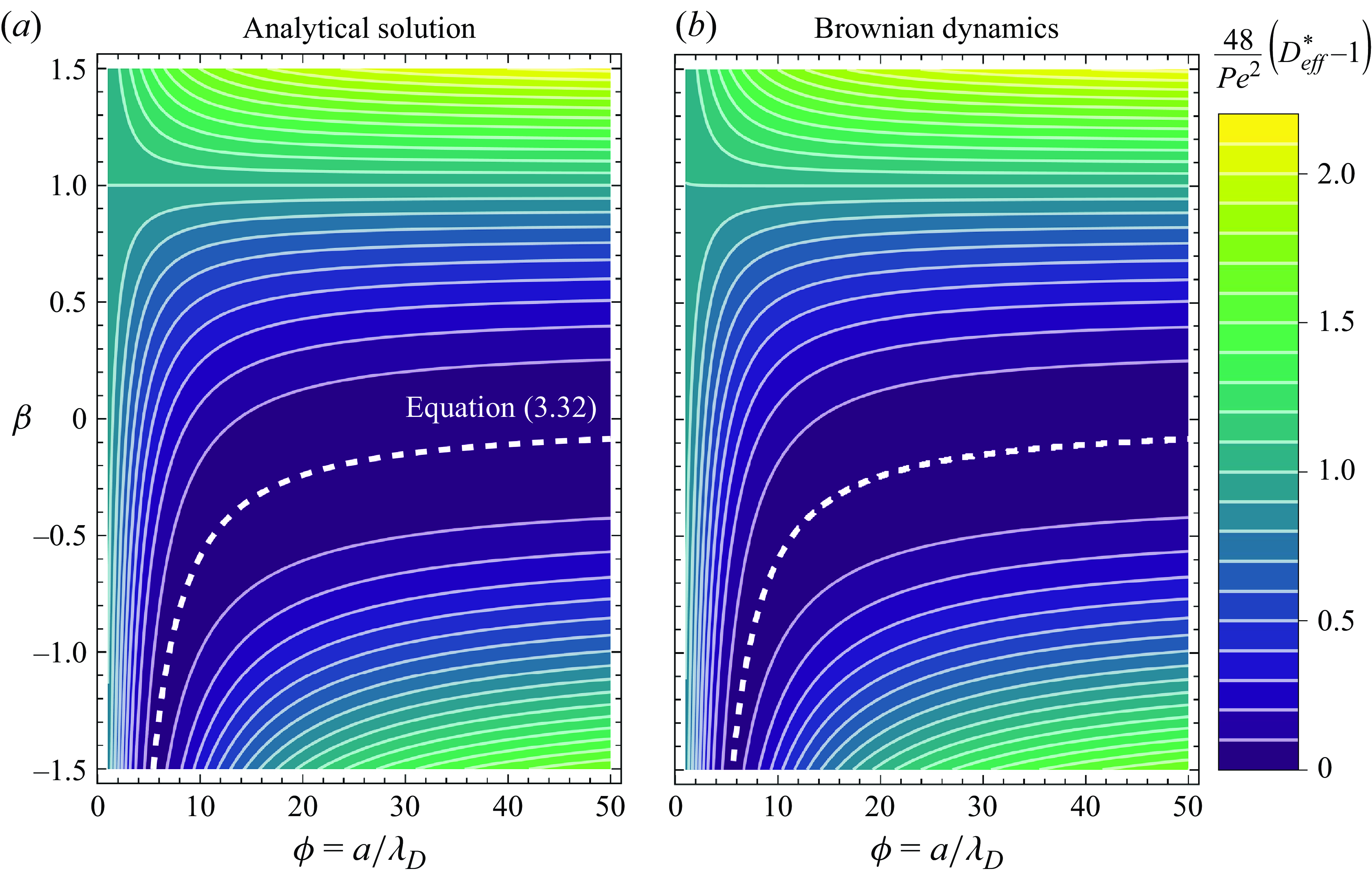

This formulation enables exploration of the full solution and in a manner most useful when EOF and PDF are not perfectly opposed. We will use this formulation to plot and benchmark the grouping

