1. Introduction

Aircraft engines are the primary source of noise during take-off and landing. In order to meet noise regulations, the nacelle of modern engines is coated with acoustic liners, which represent the state-of-the-art technology for engine noise abatement. Acoustic liners are panels with a sandwich structure, consisting of a honeycomb core, bounded by a perforated facesheet and a solid backplate (see figure 1a). They cover the nacelle inner surface, both in front of the fan and in the by-pass duct (see figure 2), and can theoretically absorb all incoming sound if the resonant frequency of the liner is tuned to the frequency of the incoming acoustic wave (Hughes & Dowling Reference Hughes and Dowling1990; Dowling & Hughes Reference Dowling and Hughes1992; Kirby & Cummings Reference Kirby and Cummings1998). In realistic conditions, several studies have shown that acoustic liners reduce fan noise by as much as 3–6 dB (Casalino, Hazir & Mann Reference Casalino, Hazir and Mann2018; Shur et al. Reference Shur, Strelets, Travin, Suzuki and Spalart2020). They are, therefore, an essential part of aircraft engines.

Figure 1. (a) Turbofan engine of a civil aircraft with acoustic liners on the air intake. (b) The typical pore size of acoustic liners used in turbofan engines.

Figure 2. Acoustic liners around the fan of a turbofan engine.

Although the sound attenuation mechanism is well understood, the aerodynamic characteristics of these surfaces are less clear. Several authors agree that liners increase aerodynamic drag as compared with a hydraulically smooth wall (Wilkinson Reference Wilkinson1983; Howerton & Jones Reference Howerton and Jones2015; Jasinski & Corke Reference Jasinski and Corke2020). However, an extensive literature study summarized in table 1 shows that reported values for the actual drag increase caused by acoustic liners vary between 2 % and 500 %. Hence, at present, we lack a theory for the prediction of the aerodynamic drag over acoustic liners.

Table 1. Dataset of previous studies of drag over acoustic liner geometries. Here ![]() $M_{\infty }$ is the Mach number,

$M_{\infty }$ is the Mach number, ![]() $\textit {Re}_{\delta }=u_0\delta /\nu$ is the Reynolds number based on the boundary layer thickness and external velocity (free-stream velocity for boundary layers or bulk flow velocity for channel flow simulations) and

$\textit {Re}_{\delta }=u_0\delta /\nu$ is the Reynolds number based on the boundary layer thickness and external velocity (free-stream velocity for boundary layers or bulk flow velocity for channel flow simulations) and ![]() $\textit {Re}_\tau$ is the friction Reynolds number. The liner geometry is defined by the orifice diameter

$\textit {Re}_\tau$ is the friction Reynolds number. The liner geometry is defined by the orifice diameter ![]() $d$, the depth of the cavity

$d$, the depth of the cavity ![]() $h$, the thickness of the facesheet

$h$, the thickness of the facesheet ![]() $t$ and the porosity

$t$ and the porosity ![]() $\sigma$. Parameter

$\sigma$. Parameter ![]() $\Delta D$ is the percentage increase in drag observed in these studies. Quantities that are approximated are denoted using the

$\Delta D$ is the percentage increase in drag observed in these studies. Quantities that are approximated are denoted using the ![]() $^{{\dagger} }$ superscript. Quantities that are approximated using Reynolds-averaged Navier–Stokes simulations of the GFIT by Zhang & Bodony (Reference Zhang and Bodony2016) are denoted using the

$^{{\dagger} }$ superscript. Quantities that are approximated using Reynolds-averaged Navier–Stokes simulations of the GFIT by Zhang & Bodony (Reference Zhang and Bodony2016) are denoted using the ![]() $^{\circledast }$ superscript.

$^{\circledast }$ superscript.

Wilkinson (Reference Wilkinson1983) was among the first to perform experiments of turbulent boundary layers over porous plates for different values of the viscous-scaled orifice diameter ![]() $d^+\unicode{x2254} d/\delta _v$, viscous-scaled plate thickness

$d^+\unicode{x2254} d/\delta _v$, viscous-scaled plate thickness ![]() $t^+\unicode{x2254} t/\delta _v$ and plate porosity (open-area ratio)

$t^+\unicode{x2254} t/\delta _v$ and plate porosity (open-area ratio) ![]() $\sigma$. Here,

$\sigma$. Here, ![]() $\delta _v=\nu _w/u_\tau$ is the viscous length scale,

$\delta _v=\nu _w/u_\tau$ is the viscous length scale, ![]() $\nu$ the kinematic viscosity of the fluid,

$\nu$ the kinematic viscosity of the fluid, ![]() $u_\tau =\sqrt {\tau _w/\rho _w}$ the friction velocity,

$u_\tau =\sqrt {\tau _w/\rho _w}$ the friction velocity, ![]() $\tau _w$ the drag per plane area and

$\tau _w$ the drag per plane area and ![]() $\rho$ the fluid density and the subscript

$\rho$ the fluid density and the subscript ![]() $w$ denotes quantities evaluated at the wall.

$w$ denotes quantities evaluated at the wall.

More recently, several experiments have been conducted in the Grazing Flow Impedance Tube (GFIT) facility at NASA (Jones et al. Reference Jones, Watson, Parrott and Smith2004a) and considerable effort has been dedicated to estimating the added drag provided by acoustic liners using a static pressure drop approach (Howerton & Jones Reference Howerton and Jones2015, Reference Howerton and Jones2016, Reference Howerton and Jones2017). These experimental campaigns considered several liner geometries, for both conventional and more exotic configurations (Howerton & Jones Reference Howerton and Jones2015, Reference Howerton and Jones2017), and reported a drag increase of between 16 % and 350 % compared with a smooth wall.

An important finding of the GFIT experiments is that the cavity depth has a negligible contribution to the total drag in the absence of acoustic waves, which instead is largely influenced by the orifice diameter, plate porosity and facesheet thickness. For instance, Howerton & Jones (Reference Howerton and Jones2015) noted that, for constant porosity, reducing the diameter of the orifices reduced drag. Similarly, Howerton & Jones (Reference Howerton and Jones2017) reported 50 % drag increase for porosity ![]() $\sigma =0.08$ and 400 % drag increase for

$\sigma =0.08$ and 400 % drag increase for ![]() $\sigma =0.3$, for the same flow conditions and approximately the same orifice diameter. Additionally, these experiments suggest that it is possible to reduce the drag penalty without harming the noise attenuation.

$\sigma =0.3$, for the same flow conditions and approximately the same orifice diameter. Additionally, these experiments suggest that it is possible to reduce the drag penalty without harming the noise attenuation.

Gustavsson et al. (Reference Gustavsson, Zhang, Cattafesta and Kreitzman2019) performed experiments over several acoustic liner geometries and reported a drag increase of between 30 % and 50 %, without incoming acoustic waves, arguing that the added drag might be even larger in the presence of incoming noise.

Numerical simulations of turbulent flows over acoustic liners are also available, but very often they rely on simplified configurations or wall models because pore-resolved simulations are computationally expensive. A common approach that has been pursued for reducing the computational cost is to simulate a single cavity rather than an array of resonators (Zhang & Bodony Reference Zhang and Bodony2011, Reference Zhang and Bodony2016; Avallone et al. Reference Avallone, Manjunath, Ragni and Casalino2019). Zhang & Bodony (Reference Zhang and Bodony2016) performed direct numerical simulation (DNS) of turbulent grazing flow over a single resonator with a cavity geometry similar to that studied by Howerton & Jones (Reference Howerton and Jones2015) in the GFIT (Jones et al. Reference Jones, Watson, Tracy and Parrott2004b). However, the simulations were at a much lower friction Reynolds number (see table 1). For a free-stream Mach number ![]() $M_\infty =0.5$, Zhang & Bodony (Reference Zhang and Bodony2016) reported a minor drag increase of

$M_\infty =0.5$, Zhang & Bodony (Reference Zhang and Bodony2016) reported a minor drag increase of ![]() $4.2\,\%$ with respect to a smooth wall in the absence of sound waves, whereas they found a drag increase of about 25 % when including sound waves with an intensity of 140 dB. These results seem to contradict experiments of Howerton & Jones (Reference Howerton and Jones2015) who reported a drag increase of about 50 % both with and without incoming sound waves, at matched Mach number and cavity geometry. This discrepancy can probably be traced back to the simplified numerical set-up wherein only one single orifice is simulated, resulting in a very low porosity

$4.2\,\%$ with respect to a smooth wall in the absence of sound waves, whereas they found a drag increase of about 25 % when including sound waves with an intensity of 140 dB. These results seem to contradict experiments of Howerton & Jones (Reference Howerton and Jones2015) who reported a drag increase of about 50 % both with and without incoming sound waves, at matched Mach number and cavity geometry. This discrepancy can probably be traced back to the simplified numerical set-up wherein only one single orifice is simulated, resulting in a very low porosity ![]() $\sigma =0.0099$, compared with

$\sigma =0.0099$, compared with ![]() $\sigma =0.08$ in the experiments.

$\sigma =0.08$ in the experiments.

Another common simplification in numerical simulation is to approximate the effect of acoustic liners with an equivalent impedance boundary condition (Tam & Auriault Reference Tam and Auriault1996), which substantially reduces the computational cost. However, the accuracy with which the impedance boundary condition represents the real acoustic liner geometry is not well understood and discrepancies can be observed in the literature. For instance, Olivetti, Sandberg & Tester (Reference Olivetti, Sandberg and Tester2015) performed DNS of turbulent pipe flow with impedance boundary conditions and did not report changes in the structure of the near-wall turbulence. On the contrary, Scalo, Bodart & Lele (Reference Scalo, Bodart and Lele2015) and Sebastian, Marx & Fortuné (Reference Sebastian, Marx and Fortuné2019) performed large-eddy simulations of turbulent channel flow with a characteristic impedance boundary condition (Fung, Ju & Tallapragada Reference Fung, Ju and Tallapragada2000; Fung & Ju Reference Fung and Ju2004), and noted significant changes in the structure of the near-wall cycle which could, in some cases, be completely replaced by Kelvin–Helmholtz-like rollers, with drag increase up to 500 %.

