1. Introduction

Nanometric thin liquid films deposited on substrates exist in a host of applications such as in lubricants (Jhon et al. Reference Jhon, Phillips, Vinay and Messer1999), coatings (Weinstein & Ruschak Reference Weinstein and Ruschak2004) and microfluidics (Stone, Stroock & Ajdari Reference Stone, Stroock and Ajdari2004). The reliability of those applications depends heavily on our understanding of their stability mechanism, which is usually investigated in the context of thin-film flows (Oron, Davis & Bankoff Reference Oron, Davis and Bankoff1997; Craster & Matar Reference Craster and Matar2009). Thin-film flows are characterised by the disparity of length scale in different dimensions, i.e. the ratio of film height ![]() $h$ to characteristic film length

$h$ to characteristic film length ![]() $\lambda$ is very small:

$\lambda$ is very small: ![]() $\chi = h/\lambda \ll 1$. This allows the adoption of a long-wave theory to derive lubrication equations from the full governing equations and boundary conditions, reducing the dimensionality and complexity of the problems (Oron et al. Reference Oron, Davis and Bankoff1997; Craster & Matar Reference Craster and Matar2009).

$\chi = h/\lambda \ll 1$. This allows the adoption of a long-wave theory to derive lubrication equations from the full governing equations and boundary conditions, reducing the dimensionality and complexity of the problems (Oron et al. Reference Oron, Davis and Bankoff1997; Craster & Matar Reference Craster and Matar2009).

Polymeric or metallic films on substrates with thicknesses below 100 nm have been observed to undergo spontaneous rupture and dewetting (Xie et al. Reference Xie, Karim, Douglas, Han and Weiss1998; Seemann, Herminghaus & Jacobs Reference Seemann, Herminghaus and Jacobs2001; Becker et al. Reference Becker, Grün, Seemann, Mantz, Jacobs, Mecke and Blossey2003; González, Diez & Sellier Reference González, Diez and Sellier2016). The dewetting mechanism in these films may be complicated due to the contamination of defects in the liquid. However, the primary dewetting mechanism for homogeneous liquid films is usually called spinodal dewetting. In this process, disjoining pressure, as a result of intermolecular forces between liquid and solid, leads to the instability of films. Basically, from the classical perspective, thermally excited capillary waves can be amplified by the disjoining pressure, but in competition with the restoring force of surface tension, such that disturbances above a critical wavelength can grow and lead to film rupture (Vrij & Overbeek Reference Vrij and Overbeek1968).

For interfacial flows at the nanoscale, thermal fluctuations can play an important role in the instability process (Moseler & Landman Reference Moseler and Landman2000; Grün, Mecke & Rauscher Reference Grün, Mecke and Rauscher2006; Zhang, Sprittles & Lockerby Reference Zhang, Sprittles and Lockerby2019). Thermal fluctuations can spontaneously generate thermal capillary waves (TCWs) and roughness on the free surface of a liquid film at rest. The magnitude of thermal roughness is usually proportional to thermal length ![]() $\sqrt {k_BT/\gamma }$ (

$\sqrt {k_BT/\gamma }$ (![]() $k_B$,

$k_B$, ![]() $T$ and

$T$ and ![]() $\gamma$ are the Boltzmann constant, temperature and surface tension, respectively) (Buff, Lovett & Stillinger Reference Buff, Lovett and Stillinger1965; MacDowell Reference MacDowell2017). Though the roughness is small and usually on the scale of nanometres, it becomes comparable to the size of films when the film thickness goes down to several nanometres. Note that micrometre roughness can also be obtained and, thus, observed optically in real space using ultra-low surface tension mixtures (

$\gamma$ are the Boltzmann constant, temperature and surface tension, respectively) (Buff, Lovett & Stillinger Reference Buff, Lovett and Stillinger1965; MacDowell Reference MacDowell2017). Though the roughness is small and usually on the scale of nanometres, it becomes comparable to the size of films when the film thickness goes down to several nanometres. Note that micrometre roughness can also be obtained and, thus, observed optically in real space using ultra-low surface tension mixtures (![]() $\gamma \sim 10^{-6}\ {\rm N}\ {\rm m}^{-1}$) (Aarts, Schmidt & Lekkerkerker Reference Aarts, Schmidt and Lekkerkerker2004). In the equilibrium state, the amplitude of TCWs, known as the static spectrum, can be described by the renowned capillary wave theory (Buff et al. Reference Buff, Lovett and Stillinger1965; Höfling & Dietrich Reference Höfling and Dietrich2015; MacDowell Reference MacDowell2017; Höfling & Dietrich Reference Höfling and Dietrich2024). Recently, an extension of the capillary wave theory has been proposed utilising a Langevin equation to describe the transient dynamics of non-equilibrium TCWs and their approach to thermal equilibrium (Zhang, Sprittles & Lockerby Reference Zhang, Sprittles and Lockerby2021). This advancement has led to the identification of a universality class governing the roughening behaviour of film surfaces (Zhang et al. Reference Zhang, Sprittles and Lockerby2021).

$\gamma \sim 10^{-6}\ {\rm N}\ {\rm m}^{-1}$) (Aarts, Schmidt & Lekkerkerker Reference Aarts, Schmidt and Lekkerkerker2004). In the equilibrium state, the amplitude of TCWs, known as the static spectrum, can be described by the renowned capillary wave theory (Buff et al. Reference Buff, Lovett and Stillinger1965; Höfling & Dietrich Reference Höfling and Dietrich2015; MacDowell Reference MacDowell2017; Höfling & Dietrich Reference Höfling and Dietrich2024). Recently, an extension of the capillary wave theory has been proposed utilising a Langevin equation to describe the transient dynamics of non-equilibrium TCWs and their approach to thermal equilibrium (Zhang, Sprittles & Lockerby Reference Zhang, Sprittles and Lockerby2021). This advancement has led to the identification of a universality class governing the roughening behaviour of film surfaces (Zhang et al. Reference Zhang, Sprittles and Lockerby2021).

The increasing importance of thermal fluctuations as the film height decreases may make the deterministic description of hydrodynamics at the nanoscale break down. For example, the breakup of liquid nanojets in molecular dynamics (MD) simulations (Moseler & Landman Reference Moseler and Landman2000; Zhao, Sprittles & Lockerby Reference Zhao, Sprittles and Lockerby2019) and experiments (Hennequin et al. Reference Hennequin, Aarts, van der Wiel, Wegdam, Eggers, Lekkerkerker and Bonn2006) shows a double-cone rupture profile, in contrast to the long-thread profile predicted by the deterministic lubrication equation (Eggers & Dupont Reference Eggers and Dupont1994). Moseler & Landman (Reference Moseler and Landman2000) pioneered in showing that the deficiency of this deterministic lubrication equation for describing nanojet dynamics can be remedied by adding a noise term of appropriate strength to the equation, which leads to a stochastic lubrication equation for nanojets. Eggers (Reference Eggers2002) later showed that the evolution of the minimum neck radius is accelerated by thermal fluctuations, leading to ![]() $h_{min}\propto (t_0-t)^{0.418}$ (where

$h_{min}\propto (t_0-t)^{0.418}$ (where ![]() $t_0$ is the rupture time) in contrast with

$t_0$ is the rupture time) in contrast with ![]() $h_{min}\propto (t_0-t)$ for the deterministic pinching. This noise-dominated breakup for nanojets has been observed in experiments using ultra-low surface tension mixtures (Hennequin et al. Reference Hennequin, Aarts, van der Wiel, Wegdam, Eggers, Lekkerkerker and Bonn2006).

$h_{min}\propto (t_0-t)$ for the deterministic pinching. This noise-dominated breakup for nanojets has been observed in experiments using ultra-low surface tension mixtures (Hennequin et al. Reference Hennequin, Aarts, van der Wiel, Wegdam, Eggers, Lekkerkerker and Bonn2006).

For nanofilm rupture, Grün et al. (Reference Grün, Mecke and Rauscher2006) and Davidovitch, Moro & Stone (Reference Davidovitch, Moro and Stone2005) independently derived the same stochastic lubrication equation for liquid films on no-slip substrates. The numerical solution to this equation (Grün et al. Reference Grün, Mecke and Rauscher2006) can resolve the discrepancy in dewetting time between experimental results (Becker et al. Reference Becker, Grün, Seemann, Mantz, Jacobs, Mecke and Blossey2003) and the solution to the deterministic counterpart. Subsequently, the rupture of thin films with the effects of thermal fluctuations has been widely investigated by numerical solutions to the stochastic film equation (Grün et al. Reference Grün, Mecke and Rauscher2006; Nesic et al. Reference Nesic, Cuerno, Moro and Kondic2015; Diez, González & Fernández Reference Diez, González and Fernández2016; Durán-Olivencia et al. Reference Durán-Olivencia, Gvalani, Kalliadasis and Pavliotis2019; Shah et al. Reference Shah, van Steijn, Kleijn and Kreutzer2019; Zitz, Scagliarini & Harting Reference Zitz, Scagliarini and Harting2021). These studies have consistently demonstrated that thermal fluctuations indeed accelerate the rupture process. The application of this stochastic film equation is not restricted to nanofilm dewetting. It has been extended to study, for example, nanodroplet spreading under an elastic sheet (Carlson Reference Carlson2018), curvature-induced film drainage (Shah et al. Reference Shah, van Steijn, Kleijn and Kreutzer2019) and mediated diffusion of particles confined in channels with a fluctuating wall (Marbach, Dean & Bocquet Reference Marbach, Dean and Bocquet2018).

In addition to numerical solutions, linear stability analyses of the stochastic film equation have also been studied a lot, which allows us to obtain the evolution of the capillary spectra of surface waves (Mecke & Rauscher Reference Mecke and Rauscher2005; Fetzer et al. Reference Fetzer, Rauscher, Seemann, Jacobs and Mecke2007; Zhang et al. Reference Zhang, Sprittles and Lockerby2019; Zhao et al. Reference Zhao, Sprittles and Lockerby2019). The analytical spectra show thermal fluctuations can massively amplify the growth of waves, shift the critical wavenumber to a larger value and cause the dominant wavelength to evolve in time (in contrast to a constant value predicted by the deterministic lubrication equation). These interesting findings have been validated both in MD simulations (Zhang et al. Reference Zhang, Sprittles and Lockerby2019) and experiments (Fetzer et al. Reference Fetzer, Rauscher, Seemann, Jacobs and Mecke2007).

The original stochastic film equation mentioned previously adopts the classical no-slip boundary condition. As the flow scale reaches nanometres, surface effects such as liquid–solid slip can have significant effects on flow behaviours (see the reviews by Lauga, Brenner & Stone Reference Lauga, Brenner, Stone, Tropea, Yarin and Foss2007; Bocquet & Charlaix Reference Bocquet and Charlaix2010). Obviously, nanofilm flows can be significantly affected by slip as well, since the ratio of slip length ![]() $b$ to the film thickness

$b$ to the film thickness ![]() $h$ can get close to unity or even much larger than unity (Bäumchen & Jacobs Reference Bäumchen and Jacobs2009). In fact, in the deterministic setting, the introduction of slip to the deterministic film equation has been studied extensively for various phenomena, such as in coating a plate (Liao, Li & Wei Reference Liao, Li and Wei2013), droplet spreading (Savva, Kalliadasis & Pavliotis Reference Savva, Kalliadasis and Pavliotis2010), film rupture (Martínez-Calvo, Moreno-Boza & Sevilla Reference Martínez-Calvo, Moreno-Boza and Sevilla2020) and falling films down a slippery plate (Ding & Wong Reference Ding and Wong2015). However, only recently has the no-slip stochastic film equation been generalised to consider slip (Zhang, Sprittles & Lockerby Reference Zhang, Sprittles and Lockerby2020), which is non-trivial and requires the usage of the Green–Kubo-type expression (Bocquet & Barrat Reference Bocquet and Barrat1994) that relates slip length to the random stress tensor at the wall. The derived slip equation is validated by the well-controlled molecular simulations (Zhang et al. Reference Zhang, Sprittles and Lockerby2020).