![]() $48\textit{Pe}^{-2}(D_{\textit{eff}}^{*}-1)$

in heatmaps where the independent variables are

$48\textit{Pe}^{-2}(D_{\textit{eff}}^{*}-1)$

in heatmaps where the independent variables are

![]() $\beta$

and

$\beta$

and

![]() $\phi$

(see figure 7). Further, we will benchmark

$\phi$

(see figure 7). Further, we will benchmark

![]() $D_{\textit{eff}}^{*}$

against Brownian dynamics simulations for the case of perfectly opposed PDF and EOF in figure 8. Lastly, we note (3.21) conveniently reduces to unity for the case of parabolic flow. Parabolic flow is achieved by pure PDF or for combinations of PDF and EOF with thick EDLs (since thick-EDL solutions also lead to parabolic EOF).

$D_{\textit{eff}}^{*}$

against Brownian dynamics simulations for the case of perfectly opposed PDF and EOF in figure 8. Lastly, we note (3.21) conveniently reduces to unity for the case of parabolic flow. Parabolic flow is achieved by pure PDF or for combinations of PDF and EOF with thick EDLs (since thick-EDL solutions also lead to parabolic EOF).

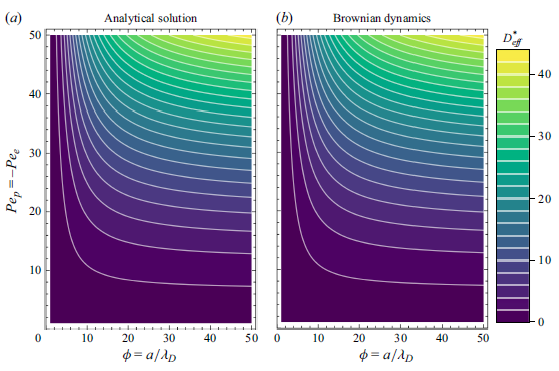

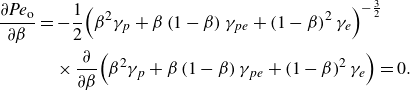

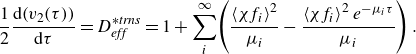

Figure 7. Contour plots of our quasi-steady analytical solution

![]() $(a)$

versus Brownian dynamics simulations

$(a)$

versus Brownian dynamics simulations

![]() $(b)$

of the normalised effective dispersion coefficient. In both cases, the effective dispersion coefficient is normalised as

$(b)$

of the normalised effective dispersion coefficient. In both cases, the effective dispersion coefficient is normalised as

![]() $48\textit{Pe}^{-2}(D_{\textit{eff}}^{*}-1)$

where

$48\textit{Pe}^{-2}(D_{\textit{eff}}^{*}-1)$

where

![]() $D_{\textit{eff}}^{*}$

is the effective dispersion coefficient. This non-dimensional quantity is plotted versus the fraction of bulk velocity caused by pressure,

$D_{\textit{eff}}^{*}$

is the effective dispersion coefficient. This non-dimensional quantity is plotted versus the fraction of bulk velocity caused by pressure,

![]() $\beta$

, and the radius scaled by Debye length,

$\beta$

, and the radius scaled by Debye length,

![]() $\phi$

. The panels cover the entire dynamics of quasi-steady dispersion for all relative EDL thicknesses and many velocity profiles. The white dashed lines show the variance-minimising contour for values of

$\phi$

. The panels cover the entire dynamics of quasi-steady dispersion for all relative EDL thicknesses and many velocity profiles. The white dashed lines show the variance-minimising contour for values of

![]() $\beta$

as a function of

$\beta$

as a function of

![]() $\phi$

. These lines are obtained from (3.32) for the analytical solution and numerically for the Brownian dynamics simulations.

$\phi$

. These lines are obtained from (3.32) for the analytical solution and numerically for the Brownian dynamics simulations.