Despite the very large discrepancies between results of previous studies, there seems to be a consensus that the added drag depends on both the orifice diameter ![]() $d$ and the porosity of the facesheet

$d$ and the porosity of the facesheet ![]() $\sigma$. This type of functional dependency has been observed in turbulent grazing flows over porous substrates, which is a hint that acoustic liners might be regarded as porous surfaces, permeable only in the wall-normal direction. Porous surfaces differ from other types of impermeable surface textures such as roughness. Flows over rough surfaces are characterized by the pressure drag induced by the topography (Leonardi et al. Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003; Leonardi & Castro Reference Leonardi and Castro2010; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). When pressure drag dominates over viscous drag, the skin-friction coefficient becomes independent of the Reynolds number, a regime that we denote as ‘fully rough’ (Schlichting Reference Schlichting1968; Leonardi et al. Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). The flow through many common porous surfaces (such as metal foams, sedimentary rocks, sandstone and conglomerates) can be characterized by the Darcy and Forchheimer permeability tensors,

$\sigma$. This type of functional dependency has been observed in turbulent grazing flows over porous substrates, which is a hint that acoustic liners might be regarded as porous surfaces, permeable only in the wall-normal direction. Porous surfaces differ from other types of impermeable surface textures such as roughness. Flows over rough surfaces are characterized by the pressure drag induced by the topography (Leonardi et al. Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003; Leonardi & Castro Reference Leonardi and Castro2010; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). When pressure drag dominates over viscous drag, the skin-friction coefficient becomes independent of the Reynolds number, a regime that we denote as ‘fully rough’ (Schlichting Reference Schlichting1968; Leonardi et al. Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003; Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). The flow through many common porous surfaces (such as metal foams, sedimentary rocks, sandstone and conglomerates) can be characterized by the Darcy and Forchheimer permeability tensors, ![]() ${\mathsf{K}}_{ij}$ and

${\mathsf{K}}_{ij}$ and ![]() $\alpha _{ij}$, which represent the ease with which flow passes through the porous surface. Our current understanding of porous surfaces is that pressure drag and permeability are intrinsically coupled because the grazing flow perceives the pores as a non-smooth surface texture (which provides pressure drag), but it is also able to penetrate into the pores. Therefore the flow has a ‘roughness’ component (pressure drag) and a ‘porous’ component (permeability), which are inseparable.

$\alpha _{ij}$, which represent the ease with which flow passes through the porous surface. Our current understanding of porous surfaces is that pressure drag and permeability are intrinsically coupled because the grazing flow perceives the pores as a non-smooth surface texture (which provides pressure drag), but it is also able to penetrate into the pores. Therefore the flow has a ‘roughness’ component (pressure drag) and a ‘porous’ component (permeability), which are inseparable.

Some authors attempted to separate these two concurring effects. For instance, Manes et al. (Reference Manes, Pokrajac, McEwan and Nikora2009) studied the similarities and differences between roughness and porous surfaces by carrying out experiments of (impermeable) rough walls with the same surface topography of porous substrates, in an attempt to isolate the effect of the permeability. They found that permeability largely contributes to the total drag and a fully rough regime did not emerge for the permeable substrate. Esteban et al. (Reference Esteban, Rodríguez-López, Ferreira and Ganapathisubramani2022) carried out experiments of permeable surfaces and delineated the effects of roughness and permeability by considering permeable surfaces with constant permeability but different thicknesses. They found that changing the thickness altered the added drag and that such an effect could be attributed to the ‘roughness’ component of the geometry. Unlike Manes et al. (Reference Manes, Pokrajac, McEwan and Nikora2009), Esteban et al. (Reference Esteban, Rodríguez-López, Ferreira and Ganapathisubramani2022) found that porous surfaces do indeed approach a fully rough regime. Breugem, Boersma & Uittenbogaard (Reference Breugem, Boersma and Uittenbogaard2006) carried out DNS of porous surfaces by modelling the substrate with a Darcy boundary condition. Those authors pointed out that the duality between ‘rough’ and ‘porous’ surface is reflected in the presence of three concurring length scales, namely the boundary layer thickness ![]() $\delta$, the pore diameter

$\delta$, the pore diameter ![]() $d$ and the square root of the permeability

$d$ and the square root of the permeability ![]() $\sqrt {{\mathsf{K}}_{ij}}$. These length scales can be converted into the friction Reynolds number

$\sqrt {{\mathsf{K}}_{ij}}$. These length scales can be converted into the friction Reynolds number ![]() $\textit {Re}_\tau =\delta /\delta _v$, the viscous-scaled pore diameter

$\textit {Re}_\tau =\delta /\delta _v$, the viscous-scaled pore diameter ![]() $d^+=d/\delta _v$ and the viscous-scaled square root of the permeability

$d^+=d/\delta _v$ and the viscous-scaled square root of the permeability ![]() $\sqrt {{\mathsf{K}}_{ij}}^+=\sqrt {{\mathsf{K}}_{ij}}/\delta _v$. The authors reason that the effects of the ‘roughness’ and ‘porous’ components are separated if there is enough separation between

$\sqrt {{\mathsf{K}}_{ij}}^+=\sqrt {{\mathsf{K}}_{ij}}/\delta _v$. The authors reason that the effects of the ‘roughness’ and ‘porous’ components are separated if there is enough separation between ![]() $d^+$ and

$d^+$ and ![]() $\sqrt {{\mathsf{K}}_{ij}}^+$ while having

$\sqrt {{\mathsf{K}}_{ij}}^+$ while having ![]() $d\ll \delta$. These conditions are somehow always assumed by models such as Darcy's boundary conditions (Breugem et al. Reference Breugem, Boersma and Uittenbogaard2006; Rosti, Cortelezzi & Quadrio Reference Rosti, Cortelezzi and Quadrio2015; Rosti, Brandt & Pinelli Reference Rosti, Brandt and Pinelli2018) and by impedance boundary conditions (Scalo et al. Reference Scalo, Bodart and Lele2015). This essentially corresponds to a surface with small pores

$d\ll \delta$. These conditions are somehow always assumed by models such as Darcy's boundary conditions (Breugem et al. Reference Breugem, Boersma and Uittenbogaard2006; Rosti, Cortelezzi & Quadrio Reference Rosti, Cortelezzi and Quadrio2015; Rosti, Brandt & Pinelli Reference Rosti, Brandt and Pinelli2018) and by impedance boundary conditions (Scalo et al. Reference Scalo, Bodart and Lele2015). This essentially corresponds to a surface with small pores ![]() $d^+\ll 70$, but very high porosity

$d^+\ll 70$, but very high porosity ![]() $\sigma$ (i.e. open-area ratio) and therefore high permeability,

$\sigma$ (i.e. open-area ratio) and therefore high permeability, ![]() $\sqrt {{\mathsf{K}}_{ij}}^+>1$.

$\sqrt {{\mathsf{K}}_{ij}}^+>1$.

Acoustic liners do not satisfy these conditions. Figure 1(b) shows that the plate porosity is relatively small, typically ![]() $\sigma =0.08\unicode{x2013}0.3$ and the orifice diameter is about 2–3 mm. The orifice diameter with respect to the boundary layer length scales can be estimated assuming an aircraft at cruise condition with free-stream Mach Number

$\sigma =0.08\unicode{x2013}0.3$ and the orifice diameter is about 2–3 mm. The orifice diameter with respect to the boundary layer length scales can be estimated assuming an aircraft at cruise condition with free-stream Mach Number ![]() $M_\infty \approx 0.3\unicode{x2013}0.6$, free-stream velocity

$M_\infty \approx 0.3\unicode{x2013}0.6$, free-stream velocity ![]() $u_{\infty } \approx 90\unicode{x2013}180\ {\rm m}\,{\rm s}^{-1}$ and kinematic viscosity

$u_{\infty } \approx 90\unicode{x2013}180\ {\rm m}\,{\rm s}^{-1}$ and kinematic viscosity ![]() $\nu \approx 3.5 \times 10^{-5}\ {\rm m}^2\ {\rm s}^{-1}$. In these conditions, we can estimate a friction Reynolds number

$\nu \approx 3.5 \times 10^{-5}\ {\rm m}^2\ {\rm s}^{-1}$. In these conditions, we can estimate a friction Reynolds number ![]() $\textit {Re}_\tau \approx 3300\unicode{x2013}5400$, with boundary layer thickness

$\textit {Re}_\tau \approx 3300\unicode{x2013}5400$, with boundary layer thickness ![]() $\delta \approx 30\ {\rm mm}$, and viscous length scale

$\delta \approx 30\ {\rm mm}$, and viscous length scale ![]() $\delta _v=5\unicode{x2013}10\ \mathrm {\mu } {\rm m}$. Therefore, acoustic liners in operating conditions have

$\delta _v=5\unicode{x2013}10\ \mathrm {\mu } {\rm m}$. Therefore, acoustic liners in operating conditions have ![]() $d/\delta \approx 0.07$ and

$d/\delta \approx 0.07$ and ![]() $d^+\approx 200\unicode{x2013}400$. The depth of a cavity is typically

$d^+\approx 200\unicode{x2013}400$. The depth of a cavity is typically ![]() $h = 40\ {\rm mm}$, corresponding to

$h = 40\ {\rm mm}$, corresponding to ![]() $h/\delta \approx 1.3$.