$h$ can get close to unity or even much larger than unity (Bäumchen & Jacobs Reference Bäumchen and Jacobs2009). In fact, in the deterministic setting, the introduction of slip to the deterministic film equation has been studied extensively for various phenomena, such as in coating a plate (Liao, Li & Wei Reference Liao, Li and Wei2013), droplet spreading (Savva, Kalliadasis & Pavliotis Reference Savva, Kalliadasis and Pavliotis2010), film rupture (Martínez-Calvo, Moreno-Boza & Sevilla Reference Martínez-Calvo, Moreno-Boza and Sevilla2020) and falling films down a slippery plate (Ding & Wong Reference Ding and Wong2015). However, only recently has the no-slip stochastic film equation been generalised to consider slip (Zhang, Sprittles & Lockerby Reference Zhang, Sprittles and Lockerby2020), which is non-trivial and requires the usage of the Green–Kubo-type expression (Bocquet & Barrat Reference Bocquet and Barrat1994) that relates slip length to the random stress tensor at the wall. The derived slip equation is validated by the well-controlled molecular simulations (Zhang et al. Reference Zhang, Sprittles and Lockerby2020).

However, the derived slip equation (Zhang et al. Reference Zhang, Sprittles and Lockerby2020) is limited to the case of weak slip ![]() $b/h \approx 1$. In many cases, the slip length can be as large as micrometres so that

$b/h \approx 1$. In many cases, the slip length can be as large as micrometres so that ![]() $b/h\gg 1$, such as flow over graphene sheets (Falk et al. Reference Falk, Sedlmeier, Joly, Netz and Bocquet2010), flow over engineered hydrophobic materials (Rothstein Reference Rothstein2010) and flow over substrates in presence of gas cavities and surface nanobubbles (Lohse & Zhang Reference Lohse and Zhang2015). For polymer liquids, increasing molecular weights can also increase the slip length up to micrometres (Bäumchen, Fetzer & Jacobs Reference Bäumchen, Fetzer and Jacobs2009). In fact, the dewetting of polymeric films on dodecyltrichlorosilane substrate (DTS), where slip length can be up to

$b/h\gg 1$, such as flow over graphene sheets (Falk et al. Reference Falk, Sedlmeier, Joly, Netz and Bocquet2010), flow over engineered hydrophobic materials (Rothstein Reference Rothstein2010) and flow over substrates in presence of gas cavities and surface nanobubbles (Lohse & Zhang Reference Lohse and Zhang2015). For polymer liquids, increasing molecular weights can also increase the slip length up to micrometres (Bäumchen, Fetzer & Jacobs Reference Bäumchen, Fetzer and Jacobs2009). In fact, the dewetting of polymeric films on dodecyltrichlorosilane substrate (DTS), where slip length can be up to ![]() $1~{\rm \mu}$m, has been examined extensively in the deterministic framework (Kargupta, Sharma & Khanna Reference Kargupta, Sharma and Khanna2004; Fetzer et al. Reference Fetzer, Jacobs, Münch, Wagner and Witelski2005; Münch, Wagner & Witelski Reference Münch, Wagner and Witelski2005; Bäumchen et al. Reference Bäumchen, Marquant, Blossey, Münch, Wagner and Jacobs2014). Notably, different levels of slip give rise to different deterministic lubrication models (Münch et al. Reference Münch, Wagner and Witelski2005). However, as we mentioned earlier, the effects of thermal fluctuations on nanofilms are significant, so a generalisation of our current understanding of the instability of strong-slip films to consider thermal fluctuations is essential.

$1~{\rm \mu}$m, has been examined extensively in the deterministic framework (Kargupta, Sharma & Khanna Reference Kargupta, Sharma and Khanna2004; Fetzer et al. Reference Fetzer, Jacobs, Münch, Wagner and Witelski2005; Münch, Wagner & Witelski Reference Münch, Wagner and Witelski2005; Bäumchen et al. Reference Bäumchen, Marquant, Blossey, Münch, Wagner and Jacobs2014). Notably, different levels of slip give rise to different deterministic lubrication models (Münch et al. Reference Münch, Wagner and Witelski2005). However, as we mentioned earlier, the effects of thermal fluctuations on nanofilms are significant, so a generalisation of our current understanding of the instability of strong-slip films to consider thermal fluctuations is essential.

So far, experimental studies on the effects of thermal fluctuations on thin-film flows are limited due to the technical difficulties associated with the spatiotemporal scale. Though the experiments of the dewetting of polymer nanofilms on no-slip SiO![]() $_{2}$-coated silicon wafers have demonstrated the great effects of thermal fluctuations (Fetzer et al. Reference Fetzer, Rauscher, Seemann, Jacobs and Mecke2007) on the growth of surface perturbations, dewetting of polymer films with strong slip and thermal fluctuations have not been considered in experiments. As such, MD simulations are a natural and convenient tool to investigate the thin-film problem at the nanoscale as thermal fluctuations are inherent in MD simulations.

$_{2}$-coated silicon wafers have demonstrated the great effects of thermal fluctuations (Fetzer et al. Reference Fetzer, Rauscher, Seemann, Jacobs and Mecke2007) on the growth of surface perturbations, dewetting of polymer films with strong slip and thermal fluctuations have not been considered in experiments. As such, MD simulations are a natural and convenient tool to investigate the thin-film problem at the nanoscale as thermal fluctuations are inherent in MD simulations.

In this work, MD simulations are employed to simulate the rupture of nanofilms on substrates with a strong slip, in comparison with the small-slip rupture. A new simulation strategy is proposed to generate strong slip in molecular simulations since the classic molecular simulations are limited to weak slip. We obtain the evolution of film surface spectra, rupture time and number of droplets after film rupture from molecular simulations. A new stochastic lubrication equation considering the strong slip is derived from fluctuating hydrodynamics (FH). A linear stability analysis of this stochastic lubrication equation leads to the analytical spectra which are validated against the MD results to establish the applicability of the new theory to predict future experiments.

This paper is organised as follows. In § 2, the stochastic lubrication equation for the strong-slip dewetting is derived from the equations of FH using a long-wave approximation. In § 3, a linear stability analysis of the newly derived stochastic equation is performed to obtain the surface spectrum. In § 4, molecular simulations of the rupture of nanofilms with the method to generate strong slip are presented. Section 5 compares the new model with molecular simulation results, and discusses new findings. In § 6, we summarise the main contributions of this work and outline future directions of research.

2. Stochastic lubrication equation for films with strong slip

2.1. Governing equations and boundary conditions

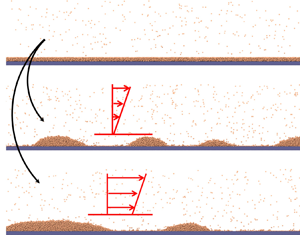

As shown in figure 1, a molecularly thin liquid film is deposited on a solid surface and destabilised by both disjoining pressure ![]() $\phi$ and thermal fluctuations

$\phi$ and thermal fluctuations ![]() $\psi$. The film is quasi-two-dimensional (quasi-2-D) confined by its size (

$\psi$. The film is quasi-two-dimensional (quasi-2-D) confined by its size (![]() $L_x$,

$L_x$, ![]() $L_y$,

$L_y$, ![]() $h$) where

$h$) where ![]() $L_x\gg L_y$ and

$L_x\gg L_y$ and ![]() $L_x\gg h$. Without slip, the stochastic thin film equation is derived in detail by Grün et al. (Reference Grün, Mecke and Rauscher2006) using a long-wave approximation (

$L_x\gg h$. Without slip, the stochastic thin film equation is derived in detail by Grün et al. (Reference Grün, Mecke and Rauscher2006) using a long-wave approximation (![]() $\chi =h_0/\lambda \ll 1$) to FH (Landau & Lifshitz Reference Landau and Lifshitz1959). The no-slip stochastic equation has been extended to consider weak slip

$\chi =h_0/\lambda \ll 1$) to FH (Landau & Lifshitz Reference Landau and Lifshitz1959). The no-slip stochastic equation has been extended to consider weak slip ![]() $b\sim O(h)$ (Zhang et al. Reference Zhang, Sprittles and Lockerby2020). Here we present the derivation of a new equation considering

$b\sim O(h)$ (Zhang et al. Reference Zhang, Sprittles and Lockerby2020). Here we present the derivation of a new equation considering ![]() $b\gg h$.

$b\gg h$.

Figure 1. Sketch of a (quasi-two-dimensional) molecularly thin liquid film on a slippery substrate. Here ![]() $h(x,t)$ is the film thickness,

$h(x,t)$ is the film thickness, ![]() $\lambda$ is the characteristic length,

$\lambda$ is the characteristic length, ![]() $u$ is the horizontal velocity,

$u$ is the horizontal velocity, ![]() $\phi$ is the thermal fluctuations,

$\phi$ is the thermal fluctuations, ![]() $\psi$ is the disjoining pressure and

$\psi$ is the disjoining pressure and ![]() $b$ is the slip length. The film has a small depth

$b$ is the slip length. The film has a small depth ![]() $L_y$ into the page.

$L_y$ into the page.

The governing equations for this problem are given by equations of FH, where thermal fluctuations are modelled by an additional random stress tensor. The (incompressible) continuum equation and momentum equations are

Here ![]() $u$ and

$u$ and ![]() $w$ are the

$w$ are the ![]() $x$ and

$x$ and ![]() $z$ components of velocity, and

$z$ components of velocity, and ![]() $\psi$ is a 2-D random stress tensor with zero mean and covariance given by

$\psi$ is a 2-D random stress tensor with zero mean and covariance given by

Here ![]() $\theta$ is the temperature. The factor

$\theta$ is the temperature. The factor ![]() $1/L_y$ appears because the films are quasi-2-D (

$1/L_y$ appears because the films are quasi-2-D (![]() $L_y \ll L_x$), allowing all variables of interest to be averaged over the

$L_y \ll L_x$), allowing all variables of interest to be averaged over the ![]() $y$ direction (Zhang et al. Reference Zhang, Sprittles and Lockerby2020).

$y$ direction (Zhang et al. Reference Zhang, Sprittles and Lockerby2020).

For boundary conditions, at ![]() $z=h$, we have the dynamic condition and kinematic condition:

$z=h$, we have the dynamic condition and kinematic condition:

Here ![]() $\boldsymbol {\sigma }=-p{{\delta }_{ij}}+\mu (\partial _{{x}_{j}}{u}_{i}+\partial _{{x}_{i}}{{u}_{j}} )$ is the hydrodynamic stress tensor (here

$\boldsymbol {\sigma }=-p{{\delta }_{ij}}+\mu (\partial _{{x}_{j}}{u}_{i}+\partial _{{x}_{i}}{{u}_{j}} )$ is the hydrodynamic stress tensor (here ![]() $i=(x,z)$ and

$i=(x,z)$ and ![]() $j=(x,z)$),

$j=(x,z)$), ![]() $\gamma$ is the surface tension,

$\gamma$ is the surface tension, ![]() $\phi (h)$ is the disjoining pressure and

$\phi (h)$ is the disjoining pressure and ![]() $\boldsymbol {n}$ is the outer normal vector at the surface

$\boldsymbol {n}$ is the outer normal vector at the surface ![]() $\boldsymbol {n}={( -\partial _x h,1 )}/{\sqrt {1+{{(\partial _x h )}^{2}}}}$.