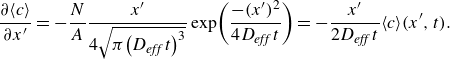

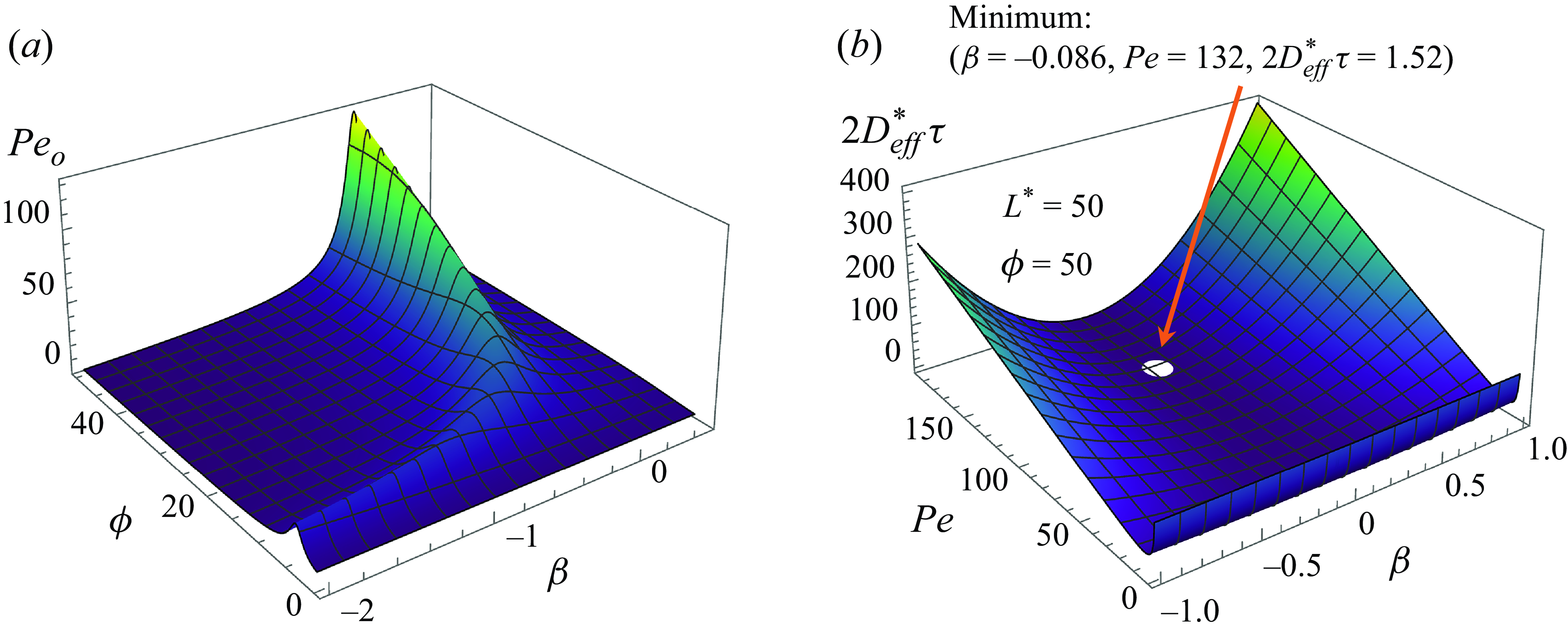

Figure 8. Contour plots of our quasi-steady analytical solution

![]() $(a)$

versus Brownian dynamics simulations

$(a)$

versus Brownian dynamics simulations

![]() $(b)$

of the dimensionless effective dispersion coefficient for the case of perfectly opposed EOF and PDF. The dimensionless dispersion coefficient

$(b)$

of the dimensionless effective dispersion coefficient for the case of perfectly opposed EOF and PDF. The dimensionless dispersion coefficient

![]() $D_{\textit{eff}}^{*}$

is plotted versus the Péclet number based on PDF,

$D_{\textit{eff}}^{*}$

is plotted versus the Péclet number based on PDF,

![]() $P\hspace{0pt}e_{p}$

, and the radius scaled by Debye length,

$P\hspace{0pt}e_{p}$

, and the radius scaled by Debye length,

![]() $\phi$

. The Péclet number based on PDF is fixed to be equal in magnitude but opposite in sign to the Péclet number based on EOF,

$\phi$

. The Péclet number based on PDF is fixed to be equal in magnitude but opposite in sign to the Péclet number based on EOF,

![]() $P\hspace{0pt}e_{e}$

. For perfectly opposed PDF and EOF,

$P\hspace{0pt}e_{e}$

. For perfectly opposed PDF and EOF,

![]() $D_{\textit{eff}}^{*}$

decreases as

$D_{\textit{eff}}^{*}$

decreases as

![]() $\phi$

decreases.