$h/\delta \approx 1.3$.

Hence, acoustic liners have low porosity, but relatively large orifices, which is the opposite of canonical porous surfaces, which can reach ![]() $\sigma >0.8$ (Breugem et al. Reference Breugem, Boersma and Uittenbogaard2006; Rosti et al. Reference Rosti, Cortelezzi and Quadrio2015). Furthermore, acoustic liners differ from canonical porous surfaces because they exhibit non-zero permeability only in the wall-normal direction, thus only one component of the Darcy (

$\sigma >0.8$ (Breugem et al. Reference Breugem, Boersma and Uittenbogaard2006; Rosti et al. Reference Rosti, Cortelezzi and Quadrio2015). Furthermore, acoustic liners differ from canonical porous surfaces because they exhibit non-zero permeability only in the wall-normal direction, thus only one component of the Darcy (![]() ${\mathsf{K}}_{ij}$) and Forchheimer (

${\mathsf{K}}_{ij}$) and Forchheimer (![]() $\alpha _{ij}$) permeability tensors is non-zero, namely

$\alpha _{ij}$) permeability tensors is non-zero, namely ![]() ${\mathsf{K}}_{22} = {\mathsf{K}}_y$ and

${\mathsf{K}}_{22} = {\mathsf{K}}_y$ and ![]() $\alpha _{22} = \alpha _y$. Therefore, the operating regime of acoustic liners would exclude them from the canonical definition of porous surfaces, although the drag dependence on the porosity would suggest the opposite.

$\alpha _{22} = \alpha _y$. Therefore, the operating regime of acoustic liners would exclude them from the canonical definition of porous surfaces, although the drag dependence on the porosity would suggest the opposite.

This literature survey shows that there have been several attempts to measure the added drag caused by acoustic liners, both experimentally and numerically, suggesting a large interest of the community in this topic. However, the discrepancies between previous studies are too large to be acceptable. This large uncertainty can be associated with the critical modelling assumptions that have been used in numerical simulations and the difficulty in measuring drag in experiments. From a more fundamental perspective, it is not clear if acoustic liners can be regarded as porous surfaces or as surface roughness, because their geometry does not fall in either of these canonical classifications.

In this work, we aim at developing a rigorous theoretical framework to characterize acoustic liners within the larger body of non-smooth surface textures. We believe that this can only be achieved by performing pore-resolved DNS, which allows us to have access to the three-dimensional flow field and to accurately measure the drag without relying on additional modelling assumptions.

2. Methodology

We solve the compressible Navier–Stokes equations for a calorically perfect gas:

where ![]() $u_i=\{u_1,u_2,u_3\}$ are the velocity components,

$u_i=\{u_1,u_2,u_3\}$ are the velocity components, ![]() $x_i=\{x_1,x_2,x_3\}=\{x,y,z\}$ are the streamwise, wall-normal and spanwise spatial coordinates,

$x_i=\{x_1,x_2,x_3\}=\{x,y,z\}$ are the streamwise, wall-normal and spanwise spatial coordinates, ![]() $\rho$ is the density,

$\rho$ is the density, ![]() $p$ is the pressure,

$p$ is the pressure, ![]() $E = c_vT +u_iu_i/2$ is the total energy per unit mass,

$E = c_vT +u_iu_i/2$ is the total energy per unit mass, ![]() $T$ is the temperature,

$T$ is the temperature, ![]() $H = E + p/\rho$ is the total enthalpy,

$H = E + p/\rho$ is the total enthalpy, ![]() $c_p$ and

$c_p$ and ![]() $c_v$ are the heat capacities at constant pressure and constant volume and

$c_v$ are the heat capacities at constant pressure and constant volume and ![]() $q_j$ and

$q_j$ and ![]() $\sigma _{ij}$ are the heat flux vector and viscous stress tensor:

$\sigma _{ij}$ are the heat flux vector and viscous stress tensor:

where ![]() $k = c_p\mu /Pr$ is the thermal conductivity. The Prandtl number is

$k = c_p\mu /Pr$ is the thermal conductivity. The Prandtl number is ![]() $Pr = 0.72$. The viscosity dependence on the temperature is accounted for using a power law with exponent

$Pr = 0.72$. The viscosity dependence on the temperature is accounted for using a power law with exponent ![]() $0.75$. We consider the plane channel flow configuration wherein the fully developed flow between two plates is driven in the streamwise direction by a uniform body force,

$0.75$. We consider the plane channel flow configuration wherein the fully developed flow between two plates is driven in the streamwise direction by a uniform body force, ![]() $\varPi$, which is adjusted every time step to maintain a constant mass flow rate and the power spent is added to the total energy equation. A uniform bulk cooling term,

$\varPi$, which is adjusted every time step to maintain a constant mass flow rate and the power spent is added to the total energy equation. A uniform bulk cooling term, ![]() $\varPi _T$, is also added to the total energy equation to maintain a constant bulk flow temperature. The bulk velocity, temperature and density are defined as

$\varPi _T$, is also added to the total energy equation to maintain a constant bulk flow temperature. The bulk velocity, temperature and density are defined as

where ![]() $V=L_x\times 2\delta \times L_z$ is the fluid volume between the top and bottom perforated plates (see figure 3). The volume of fluid within the cavities is, therefore, not considered while calculating the driving pressure gradient.

$V=L_x\times 2\delta \times L_z$ is the fluid volume between the top and bottom perforated plates (see figure 3). The volume of fluid within the cavities is, therefore, not considered while calculating the driving pressure gradient.

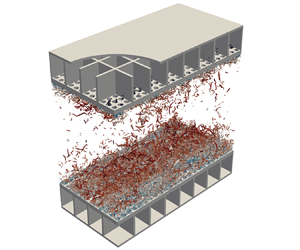

Figure 3. (a) Sketch of the computational domain. Turbulent channel flow configuration with box dimensions ![]() $L_x \times L_y \times L_z$. Different porosities are considered by increasing the number of holes per cavity. (b–d) The three different porosities,

$L_x \times L_y \times L_z$. Different porosities are considered by increasing the number of holes per cavity. (b–d) The three different porosities, ![]() $\sigma$.

$\sigma$.

The Navier–Stokes equations are solved using the solver STREAmS (Bernardini et al. Reference Bernardini, Modesti, Salvadore and Pirozzoli2021). The nonlinear terms in the Navier–Stokes equations are discretized using an energy-conservative scheme in locally conservative form (Pirozzoli Reference Pirozzoli2010). The viscous terms are expanded into a Laplacian form and approximated with sixth-order central finite-difference formulas to avoid odd–even decoupling phenomena. Time stepping is carried out using Wray's three-stage third-order Runge–Kutta scheme (Spalart, Moser & Rogers Reference Spalart, Moser and Rogers1991).

The complexity of the roughness geometry is handled using a ghost-point-forcing immersed boundary method to treat arbitrarily complex geometries (Piquet, Roussel & Hadjadj Reference Piquet, Roussel and Hadjadj2016; Vanna, Picano & Benini Reference Vanna, Picano and Benini2020). The geometry of the solid body is provided in OFF format for three-dimensional objects, and the computational geometry library CGAL (Project 2022) is used to perform the ray-tracing algorithm. This allows us to define the grid nodes belonging to the fluid and the solid, and to compute the distance of each point from the interface. To retain the same computational stencil close to the boundaries, the first three layers of interface points inside the body are tagged as ghost nodes. For each ghost node, we identify a reflected point along the wall-normal, laying inside the fluid domain. We interpolate the solution at the reflected point using a trilinear interpolation and use the values at the reflected points to fill the ghost nodes inside the body to apply the desired boundary condition. An extensive description of the algorithm is available in the work by Vanna et al. (Reference Vanna, Picano and Benini2020), and validation of the present implementation is available in Appendix A and in the paper by Modesti et al. (Reference Modesti, Sathyanarayana, Salvadore and Bernardini2022).

The simulations are carried out in a rectangular box of size ![]() $L_x \times L_y \times L_z = 3\delta \times 2 (\delta + h) \times 1.5\delta$, where

$L_x \times L_y \times L_z = 3\delta \times 2 (\delta + h) \times 1.5\delta$, where ![]() $\delta$ is the channel half-width and

$\delta$ is the channel half-width and ![]() $h$ the cavity depth. This box size is smaller than is usually recommended for DNS (Lozano-Durán & Jiménez Reference Lozano-Durán and Jiménez2014). However, similar and even smaller box sizes have been used previously to aid parametric analysis of rough-wall turbulent flows (Chung et al. Reference Chung, Chan, MacDonald, Hutchins and Ooi2015; MacDonald et al. Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017; Di Giorgio et al. Reference Di Giorgio, Leonardi, Pirozzoli and Orlandi2020; Yang et al. Reference Yang, Stroh, Chung and Forooghi2022) through comparison with smooth-wall simulations with the same box size. We use uniform mesh spacing in the streamwise and spanwise directions. In the wall-normal direction, the mesh is clustered towards the facesheet walls and coarsened towards the backplate and the channel centre. The simulations are performed at bulk Mach number

$h$ the cavity depth. This box size is smaller than is usually recommended for DNS (Lozano-Durán & Jiménez Reference Lozano-Durán and Jiménez2014). However, similar and even smaller box sizes have been used previously to aid parametric analysis of rough-wall turbulent flows (Chung et al. Reference Chung, Chan, MacDonald, Hutchins and Ooi2015; MacDonald et al. Reference MacDonald, Chung, Hutchins, Chan, Ooi and García-Mayoral2017; Di Giorgio et al. Reference Di Giorgio, Leonardi, Pirozzoli and Orlandi2020; Yang et al. Reference Yang, Stroh, Chung and Forooghi2022) through comparison with smooth-wall simulations with the same box size. We use uniform mesh spacing in the streamwise and spanwise directions. In the wall-normal direction, the mesh is clustered towards the facesheet walls and coarsened towards the backplate and the channel centre. The simulations are performed at bulk Mach number ![]() $M_b = u_b/c_w = 0.3$, where