$\boldsymbol {n}={( -\partial _x h,1 )}/{\sqrt {1+{{(\partial _x h )}^{2}}}}$.

At ![]() $z=0$, the impermeable condition and Navier's slip boundary condition are separately given by

$z=0$, the impermeable condition and Navier's slip boundary condition are separately given by

where ![]() $b$ is the slip length. The covariance of the random shear stress at the wall is given by (Bocquet & Barrat Reference Bocquet and Barrat1994; Zhang et al. Reference Zhang, Sprittles and Lockerby2020):

$b$ is the slip length. The covariance of the random shear stress at the wall is given by (Bocquet & Barrat Reference Bocquet and Barrat1994; Zhang et al. Reference Zhang, Sprittles and Lockerby2020):

Navier's slip condition is chosen because it has been validated extensively by both experiments and MD simulations (see the reviews by Lauga et al. Reference Lauga, Brenner, Stone, Tropea, Yarin and Foss2007; Bocquet & Charlaix Reference Bocquet and Charlaix2010). However, there are many other forms of slip boundary conditions, as discussed by Sibley et al. (Reference Sibley, Nold, Savva and Kalliadasis2015).

2.2. A long-wave approximation

To derive a lubrication equation, (2.1)–(2.6a,b) have to be scaled based on the dominant mechanism of momentum balance, which varies with the level of slip length (Münch et al. Reference Münch, Wagner and Witelski2005). Classically, for the weak-slip case, the momentum balance happens in the horizontal direction ![]() $\partial _x p \sim \mu \partial _{zz}u$, which means

$\partial _x p \sim \mu \partial _{zz}u$, which means ![]() $ph_0/(\mu u_0) \sim 1/\chi$, where

$ph_0/(\mu u_0) \sim 1/\chi$, where ![]() $u_0$ is the characteristic velocity. At the free surface, surface tension has to be balanced with pressure

$u_0$ is the characteristic velocity. At the free surface, surface tension has to be balanced with pressure ![]() $p=-\gamma \partial _{xx} h$, which means

$p=-\gamma \partial _{xx} h$, which means ![]() $\gamma /(\mu u_0)\sim 1/\chi ^3$. At the solid surface, the order of slip length is

$\gamma /(\mu u_0)\sim 1/\chi ^3$. At the solid surface, the order of slip length is ![]() $b\sim h_0$. Therefore, the pressure term, surface tension term, and slip length will be scaled to

$b\sim h_0$. Therefore, the pressure term, surface tension term, and slip length will be scaled to ![]() $P=\chi ph_0/(\mu u_0)$,

$P=\chi ph_0/(\mu u_0)$, ![]() $\varGamma =\chi ^3 \gamma /(\mu u_0)$, and

$\varGamma =\chi ^3 \gamma /(\mu u_0)$, and ![]() $B=b/h_0$.

$B=b/h_0$.

However, for the strong-slip (including free slip) flow, the velocity profile essentially becomes uniform (plug flow) instead of being parabolic so that the momentum balance happens in the vertical direction ![]() $\partial _z p \sim \mu \partial _{zz}w$ (Münch et al. Reference Münch, Wagner and Witelski2005), which leads to the scaling

$\partial _z p \sim \mu \partial _{zz}w$ (Münch et al. Reference Münch, Wagner and Witelski2005), which leads to the scaling ![]() $ph_0/(\mu u_0) \sim \chi$ and

$ph_0/(\mu u_0) \sim \chi$ and ![]() $\gamma /(\mu u_0)\sim 1/\chi$. These scalings need the slip length to be strong and

$\gamma /(\mu u_0)\sim 1/\chi$. These scalings need the slip length to be strong and ![]() $b\sim h_0\chi ^{-2}$ (Münch et al. Reference Münch, Wagner and Witelski2005).

$b\sim h_0\chi ^{-2}$ (Münch et al. Reference Münch, Wagner and Witelski2005).

As for the scaling of the random stress tensor, it may be scaled the same as the scale of their deterministic counterparts (Grün et al. Reference Grün, Mecke and Rauscher2006). For example, ![]() $\psi _{xx}\sim \mu \partial _x u \sim \mu u_0/\lambda$ and

$\psi _{xx}\sim \mu \partial _x u \sim \mu u_0/\lambda$ and ![]() $\psi _{zz}\sim \mu \partial _z w \sim \mu u_0/\lambda$. Note that, in this way, two scaling exists for

$\psi _{zz}\sim \mu \partial _z w \sim \mu u_0/\lambda$. Note that, in this way, two scaling exists for ![]() $\psi _{zx}$:

$\psi _{zx}$: ![]() $\psi _{zx}\sim \mu \partial _x w \sim \mu \chi u_0/\lambda$ and

$\psi _{zx}\sim \mu \partial _x w \sim \mu \chi u_0/\lambda$ and ![]() $\psi _{zx}\sim \mu \partial _z u \sim \mu u_0/(\chi \lambda )$. The former is used to keep

$\psi _{zx}\sim \mu \partial _z u \sim \mu u_0/(\chi \lambda )$. The former is used to keep ![]() $\psi _{zx }$ at a lower order. In summary, the following scalings are used:

$\psi _{zx }$ at a lower order. In summary, the following scalings are used:

\begin{align} \left. \begin{gathered} X=\frac{x}{\lambda },Z=\frac{z}{{{h}_{0}}},H=\frac{h}{{{h}_{0}}},B=\frac{b}{{{h}_{0}}\chi^{-2}},U=\frac{u}{{{u}_{0}}},W=\frac{w}{\chi {{u}_{0}}},T=\frac{{{u}_{0}}t}{\lambda },\varGamma =\frac{\chi \gamma }{\mu {{u}_{0}}},\\ \left(P,\varPhi \right)=\frac{{{h}_{0}}}{\chi {{u}_{0}}\mu }\left(\,p,\phi \right),\left( {{\varPsi }_{xx}},{{\varPsi }_{zz}} \right)=\frac{\lambda }{{{u}_{0}}\mu }\left( {{\psi }_{xx}},{{\psi }_{zz}} \right),\left( {{\varPsi }_{xz}},{{\varPsi }_{zx}} \right)=\frac{{\lambda}}{{{\chi }}{{u}_{0}}\mu }\left( {{\psi }_{xz}},{{\psi }_{zx}} \right). \end{gathered} \right\} \end{align}

\begin{align} \left. \begin{gathered} X=\frac{x}{\lambda },Z=\frac{z}{{{h}_{0}}},H=\frac{h}{{{h}_{0}}},B=\frac{b}{{{h}_{0}}\chi^{-2}},U=\frac{u}{{{u}_{0}}},W=\frac{w}{\chi {{u}_{0}}},T=\frac{{{u}_{0}}t}{\lambda },\varGamma =\frac{\chi \gamma }{\mu {{u}_{0}}},\\ \left(P,\varPhi \right)=\frac{{{h}_{0}}}{\chi {{u}_{0}}\mu }\left(\,p,\phi \right),\left( {{\varPsi }_{xx}},{{\varPsi }_{zz}} \right)=\frac{\lambda }{{{u}_{0}}\mu }\left( {{\psi }_{xx}},{{\psi }_{zz}} \right),\left( {{\varPsi }_{xz}},{{\varPsi }_{zx}} \right)=\frac{{\lambda}}{{{\chi }}{{u}_{0}}\mu }\left( {{\psi }_{xz}},{{\psi }_{zx}} \right). \end{gathered} \right\} \end{align}Adopting these scalings (2.8), the rescaled and dimensionless continuum and momentum equations are

Here the Reynolds number is ![]() ${Re}={\rho u_0 h_0 }/{\mu }$. As the characteristic velocity is

${Re}={\rho u_0 h_0 }/{\mu }$. As the characteristic velocity is ![]() $u_0\sim \chi {\gamma }/{\mu }$,

$u_0\sim \chi {\gamma }/{\mu }$, ![]() ${Re}$ can be also written as

${Re}$ can be also written as ![]() ${Re}=\chi {\rho \gamma h_0 }/{\mu ^2}=\chi {La}$, where

${Re}=\chi {\rho \gamma h_0 }/{\mu ^2}=\chi {La}$, where ![]() $La={\rho \gamma h_0 }/{\mu ^2}$ is the Laplace number. The

$La={\rho \gamma h_0 }/{\mu ^2}$ is the Laplace number. The ![]() ${La}$ is assumed to be of order one.

${La}$ is assumed to be of order one.

In terms of the rescaled boundary conditions,

$$\begin{gather}

-P{\,+\,}\frac{1}{1{\,+\,}{{\chi

}^{2}}{{\left( {{\partial }_{X}}H \right)}^{2}}}\left\{

2\left[ 1{\,-\,}{{\chi }^{2}}{{\left( {{\partial }_{X}}H

\right)}^{2}} \right]{{\partial }_{Z}} W{\,-\,}2{{\partial

}_{X}}H\left( {{\partial }_{Z}}U+{{\chi }^{2}}{{\partial

}_{X}}W \right){\,+\,}{{\chi }^{2}}{{\left( {{\partial }_{X}}H

\right)}^{2}}{{\varPsi }_{xx}} \right. \nonumber\\

-\left.{{\chi }^{2}}{{\partial }_{X}}H\left( {{\varPsi

}_{xz}}+{{\varPsi }_{zx}} \right)+{{\varPsi }_{zz}}

\right\} =\varGamma \frac{{{\partial }_{XX}}H}{{{\left[

1+{{\chi }^{2}}{{\left( {{\partial }_{X}}H \right)}^{2}}

\right]}^{3/2}}}+\varPhi, \quad \text{at }

z=H,\end{gather}$$

$$\begin{gather}

-P{\,+\,}\frac{1}{1{\,+\,}{{\chi

}^{2}}{{\left( {{\partial }_{X}}H \right)}^{2}}}\left\{

2\left[ 1{\,-\,}{{\chi }^{2}}{{\left( {{\partial }_{X}}H

\right)}^{2}} \right]{{\partial }_{Z}} W{\,-\,}2{{\partial

}_{X}}H\left( {{\partial }_{Z}}U+{{\chi }^{2}}{{\partial

}_{X}}W \right){\,+\,}{{\chi }^{2}}{{\left( {{\partial }_{X}}H

\right)}^{2}}{{\varPsi }_{xx}} \right. \nonumber\\

-\left.{{\chi }^{2}}{{\partial }_{X}}H\left( {{\varPsi

}_{xz}}+{{\varPsi }_{zx}} \right)+{{\varPsi }_{zz}}

\right\} =\varGamma \frac{{{\partial }_{XX}}H}{{{\left[

1+{{\chi }^{2}}{{\left( {{\partial }_{X}}H \right)}^{2}}

\right]}^{3/2}}}+\varPhi, \quad \text{at }

z=H,\end{gather}$$ $$\begin{gather}

2{{\chi }^{2}}{\partial_X

H}\left[ \left( {\partial_Z W}-{\partial_X U}

\right)+\frac{1}{2}\left( {{\varPsi }_{zz}}-{{\varPsi

}_{xx}} \right) \right]\nonumber\\ +\left[ 1-{{\chi

}^{2}}{{\left({\partial_X H} \right)}^{2}} \right]\left(

{\partial_Z U}+{{\chi }^{2}}{\partial_X W}+{{\chi

}^{2}}{{\varPsi }_{zx}} \right)=0\ \text{at}\

z=H , \end{gather}$$

$$\begin{gather}

2{{\chi }^{2}}{\partial_X

H}\left[ \left( {\partial_Z W}-{\partial_X U}

\right)+\frac{1}{2}\left( {{\varPsi }_{zz}}-{{\varPsi

}_{xx}} \right) \right]\nonumber\\ +\left[ 1-{{\chi

}^{2}}{{\left({\partial_X H} \right)}^{2}} \right]\left(

{\partial_Z U}+{{\chi }^{2}}{\partial_X W}+{{\chi

}^{2}}{{\varPsi }_{zx}} \right)=0\ \text{at}\

z=H , \end{gather}$$ The rescaled equations can be approximately solved by the perturbation expansion of ![]() $U,W,P,\varPsi,H$:

$U,W,P,\varPsi,H$:

Then, at leading orders of governing equations, one can get

For boundary conditions, their leading-order forms are

Using leading-order equations, we find

which leads to the first equation of the desired stochastic lubrication equation:

In the next order, the governing equation that will be used is,

and the boundary condition that will be needed is

Integrating (2.22) from ![]() $0$ to

$0$ to ![]() $H_0$ and using boundary conditions (2.23) and (2.24) leads to

$H_0$ and using boundary conditions (2.23) and (2.24) leads to

\begin{align} & H_0\left[

{La}\left({\partial_T {{U}_{0}}}+{{U}_{0}}{\partial_X

{{U}_{0}}}\right) \right] =H_0\left[ 3{{{\partial_{XX}

}}{{U}_{0}}}+{\partial_X }\left( \varGamma {{{\partial

}_{XX}}H_0}+\varPhi \right) \right]\nonumber\\ &\qquad

+\left({\partial_Z {{U}_{1}}}+{{\varPsi }_{zx0}}

\right){{|}_{Z=H_0}}-\left({\partial_Z {{U}_{1}}}+{{\varPsi

}_{zx0}} \right){{|}_{Z=0}}+\int_{0}^{H_0}{{\partial_X

}\left( {{\varPsi }_{xx0}}-{{\varPsi }_{zz0}} \right)\,{\rm

d}Z} \nonumber\\ &\quad =H_0{\partial_X

}\left(\varGamma{\partial_{XX}H_0}+\varPhi

\right)+4{\partial_X }\left( H_0{\partial_X {{U}_{0}}}

\right)\notag\\ &\qquad -\frac{{{U}_{0}}}{B}+{\partial_X}\int_{0}^{H_0}{\left(

{{\varPsi }_{xx0}}-{{\varPsi }_{zz0}} \right)\,{\rm

d}Z}-{{\varPsi }_{zx0}}{{|}_{Z=0}} .

\end{align}

\begin{align} & H_0\left[

{La}\left({\partial_T {{U}_{0}}}+{{U}_{0}}{\partial_X

{{U}_{0}}}\right) \right] =H_0\left[ 3{{{\partial_{XX}

}}{{U}_{0}}}+{\partial_X }\left( \varGamma {{{\partial

}_{XX}}H_0}+\varPhi \right) \right]\nonumber\\ &\qquad

+\left({\partial_Z {{U}_{1}}}+{{\varPsi }_{zx0}}

\right){{|}_{Z=H_0}}-\left({\partial_Z {{U}_{1}}}+{{\varPsi

}_{zx0}} \right){{|}_{Z=0}}+\int_{0}^{H_0}{{\partial_X

}\left( {{\varPsi }_{xx0}}-{{\varPsi }_{zz0}} \right)\,{\rm

d}Z} \nonumber\\ &\quad =H_0{\partial_X

}\left(\varGamma{\partial_{XX}H_0}+\varPhi

\right)+4{\partial_X }\left( H_0{\partial_X {{U}_{0}}}

\right)\notag\\ &\qquad -\frac{{{U}_{0}}}{B}+{\partial_X}\int_{0}^{H_0}{\left(

{{\varPsi }_{xx0}}-{{\varPsi }_{zz0}} \right)\,{\rm

d}Z}-{{\varPsi }_{zx0}}{{|}_{Z=0}} .

\end{align}

The Leibniz integral rule is used here. The covariance of ![]() $\varPsi _{zx0}{|}_{Z=0}$ is given by the Green–Kubo expression for slip length

$\varPsi _{zx0}{|}_{Z=0}$ is given by the Green–Kubo expression for slip length ![]() $\langle \varPsi _{zx}{{|}_{Z=0}}(X,T)\varPsi '_{zx}{{|}_{Z=0}}(X',T')\rangle =({2 {{k}_{B}}\theta }/{\chi ^2 \mu u_0 b L_y})\delta (X-X')\delta (T-T')$ (Zhang et al. Reference Zhang, Sprittles and Lockerby2020). In terms of the integral of the white noise in (2.25), as

$\langle \varPsi _{zx}{{|}_{Z=0}}(X,T)\varPsi '_{zx}{{|}_{Z=0}}(X',T')\rangle =({2 {{k}_{B}}\theta }/{\chi ^2 \mu u_0 b L_y})\delta (X-X')\delta (T-T')$ (Zhang et al. Reference Zhang, Sprittles and Lockerby2020). In terms of the integral of the white noise in (2.25), as ![]() ${\varPsi }_{xx0}$ is uncorrelated with

${\varPsi }_{xx0}$ is uncorrelated with ![]() ${\varPsi }_{zz0}$, they can be combined as

${\varPsi }_{zz0}$, they can be combined as ![]() $\sqrt 2{\varPsi }_{xx0}$. Now using the theorem provided in the appendix of Zhang et al. (Reference Zhang, Sprittles and Lockerby2020), the integral of the white noise is

$\sqrt 2{\varPsi }_{xx0}$. Now using the theorem provided in the appendix of Zhang et al. (Reference Zhang, Sprittles and Lockerby2020), the integral of the white noise is

$$\begin{gather} {\partial_X }\int_{0}^{H_0}{\left( {{\varPsi }_{xx0}}-{{\varPsi }_{zz0}} \right)\,{\rm d}z} =\sqrt{2}{\partial_X }\int_{0}^{H_0}{ {{\varPsi }_{xx0}} \, {\rm d}z} \nonumber\\ =\sqrt{2}{\partial_X }\left( \sqrt{H_0}\mathrm{Re} \right) , \end{gather}$$

$$\begin{gather} {\partial_X }\int_{0}^{H_0}{\left( {{\varPsi }_{xx0}}-{{\varPsi }_{zz0}} \right)\,{\rm d}z} =\sqrt{2}{\partial_X }\int_{0}^{H_0}{ {{\varPsi }_{xx0}} \, {\rm d}z} \nonumber\\ =\sqrt{2}{\partial_X }\left( \sqrt{H_0}\mathrm{Re} \right) , \end{gather}$$

where ![]() $\langle {{\mathrm {Re}(X,T)}}{{\mathrm {Re}(X',T') }}' \rangle =({4 {{k}_{B}}\theta }/{\mu u_0 h_0 L_y})\delta ( X-X' )\delta ( T-T' )$.

$\langle {{\mathrm {Re}(X,T)}}{{\mathrm {Re}(X',T') }}' \rangle =({4 {{k}_{B}}\theta }/{\mu u_0 h_0 L_y})\delta ( X-X' )\delta ( T-T' )$.

Putting (2.21) and (2.25) together and returning to their dimensional forms, we arrive at the stochastic lubrication equation for films with strong slip (referred to as S-S model hereafter)

$$\begin{gather}\rho \left({\partial_t u}+u{\partial_x u}\right)={\partial_x}\left( -\gamma {{{\partial_{xx} }}h}+\phi \right)+\frac{4\mu }{h}{\partial_x }\left(h{\partial_x u}\right)-\frac{\mu }{h}\frac{u}{b}+\frac{1}{h}\left[ 2 {\partial_x }\left( \sqrt{h}{{\xi }_{1}} \right)-\frac{\sqrt b}{b}{{\xi }_{2}}, \right] \end{gather}$$

$$\begin{gather}\rho \left({\partial_t u}+u{\partial_x u}\right)={\partial_x}\left( -\gamma {{{\partial_{xx} }}h}+\phi \right)+\frac{4\mu }{h}{\partial_x }\left(h{\partial_x u}\right)-\frac{\mu }{h}\frac{u}{b}+\frac{1}{h}\left[ 2 {\partial_x }\left( \sqrt{h}{{\xi }_{1}} \right)-\frac{\sqrt b}{b}{{\xi }_{2}}, \right] \end{gather}$$

where the covariance of the noise term is ![]() $\langle {{\xi _i(x,t) }}{{\xi _j (x',t')}} \rangle =({2\mu {{k}_{B}}\theta }/{L_y})\delta _{ij}\delta ( x-x' )\delta ( t-t' )$.

$\langle {{\xi _i(x,t) }}{{\xi _j (x',t')}} \rangle =({2\mu {{k}_{B}}\theta }/{L_y})\delta _{ij}\delta ( x-x' )\delta ( t-t' )$.

The above-derived stochastic lubrication equation validates for the strong slip length on the order of ![]() $b\sim h_0\chi ^{-2}$. In terms of the weak slip

$b\sim h_0\chi ^{-2}$. In terms of the weak slip ![]() $b\sim h_0$, a similar long-wave approximation to FH equations (see Zhang et al. (Reference Zhang, Sprittles and Lockerby2020) for details) can result in the weak-slip stochastic lubrication equation (referred to as W-S model hereafter)

$b\sim h_0$, a similar long-wave approximation to FH equations (see Zhang et al. (Reference Zhang, Sprittles and Lockerby2020) for details) can result in the weak-slip stochastic lubrication equation (referred to as W-S model hereafter)

\begin{equation} {\partial_t h}=\frac{1}{\mu }{\partial_x }\left[\left(\frac{1}{3}{{h}^{3}}+b{{h}^{2}}\right){\partial_x}\left(-\gamma{\partial_{xx} h}+\phi\right)+\sqrt{\frac{1}{3}{{h}^{3}}+b{{h}^{2}}}\xi_3 \right], \end{equation}

\begin{equation} {\partial_t h}=\frac{1}{\mu }{\partial_x }\left[\left(\frac{1}{3}{{h}^{3}}+b{{h}^{2}}\right){\partial_x}\left(-\gamma{\partial_{xx} h}+\phi\right)+\sqrt{\frac{1}{3}{{h}^{3}}+b{{h}^{2}}}\xi_3 \right], \end{equation}

where the noise ![]() $\xi _3$ has zero mean and covariance

$\xi _3$ has zero mean and covariance ![]() $\langle \xi _3(x,t)\xi _3(x',t')\rangle =({2\mu k_B \theta }/{L_y})\delta (x-x')\delta (t-t')$. As the W-S model works for the no-slip case (

$\langle \xi _3(x,t)\xi _3(x',t')\rangle =({2\mu k_B \theta }/{L_y})\delta (x-x')\delta (t-t')$. As the W-S model works for the no-slip case (![]() $b=0$), the S-S model validates for the free-slip case (

$b=0$), the S-S model validates for the free-slip case (![]() $b=\infty$) where the terms containing

$b=\infty$) where the terms containing ![]() $b$ in (2.27) vanish. Interestingly, this free-slip model can be applied to study free films such as foam films (Erneux & Davis Reference Erneux and Davis1993; Vaynblat, Lister & Witelski Reference Vaynblat, Lister and Witelski2001). Note that the free-slip model has not been reported previously.

$b$ in (2.27) vanish. Interestingly, this free-slip model can be applied to study free films such as foam films (Erneux & Davis Reference Erneux and Davis1993; Vaynblat, Lister & Witelski Reference Vaynblat, Lister and Witelski2001). Note that the free-slip model has not been reported previously.

