Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Hatada, R.

Baba, K.

Flege, S.

Nakao, S.

and

Ensinger, W.

2012.

Preparation of Diamond-like Carbon Films by Plasma Source Ion Implantation with External Glow Discharge.

Transactions of the Materials Research Society of Japan,

Vol. 37,

Issue. 2,

p.

227.

Popa, A. C.

Stan, G. E.

Husanu, M. A.

Pasuk, I.

Popescu, I. D.

Popescu, A. C.

and

Mihailescu, I. N.

2013.

Multi-layer haemocompatible diamond-like carbon coatings obtained by combined radio frequency plasma enhanced chemical vapor deposition and magnetron sputtering.

Journal of Materials Science: Materials in Medicine,

Vol. 24,

Issue. 12,

p.

2695.

Flege, S.

Hatada, R.

Ensinger, W.

and

Baba, K.

2014.

Improved adhesion of DLC films on copper substrates by preimplantation.

Surface and Coatings Technology,

Vol. 256,

Issue. ,

p.

37.

Hatada, R.

Flege, S.

Bobrich, A.

Ensinger, W.

and

Baba, K.

2014.

Surface modification and corrosion properties of implanted and DLC coated stainless steel by plasma based ion implantation and deposition.

Surface and Coatings Technology,

Vol. 256,

Issue. ,

p.

23.

Das, Debajyoti

and

Banerjee, Amit

2015.

Anti-reflection coatings for silicon solar cells from hydrogenated diamond like carbon.

Applied Surface Science,

Vol. 345,

Issue. ,

p.

204.

Zahid, Rehan

Masjuki, Haji Hassan

Varman, Mahendra

Kalam, Muhammad Abul

Mufti, Riaz Ahmad

Mohd Zulkifli, Nurin Wahidah Binti

Gulzar, Mubashir

and

Nor Azman, Siti Safiyah Binti

2016.

Influence of intrinsic and extrinsic conditions on the tribological characteristics of diamond-like carbon coatings: A review.

Journal of Materials Research,

Vol. 31,

Issue. 13,

p.

1814.

Chang, Ya Chen

Liao, Wei Bo

Wei, Hung Sen

Liao, Yan Yu

Chen, Hung Pin

and

Kuo, Chien Cheng

2018.

Fabrication of Transparent Very Thin SiOx Doped Diamond-Like Carbon Films on a Glass Substrate.

Coatings,

Vol. 8,

Issue. 7,

p.

240.

Hatada, Ruriko

Flege, Stefan

Ashraf, Muhammad Naeem

Timmermann, Arne

Schmid, Christoph

and

Ensinger, Wolfgang

2020.

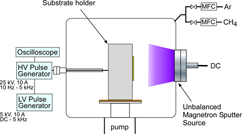

The Influence of Preparation Conditions on the Structural Properties and Hardness of Diamond-Like Carbon Films, Prepared by Plasma Source Ion Implantation.

Coatings,

Vol. 10,

Issue. 4,

p.

360.

Zhang, Tengfei

Xu, Zhaoying

Wang, Jinbiao

Huang, Weijiu

Hou, Xiaodong

Paddea, Sanjooram

and

Su, Yongyao

2021.

Failure Behavior of Hydrogenated and Hydrogen Free Diamond Like Carbon (DLC) Films in Water Environment.

Journal of Bio- and Tribo-Corrosion,

Vol. 7,

Issue. 4,

Alamgir, Asad

Bogatov, Andrei

Jõgiaas, Taivo

Viljus, Mart

Raadik, Taavi

Kübarsepp, Jakob

Sergejev, Fjodor

Lümkemann, Andreas

Kluson, Jan

and

Podgursky, Vitali

2022.

High-Temperature Oxidation Resistance and Tribological Properties of Al2O3/ta-C Coating.

Coatings,

Vol. 12,

Issue. 4,

p.

547.

Saha, Sucharita

and

Das, Debajyoti

2022.

Growth of diamond-like carbon films with significant nanocrystalline phases in a low-pressure high-density CH4 plasma in ICP-CVD: Effect of negative dc substrate bias.

Applied Surface Science,

Vol. 596,

Issue. ,

p.

153638.