$M_b = u_b/c_w = 0.3$, where ![]() $c_w$ is the speed of sound at the wall. This value of Mach number is representative of the values encountered inside aircraft air intakes, where the flow is decelerated before reaching the fan. We also note that at this Mach number and in the absence of incoming acoustic waves, we do not expect significant compressibility effects, as the friction Mach number does not exceed

$c_w$ is the speed of sound at the wall. This value of Mach number is representative of the values encountered inside aircraft air intakes, where the flow is decelerated before reaching the fan. We also note that at this Mach number and in the absence of incoming acoustic waves, we do not expect significant compressibility effects, as the friction Mach number does not exceed ![]() $M_\tau =u_\tau /c_w<0.02$ for any of the flow cases. The bulk-to-wall temperature ratio is fixed at

$M_\tau =u_\tau /c_w<0.02$ for any of the flow cases. The bulk-to-wall temperature ratio is fixed at ![]() $T_b/T_w = 1$, which corresponds to an isothermal cold wall with

$T_b/T_w = 1$, which corresponds to an isothermal cold wall with ![]() $T_w/T_{aw} = 0.984$, where

$T_w/T_{aw} = 0.984$, where ![]() $T_{aw}$ is the adiabatic wall temperature based on the bulk Mach number.

$T_{aw}$ is the adiabatic wall temperature based on the bulk Mach number.

We choose the liner geometry to match as closely as possible the orifice size of acoustic liners in operating conditions. The acoustic liner comprises a total of 64 cavities: an array of ![]() $8 \times 4$ in the streamwise and spanwise directions on the upper and lower walls. Each cavity has a square cross-section with a side length

$8 \times 4$ in the streamwise and spanwise directions on the upper and lower walls. Each cavity has a square cross-section with a side length ![]() $\lambda _c = 0.335 \delta$ and depth

$\lambda _c = 0.335 \delta$ and depth ![]() $h = 0.5 \delta$. The orifices have a diameter of

$h = 0.5 \delta$. The orifices have a diameter of ![]() $d = 0.08 \delta$ and the cavity walls have a thickness of

$d = 0.08 \delta$ and the cavity walls have a thickness of ![]() $0.02 \delta$.

$0.02 \delta$.

We carry out simulations at three friction Reynolds numbers ![]() $\textit {Re}_\tau = {500, 1000, 2000}$, corresponding to viscous-scaled diameters

$\textit {Re}_\tau = {500, 1000, 2000}$, corresponding to viscous-scaled diameters ![]() $d^+ = {40, 80, 160}$. Additionally, we increase the liner porosity between

$d^+ = {40, 80, 160}$. Additionally, we increase the liner porosity between ![]() $\sigma \approx 0.036$ and

$\sigma \approx 0.036$ and ![]() $0.32$ by varying the number of orifices per cavity between 1 and 9. We also vary the facesheet thickness. The dataset is complemented by smooth-wall simulations at matching Reynolds numbers. Flow cases are named with the letter

$0.32$ by varying the number of orifices per cavity between 1 and 9. We also vary the facesheet thickness. The dataset is complemented by smooth-wall simulations at matching Reynolds numbers. Flow cases are named with the letter ![]() $S$-

$S$-![]() $\textit {Re}$ or

$\textit {Re}$ or ![]() $L$-

$L$-![]() $\textit {Re}_{\sigma (\%)}$, depending on if they are smooth wall (

$\textit {Re}_{\sigma (\%)}$, depending on if they are smooth wall (![]() $S$) or liner configurations (

$S$) or liner configurations (![]() $L$), followed by the Reynolds number: low (

$L$), followed by the Reynolds number: low (![]() $L$) for

$L$) for ![]() $\textit {Re}_\tau \approx 500$, medium (

$\textit {Re}_\tau \approx 500$, medium (![]() $M$) for

$M$) for ![]() $\textit {Re}_\tau \approx 1000$ and high (

$\textit {Re}_\tau \approx 1000$ and high (![]() $H$) for

$H$) for ![]() $\textit {Re}_\tau \approx 1000$. For liner cases,

$\textit {Re}_\tau \approx 1000$. For liner cases, ![]() $\sigma (\%)$ is the facesheet porosity, expressed as a percentage. The naming convention of the liner cases also contains information about the thickness of the facesheet. Cases

$\sigma (\%)$ is the facesheet porosity, expressed as a percentage. The naming convention of the liner cases also contains information about the thickness of the facesheet. Cases ![]() $L$-

$L$-![]() $\textit {Re}_{\sigma (\%)}$ have a facesheet thickness of

$\textit {Re}_{\sigma (\%)}$ have a facesheet thickness of ![]() $t = d$ and cases

$t = d$ and cases ![]() $L_t$-

$L_t$-![]() $\textit {Re}_{\sigma (\%)}$ have a facesheet thickness of

$\textit {Re}_{\sigma (\%)}$ have a facesheet thickness of ![]() $t=d/2$. For example, flow case

$t=d/2$. For example, flow case ![]() $L$-

$L$-![]() $M_{32}$ indicates a liner flow case at

$M_{32}$ indicates a liner flow case at ![]() $\textit {Re}_\tau \approx 1000$ with facesheet thickness

$\textit {Re}_\tau \approx 1000$ with facesheet thickness ![]() $t/d=1$ and a porosity of 32 %. Details of all flow cases are reported in table 2. The same wall-normal mesh is employed for cases with thickness

$t/d=1$ and a porosity of 32 %. Details of all flow cases are reported in table 2. The same wall-normal mesh is employed for cases with thickness ![]() $t=d$ and

$t=d$ and ![]() $t=d/2$. This ensures that, at a minimum, 25 grid points are used to resolve the facesheet thickness at

$t=d/2$. This ensures that, at a minimum, 25 grid points are used to resolve the facesheet thickness at ![]() $\textit {Re}_\tau = 500$ and

$\textit {Re}_\tau = 500$ and ![]() $t=d/2$. Note that whereas 40 points are used to resolve the orifice diameter in the streamwise and spanwise direction for cases with

$t=d/2$. Note that whereas 40 points are used to resolve the orifice diameter in the streamwise and spanwise direction for cases with ![]() $t=d$,

$t=d$, ![]() $t=d/2$ and 26 points are used for flow cases with

$t=d/2$ and 26 points are used for flow cases with ![]() $t=d/2$. This resolution is well within the viscous spacing typically accepted in DNS, and it does not affect the results, as we show in the mesh refinement study detailed in Appendix B. The orifice configurations within a cavity, along with a sketch of the entire domain, are shown in figure 3. We compare the results of the liner simulations with smooth-wall simulations at approximately matching friction Reynolds numbers. Quantities that are non-dimensionalized by

$t=d/2$. This resolution is well within the viscous spacing typically accepted in DNS, and it does not affect the results, as we show in the mesh refinement study detailed in Appendix B. The orifice configurations within a cavity, along with a sketch of the entire domain, are shown in figure 3. We compare the results of the liner simulations with smooth-wall simulations at approximately matching friction Reynolds numbers. Quantities that are non-dimensionalized by ![]() $\delta _v$ and

$\delta _v$ and ![]() $u_{\tau }$ are denoted by a ‘

$u_{\tau }$ are denoted by a ‘![]() $+$’ superscript.

$+$’ superscript.

Table 2. The DNS dataset comprising smooth (![]() $S$-

$S$-![]() $\textit {Re}$) and liner (

$\textit {Re}$) and liner (![]() $L$-

$L$-![]() $\textit {Re}_{\sigma (\%)}$ and

$\textit {Re}_{\sigma (\%)}$ and ![]() $L_t$-

$L_t$-![]() $\textit {Re}_{\sigma (\%)}$) cases where

$\textit {Re}_{\sigma (\%)}$) cases where ![]() $\textit {Re}=\{L,M,H\}$ correspond to the three Reynolds numbers

$\textit {Re}=\{L,M,H\}$ correspond to the three Reynolds numbers ![]() $\textit {Re}\approx 500$ (low),

$\textit {Re}\approx 500$ (low), ![]() $\textit {Re}\approx 1000$ (medium) and

$\textit {Re}\approx 1000$ (medium) and ![]() $\textit{Re}\approx 2000$ (high) and

$\textit{Re}\approx 2000$ (high) and ![]() $\sigma$ is the porosity of the liner case. Cases

$\sigma$ is the porosity of the liner case. Cases ![]() $L_t$-

$L_t$-![]() $\textit {Re}_{\sigma (\%)}$ have plate thickness

$\textit {Re}_{\sigma (\%)}$ have plate thickness ![]() $t/d=0.5$ and flow cases

$t/d=0.5$ and flow cases ![]() $L$-

$L$-![]() $\textit {Re}_{\sigma (\%)}$ have

$\textit {Re}_{\sigma (\%)}$ have ![]() $t/d=1$, where

$t/d=1$, where ![]() $d$ is the orifice diameter. Parameters

$d$ is the orifice diameter. Parameters ![]() ${\mathsf{K}}_y$ and

${\mathsf{K}}_y$ and ![]() $\alpha _y$ are the Darcy and Forchheimer wall-normal permeabilities,

$\alpha _y$ are the Darcy and Forchheimer wall-normal permeabilities, ![]() $\Delta U^+$ is the Hama roughness function measured at

$\Delta U^+$ is the Hama roughness function measured at ![]() $y^+ + \ell _T^+=100$, where

$y^+ + \ell _T^+=100$, where ![]() $\ell _T$ is the virtual origin shift, and

$\ell _T$ is the virtual origin shift, and ![]() $C_f=2/u_\delta ^{+2}$ is the skin-friction coefficient, where

$C_f=2/u_\delta ^{+2}$ is the skin-friction coefficient, where ![]() $u_\delta ^+$ is the viscous-scaled streamwise velocity at the channel centreline. Simulations are performed in a computational box with dimensions

$u_\delta ^+$ is the viscous-scaled streamwise velocity at the channel centreline. Simulations are performed in a computational box with dimensions ![]() $L_x \times L_y \times L_z = 3\delta \times 2(\delta +h) \times 1.5\delta$. Spacings

$L_x \times L_y \times L_z = 3\delta \times 2(\delta +h) \times 1.5\delta$. Spacings ![]() $\Delta x^+$ and

$\Delta x^+$ and ![]() $\Delta z^+$ are the viscous-scaled mesh spacing in the streamwise and spanwise direction, and

$\Delta z^+$ are the viscous-scaled mesh spacing in the streamwise and spanwise direction, and ![]() $\Delta y^+_{{min}}$ is the minimum mesh spacing in the wall-normal direction. Interval

$\Delta y^+_{{min}}$ is the minimum mesh spacing in the wall-normal direction. Interval ![]() $T_{{av}} u_\tau /\delta$ is the time-averaging interval.