3. Surface spectrum for films with strong slip

With the newly developed S-S model (2.27), the spectrum of surface waves in linear stages is derived here. We first rewrite the noise ![]() $\xi$ in terms of the white noise

$\xi$ in terms of the white noise ![]() $N$ with unit variance

$N$ with unit variance ![]() $\langle {{N_i}}{{N_j }}' \rangle =\delta _{ij}\delta ( x-x' )\delta ( t-t' )$, and linearise (2.27) with

$\langle {{N_i}}{{N_j }}' \rangle =\delta _{ij}\delta ( x-x' )\delta ( t-t' )$, and linearise (2.27) with ![]() $h=h_0+\tilde {h}$,

$h=h_0+\tilde {h}$, ![]() $u=0+\tilde {u}$ and

$u=0+\tilde {u}$ and ![]() $N=0+\tilde {N}$:

$N=0+\tilde {N}$:

\begin{equation} \frac{{{\partial }^{2}}\tilde{h}}{\partial {{t}^{2}}}=\frac{\mu }{\rho }\frac{\partial }{\partial t}\left[ 4\frac{{{\partial }^{2}}\tilde{h}}{\partial {{x}^{2}}}-\frac{{\tilde{h}}}{{{h}_{0}}b} \right]-\frac{{{h}_{0}}}{\rho }\left[ \frac{\partial \phi }{\partial h}\frac{{{\partial }^{2}}\tilde{h}}{\partial {{x}^{2}}}+\gamma \frac{{{\partial }^{4}}\tilde{h}}{\partial {{x}^{4}}} \right]-f_1\frac{{{\partial }^{2}}{\tilde{N}_{1}}}{\partial {{x}^{2}}}+f_2\frac{\partial {\tilde{N}_{2}}}{\partial x}, \end{equation}

\begin{equation} \frac{{{\partial }^{2}}\tilde{h}}{\partial {{t}^{2}}}=\frac{\mu }{\rho }\frac{\partial }{\partial t}\left[ 4\frac{{{\partial }^{2}}\tilde{h}}{\partial {{x}^{2}}}-\frac{{\tilde{h}}}{{{h}_{0}}b} \right]-\frac{{{h}_{0}}}{\rho }\left[ \frac{\partial \phi }{\partial h}\frac{{{\partial }^{2}}\tilde{h}}{\partial {{x}^{2}}}+\gamma \frac{{{\partial }^{4}}\tilde{h}}{\partial {{x}^{4}}} \right]-f_1\frac{{{\partial }^{2}}{\tilde{N}_{1}}}{\partial {{x}^{2}}}+f_2\frac{\partial {\tilde{N}_{2}}}{\partial x}, \end{equation}

where the factors ![]() ${{f}_{1}}=\sqrt {8\mu {{k}_{B}}\theta {{h}_{0}L_y}}/{(\rho L_y) }$ and

${{f}_{1}}=\sqrt {8\mu {{k}_{B}}\theta {{h}_{0}L_y}}/{(\rho L_y) }$ and ![]() ${{f}_{2}}=\sqrt {{2\mu {{k}_{B}}\theta }{b}L_y}/{(\rho b L_y) }$. Note that the second derivative of

${{f}_{2}}=\sqrt {{2\mu {{k}_{B}}\theta }{b}L_y}/{(\rho b L_y) }$. Note that the second derivative of ![]() $\tilde {h}$ with respect to

$\tilde {h}$ with respect to ![]() $t$ comes from putting the linearised (2.27a) into the linearised (2.27b) to eliminate the variable

$t$ comes from putting the linearised (2.27a) into the linearised (2.27b) to eliminate the variable ![]() $\tilde {u}$. Then a Fourier transform of (3.1) is performed using

$\tilde {u}$. Then a Fourier transform of (3.1) is performed using ![]() $\hat {h}(q,t)=\int _{-\infty }^{\infty }\tilde {h}(x,t){{\textrm {e}}^-}^{\textrm {i}qx}\,\textrm {d}\kern0.06em x$ and

$\hat {h}(q,t)=\int _{-\infty }^{\infty }\tilde {h}(x,t){{\textrm {e}}^-}^{\textrm {i}qx}\,\textrm {d}\kern0.06em x$ and ![]() $\hat {N}(q,t)=\int _{-\infty }^{\infty }\tilde {N}(x,t){{\textrm {e}}^-}^{\textrm {i}qx}\,\textrm {d}\kern0.06em x$ to get

$\hat {N}(q,t)=\int _{-\infty }^{\infty }\tilde {N}(x,t){{\textrm {e}}^-}^{\textrm {i}qx}\,\textrm {d}\kern0.06em x$ to get

Here

The solution of (3.2) can be represented as the linear superposition of two contributions (Zhang et al. Reference Zhang, Sprittles and Lockerby2019; Zhao et al. Reference Zhao, Sprittles and Lockerby2019)

where ![]() ${{\hat {h}}_{{det}}}$ is the solution to the deterministic part of (3.2) and

${{\hat {h}}_{{det}}}$ is the solution to the deterministic part of (3.2) and ![]() ${{\hat {h}}_{{sto}}}$ is the contribution purely caused by thermal fluctuations. To find

${{\hat {h}}_{{sto}}}$ is the contribution purely caused by thermal fluctuations. To find ![]() ${{\hat {h}}_{{det}}}$, the deterministic equation

${{\hat {h}}_{{det}}}$, the deterministic equation

is solved by Laplace transform. Using ![]() $g(q,s)=\int _{0}^{\infty }{\hat {h}(q,t){{\textrm {e}}^-}^{\textrm {i}ts}\,\textrm {d}}t$ and assuming

$g(q,s)=\int _{0}^{\infty }{\hat {h}(q,t){{\textrm {e}}^-}^{\textrm {i}ts}\,\textrm {d}}t$ and assuming ![]() ${\partial \hat {h}}/{\partial t}{{|}_{t=0}}$, one can get

${\partial \hat {h}}/{\partial t}{{|}_{t=0}}$, one can get

whose inverse Laplace transform is

Here ![]() $\omega _{i=1,2}=({-C\pm \sqrt {C^2-4D}})/{2}$ is the solution to

$\omega _{i=1,2}=({-C\pm \sqrt {C^2-4D}})/{2}$ is the solution to ![]() $s^2+Cs+D=0$. Notably,

$s^2+Cs+D=0$. Notably, ![]() $\omega _1$ is the dispersion relation (growth rate) of the deterministic lubrication equation, namely, (2.27) without the noise terms.

$\omega _1$ is the dispersion relation (growth rate) of the deterministic lubrication equation, namely, (2.27) without the noise terms.

To obtain ![]() $\hat h_{sto}$, one has to determine the impulse response of the linear system. Using the Laplace transform of

$\hat h_{sto}$, one has to determine the impulse response of the linear system. Using the Laplace transform of ![]() ${{{\partial }^{2}}\hat {h}}/{\partial {{t}^{2}}}+C({\partial \hat {h}}/{\partial t})+D\hat {h}=\delta$, and assuming

${{{\partial }^{2}}\hat {h}}/{\partial {{t}^{2}}}+C({\partial \hat {h}}/{\partial t})+D\hat {h}=\delta$, and assuming ![]() $\hat {h}(q,0)=0$, it is found

$\hat {h}(q,0)=0$, it is found

The impulse response is, thus, the inverse Laplace transform of (3.8)

Now with thermal fluctuations ![]() $f_1{{q}^{2}}\hat {N}_1$ and

$f_1{{q}^{2}}\hat {N}_1$ and ![]() $f_2 qi\hat {N}_2$ as input, we find

$f_2 qi\hat {N}_2$ as input, we find

As ![]() $\hat {h}$ is both a random and complex variable, the root mean square (r.m.s.) of its norm is sought, namely, surface spectrum,

$\hat {h}$ is both a random and complex variable, the root mean square (r.m.s.) of its norm is sought, namely, surface spectrum,

where from (3.7)

and from (3.10)

\begin{align} \overline{{{\left| {{\hat{h}}_{sto}} \right|}^{2}}}&={{{\left| \,{f_1 q^2}\int_{0}^{t}{\hat{N}_1\left( q,t-\tau \right)}F(q,\tau )\,{\rm d}\tau \right|}^{2}}} +{{{\left| \,{f_2 q {\rm i}}\int_{0}^{t}{\hat{N}_1\left( q,t-\tau \right)}F(q,\tau )\,{\rm d}\tau \right|}^{2}}} \nonumber\\ & ={{{\left| \,{f_1 q^2} \right|}^{2}}\int_{0}^{t}{{{\left| \hat{N}_1\left( q,t-\tau \right) \right|}^{2}}}F{{(q,\tau )}^{2}}\,{\rm d}\tau }+{{{\left| \,{f_2 q {\rm i}} \right|}^{2}}\int_{0}^{t}{{{\left| \hat{N}_1\left( q,t-\tau \right) \right|}^{2}}}F{{(q,\tau )}^{2}}\,{\rm d}\tau } \nonumber\\ & =\left( {{\left| \,{f_1 q^2} \right|}^{2}}+{{\left| \,{f_q q {\rm i}} \right|}^{2}} \right){{L}_{x}}\int_{0}^{t}{F{{(q,\tau )}^{2}}}\,{\rm d}\tau \nonumber\\ & =\frac{2\mu {{k}_{B}}T{{L}_{x}}{{q}^{2}}}{{{\rho }^{2}}{{L}_{y}}\left( {{C}^{2}}-4D \right)}\left( 4{{h}_{0}}{{q}^{2}}+\frac{1}{b} \right)\left[ \frac{{{{\rm e}}^{2{{\omega }_{1}}t}}-1}{2{{\omega }_{1}}}+\frac{{{{\rm e}}^{2{{\omega }_{2}}t}}-1}{2{{\omega }_{2}}}+\frac{2\left( {{{\rm e}}^{-Ct}}-1 \right)}{C} \right]. \end{align}

\begin{align} \overline{{{\left| {{\hat{h}}_{sto}} \right|}^{2}}}&={{{\left| \,{f_1 q^2}\int_{0}^{t}{\hat{N}_1\left( q,t-\tau \right)}F(q,\tau )\,{\rm d}\tau \right|}^{2}}} +{{{\left| \,{f_2 q {\rm i}}\int_{0}^{t}{\hat{N}_1\left( q,t-\tau \right)}F(q,\tau )\,{\rm d}\tau \right|}^{2}}} \nonumber\\ & ={{{\left| \,{f_1 q^2} \right|}^{2}}\int_{0}^{t}{{{\left| \hat{N}_1\left( q,t-\tau \right) \right|}^{2}}}F{{(q,\tau )}^{2}}\,{\rm d}\tau }+{{{\left| \,{f_2 q {\rm i}} \right|}^{2}}\int_{0}^{t}{{{\left| \hat{N}_1\left( q,t-\tau \right) \right|}^{2}}}F{{(q,\tau )}^{2}}\,{\rm d}\tau } \nonumber\\ & =\left( {{\left| \,{f_1 q^2} \right|}^{2}}+{{\left| \,{f_q q {\rm i}} \right|}^{2}} \right){{L}_{x}}\int_{0}^{t}{F{{(q,\tau )}^{2}}}\,{\rm d}\tau \nonumber\\ & =\frac{2\mu {{k}_{B}}T{{L}_{x}}{{q}^{2}}}{{{\rho }^{2}}{{L}_{y}}\left( {{C}^{2}}-4D \right)}\left( 4{{h}_{0}}{{q}^{2}}+\frac{1}{b} \right)\left[ \frac{{{{\rm e}}^{2{{\omega }_{1}}t}}-1}{2{{\omega }_{1}}}+\frac{{{{\rm e}}^{2{{\omega }_{2}}t}}-1}{2{{\omega }_{2}}}+\frac{2\left( {{{\rm e}}^{-Ct}}-1 \right)}{C} \right]. \end{align}

Here we have used ![]() $\overline {{{| \hat {N}( q,t ) |}^{2}}}={{L}_{x}}$, due to the finite length of the discrete Fourier transform used in MD simulations. Thus, we derive the spectrum of surface waves of a bounded film with strong slip as