$\phi$

decreases.

We now continue with our derivation for the two-dimensional concentration field. We first evaluate the solution of (3.17) for an initial delta function condition for the solute of the form

where

![]() $N/A$

is the moles of solute per unit cross-sectional area of the channel, and the delta function

$N/A$

is the moles of solute per unit cross-sectional area of the channel, and the delta function

![]() $\delta (x)$

has dimensions of inverse length. Defining

$\delta (x)$

has dimensions of inverse length. Defining

![]() $x^{\prime}=x-\langle u\rangle t$

as an axial coordinate for a reference frame moving at net bulk velocity, the area-averaged solute distribution for this fundamental case is

$x^{\prime}=x-\langle u\rangle t$

as an axial coordinate for a reference frame moving at net bulk velocity, the area-averaged solute distribution for this fundamental case is

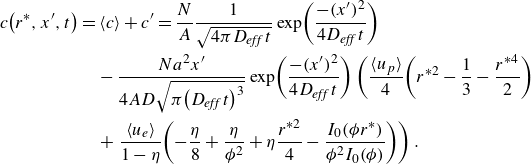

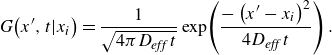

This solution can be interpreted as the Green’s function (also know as heat kernel) for (3.17) which, as we discuss in the next section, can be used to construct a wide variety of solutions for more complex initial conditions. Further, the first derivative of (3.23) with respect to axial dimension is

\begin{equation} \frac{\partial \!\left\langle c\right\rangle }{\partial x^{\prime}}=-\frac{N}{A}\frac{x^{\prime}}{4\sqrt{\pi \!\left(D_{\textit{eff}}\,t\right)^{3}}}\exp\!\left(\frac{-(x^{\prime})^{2}}{4D_{\textit{eff}}\,t}\right)=-\frac{x^{\prime}}{2D_{\textit{eff}}\,t}\!\left\langle c\right\rangle \! (x^{\prime},t) .\end{equation}