$T_{{av}} u_\tau /\delta$ is the time-averaging interval.

The near-wall flow is spatially inhomogeneous due to the acoustic liner. Therefore, flow statistics are calculated by averaging in time and over the cavity phase ![]() $\lambda = 0.375\delta$ in the streamwise and spanwise directions, using both Favre (

$\lambda = 0.375\delta$ in the streamwise and spanwise directions, using both Favre (![]() $\tilde {\cdot }$) and Reynolds (

$\tilde {\cdot }$) and Reynolds (![]() $\bar {\cdot }$) ensemble averages:

$\bar {\cdot }$) ensemble averages:

Additionally, we use angle brackets ![]() $\langle \cdot \rangle$ to denote intrinsic averages (average over the fluid only) in the wall-parallel directions. With this notation, the ensemble-averaged Reynolds stress tensor is

$\langle \cdot \rangle$ to denote intrinsic averages (average over the fluid only) in the wall-parallel directions. With this notation, the ensemble-averaged Reynolds stress tensor is ![]() $\tau _{ij}(x,y,z)=\bar {\rho }\widetilde {u_i''u_j''}$. The wall-normal coordinate is measured upwards from the surface of the facesheet such that

$\tau _{ij}(x,y,z)=\bar {\rho }\widetilde {u_i''u_j''}$. The wall-normal coordinate is measured upwards from the surface of the facesheet such that ![]() $y/\delta =-h$ corresponds to the bottom surface of the cavity. For comparing the smooth-wall and the liner cases, a virtual origin shift

$y/\delta =-h$ corresponds to the bottom surface of the cavity. For comparing the smooth-wall and the liner cases, a virtual origin shift ![]() $\ell _T$ is also introduced. The virtual origin is measured positively downwards from the surface of the facesheet. More details about the virtual origin are provided in § 3.3.

$\ell _T$ is also introduced. The virtual origin is measured positively downwards from the surface of the facesheet. More details about the virtual origin are provided in § 3.3.

3. Results

3.1. Instantaneous flow

We begin our analysis by inspecting an instantaneous visualization of flow case ![]() $L$-

$L$-![]() $H_{32}$ at friction Reynolds number

$H_{32}$ at friction Reynolds number ![]() $\textit {Re}_\tau =2000$. Figure 4 shows the streamwise velocity in the wall-normal planes and vortical structures visualized using the

$\textit {Re}_\tau =2000$. Figure 4 shows the streamwise velocity in the wall-normal planes and vortical structures visualized using the ![]() $Q$-criterion. The near-wall region is populated by small-scale structures indicating intense turbulence activity close to the wall, whereas the flow below the cavities is more quiescent, although some vortices penetrate below the facesheet.

$Q$-criterion. The near-wall region is populated by small-scale structures indicating intense turbulence activity close to the wall, whereas the flow below the cavities is more quiescent, although some vortices penetrate below the facesheet.

Figure 4. Instantaneous flow field from DNS of turbulent channel flow at ![]() $\textit {Re}_{\tau } = 2000$ and bulk Mach number

$\textit {Re}_{\tau } = 2000$ and bulk Mach number ![]() $M_b = 0.3$. The streamwise velocity is shown in an

$M_b = 0.3$. The streamwise velocity is shown in an ![]() $x\unicode{x2013}y$ plane and a

$x\unicode{x2013}y$ plane and a ![]() $y\unicode{x2013}z$ plane. Vortical structures are visualized using the

$y\unicode{x2013}z$ plane. Vortical structures are visualized using the ![]() $Q$-criterion.

$Q$-criterion.

Figure 5 shows contours of the instantaneous streamwise (figure 5a,b) and wall-normal (figure 5c,d) velocity in a wall-parallel plane above the facesheet for flow case ![]() $L$-

$L$-![]() $H_{32}$. The streamwise velocity is significantly altered as compared with the smooth wall and near-wall streaks are shorter over the liner. A similar break-up of the streaks was also observed by Orlandi & Leonardi (Reference Orlandi and Leonardi2006) for different roughness geometries. Here, the streaky structures can still be discerned, suggesting a modification rather than a complete replacement of the near-wall cycle.

$H_{32}$. The streamwise velocity is significantly altered as compared with the smooth wall and near-wall streaks are shorter over the liner. A similar break-up of the streaks was also observed by Orlandi & Leonardi (Reference Orlandi and Leonardi2006) for different roughness geometries. Here, the streaky structures can still be discerned, suggesting a modification rather than a complete replacement of the near-wall cycle.

Figure 5. Instantaneous streamwise (a,b) and wall-normal (c,d) velocity fluctuations in an ![]() $x\unicode{x2013}z$ plane at

$x\unicode{x2013}z$ plane at ![]() $y^+ + \ell _T^+=12$ for flow case

$y^+ + \ell _T^+=12$ for flow case ![]() $S$-

$S$-![]() $H$ (a,c) and flow case

$H$ (a,c) and flow case ![]() $L$-

$L$-![]() $H_{32}$ (b,d) at

$H_{32}$ (b,d) at ![]() $\textit {Re}_{\tau } \approx 2000$. The position of the orifices is shown at the bottom-left corner, for one cavity only. The virtual origin

$\textit {Re}_{\tau } \approx 2000$. The position of the orifices is shown at the bottom-left corner, for one cavity only. The virtual origin ![]() $\ell _T$ is defined in § 3.3.

$\ell _T$ is defined in § 3.3.

These observations are in line with previous studies of permeable walls, which reported shorter streaks caused by the higher wall-normal velocity fluctuations (Kuwata & Suga Reference Kuwata and Suga2019). We also observe higher wall-normal velocity fluctuations as compared with the smooth wall, mainly concentrated at the orifices (figure 5). The wall-normal velocity fluctuations seem reminiscent of the underlying surface pattern, as the position of the orifices can easily be discerned in the contours of ![]() $u_2'$, suggesting that turbulence in the near-wall region is modulated by the surface topography (Abderrahaman-Elena, Fairhall & García-Mayoral Reference Abderrahaman-Elena, Fairhall and García-Mayoral2019).

$u_2'$, suggesting that turbulence in the near-wall region is modulated by the surface topography (Abderrahaman-Elena, Fairhall & García-Mayoral Reference Abderrahaman-Elena, Fairhall and García-Mayoral2019).

Figure 6 shows a snapshot of the wall-normal velocity in an ![]() $x\unicode{x2013}y$ plane, where we observe that the effect of the liner on the flow is concentrated near the wall and inside the cavities. Inside the orifices, high wall-normal velocity fluctuations are visible, and they are notably higher at the downstream edge. Wall-normal velocity fluctuations penetrate inside the cavities forming a jet-like flow which extends down to

$x\unicode{x2013}y$ plane, where we observe that the effect of the liner on the flow is concentrated near the wall and inside the cavities. Inside the orifices, high wall-normal velocity fluctuations are visible, and they are notably higher at the downstream edge. Wall-normal velocity fluctuations penetrate inside the cavities forming a jet-like flow which extends down to ![]() $0.2\delta$ below the facesheet, indicating important inertial effects inside the orifices.

$0.2\delta$ below the facesheet, indicating important inertial effects inside the orifices.

Figure 6. Wall-normal velocity fluctuations in an ![]() $x\unicode{x2013}y$ plane for flow case

$x\unicode{x2013}y$ plane for flow case ![]() $S$-

$S$-![]() $H$ (a) and flow case

$H$ (a) and flow case ![]() $L$-

$L$-![]() $H_{32}$ (b) at

$H_{32}$ (b) at ![]() $\textit {Re}_{\tau } \approx 2000$. Grey patches represent solid wall regions.

$\textit {Re}_{\tau } \approx 2000$. Grey patches represent solid wall regions.

3.2. Mean flow

In order to quantify the flow penetration and inertial effects inside the orifices, we report the mean wall-normal velocity and wall-normal Reynolds stress component for liner flow cases with ![]() $t=d$ in figure 7. Away from the facesheet, the flow is homogeneous in the wall-parallel directions, indicating that the effect of the liner is primarily contained in the near-wall region. The mean flow is highly three-dimensional close to the liner. The wall-normal velocity is negative at the downstream edge of the orifice, suggesting that flow penetrates inside the orifices, and positive at the upstream edge due to the mean flow recirculation inside the pore, separating the region above and below the facesheet. The vortex is asymmetric, and the negative values of

$t=d$ in figure 7. Away from the facesheet, the flow is homogeneous in the wall-parallel directions, indicating that the effect of the liner is primarily contained in the near-wall region. The mean flow is highly three-dimensional close to the liner. The wall-normal velocity is negative at the downstream edge of the orifice, suggesting that flow penetrates inside the orifices, and positive at the upstream edge due to the mean flow recirculation inside the pore, separating the region above and below the facesheet. The vortex is asymmetric, and the negative values of ![]() $\tilde {u}_2$ are always higher than the positive ones. Moreover, we note that the intensity of

$\tilde {u}_2$ are always higher than the positive ones. Moreover, we note that the intensity of ![]() $\tilde {u}_2$ is, primarily, a function of the viscous-scaled orifice diameter, whereas it seems less dependent on the porosity of the plate.