$\overline {{{| \hat {N}( q,t ) |}^{2}}}={{L}_{x}}$, due to the finite length of the discrete Fourier transform used in MD simulations. Thus, we derive the spectrum of surface waves of a bounded film with strong slip as

\begin{align} S\left(q,t\right) & =\left\{\overline{{{\left| \hat{h}(q,0) \right|}^{2}}}{{\left[ \frac{{{{\rm e}}^{{{\omega }_{1}}t}}+{{{\rm e}}^{{{\omega }_{2}}t}}}{2}+\frac{C}{2\sqrt{{{C}^{2}}-4D}}\left( {{{\rm e}}^{{{\omega }_{1}}t}}-{{{\rm e}}^{{{\omega }_{2}}t}} \right) \right]}^{2}} \right.\nonumber\\ & \quad \left.+\,\frac{2\mu {{k}_{B}}T{{L}_{x}}{{q}^{2}}}{{{\rho }^{2}}{{L}_{y}}\left( {{C}^{2}}-4D \right)}\left( 4{{h}_{0}}{{q}^{2}}+\frac{1}{b} \right)\left[ \frac{{{{\rm e}}^{2{{\omega }_{1}}t}}-1}{2{{\omega }_{1}}}+\frac{{{{\rm e}}^{2{{\omega }_{2}}t}}-1}{2{{\omega }_{2}}}+\frac{2\left( {{{\rm e}}^{-Ct}}-1 \right)}{C} \right]\right\}^{1/2}. \end{align}

\begin{align} S\left(q,t\right) & =\left\{\overline{{{\left| \hat{h}(q,0) \right|}^{2}}}{{\left[ \frac{{{{\rm e}}^{{{\omega }_{1}}t}}+{{{\rm e}}^{{{\omega }_{2}}t}}}{2}+\frac{C}{2\sqrt{{{C}^{2}}-4D}}\left( {{{\rm e}}^{{{\omega }_{1}}t}}-{{{\rm e}}^{{{\omega }_{2}}t}} \right) \right]}^{2}} \right.\nonumber\\ & \quad \left.+\,\frac{2\mu {{k}_{B}}T{{L}_{x}}{{q}^{2}}}{{{\rho }^{2}}{{L}_{y}}\left( {{C}^{2}}-4D \right)}\left( 4{{h}_{0}}{{q}^{2}}+\frac{1}{b} \right)\left[ \frac{{{{\rm e}}^{2{{\omega }_{1}}t}}-1}{2{{\omega }_{1}}}+\frac{{{{\rm e}}^{2{{\omega }_{2}}t}}-1}{2{{\omega }_{2}}}+\frac{2\left( {{{\rm e}}^{-Ct}}-1 \right)}{C} \right]\right\}^{1/2}. \end{align}Equations (3.14) and (2.27) are the main contributions of this work. For the W-S model, the analytical spectrum is (Zhang et al. Reference Zhang, Sprittles and Lockerby2020)

\begin{equation} S\left(q,t\right)=\sqrt{\overline{{{\left| \hat{h}(q,0) \right|}^{2}}}{{{\rm e}}^{2{{\omega }_{3}}(q)t}}+\frac{{{L}_{x}}}{{{L}_{y}}}\frac{{{k}_{B}}T}{\gamma {{q}^{2}}+\left.\left( {\rm d}\phi /{\rm d}h \right)\right.|_{h_0}}\left[1-{{{\rm e}}^{2{{\omega }_{3}}(q)t}}\right]}, \end{equation}

\begin{equation} S\left(q,t\right)=\sqrt{\overline{{{\left| \hat{h}(q,0) \right|}^{2}}}{{{\rm e}}^{2{{\omega }_{3}}(q)t}}+\frac{{{L}_{x}}}{{{L}_{y}}}\frac{{{k}_{B}}T}{\gamma {{q}^{2}}+\left.\left( {\rm d}\phi /{\rm d}h \right)\right.|_{h_0}}\left[1-{{{\rm e}}^{2{{\omega }_{3}}(q)t}}\right]}, \end{equation}where the dispersion relation is

4. MD simulations and a new slip-generating method

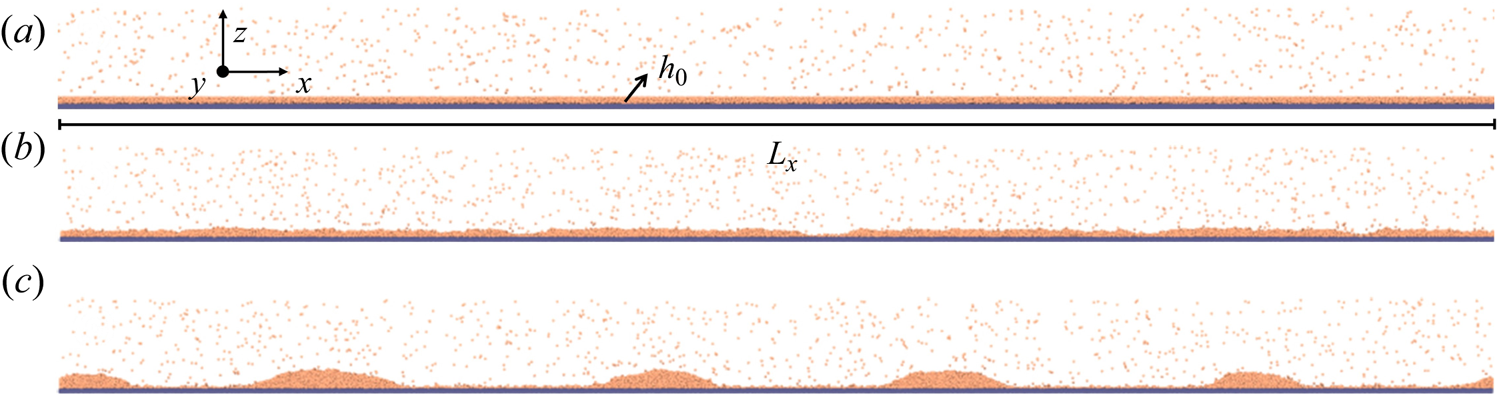

MD simulations are performed to simulate the instability of nanofilms on the strong-slip solid and the weak-slip solid. The open-source MD code LAMMPS (Plimpton Reference Plimpton1995) is adopted. As shown in figure 2(a), the liquid film is composed of liquid argon (represented in orange) and it is simulated with the standard Lennard-Jones (LJ) 12-6 potential:

\begin{equation} U({{r}_{ij}}) = \begin{cases} 4\varepsilon \left[ {{\left( \dfrac{\sigma }{{{r}_{ij}}} \right)}^{12}}-{{\left( \dfrac{\sigma }{{{r}_{ij}}} \right)}^{6}} \right], & \text{if}\ {{r}_{ij}}\le {{r}_{c}},\\ 0, & \text{if}\ {{r}_{ij}}>{{r}_{c}}. \end{cases} \end{equation}

\begin{equation} U({{r}_{ij}}) = \begin{cases} 4\varepsilon \left[ {{\left( \dfrac{\sigma }{{{r}_{ij}}} \right)}^{12}}-{{\left( \dfrac{\sigma }{{{r}_{ij}}} \right)}^{6}} \right], & \text{if}\ {{r}_{ij}}\le {{r}_{c}},\\ 0, & \text{if}\ {{r}_{ij}}>{{r}_{c}}. \end{cases} \end{equation}

Here ![]() $r_{ij}$ is the distance between two atoms and

$r_{ij}$ is the distance between two atoms and ![]() $ij$ represent pairwise particles. The energy parameter

$ij$ represent pairwise particles. The energy parameter ![]() $\varepsilon$ is

$\varepsilon$ is ![]() $1.67\times {10^{-21}}$ J and the length parameter

$1.67\times {10^{-21}}$ J and the length parameter ![]() $\sigma$ is

$\sigma$ is ![]() $0.34\ \textrm {nm}$. We use

$0.34\ \textrm {nm}$. We use ![]() $r_c=5.5 \sigma$ as the cutoff distance, beyond which the interaction vanishes.

$r_c=5.5 \sigma$ as the cutoff distance, beyond which the interaction vanishes.

Figure 2. Rupture of thin liquid films with strong slip in molecular simulations. (a) Initial setting of a liquid film with a flat free surface. The film has a small depth ![]() $L_y$ into the page. (b) Growth of perturbations and film rupture. (c) Droplet formation after the film ruptures. Note that the wall coloured in blue only denotes the position of the solid boundary as the method of a virtual wall is used in simulations.

$L_y$ into the page. (b) Growth of perturbations and film rupture. (c) Droplet formation after the film ruptures. Note that the wall coloured in blue only denotes the position of the solid boundary as the method of a virtual wall is used in simulations.

The temperature of this system is kept at ![]() $T=85$ K using the Nosé–Hoover thermostat. At this temperature, the mass density is

$T=85$ K using the Nosé–Hoover thermostat. At this temperature, the mass density is ![]() $\rho =1.4\times 10^3\ \textrm {kg}\ \textrm {m}^{-3}$ and the number density is

$\rho =1.4\times 10^3\ \textrm {kg}\ \textrm {m}^{-3}$ and the number density is ![]() $n=0.83/\sigma ^3$. The density of the vapour phase is about

$n=0.83/\sigma ^3$. The density of the vapour phase is about ![]() $(1/400) \rho$ so that the effects of vapour on the film are neglected. The surface tension of liquid is

$(1/400) \rho$ so that the effects of vapour on the film are neglected. The surface tension of liquid is ![]() $\gamma = 1.52\times {10^{-2}}\ \textrm {N}\ \textrm {m}^{-1}$ and the dynamic viscosity is

$\gamma = 1.52\times {10^{-2}}\ \textrm {N}\ \textrm {m}^{-1}$ and the dynamic viscosity is ![]() $\mu = 2.87\times {10^{-4}}\ \textrm {kg}\ (\textrm {ms})^{-1}$ (Zhang et al. Reference Zhang, Sprittles and Lockerby2020). The time step for all simulations is

$\mu = 2.87\times {10^{-4}}\ \textrm {kg}\ (\textrm {ms})^{-1}$ (Zhang et al. Reference Zhang, Sprittles and Lockerby2020). The time step for all simulations is ![]() $0.004\sqrt {\varepsilon /(m\sigma ^2)}$ where

$0.004\sqrt {\varepsilon /(m\sigma ^2)}$ where ![]() $m$ is the atomic mass of argon.

$m$ is the atomic mass of argon.

The initial dimensions of the liquid film (see figure 2a) are chosen as ![]() $L_x=313.90\ \textrm {nm}$,

$L_x=313.90\ \textrm {nm}$, ![]() $L_y=3.14\ \textrm {nm}$. The height of the film varies for three different cases (

$L_y=3.14\ \textrm {nm}$. The height of the film varies for three different cases (![]() $h_0=1.2\ \textrm {nm}$, 1.6 nm and 3.14 nm). Therefore, the film is thin (

$h_0=1.2\ \textrm {nm}$, 1.6 nm and 3.14 nm). Therefore, the film is thin (![]() $L_x\gg h_0$), and the film is quasi-2-D (

$L_x\gg h_0$), and the film is quasi-2-D (![]() $L_x\gg L_y$) to save computational costs. To prepare the initial configuration of the liquid film, the liquid film slab with the desired size is cut from a periodic box of liquid atoms, which makes the film surface flat initially.

$L_x\gg L_y$) to save computational costs. To prepare the initial configuration of the liquid film, the liquid film slab with the desired size is cut from a periodic box of liquid atoms, which makes the film surface flat initially.