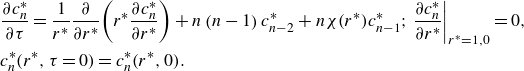

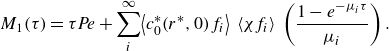

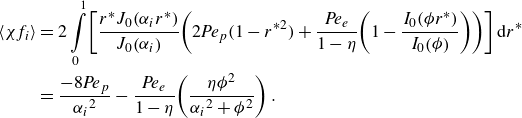

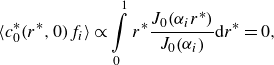

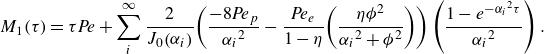

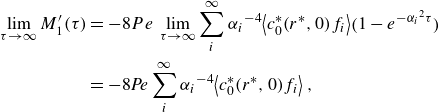

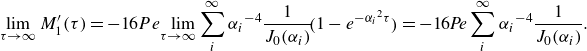

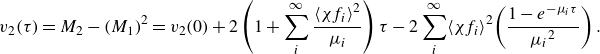

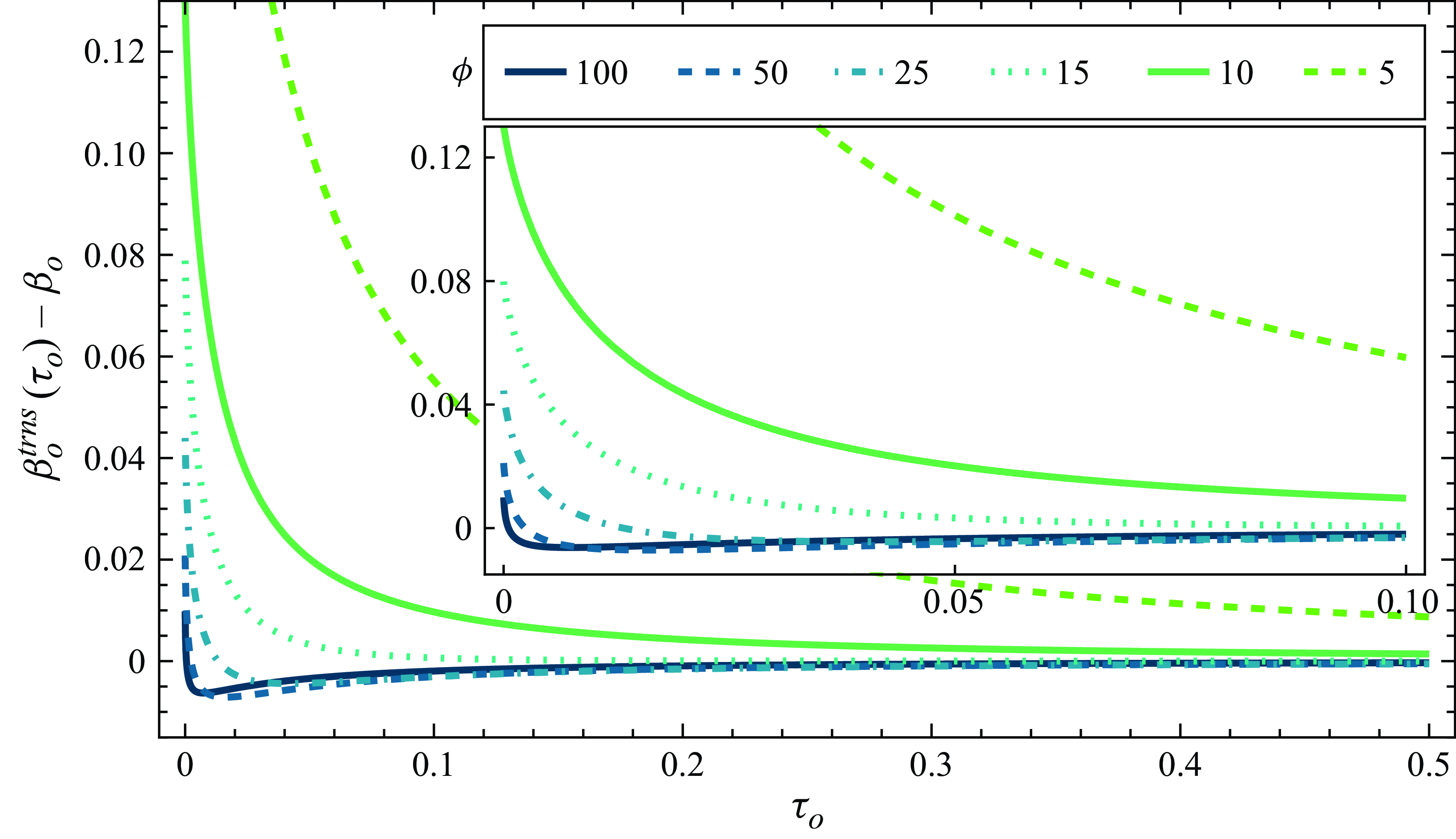

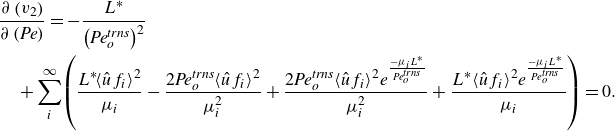