$\tilde {u}_2$ is, primarily, a function of the viscous-scaled orifice diameter, whereas it seems less dependent on the porosity of the plate.

Figure 7. Mean wall-normal velocity ![]() $\tilde {u}_2$ (a–f) and wall-normal Reynolds stress

$\tilde {u}_2$ (a–f) and wall-normal Reynolds stress ![]() $\tau _{22}$ (g–l) over a liner cavity for flow cases

$\tau _{22}$ (g–l) over a liner cavity for flow cases ![]() $L$-

$L$-![]() $L_{3}$ (a,g),

$L_{3}$ (a,g), ![]() $L$-

$L$-![]() $L_{14}$ (b,h),

$L_{14}$ (b,h), ![]() $L$-

$L$-![]() $L_{32}$ (c,i),

$L_{32}$ (c,i), ![]() $L$-

$L$-![]() $M_{14}$ (d,j),

$M_{14}$ (d,j), ![]() $L$-

$L$-![]() $M_{32}$ (e,k) and

$M_{32}$ (e,k) and ![]() $L$-

$L$-![]() $H_{32}$ (f,l).

$H_{32}$ (f,l).

For sufficiently large ![]() $d^+$, we observe high values of the wall-normal velocity extending down into the cavity, resembling a jet-like flow also observed in the instantaneous flow in figure 6. This jet-like mean flow is accompanied by high wall-normal velocity fluctuations inside the orifice, as shown in figure 7(g–l). Also the wall-normal velocity fluctuations

$d^+$, we observe high values of the wall-normal velocity extending down into the cavity, resembling a jet-like flow also observed in the instantaneous flow in figure 6. This jet-like mean flow is accompanied by high wall-normal velocity fluctuations inside the orifice, as shown in figure 7(g–l). Also the wall-normal velocity fluctuations ![]() $\tau _{22}$ are higher at the downstream edge of the orifice, where they reach values comparable to, or even higher than, the peak in the near-wall cycle. This is particularly true for liner cases

$\tau _{22}$ are higher at the downstream edge of the orifice, where they reach values comparable to, or even higher than, the peak in the near-wall cycle. This is particularly true for liner cases ![]() $L$-

$L$-![]() $M_{32}$ and

$M_{32}$ and ![]() $L$-

$L$-![]() $H_{32}$ (figure 7k,l) where

$H_{32}$ (figure 7k,l) where ![]() $\tau _{22}$ is higher below the facesheet than in the near-wall cycle above the facesheet. These high wall-normal velocity fluctuations are a symptom of inertial effects inside the orifices. A comparison between liner flow cases with

$\tau _{22}$ is higher below the facesheet than in the near-wall cycle above the facesheet. These high wall-normal velocity fluctuations are a symptom of inertial effects inside the orifices. A comparison between liner flow cases with ![]() $t=d$ indicates that

$t=d$ indicates that ![]() $\tau _{22}$ seems to depend on both

$\tau _{22}$ seems to depend on both ![]() $\sigma$ and

$\sigma$ and ![]() $d^+$.

$d^+$.

We also investigate the effect of the plate thickness, using flow cases ![]() $L_t$-

$L_t$-![]() $L_{14}$,

$L_{14}$, ![]() $L_t$-

$L_t$-![]() $M_{14}$ and

$M_{14}$ and ![]() $L_t$-

$L_t$-![]() $M_{32}$, which have

$M_{32}$, which have ![]() $t=0.5d$. Reducing the thickness causes an increase of the mean wall-normal velocity (compare figures 7e and 8c) and its fluctuations (compare figures 7k and 8f) within the orifice. Wall-normal velocity fluctuations have been correlated with drag increase over rough surfaces (Orlandi & Leonardi Reference Orlandi and Leonardi2006) as they are indicative of momentum transfer between the the crest and the trough in the case of roughness, and the regions above and below the facesheet for acoustic liners. Therefore, this qualitative analysis suggests that the added drag over acoustic liners might depend on

$t=0.5d$. Reducing the thickness causes an increase of the mean wall-normal velocity (compare figures 7e and 8c) and its fluctuations (compare figures 7k and 8f) within the orifice. Wall-normal velocity fluctuations have been correlated with drag increase over rough surfaces (Orlandi & Leonardi Reference Orlandi and Leonardi2006) as they are indicative of momentum transfer between the the crest and the trough in the case of roughness, and the regions above and below the facesheet for acoustic liners. Therefore, this qualitative analysis suggests that the added drag over acoustic liners might depend on ![]() $d^+$,

$d^+$, ![]() $\sigma$ and

$\sigma$ and ![]() $t/d$, as we discuss further in the following section.

$t/d$, as we discuss further in the following section.

Figure 8. Mean wall-normal velocity ![]() $\tilde {u}_2$ (a–c) and wall-normal Reynolds stress

$\tilde {u}_2$ (a–c) and wall-normal Reynolds stress ![]() $\tau _{22}$ (d–f) over a liner cavity for flow cases

$\tau _{22}$ (d–f) over a liner cavity for flow cases ![]() $L_t$-

$L_t$-![]() $L_{14}$ (a,d),

$L_{14}$ (a,d), ![]() $L_t$-

$L_t$-![]() $M_{14}$ (b,e) and

$M_{14}$ (b,e) and ![]() $L_t$-

$L_t$-![]() $M_{32}$ (c,f).

$M_{32}$ (c,f).

3.3. Virtual origin and drag increase

On smooth walls, there is no ambiguity on the wall-normal origin of the flow, which is always at the wall, where both the mean velocity and Reynolds stresses are zero. The presence of complex surface patterns introduces uncertainty on the wall-normal origin location, which can be relevant when comparing rough wall results with the solution for a corresponding smooth wall.

This virtual origin is a flow property, and it can be interpreted as the wall-normal location where the outer flow perceives the wall. Several methods to estimate the virtual origin have been proposed (Jackson Reference Jackson1981; Choi, Moin & Kim Reference Choi, Moin and Kim1993; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021). In the present work, we calculate the origin of turbulence ![]() $\ell _T$ following the approach of Ibrahim et al. (Reference Ibrahim, Gómez-de Segura, Chung and García-Mayoral2021), namely we shift the Reynolds shear stress profile of the liner cases to match the smooth wall one. The virtual origin is located

$\ell _T$ following the approach of Ibrahim et al. (Reference Ibrahim, Gómez-de Segura, Chung and García-Mayoral2021), namely we shift the Reynolds shear stress profile of the liner cases to match the smooth wall one. The virtual origin is located ![]() $\ell _T$ below the surface of the facesheet (figure 9), meaning that the near-wall cycle tends to penetrate inside the orifices, as is also clear from the high values of the Reynolds shear stress in figure 10(a), and from instantaneous flow visualizations. The virtual origin shift is limited to a few wall units

$\ell _T$ below the surface of the facesheet (figure 9), meaning that the near-wall cycle tends to penetrate inside the orifices, as is also clear from the high values of the Reynolds shear stress in figure 10(a), and from instantaneous flow visualizations. The virtual origin shift is limited to a few wall units ![]() $\ell _T^+ \leqslant 5$ for all flow cases, but accounting for this displacement allows us to restore a very good match with the smooth-wall data down to the viscous sublayer (figure 10b), confirming that at least part of the effect of the liner can be accounted for by an origin shift.

$\ell _T^+ \leqslant 5$ for all flow cases, but accounting for this displacement allows us to restore a very good match with the smooth-wall data down to the viscous sublayer (figure 10b), confirming that at least part of the effect of the liner can be accounted for by an origin shift.

Figure 9. Schematic depicting the virtual origin of the flow configuration.

Figure 10. Intrinsic averaged Reynolds shear stress ![]() $\langle \tau _{12} \rangle$ as a function of the wall-normal distance for smooth wall flow cases with

$\langle \tau _{12} \rangle$ as a function of the wall-normal distance for smooth wall flow cases with ![]() $t=d$ (dashed) and liner flow cases (solid with symbols), before virtual origin correction (a) and after virtual origin correction (b). Symbols indicate different porosities:

$t=d$ (dashed) and liner flow cases (solid with symbols), before virtual origin correction (a) and after virtual origin correction (b). Symbols indicate different porosities: ![]() $\sigma =0.0357$ (blue circles),

$\sigma =0.0357$ (blue circles), ![]() $\sigma =0.143$ (green squares) and

$\sigma =0.143$ (green squares) and ![]() $\sigma =0.322$ (red triangles).

$\sigma =0.322$ (red triangles).

Having estimated the virtual origin, we can now draw meaningful comparisons between the smooth-wall and liner statistics. Figure 11 shows the mean velocity profiles in viscous units for all flow cases. The mean velocity profiles over the liner show a downward shift ![]() $\Delta U^+$ with the respect to the baseline smooth wall, indicating that the flow experiences higher drag. Despite the shift, velocity profiles are parallel to each other, which supports outer-layer similarity, as is typical of many rough surfaces (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). The von Kármán constant is

$\Delta U^+$ with the respect to the baseline smooth wall, indicating that the flow experiences higher drag. Despite the shift, velocity profiles are parallel to each other, which supports outer-layer similarity, as is typical of many rough surfaces (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). The von Kármán constant is ![]() $\kappa \approx 0.39$ for both liner and smooth-wall cases.