Conventionally, the solid wall, serving as the boundary condition for the film, is simulated using real solid atoms (real wall) (Willis & Freund Reference Willis and Freund2009; Zhang et al. Reference Zhang, Sprittles and Lockerby2019, Reference Zhang, Sprittles and Lockerby2020, Reference Zhang, Sprittles and Lockerby2021). In our previous work (Zhang et al. Reference Zhang, Sprittles and Lockerby2019, Reference Zhang, Sprittles and Lockerby2020, Reference Zhang, Sprittles and Lockerby2021), for a real wall, the solid is platinum with its isotropic ![]() $\langle 100\rangle$ surface in contact with the liquid. The liquid–solid interactions are modelled by the same 12-6 LJ potential with

$\langle 100\rangle$ surface in contact with the liquid. The liquid–solid interactions are modelled by the same 12-6 LJ potential with ![]() $\sigma _{ls}=0.8\sigma$ for the length parameter and

$\sigma _{ls}=0.8\sigma$ for the length parameter and ![]() $\varepsilon _{ls} =k\varepsilon$. Conventionally, one may vary the energy parameter

$\varepsilon _{ls} =k\varepsilon$. Conventionally, one may vary the energy parameter ![]() $\varepsilon _{ls}$ to obtain different levels of slip length. For example,

$\varepsilon _{ls}$ to obtain different levels of slip length. For example, ![]() $b=0.68\ \textrm {nm}$ using

$b=0.68\ \textrm {nm}$ using ![]() $k=0.65$ whereas

$k=0.65$ whereas ![]() $b=8.8\ \textrm {nm}$ using

$b=8.8\ \textrm {nm}$ using ![]() $k=0.2$ (Zhang et al. Reference Zhang, Sprittles and Lockerby2021). The disjoining pressure and contact angles of liquid argon on the solid are also changed in this way. However, the slip length obtained using the real solid is usually in the range of a few tens of nanometres (Bocquet & Charlaix Reference Bocquet and Charlaix2010) in MD simulations, which cannot match the micrometre slip length present in experiments. The origin of strong slip in experiments, as discussed earlier in the introduction, is usually complicated and cannot be straightforwardly simulated in previous MD simulations using LJ potentials. The use of a real solid wall with cutoff-distance-limited intermolecular interactions between liquid and solid also means that the disjoining pressure due to the solid vanishes when the film height is larger than the cutoff distance (Willis & Freund Reference Willis and Freund2009; Zhang & Ding Reference Zhang and Ding2023), which is undesired.

$k=0.2$ (Zhang et al. Reference Zhang, Sprittles and Lockerby2021). The disjoining pressure and contact angles of liquid argon on the solid are also changed in this way. However, the slip length obtained using the real solid is usually in the range of a few tens of nanometres (Bocquet & Charlaix Reference Bocquet and Charlaix2010) in MD simulations, which cannot match the micrometre slip length present in experiments. The origin of strong slip in experiments, as discussed earlier in the introduction, is usually complicated and cannot be straightforwardly simulated in previous MD simulations using LJ potentials. The use of a real solid wall with cutoff-distance-limited intermolecular interactions between liquid and solid also means that the disjoining pressure due to the solid vanishes when the film height is larger than the cutoff distance (Willis & Freund Reference Willis and Freund2009; Zhang & Ding Reference Zhang and Ding2023), which is undesired.

Here we propose a new approach to allow us to generate any values of slip length simply in MD simulations and allow disjoining pressure to be effective at infinite distances physically. Instead of simulating a real wall, we apply a force to fluid atoms to mimic the fluid–substrate interactions and the force acts as the virtual wall, based on the work of (Steele Reference Steele1973; Barrat & Bocquet Reference Barrat and Bocquet1999; Hadjiconstantinou Reference Hadjiconstantinou2021). The (total) force ![]() $\boldsymbol {f}$ for a fluid atom interacting with a face-centred-cubic solid substrate by the LJ potential has been calculated analytically by Steele (Reference Steele1973) and it is adopted here with some modifications (see Appendix A for detailed discussions):

$\boldsymbol {f}$ for a fluid atom interacting with a face-centred-cubic solid substrate by the LJ potential has been calculated analytically by Steele (Reference Steele1973) and it is adopted here with some modifications (see Appendix A for detailed discussions):

\begin{equation} \left. \begin{aligned} \boldsymbol{f} & ={{f}_{x}}\boldsymbol{e_x}+{{f}_{z}}\boldsymbol{e_z},\quad \text{with} \\ {{f}_{x}} & =\frac{{{(2{\rm \pi} )}^{2}}\varepsilon}{100{\ell}_{s}^{3}}\left[ \frac{ {{\sigma }^{12}}}{30}{{\left( \frac{{\rm \pi} }{{{\ell}_{s}}z} \right)}^{5}}{{{\rm K}}_{5}}\left( \frac{2{\rm \pi} }{{{\ell}_{s}}}z \right)-2{{\sigma }^{6}} {{\left( \frac{{\rm \pi} }{{{\ell}_{s}}z} \right)}^{2}}{{{\rm K}}_{2}}\left( \frac{2{\rm \pi} }{{{\ell}_{s}}}z \right) \right]\sin \left( \frac{2{\rm \pi} }{{{\ell}_{s}}}x \right),\\ {{f}_{z}} & =-\frac{{\rm d}U_0 \left(z\right)}{{\rm d}z}. \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} \boldsymbol{f} & ={{f}_{x}}\boldsymbol{e_x}+{{f}_{z}}\boldsymbol{e_z},\quad \text{with} \\ {{f}_{x}} & =\frac{{{(2{\rm \pi} )}^{2}}\varepsilon}{100{\ell}_{s}^{3}}\left[ \frac{ {{\sigma }^{12}}}{30}{{\left( \frac{{\rm \pi} }{{{\ell}_{s}}z} \right)}^{5}}{{{\rm K}}_{5}}\left( \frac{2{\rm \pi} }{{{\ell}_{s}}}z \right)-2{{\sigma }^{6}} {{\left( \frac{{\rm \pi} }{{{\ell}_{s}}z} \right)}^{2}}{{{\rm K}}_{2}}\left( \frac{2{\rm \pi} }{{{\ell}_{s}}}z \right) \right]\sin \left( \frac{2{\rm \pi} }{{{\ell}_{s}}}x \right),\\ {{f}_{z}} & =-\frac{{\rm d}U_0 \left(z\right)}{{\rm d}z}. \end{aligned} \right\} \end{equation}

Here ![]() $\boldsymbol {e}_x$ and

$\boldsymbol {e}_x$ and ![]() $\boldsymbol {e}_z$ are unit vectors in the

$\boldsymbol {e}_z$ are unit vectors in the ![]() $x$ and

$x$ and ![]() $z$ direction,

$z$ direction, ![]() $\ell _s$ is the lattice spacing and

$\ell _s$ is the lattice spacing and ![]() $\textrm {K}_5$ and

$\textrm {K}_5$ and ![]() $\textrm {K}_2$ are the modified Bessel functions of the second kind. The applied force in the

$\textrm {K}_2$ are the modified Bessel functions of the second kind. The applied force in the ![]() $x$ direction

$x$ direction ![]() $f_x$ decays rapidly with

$f_x$ decays rapidly with ![]() $z$:

$z$: ![]() $f_x$ is closely related to slip length and its sinusoidal-form force represents the energy corrugation of the solid surface. A smaller lattice spacing

$f_x$ is closely related to slip length and its sinusoidal-form force represents the energy corrugation of the solid surface. A smaller lattice spacing ![]() $\ell _s$ results in a smooth surface energy distribution and then a larger slip length (Thompson & Robbins Reference Thompson and Robbins1990; Barrat & Bocquet Reference Barrat and Bocquet1999; Hadjiconstantinou Reference Hadjiconstantinou2021). In our MD simulations, the functions

$\ell _s$ results in a smooth surface energy distribution and then a larger slip length (Thompson & Robbins Reference Thompson and Robbins1990; Barrat & Bocquet Reference Barrat and Bocquet1999; Hadjiconstantinou Reference Hadjiconstantinou2021). In our MD simulations, the functions ![]() $\textrm {K}_5$ and

$\textrm {K}_5$ and ![]() $\textrm {K}_2$ are approximated by

$\textrm {K}_2$ are approximated by ![]() $(({{\rm \pi} }/{2x})^{1/2})\textrm {e}^{-x}$ for simplicity. Here

$(({{\rm \pi} }/{2x})^{1/2})\textrm {e}^{-x}$ for simplicity. Here ![]() $U_0 (z)$ is the total interaction energy exerted on a liquid molecule by the (continuous) substrate. As shown in Appendix A,

$U_0 (z)$ is the total interaction energy exerted on a liquid molecule by the (continuous) substrate. As shown in Appendix A, ![]() $U_0(z)$ is related to the function of disjoining pressure as

$U_0(z)$ is related to the function of disjoining pressure as ![]() $U_0(z)=-\phi (z)/n$. Note that disjoining pressure is a function of film height

$U_0(z)=-\phi (z)/n$. Note that disjoining pressure is a function of film height ![]() $h$. One has to replace

$h$. One has to replace ![]() $h$ with

$h$ with ![]() $z$ while the form of the function itself is the same.

$z$ while the form of the function itself is the same.

Here ![]() $\phi$ takes the usual form (Israelachvili Reference Israelachvili2011):

$\phi$ takes the usual form (Israelachvili Reference Israelachvili2011):

where typical values ![]() $A=1.7\times 10^{-20}$ J and

$A=1.7\times 10^{-20}$ J and ![]() $M=0.018\varepsilon \sigma ^6$ are used. This form of disjoining pressure

$M=0.018\varepsilon \sigma ^6$ are used. This form of disjoining pressure ![]() $h^{-3}-h^{-9}$ is obtained by integrating the 12-6 LJ potential over the entire substrate assuming the substrate is continuous, as shown in Appendix A and (Dietrich Reference Dietrich1988; Schick Reference Schick1990; Carey & Wemhoff Reference Carey and Wemhoff2005; Israelachvili Reference Israelachvili2011; MacDowell et al. Reference MacDowell, Benet, Katcho and Palanco2014). There are many other forms of disjoining potential resulting from different liquid and solid properties (Becker et al. Reference Becker, Grün, Seemann, Mantz, Jacobs, Mecke and Blossey2003).

$h^{-3}-h^{-9}$ is obtained by integrating the 12-6 LJ potential over the entire substrate assuming the substrate is continuous, as shown in Appendix A and (Dietrich Reference Dietrich1988; Schick Reference Schick1990; Carey & Wemhoff Reference Carey and Wemhoff2005; Israelachvili Reference Israelachvili2011; MacDowell et al. Reference MacDowell, Benet, Katcho and Palanco2014). There are many other forms of disjoining potential resulting from different liquid and solid properties (Becker et al. Reference Becker, Grün, Seemann, Mantz, Jacobs, Mecke and Blossey2003).

We vary the lattice spacing ![]() $\ell _s$ and see what the slip length is from independent simulations where a pressure-driven flow goes past a substrate as shown by the MD snapshot in figure 3. The pressure gradient is created by applying a body force

$\ell _s$ and see what the slip length is from independent simulations where a pressure-driven flow goes past a substrate as shown by the MD snapshot in figure 3. The pressure gradient is created by applying a body force ![]() $g$ to the fluid. For

$g$ to the fluid. For ![]() $\ell _s=0.37\ \textrm {nm}$, one can see that the velocity profile in MD (blue squares in figure 3) is parabolic. However, for

$\ell _s=0.37\ \textrm {nm}$, one can see that the velocity profile in MD (blue squares in figure 3) is parabolic. However, for ![]() $\ell _s=0.10\ \textrm {nm}$, the velocity profile in MD (black triangles in figure 3) is nearly constant (plug flow).

$\ell _s=0.10\ \textrm {nm}$, the velocity profile in MD (black triangles in figure 3) is nearly constant (plug flow).