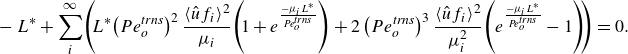

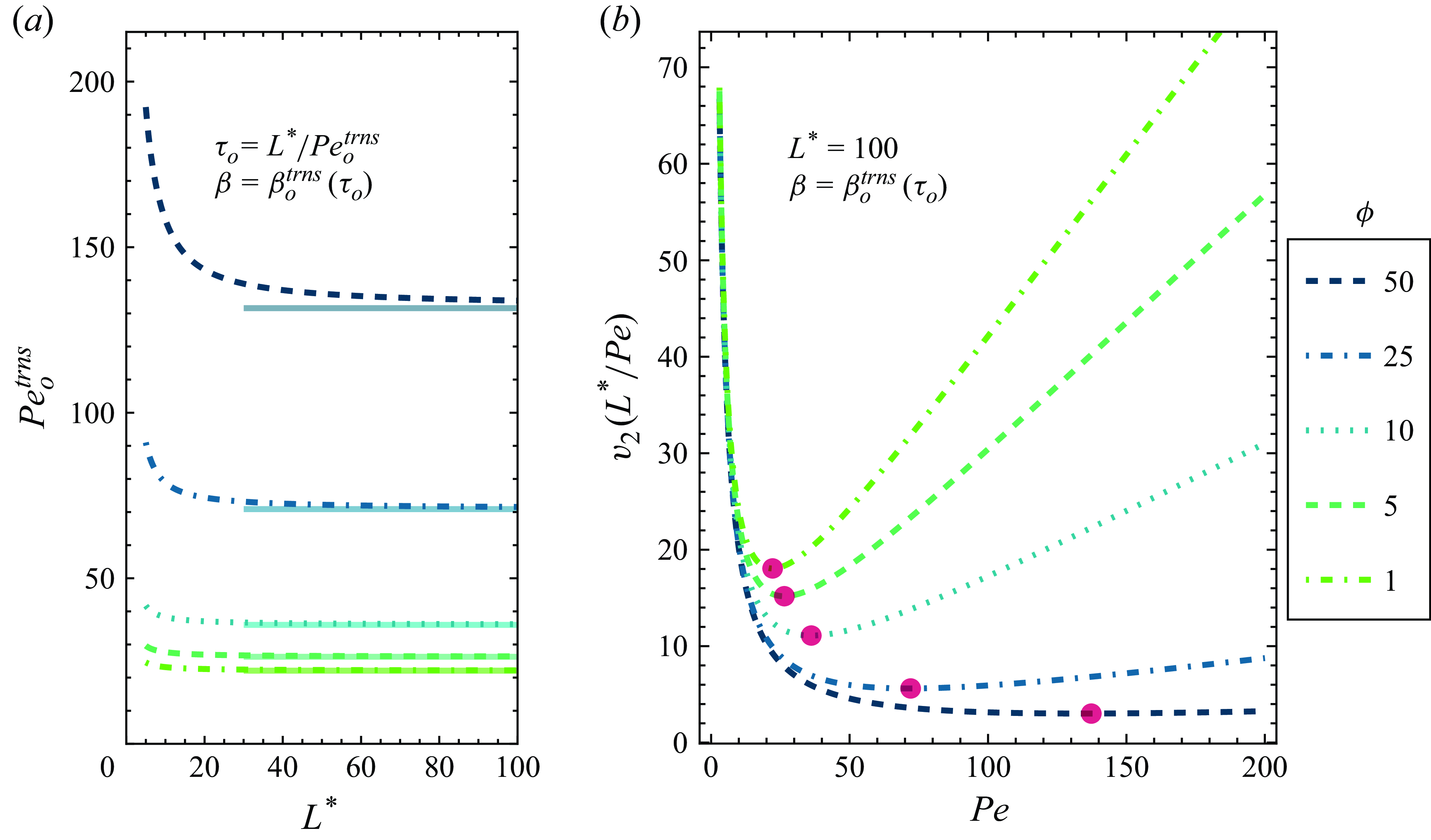

\begin{equation} \frac{\partial \!\left\langle c\right\rangle }{\partial x^{\prime}}=-\frac{N}{A}\frac{x^{\prime}}{4\sqrt{\pi \!\left(D_{\textit{eff}}\,t\right)^{3}}}\exp\!\left(\frac{-(x^{\prime})^{2}}{4D_{\textit{eff}}\,t}\right)=-\frac{x^{\prime}}{2D_{\textit{eff}}\,t}\!\left\langle c\right\rangle \! (x^{\prime},t) .\end{equation}