$\kappa \approx 0.39$ for both liner and smooth-wall cases.

Figure 11. Intrinsic averaged mean streamwise velocity for smooth-wall flow cases (dashed lines) and liner flow cases with ![]() $t=d$ (a) and

$t=d$ (a) and ![]() $t=d/2$ (b) as a function of the wall-normal distance. Symbols indicate different porosities:

$t=d/2$ (b) as a function of the wall-normal distance. Symbols indicate different porosities: ![]() $\sigma =0.0357$ (blue circles),

$\sigma =0.0357$ (blue circles), ![]() $\sigma =0.143$ (green squares) and

$\sigma =0.143$ (green squares) and ![]() $\sigma =0.322$ (red triangles).

$\sigma =0.322$ (red triangles).

This is in contrast to the work of Breugem et al. (Reference Breugem, Boersma and Uittenbogaard2006) and Kuwata & Suga (Reference Kuwata and Suga2016b), who reported different values of ![]() $\kappa$ over permeable surfaces. The discrepancy could be due to the low Reynolds number of previous studies (maximum

$\kappa$ over permeable surfaces. The discrepancy could be due to the low Reynolds number of previous studies (maximum ![]() $\textit {Re}_\tau \approx 350$ for smooth impermeable cases), or perhaps to the use of Darcy-type boundary conditions, as compared with pore-resolved simulations. The flow cases with low porosity,

$\textit {Re}_\tau \approx 350$ for smooth impermeable cases), or perhaps to the use of Darcy-type boundary conditions, as compared with pore-resolved simulations. The flow cases with low porosity, ![]() $\sigma =0.0357$ and

$\sigma =0.0357$ and ![]() $d^+=40$ (circles), show a smooth-wall-like behaviour with very minor changes in the mean velocity profile. However, a departure from the smooth-wall velocity profile becomes evident as either

$d^+=40$ (circles), show a smooth-wall-like behaviour with very minor changes in the mean velocity profile. However, a departure from the smooth-wall velocity profile becomes evident as either ![]() $\sigma$ or

$\sigma$ or ![]() $d^+$ is increased or

$d^+$ is increased or ![]() $t/d$ is decreased.

$t/d$ is decreased.

A fundamental question is whether acoustic liners exhibit a fully rough regime, namely whether the Hama roughness function follows a logarithmic law:

where ![]() $\ell$ is a suitable length scale of the liner geometry. In canonical

$\ell$ is a suitable length scale of the liner geometry. In canonical ![]() $k$-type roughness,

$k$-type roughness, ![]() $\ell$ is simply the roughness height; however, for acoustic liners different choices are possible. Unlike canonical roughness, there is no protrusion into the flow and therefore the definition of a suitable length scale is not straightforward. It is clear that it depends upon the geometrical parameters of the orifice, namely the porosity, orifice diameter and plate thickness. However, as is apparent in figure 12(a), none of these parameters can account for the effect of the liner on their own. For instance, flow cases

$\ell$ is simply the roughness height; however, for acoustic liners different choices are possible. Unlike canonical roughness, there is no protrusion into the flow and therefore the definition of a suitable length scale is not straightforward. It is clear that it depends upon the geometrical parameters of the orifice, namely the porosity, orifice diameter and plate thickness. However, as is apparent in figure 12(a), none of these parameters can account for the effect of the liner on their own. For instance, flow cases ![]() $L$-

$L$-![]() $L_{14}$ and

$L_{14}$ and ![]() $L$-

$L$-![]() $L_{32}$ have the same

$L_{32}$ have the same ![]() $t/d$ and approximately the same

$t/d$ and approximately the same ![]() $d^+$, but different porosity and therefore a different

$d^+$, but different porosity and therefore a different ![]() $\Delta U^+$. Similarly, cases

$\Delta U^+$. Similarly, cases ![]() $L$-

$L$-![]() $L_{32}$ and

$L_{32}$ and ![]() $L$-

$L$-![]() $M_{32}$ have the same porosity and

$M_{32}$ have the same porosity and ![]() $t/d$, but case

$t/d$, but case ![]() $L$-

$L$-![]() $M_{32}$ has a larger viscous-scaled diameter, leading to a larger

$M_{32}$ has a larger viscous-scaled diameter, leading to a larger ![]() $\Delta U^+$ (see table 2). An increase in

$\Delta U^+$ (see table 2). An increase in ![]() $\Delta U^+$ is also noted if the thickness is decreased and the other two parameters are constant.

$\Delta U^+$ is also noted if the thickness is decreased and the other two parameters are constant.

Figure 12. Plots of ![]() $\Delta U^+$ as a function of the viscous-scaled orifice diameter

$\Delta U^+$ as a function of the viscous-scaled orifice diameter ![]() $d^+$ (a) and the Darcy permeability (b). Different line types indicate different facesheet thicknesses: solid (

$d^+$ (a) and the Darcy permeability (b). Different line types indicate different facesheet thicknesses: solid (![]() $t=d$) and dashed (

$t=d$) and dashed (![]() $t=d/2$). Symbols indicate different porosities:

$t=d/2$). Symbols indicate different porosities: ![]() $\sigma =0.0357$ (blue circles),

$\sigma =0.0357$ (blue circles), ![]() $\sigma =0.143$ (green squares) and

$\sigma =0.143$ (green squares) and ![]() $\sigma =0.322$ (red triangles).

$\sigma =0.322$ (red triangles).

Other candidate length scales can be inferred by regarding acoustic liners as porous surfaces. The flow normal to a porous plate is characterized by the pressure drop through the facesheet ![]() $\Delta P$, which can be expressed as the sum of two contributions (Lee & Yang Reference Lee and Yang1997; Bae & Kim Reference Bae and Kim2016):

$\Delta P$, which can be expressed as the sum of two contributions (Lee & Yang Reference Lee and Yang1997; Bae & Kim Reference Bae and Kim2016):

where ![]() $\textit {Re}_p = d U_p/\nu$ is the pore Reynolds number,

$\textit {Re}_p = d U_p/\nu$ is the pore Reynolds number, ![]() $U_p$ is the volume-averaged wall-normal velocity inside the orifice,

$U_p$ is the volume-averaged wall-normal velocity inside the orifice, ![]() $U_t = \sigma U_p$ is the superficial velocity,

$U_t = \sigma U_p$ is the superficial velocity, ![]() ${\mathsf{K}}_y$ is the wall-normal Darcy permeability coefficient and

${\mathsf{K}}_y$ is the wall-normal Darcy permeability coefficient and ![]() $\alpha _y$ is the wall-normal Forchheimer coefficient.

$\alpha _y$ is the wall-normal Forchheimer coefficient.

The Darcy permeability has the physical dimension of an area whereas the Forchheimer coefficient is the inverse of a length scale, and they are both related to the ease with which the flow passes through the plate because both contribute to the pressure drop. Their relative importance depends on ![]() $\textit {Re}_p$: Darcy permeability dominates at low pore Reynolds number (

$\textit {Re}_p$: Darcy permeability dominates at low pore Reynolds number (![]() $\textit {Re}_p \leqslant O(1)$) whereas the Forchheimer permeability becomes relevant from

$\textit {Re}_p \leqslant O(1)$) whereas the Forchheimer permeability becomes relevant from ![]() $\textit {Re}_p\gtrsim 5$. The permeability coefficients are measured by simulating a laminar flow in the direction perpendicular to the facesheet for a single cavity and measuring the pressure drop as a function of the mass flow rate through the porous medium. Different mass flow rates have been simulated, which allows us to estimate the permeability coefficients of the Darcy–Forchheimer law. More details and an extensive discussion of Darcy and Forchheimer drag is available in our recent work (Shahzad, Hickel & Modesti Reference Shahzad, Hickel and Modesti2022), where we calculate the Darcy permeability and the Forchheimer coefficient of perforated plates that match the present DNS dataset and compare the results with available engineering formulas.

$\textit {Re}_p\gtrsim 5$. The permeability coefficients are measured by simulating a laminar flow in the direction perpendicular to the facesheet for a single cavity and measuring the pressure drop as a function of the mass flow rate through the porous medium. Different mass flow rates have been simulated, which allows us to estimate the permeability coefficients of the Darcy–Forchheimer law. More details and an extensive discussion of Darcy and Forchheimer drag is available in our recent work (Shahzad, Hickel & Modesti Reference Shahzad, Hickel and Modesti2022), where we calculate the Darcy permeability and the Forchheimer coefficient of perforated plates that match the present DNS dataset and compare the results with available engineering formulas.

If we regard acoustic liners as porous surfaces, two relevant length scales for the flow are the square root of the Darcy permeability ![]() $\sqrt {{\mathsf{K}}_y}$ and the inverse of the Forchheimer coefficient

$\sqrt {{\mathsf{K}}_y}$ and the inverse of the Forchheimer coefficient ![]() $1/\alpha _y$, besides the orifice diameter. We show

$1/\alpha _y$, besides the orifice diameter. We show ![]() $\Delta U^+$ as a function of the viscous-scaled orifice diameter and the square root of the wall-normal Darcy permeability in figure 12. Data show that neither the orifice diameter nor the square root of the Darcy permeability is a suitable length scale for predicting the drag increase, as we find a clear non-monotonic trend (see figure 12). Instead, we find that

$\Delta U^+$ as a function of the viscous-scaled orifice diameter and the square root of the wall-normal Darcy permeability in figure 12. Data show that neither the orifice diameter nor the square root of the Darcy permeability is a suitable length scale for predicting the drag increase, as we find a clear non-monotonic trend (see figure 12). Instead, we find that ![]() $\Delta U^+$ shows a very promising trend when reported as a function of the inverse of the viscous-scaled Forchheimer coefficient, suggesting that

$\Delta U^+$ shows a very promising trend when reported as a function of the inverse of the viscous-scaled Forchheimer coefficient, suggesting that ![]() $1/\alpha _y^+$ is the most appropriate length scale for characterizing the additional drag (figure 13).