Figure 3. Slip length measured using pressure-driven flows past the substrate in molecular simulations. MD results of velocity (symbols) are fitted with analytical solutions (solid lines) to obtain slip length.

The generated velocity distribution is

Here ![]() $z_1=0$ and

$z_1=0$ and ![]() $z_2=9.2\sigma$ are the positions of the wall and the free surface, respectively. This prediction (solid lines in figure 3) is used to fit the MD results (symbols in figure 3) to obtain the slip length. For

$z_2=9.2\sigma$ are the positions of the wall and the free surface, respectively. This prediction (solid lines in figure 3) is used to fit the MD results (symbols in figure 3) to obtain the slip length. For ![]() $\ell _s=0.37\ \textrm {nm}$, a nearly no-slip surface

$\ell _s=0.37\ \textrm {nm}$, a nearly no-slip surface ![]() $b=0.2\ \textrm {nm}$ is achieved. For

$b=0.2\ \textrm {nm}$ is achieved. For ![]() $\ell _s=0.10\ \textrm {nm}$, a strong slip length of

$\ell _s=0.10\ \textrm {nm}$, a strong slip length of ![]() $b=400\ \textrm {nm}$ is obtained. Note that the choice of thermostats may have a slight influence on the slip length. For example, for water flows inside carbon nanotubes, the Berendsen and Nosé–Hoover thermostats result in very similar slip length, while a smaller slip length is found under the influence of the Langevin thermostat (Sam et al. Reference Sam, Kannam, Hartkamp and Sathian2017). Thus, the same thermostats should be chosen when measuring the slip length from pressure-driven flows and simulating nanofilm dewetting.

$b=400\ \textrm {nm}$ is obtained. Note that the choice of thermostats may have a slight influence on the slip length. For example, for water flows inside carbon nanotubes, the Berendsen and Nosé–Hoover thermostats result in very similar slip length, while a smaller slip length is found under the influence of the Langevin thermostat (Sam et al. Reference Sam, Kannam, Hartkamp and Sathian2017). Thus, the same thermostats should be chosen when measuring the slip length from pressure-driven flows and simulating nanofilm dewetting.

To mimic experimental conditions of polymer films on octadecyltrichlorosilane (OTS) and DTS substrates (Lessel et al. Reference Lessel, McGraw, Bäumchen and Jacobs2017), where contact angles (disjoining pressure) are about the same for both cases but slip length is very different (no slip on OTS in contrast to 500 nm slip length on DTS), we thus keep the disjoining pressure (4.3) the same for the simulations of weak-slip nanofilm dewetting and strong-slip nanofilm dewetting. In our simulations, the contact angles of drops after film dewetting for both cases are measured to be about ![]() $40^{\circ }$. This can also facilitate the comparison between weak-slip dewetting and strong-slip dewetting in simulations as the slip length is the only variable. Classically, disjoining pressure decreases with increasing slip length and contact angles. This is, however, far from being universal, as discussed previously for the case of polymer films on OTS and DTS substrates. Liquids on hydrophilic substrates with small contact angles can also have large slip length (Rothstein Reference Rothstein2010; Ho et al. Reference Ho, Papavassiliou, Lee and Striolo2011). As shown in Appendix A, the proposed simulation technique is general and it can include the classic results where slip length and disjoining pressure are coupled and disjoining pressure decreases with increasing slip length and contact angles. As the virtual force is obtained by integrating the LJ potential (especially for

$40^{\circ }$. This can also facilitate the comparison between weak-slip dewetting and strong-slip dewetting in simulations as the slip length is the only variable. Classically, disjoining pressure decreases with increasing slip length and contact angles. This is, however, far from being universal, as discussed previously for the case of polymer films on OTS and DTS substrates. Liquids on hydrophilic substrates with small contact angles can also have large slip length (Rothstein Reference Rothstein2010; Ho et al. Reference Ho, Papavassiliou, Lee and Striolo2011). As shown in Appendix A, the proposed simulation technique is general and it can include the classic results where slip length and disjoining pressure are coupled and disjoining pressure decreases with increasing slip length and contact angles. As the virtual force is obtained by integrating the LJ potential (especially for ![]() $f_x$), this simulation technique is limited for the system where liquid and solid interact with LJ potential.

$f_x$), this simulation technique is limited for the system where liquid and solid interact with LJ potential.

With the wall modelled by the virtual force, the simulations of nanofilm dewetting are run for 2 ns for the case of ![]() $h_0=1.2\ \textrm {nm}$, 10 ns for

$h_0=1.2\ \textrm {nm}$, 10 ns for ![]() $h_0=1.6\ \textrm {nm}$ and 100 ns for

$h_0=1.6\ \textrm {nm}$ and 100 ns for ![]() $h_0=3.14\ \textrm {nm}$.

$h_0=3.14\ \textrm {nm}$.

5. Results and discussion

5.1. Evolving spectra of an unstable film with strong slip

As shown in figure 2, a flat film deposited on the substrate experiences the spontaneous growth of perturbations on its surface, leading to film rupture (see figure 2b) and droplet formation (see figure 2c). To reveal the instability mechanism in the case of the strong-slip dewetting, the evolution of its surface spectra is obtained from MD simulations.

The instantaneous liquid–vapour interface ![]() $h(x,t)$, defined by the usual equimolar surface, is extracted from MD simulations (see (Zhang et al. Reference Zhang, Sprittles and Lockerby2019) for methods). A discrete Fourier transform of

$h(x,t)$, defined by the usual equimolar surface, is extracted from MD simulations (see (Zhang et al. Reference Zhang, Sprittles and Lockerby2019) for methods). A discrete Fourier transform of ![]() $h(x,t)$ is performed to obtain the amplitude of surface modes

$h(x,t)$ is performed to obtain the amplitude of surface modes ![]() $\hat {h}(q,t)$. The surface spectra are thus calculated from the average (r.m.s.) of 40 independent simulations.

$\hat {h}(q,t)$. The surface spectra are thus calculated from the average (r.m.s.) of 40 independent simulations.

The symbols in figure 4(a) represent the MD spectra for the film with thickness ![]() $h=1.2\ \textrm {nm}$ and slip length

$h=1.2\ \textrm {nm}$ and slip length ![]() $b=400\ \textrm {nm}$ at three different times. Compared with the weak-slip case (

$b=400\ \textrm {nm}$ at three different times. Compared with the weak-slip case (![]() $b=0.2\ \textrm {nm}$) presented in figure 4(b), one can see that the transient characteristics of the spectra are strongly influenced by the slip length. The spectra for the strong-slip case grow faster than the spectra for the weak-slip case by comparing the blue triangles in figure 4(a) with the wine triangles in figure 4(b). The dominant wavenumber

$b=0.2\ \textrm {nm}$) presented in figure 4(b), one can see that the transient characteristics of the spectra are strongly influenced by the slip length. The spectra for the strong-slip case grow faster than the spectra for the weak-slip case by comparing the blue triangles in figure 4(a) with the wine triangles in figure 4(b). The dominant wavenumber ![]() $q_d$ (the one with the maximum amplitude) at different times in the strong-slip dewetting are smaller than those in the weak-slip dewetting (e.g. at

$q_d$ (the one with the maximum amplitude) at different times in the strong-slip dewetting are smaller than those in the weak-slip dewetting (e.g. at ![]() $t=0.43$ ns,

$t=0.43$ ns, ![]() $q_d\approx 0.25\ \textrm {nm}^{-1}$ for the strong-slip case in figure 4(a) in contrast to

$q_d\approx 0.25\ \textrm {nm}^{-1}$ for the strong-slip case in figure 4(a) in contrast to ![]() $q_d\approx 0.50\ \textrm {nm}^{-1}$ for the weak-slip case in figure 4b).

$q_d\approx 0.50\ \textrm {nm}^{-1}$ for the weak-slip case in figure 4b).

Figure 4. Evolution of the capillary spectra for the film with the thickness ![]() $h=1.2\ \textrm {nm}$ at three different times. (a) The film has a strong slip length

$h=1.2\ \textrm {nm}$ at three different times. (a) The film has a strong slip length ![]() $b=400\ \textrm {nm}$. Solid lines represent the prediction of the full S-S model whereas dashed lines are the S-S model without the inertial terms. (b) The film has a weak slip length

$b=400\ \textrm {nm}$. Solid lines represent the prediction of the full S-S model whereas dashed lines are the S-S model without the inertial terms. (b) The film has a weak slip length ![]() $b=0.2\ \textrm {nm}$.

$b=0.2\ \textrm {nm}$.

The proposed stochastic models (S-S model and W-S model) and their analytical spectra are used to predict the MD spectra. In our MD simulations, the initial setting of the film surface is flat ![]() $|\hat {h}(q,0)|\approx 0$, so that the deterministic contribution to the surface spectra is

$|\hat {h}(q,0)|\approx 0$, so that the deterministic contribution to the surface spectra is ![]() $|\hat {h}_{det}|\approx 0$. As elaborately investigated in our previous work (Zhang et al. Reference Zhang, Sprittles and Lockerby2019, Reference Zhang, Sprittles and Lockerby2020, Reference Zhang, Sprittles and Lockerby2021), the capillary spectra for weak-slip film can be predicted well by the W-S model, see e.g. the solid lines in figure 4(b). However, the W-S model does not apply to the case where the slip is strong, since the W-S model with

$|\hat {h}_{det}|\approx 0$. As elaborately investigated in our previous work (Zhang et al. Reference Zhang, Sprittles and Lockerby2019, Reference Zhang, Sprittles and Lockerby2020, Reference Zhang, Sprittles and Lockerby2021), the capillary spectra for weak-slip film can be predicted well by the W-S model, see e.g. the solid lines in figure 4(b). However, the W-S model does not apply to the case where the slip is strong, since the W-S model with ![]() $b=400\ \textrm {nm}$ leads to enormous overpredictions compared with MD results (not shown). This is because the derivation of the W-S model requires the slip length on the order of the film thickness. To predict the spectra of the unstable film with strong slip

$b=400\ \textrm {nm}$ leads to enormous overpredictions compared with MD results (not shown). This is because the derivation of the W-S model requires the slip length on the order of the film thickness. To predict the spectra of the unstable film with strong slip ![]() $b=400\ \textrm {nm}$, the analytical spectra (3.14) of the newly derived S-S model is adopted and it agrees excellently with MD results (see the solid lines in figure 4a). The symbols in figure 5(a) show the MD spectra for the film with a larger thickness

$b=400\ \textrm {nm}$, the analytical spectra (3.14) of the newly derived S-S model is adopted and it agrees excellently with MD results (see the solid lines in figure 4a). The symbols in figure 5(a) show the MD spectra for the film with a larger thickness ![]() $h=1.6\ \textrm {nm}$. Again, our analytical spectra can predict the MD results very well. Note that for large wavenumbers, the spectra at different times simply collapse into the static spectrum

$h=1.6\ \textrm {nm}$. Again, our analytical spectra can predict the MD results very well. Note that for large wavenumbers, the spectra at different times simply collapse into the static spectrum ![]() $S_s=\sqrt {L_x k_BT/(L_y\gamma q^2)}$.

$S_s=\sqrt {L_x k_BT/(L_y\gamma q^2)}$.

Figure 5. Evolution of the capillary spectra for the film with the thickness ![]() $h=1.6\ \textrm {nm}$ at three different times. (a) The film has a strong slip length

$h=1.6\ \textrm {nm}$ at three different times. (a) The film has a strong slip length ![]() $b=400\ \textrm {nm}$. (b) The film has a weak slip length

$b=400\ \textrm {nm}$. (b) The film has a weak slip length ![]() $b=0.2\ \textrm {nm}$.

$b=0.2\ \textrm {nm}$.