$1/\alpha _y^+$ is the most appropriate length scale for characterizing the additional drag (figure 13).

Figure 13. Plots of ![]() $\Delta U^+$ (a) and the roughness sublayer height (b) as a function of the inverse of the Forchheimer coefficient,

$\Delta U^+$ (a) and the roughness sublayer height (b) as a function of the inverse of the Forchheimer coefficient, ![]() $1/\alpha _y^+$. Different line types indicate different facesheet thicknesses: solid (

$1/\alpha _y^+$. Different line types indicate different facesheet thicknesses: solid (![]() $t=d$) and thick dashed (

$t=d$) and thick dashed (![]() $t=d/2$). The thin dashed line in (a) indicates

$t=d/2$). The thin dashed line in (a) indicates ![]() $\Delta U^+ = \kappa ^{-1} \log (1/\alpha _y^+)-3.5$. Symbols indicate different porosities:

$\Delta U^+ = \kappa ^{-1} \log (1/\alpha _y^+)-3.5$. Symbols indicate different porosities: ![]() $\sigma =0.0357$ (blue circles),

$\sigma =0.0357$ (blue circles), ![]() $\sigma =0.143$ (green squares) and

$\sigma =0.143$ (green squares) and ![]() $\sigma =0.322$ (red triangles). The black filled circles indicate Nikuradse's data (Nikuradse Reference Nikuradse1933).

$\sigma =0.322$ (red triangles). The black filled circles indicate Nikuradse's data (Nikuradse Reference Nikuradse1933).

This is consistent with the importance of inertia due to the very high wall-normal velocity fluctuations experienced inside the orifice, as observed in figure 7. Hence, the Darcy permeability, which is commonly associated with the pressure drop in the limit case of Stokes flow, is no longer the dominant term. This is further elaborated upon in § 3.4. Additional supportive evidence that ![]() $1/\alpha _y$ is the relevant length scale is provided by figure 13(b), showing a nearly linear relation between the inverse of the Forchheimer coefficient and the roughness sublayer. The roughness sublayer is defined as the wall-normal location, measured upwards from the virtual origin, where the time-averaged flow becomes homogeneous in the wall-parallel directions (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). It is a measure of the wall-normal extension of the liner influence, and has been correlated often with the relevant roughness length scale (Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991; Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021).

$1/\alpha _y$ is the relevant length scale is provided by figure 13(b), showing a nearly linear relation between the inverse of the Forchheimer coefficient and the roughness sublayer. The roughness sublayer is defined as the wall-normal location, measured upwards from the virtual origin, where the time-averaged flow becomes homogeneous in the wall-parallel directions (Chung et al. Reference Chung, Hutchins, Schultz and Flack2021). It is a measure of the wall-normal extension of the liner influence, and has been correlated often with the relevant roughness length scale (Raupach, Antonia & Rajagopalan Reference Raupach, Antonia and Rajagopalan1991; Chan et al. Reference Chan, MacDonald, Chung, Hutchins and Ooi2018; Modesti et al. Reference Modesti, Endrikat, Hutchins and Chung2021).

Moreover, the data in figure 13(a) show good agreement with data for classical sand-grain roughness of Nikuradse (Reference Nikuradse1933), supporting the emergence of a fully rough regime:

with ![]() $C \approx -3.5$.

$C \approx -3.5$.

For ![]() $t/d=1$, our data match very well the sand-grain roughness of Nikuradse (Reference Nikuradse1933) with

$t/d=1$, our data match very well the sand-grain roughness of Nikuradse (Reference Nikuradse1933) with ![]() $k_s^+ \approx 1/\alpha _y^+$ being the equivalent sand-grain roughness height. For flow cases with a lower plate thickness

$k_s^+ \approx 1/\alpha _y^+$ being the equivalent sand-grain roughness height. For flow cases with a lower plate thickness ![]() $t/d=0.5$, we observe a similar trend, although the fully rough regime is not reached, and flow cases at higher

$t/d=0.5$, we observe a similar trend, although the fully rough regime is not reached, and flow cases at higher ![]() $1/\alpha _y^+$ would be necessary to determine

$1/\alpha _y^+$ would be necessary to determine ![]() $k_s^+$ more accurately.

$k_s^+$ more accurately.

The existence of a fully rough regime is in line with the observations of Esteban et al. (Reference Esteban, Rodríguez-López, Ferreira and Ganapathisubramani2022), who note a fully rough regime in their experiments over porous foams. However, in their case, the relevant length scale is the square root of the Darcy permeability.

The fully rough regime is usually associated with the dominance of pressure drag over viscous drag, and the same appears to hold for acoustic liners. In table 3 we report the skin-friction coefficient, decomposed into its viscous and pressure contributions, which shows that pressure drag is nearly negligible for flow case ![]() $L$-

$L$-![]() $L_{3}$, whereas it becomes comparable to viscous drag for flow case

$L_{3}$, whereas it becomes comparable to viscous drag for flow case ![]() $L$-

$L$-![]() $H_{32}$. The same trend is also observed for cases with lower plate thickness. Even though pressure drag is still contributing for less than 50 % for flow case

$H_{32}$. The same trend is also observed for cases with lower plate thickness. Even though pressure drag is still contributing for less than 50 % for flow case ![]() $L$-

$L$-![]() $H_{32}$, we believe that the trend is rather clear and it supports the emergence of a fully rough regime for acoustic liners.

$H_{32}$, we believe that the trend is rather clear and it supports the emergence of a fully rough regime for acoustic liners.

Table 3. Contribution of pressure (![]() $C_{f,p}$) and viscous (

$C_{f,p}$) and viscous (![]() $C_{f,v}$) drag to the skin-friction coefficient of acoustic liners.

$C_{f,v}$) drag to the skin-friction coefficient of acoustic liners.

The relevance of pressure drag can also be demonstrated by analysing the mean momentum balance in the streamwise direction:

\begin{equation} \dfrac{\partial \bar{\rho} \tilde{u}_1 \tilde{u}_j }{\partial x_j} + \dfrac{\partial \bar{\rho}\widetilde{u_1'' u_j''} }{\partial x_j} ={-} \dfrac{\partial \bar{p} }{\partial x_1} + \dfrac{\partial \tilde{\sigma}_{1j} }{\partial x_j} + \bar{\varPi}. \end{equation}

\begin{equation} \dfrac{\partial \bar{\rho} \tilde{u}_1 \tilde{u}_j }{\partial x_j} + \dfrac{\partial \bar{\rho}\widetilde{u_1'' u_j''} }{\partial x_j} ={-} \dfrac{\partial \bar{p} }{\partial x_1} + \dfrac{\partial \tilde{\sigma}_{1j} }{\partial x_j} + \bar{\varPi}. \end{equation}Figure 14 shows the contribution of the different terms in (3.4), close to the orifice. Viscous diffusion becomes less relevant as the Reynolds number increases, whereas the intensity of turbulent convection increases, although the maximum value is confined very close to the wall, and inside the orifices. The magnitude of the pressure gradient term is constant for all considered Reynolds numbers, and its maximum location shifts downward into the orifices as the Reynolds number increases. The figure shows that the contribution of the pressure gradient is significant and its relative importance grows as the viscous sublayer becomes thinner. We also note that increasing the number of holes (porosity) increases the pressure drag, as each orifice seems to contribute approximately the same, independently of its location.

Figure 14. Contours of viscous diffusion (a,d,g,j,m,p), turbulent convection (b,e,h,k,n,q) and pressure gradient (c,f,i,l,o,r) normalized by ![]() $\tau _w/\delta _v$ for cases

$\tau _w/\delta _v$ for cases ![]() $L$-

$L$-![]() $L_{3}$ (a–c),

$L_{3}$ (a–c), ![]() $L$-

$L$-![]() $L_{14}$ (d–f),

$L_{14}$ (d–f), ![]() $L$-

$L$-![]() $L_{32}$ (g–i),

$L_{32}$ (g–i), ![]() $L$-

$L$-![]() $M_{14}$ ( j–l),

$M_{14}$ ( j–l), ![]() $L$-

$L$-![]() $M_{32}$ (m–o) and

$M_{32}$ (m–o) and ![]() $L$-

$L$-![]() $H_{32}$ (p–r).

$H_{32}$ (p–r).

The values of the friction coefficient reported in table 3 only apply to the Reynolds number of the present DNS, which is much lower than in a realistic configuration. Fortunately, the existence of a fully rough regime simplifies the modelling of acoustic liners and makes it easy to estimate the drag increase they induce in operating conditions. As discussed in § 1, the friction Reynolds number over acoustic liners is ![]() $\textit {Re}_\tau \approx 5400$, and the viscous-scaled inverse of the Forchhemeir coefficient for a geometry with

$\textit {Re}_\tau \approx 5400$, and the viscous-scaled inverse of the Forchhemeir coefficient for a geometry with ![]() $d/\delta \approx 0.08$,

$d/\delta \approx 0.08$, ![]() $t/d\approx 1$ and

$t/d\approx 1$ and ![]() $\sigma \approx 0.3$ is

$\sigma \approx 0.3$ is ![]() $1/\alpha _y^+\approx 55$ (Shahzad et al. Reference Shahzad, Hickel and Modesti2022). Assuming that a fully rough regime exists, then (3.3) returns